The global manufacturing directories market is experiencing steady growth, driven by increasing demand for streamlined supplier discovery, digital transformation in industrial sectors, and the need for supply chain transparency. According to Mordor Intelligence, the industrial manufacturing market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, bolstering the relevance of comprehensive manufacturing directories that connect buyers with vetted producers. These platforms have become critical tools for procurement professionals, engineers, and sourcing managers seeking precision, compliance, and scalability in supplier selection. As globalization and reshoring initiatives reshape production networks, manufacturers are increasingly relying on curated directories to access capabilities in machining, fabrication, injection molding, and advanced automation. The rise of digital procurement ecosystems, supported by data analytics and AI-driven matching, is further accelerating adoption. In this evolving landscape, leading manufacturing directory providers are not only aggregating supplier data but also offering verification, benchmarking, and supply chain risk insights—transforming how industries source and collaborate. The following list highlights nine of the top manufacturing directory manufacturers shaping this data-powered industrial future.

Top 9 Manufacturing Directory Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Resources

Domain Est. 1995

Website: cfda.com

Key Highlights: The Production Directory is an open-access directory of over 300 U.S. fashion manufacturers that was created to help make more direct connections between ……

#2 Industrial Quick Search

Domain Est. 2000

Website: industrialquicksearch.com

Key Highlights: As a North American manufacturing company directory, IQS Directory offers the ability to compare potential vendors with ease….

#3 IQS Directory: OEM Manufacturers

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: Discover a comprehensive industrial directory at IQS, connecting you to top OEM manufacturers, suppliers & distributors. Streamline your sourcing needs ……

#4 Directory

Domain Est. 1995

Website: nam.org

Key Highlights: The National Association of Manufacturers (NAM) represents 14,000 member companies from across the country, in every industrial sector. We are the nation’s most ……

#5 https://www.mfg.com/manufacturer

Domain Est. 1991

#6 Membership Directory

Domain Est. 1998 | Founded: 1961

Website: sfma.org

Key Highlights: The South Florida Manufacturers Association (SFMA) has held the distinction of being the #1 resource for manufacturers in South Florida since 1961….

#7 Made in the USA Directory

Domain Est. 2000

Website: trade.gov

Key Highlights: The Directory covers everything from spinners, weavers, and nonwoven manufacturers to cut-and-sew, printers, finishers, and more!…

#8 GEORGIA MANUFACTURING DIRECTORY

Domain Est. 2011

Website: nextgenerationmfg.org

Key Highlights: This is a free, searchable directory including the more than 10,000 manufacturers in the State. If you are looking for suppliers or manufacturer partners in the ……

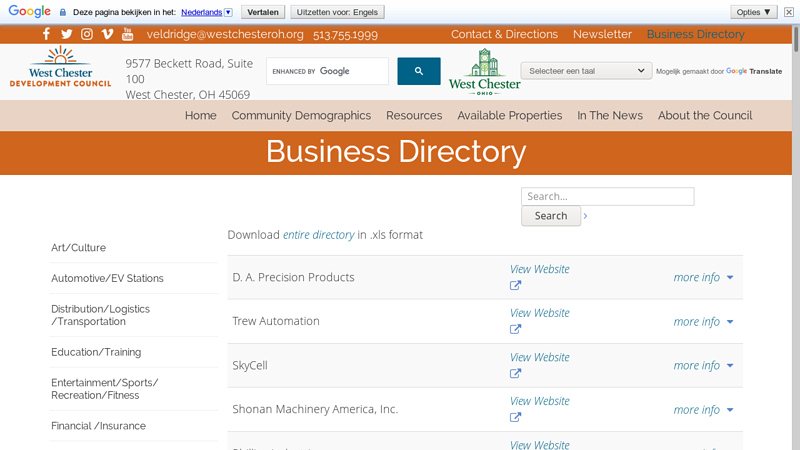

#9 Manufacturing Business Directory

Domain Est. 2003

Website: westchesterdevelopment.com

Key Highlights: Business directory of manufacturing companies located in West Chester Township, Butler County, Ohio….

Expert Sourcing Insights for Manufacturing Directory

2026 Market Trends for Manufacturing Directory

As we approach 2026, the landscape for Manufacturing Directories is undergoing a significant transformation driven by technological innovation, evolving industry demands, and global economic shifts. These directories—once static listings of manufacturers—are evolving into dynamic, data-driven platforms that facilitate smarter sourcing, supply chain resilience, and digital collaboration. Below are the key market trends shaping the future of Manufacturing Directories in 2026.

Digital Transformation and AI Integration

Manufacturing Directories are increasingly leveraging artificial intelligence (AI) and machine learning to enhance search functionality, recommend suppliers, and validate data accuracy. By 2026, AI-powered platforms will offer predictive analytics, enabling procurement teams to assess supplier risk, delivery reliability, and production capacity in real time. Natural language processing (NLP) will allow users to search using conversational queries, improving accessibility and user experience.

Emphasis on Supply Chain Transparency

With rising regulatory demands and consumer awareness, transparency in sourcing has become critical. Manufacturing Directories in 2026 will prioritize verified data on sustainability practices, certifications (such as ISO 14001 or ISO 9001), and ethical labor standards. Blockchain integration is expected to play a growing role in verifying the authenticity of manufacturer claims, providing immutable records of compliance and production history.

Growth of Industry 4.0 and Smart Manufacturing

As more manufacturers adopt Industry 4.0 technologies—such as IoT, smart sensors, and digital twins—Manufacturing Directories are evolving to include technical capabilities as searchable attributes. Platforms will allow buyers to filter suppliers based on smart factory readiness, automation level, or real-time production monitoring. This shift supports advanced manufacturing ecosystems and promotes collaboration between tech-forward suppliers and OEMs.

Regionalization and Nearshoring Trends

Global disruptions have accelerated the trend toward regional supply chains. By 2026, Manufacturing Directories will increasingly segment listings by geographic proximity, trade zone compliance (e.g., USMCA, EU), and local content requirements. This supports nearshoring and onshoring strategies, particularly in North America, Europe, and Southeast Asia, where governments are incentivizing local production.

Integration with Procurement and ERP Systems

Manufacturing Directories are no longer standalone tools. In 2026, they will be deeply integrated with enterprise resource planning (ERP) and procurement software, enabling seamless supplier onboarding, automated RFQ (Request for Quotation) distribution, and performance tracking. This interoperability reduces friction in the sourcing process and enhances decision-making speed.

Rise of Niche and Specialized Directories

Generalist directories are being supplemented—and in some cases replaced—by specialized platforms focusing on specific sectors such as aerospace, medical devices, or sustainable materials. These niche directories offer higher data relevance and cater to industries with stringent compliance and technical requirements, making them essential tools for targeted sourcing.

Data Quality and Verification as a Competitive Advantage

With the proliferation of online supplier listings, data accuracy has become a key differentiator. Leading Manufacturing Directories in 2026 will invest heavily in verification processes, including on-site audits, third-party certifications, and AI-driven anomaly detection. Platforms offering “verified” or “curated” supplier badges will gain trust and market share.

Mobile-First and Global Accessibility

Mobile access to Manufacturing Directories is expanding, particularly in emerging markets. By 2026, user-friendly mobile applications with offline capabilities and multilingual support will enable global buyers and suppliers to connect anytime, anywhere. This democratization of access supports small and medium-sized manufacturers (SMMs) in gaining visibility on international markets.

Conclusion

The Manufacturing Directory of 2026 is no longer a simple catalog—it is a strategic, intelligent, and interconnected platform essential for modern supply chain management. Success will depend on agility, data integrity, and the ability to adapt to the accelerating pace of digital and industrial change. Companies that embrace these trends will gain a competitive edge in sourcing, collaboration, and operational resilience.

Common Pitfalls When Sourcing from Manufacturing Directories (Quality and Intellectual Property Risks)

Sourcing from manufacturing directories can streamline supplier discovery, but overlooking critical risks—particularly around quality and intellectual property (IP)—can lead to costly setbacks. Below are key pitfalls to watch for:

Inadequate Quality Verification

Manufacturing directories often list suppliers based on self-reported information, which may not reflect actual capabilities. Without rigorous vetting, businesses risk partnering with manufacturers that fail to meet required quality standards, leading to defective products, delays, and reputational damage.

Lack of On-Site Audits

Many directories do not require or verify on-site audits. Suppliers may claim certifications (e.g., ISO 9001) that are outdated or falsified. Skipping independent audits increases the likelihood of poor production practices and inconsistent output.

Overreliance on Directory Listings

Treating directory entries as endorsements can be misleading. Inclusion in a directory does not equate to reliability or capability. Companies must conduct independent due diligence rather than relying solely on directory profiles.

Insufficient IP Protection Measures

Manufacturers in certain regions may have weak enforcement of intellectual property rights. Sharing designs or technical specifications without proper safeguards—such as NDAs or IP assignment agreements—exposes innovators to the risk of design theft or unauthorized production.

Unclear Ownership and Legal Jurisdiction

Contracts with overseas manufacturers may not clearly define IP ownership or the governing legal jurisdiction. This ambiguity can complicate enforcement if a supplier replicates and sells your product independently.

Use of Subcontractors Without Approval

Some manufacturers outsource work to unauthorized subcontractors without client consent. This not only dilutes quality control but also increases the risk of IP exposure, as designs may be shared with third parties lacking confidentiality agreements.

Failure to Secure Proper Agreements

Entering production without comprehensive contracts covering quality specifications, IP rights, confidentiality, and termination clauses leaves buyers vulnerable. Verbal agreements or informal understandings are insufficient for international sourcing.

Geographic and Cultural Misalignment

Differences in regulatory standards, business practices, and communication styles can exacerbate quality and IP risks. Misunderstandings due to language barriers or cultural norms may result in non-compliant products or unintended IP disclosures.

By recognizing these pitfalls and implementing robust verification processes—including audits, legal agreements, and ongoing monitoring—companies can better protect their quality standards and intellectual property when sourcing through manufacturing directories.

Logistics & Compliance Guide for Manufacturing Directory

This guide outlines essential logistics and compliance considerations for manufacturers listed in or seeking inclusion in a Manufacturing Directory. Adhering to these standards enhances operational efficiency, ensures legal compliance, and builds trust with partners, customers, and regulators.

Supply Chain Management

Establish a resilient and transparent supply chain by mapping suppliers, monitoring lead times, and evaluating risks such as geopolitical instability or material shortages. Implement supplier qualification processes and maintain strong communication channels to ensure continuity and quality.

Transportation & Distribution

Select appropriate transportation modes—road, rail, air, or sea—based on product type, delivery timelines, and cost. Optimize loading, routing, and scheduling to minimize delays and reduce carbon footprint. Use certified logistics partners and ensure proper packaging to prevent damage during transit.

Inventory Management

Maintain accurate inventory records using systems such as ERP or WMS to track raw materials, work-in-progress, and finished goods. Apply lean principles like Just-in-Time (JIT) where feasible to reduce carrying costs while ensuring adequate stock levels to meet demand.

Regulatory Compliance

Comply with all relevant local, national, and international regulations, including:

- Product Safety Standards (e.g., ISO, CE, UL)

- Environmental Regulations (e.g., EPA, REACH, RoHS)

- Labor Laws (e.g., OSHA, Fair Labor Standards)

- Import/Export Controls (e.g., customs documentation, ITAR, EAR)

Regularly audit operations to ensure ongoing compliance and update certifications as needed.

Trade Documentation

Prepare and maintain accurate documentation for domestic and international shipments, including:

- Commercial invoices

- Packing lists

- Bills of lading

- Certificates of origin

- Import/export licenses

Ensure all documents reflect correct Harmonized System (HS) codes for tariff classification.

Quality Assurance & Traceability

Implement quality management systems (e.g., ISO 9001) to monitor production processes and product consistency. Maintain traceability from raw materials to final product through batch/lot numbering and digital tracking systems, especially critical in regulated industries.

Sustainability & Environmental Responsibility

Adopt environmentally sustainable practices such as waste reduction, energy efficiency, and recycling. Comply with environmental reporting requirements and consider third-party certifications (e.g., ISO 14001) to demonstrate commitment to sustainability.

Data Security & Cyber Compliance

Protect sensitive operational and customer data through cybersecurity measures and compliance with data protection laws (e.g., GDPR, CCPA). Secure digital systems used in logistics and production planning against unauthorized access.

Continuous Improvement & Auditing

Conduct regular internal audits and risk assessments. Use feedback and performance metrics to refine logistics processes and compliance protocols. Stay informed about regulatory changes and industry best practices to remain competitive and compliant.

Conclusion: Sourcing a Manufacturing Directory

In conclusion, sourcing a reliable manufacturing directory is a critical step in building a successful supply chain, whether for procurement, product development, or outsourcing needs. A well-curated directory provides access to verified manufacturers, enhances operational efficiency, reduces sourcing risks, and supports informed decision-making. It streamlines the identification of capable suppliers based on location, certifications, production capacity, and specialty, ultimately saving time and reducing costs.

When selecting a manufacturing directory, it is essential to evaluate data accuracy, comprehensiveness, update frequency, and user reviews. Prioritizing platforms with vetted listings and transparent supplier information ensures higher reliability and minimizes the risk of partnering with substandard vendors. Furthermore, leveraging both global and niche-specific directories can provide a competitive advantage by uncovering innovative or cost-effective manufacturing solutions.

Ultimately, an effective manufacturing directory is not just a list of suppliers—it is a strategic resource that empowers businesses to scale, innovate, and remain agile in a dynamic global market. Investing time and effort into choosing the right directory lays the foundation for sustainable sourcing success.