The global market for precision fasteners, including M2 nuts, is witnessing steady expansion driven by rising demand across automotive, electronics, and industrial manufacturing sectors. According to Grand View Research, the global fasteners market was valued at USD 109.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing production of lightweight vehicles, expanding infrastructure projects, and the miniaturization of electronic devices—applications where small-format fasteners like M2 nuts are critical. As OEMs and contract manufacturers prioritize supply chain reliability, material quality, and precision tolerances, the need for reputable M2 nut suppliers has intensified. With Asia-Pacific dominating both production and consumption—China, Japan, and South Korea leading in precision manufacturing—the competitive landscape features both established industrial players and agile specialty manufacturers. Based on production capacity, quality certifications, global reach, and customer reviews, the following are the top 10 M2 nut manufacturers shaping the industry in 2024.

Top 10 M2 Nut Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China M2 Nut Manufacturer and Supplier, Factory

Domain Est. 2018

Website: qb-inds.com

Key Highlights: Looking for a reliable M2 Nut supplier? Choose us – a leading manufacturer and supplier from China. We offer top-quality M2 Nuts directly from our factory….

#2 HEX NUT (M2)

Domain Est. 1996

Website: alliedelectronics.com

Key Highlights: Thumbnail Filmstrip of HEX NUT (M2) Images. Purchase HEX NUT (M2). Part Number: 1-50301. HEX NUT (M2). $0.99. Manufacturer Logo. Description. HEX NUT…

#3 m2 stainless steel hex nuts online manufacture

Domain Est. 2021

Website: ss-bolt.com

Key Highlights: Good quality m2 stainless steel hex nuts from m2 stainless steel hex nuts manufacturers, We sell m2 stainless steel hex nuts online from China….

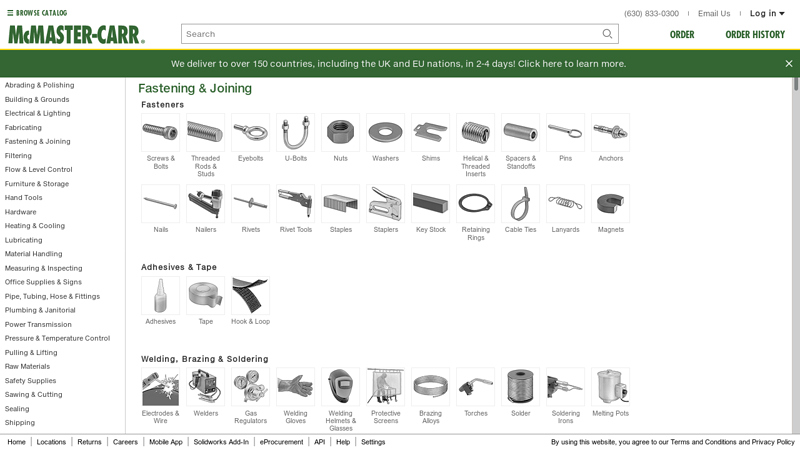

#4 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

#5 Product Finder

Domain Est. 1996

Website: pemnet.com

Key Highlights: Use the product finder to browse for parts, datasheets, inventory, and CAD files, with hundreds of filter options to help narrow your search….

#6 M2 x .4mm Hex Nuts A2 Stainless Steel 50 Pcs.

Domain Est. 2000

Website: fastener-express.com

Key Highlights: In stock Free delivery over $100Fastener Express offers one of the largest selection of high quality fasteners on the web. Specializing in aluminum screws, nuts and washers….

#7 M2

Domain Est. 2004

#8 Brass Hex Nuts

Domain Est. 2012

Website: marcelamexia.com

Key Highlights: Rating 4.4 (1,240) These are high-quality Brass Hex Nuts, made to the German DIN 934 standard. They’re brand new. You’re getting them in less common but useful smaller metric ……

#9 M2.5 Stainless Steel Hex Nut (20PCS) – AB001

Domain Est. 2019

Website: us.store.bambulab.com

Key Highlights: In stock Free deliveryM2.5 Stainless Steel Hex Nut 1. Stainless steel hex nuts. 2. Used in conjunction with screws to fasten parts, can be concealed in hexagonal slots….

#10 M2.5 Nuts

Domain Est. 2020

Website: botland.store

Key Highlights: Specification. Hex nut; Thread: M2,5; Material: steel; Height: 2 mm; Thread pitch 0.45 mm; Spanner size: 5 mm; The norm of BN: 109; DIN norm: 934 ……

Expert Sourcing Insights for M2 Nut

H2: Market Trends for M2 Nuts in 2026

The global market for M2 nuts—small metric fasteners with a 2mm nominal diameter—is expected to experience steady growth and notable shifts in 2026, driven by advancements in miniaturization, rising demand in high-tech industries, and evolving supply chain dynamics. Below is an analysis of key trends shaping the M2 nut market during this period.

1. Increased Demand in Electronics and IoT Devices

The proliferation of compact consumer electronics, wearable technology, and Internet of Things (IoT) devices continues to drive demand for miniature fasteners like M2 nuts. As manufacturers prioritize sleek, lightweight designs, the need for precision-engineered M2 components has intensified. In 2026, the electronics sector is projected to be the largest consumer of M2 nuts, particularly in smartphones, smartwatches, hearing aids, and medical wearables.

2. Growth in Medical Device Manufacturing

The medical technology sector is a key growth driver for M2 nuts due to their use in surgical instruments, diagnostic equipment, and implantable devices. With global healthcare investment rising and an aging population increasing demand for advanced medical devices, the need for reliable, corrosion-resistant M2 fasteners—often made from stainless steel or titanium—is expected to surge in 2026.

3. Shift Toward High-Performance Materials

Material innovation is a defining trend. While traditional carbon steel M2 nuts remain common, there is growing preference for specialty alloys such as A2/A4 stainless steel, brass, and aluminum for enhanced corrosion resistance, conductivity, or weight reduction. In 2026, suppliers are increasingly offering coated or passivated M2 nuts to meet stringent environmental and performance standards, especially in automotive and aerospace applications.

4. Automotive Electrification and Lightweighting

The electric vehicle (EV) revolution is influencing fastener demand. Although M2 nuts are not typically used in structural components, they play a critical role in electronic control units (ECUs), sensor modules, and interior electronics. As automakers focus on reducing vehicle weight and improving efficiency, the use of lightweight M2 fasteners in non-load-bearing applications is expanding.

5. Supply Chain Localization and Resilience

In response to geopolitical tensions and post-pandemic disruptions, many manufacturers are reshoring or nearshoring their supply chains. In 2026, this trend is prompting regional production hubs in North America, Europe, and Southeast Asia to increase local M2 nut manufacturing to reduce lead times and dependency on Asian imports, particularly from China.

6. Automation and Precision Manufacturing

The production of M2 nuts in 2026 is increasingly dominated by automated cold-forming and CNC machining processes. Enhanced quality control through AI-driven inspection systems ensures tighter tolerances and consistency, which is essential for high-reliability sectors like aerospace and medical devices.

7. Sustainability and Regulatory Compliance

Environmental regulations are pushing manufacturers to adopt sustainable practices. In 2026, recyclability, reduced waste in production, and compliance with RoHS and REACH directives are becoming standard requirements. Leading M2 nut producers are investing in eco-friendly coatings and energy-efficient manufacturing to align with ESG (Environmental, Social, and Governance) goals.

8. Price Volatility and Raw Material Costs

Fluctuations in steel and specialty metal prices continue to impact M2 nut pricing. While demand remains strong, cost pressures may lead to increased consolidation among suppliers and greater interest in alternative materials or bulk purchasing agreements to stabilize input costs.

Conclusion:

By 2026, the M2 nut market is characterized by strong demand from high-growth technology sectors, a shift toward advanced materials and localized production, and a focus on precision and sustainability. Manufacturers who invest in innovation, quality assurance, and supply chain resilience are best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing M2 Nuts (Quality and IP)

Sourcing M2 nuts—particularly in high volumes or for precision applications—can present several challenges related to both product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable supply chains and protects your business interests.

Quality-Related Pitfalls

1. Inconsistent Thread Accuracy and Tolerances

M2 nuts require precise threading due to their small size. Poorly manufactured nuts may have incorrect pitch, thread form, or diameter tolerances (e.g., not meeting ISO 965 standards). This leads to cross-threading, stripping, or poor assembly performance, especially in delicate electronics or medical devices.

2. Substandard Material Composition

Suppliers may use low-grade steel or non-compliant alloys, claiming “stainless steel” or “zinc-plated” without meeting required specifications (e.g., A2-70 or A4-80 for stainless). This compromises corrosion resistance, strength, and longevity, increasing the risk of premature failure.

3. Inadequate or Inconsistent Surface Finishes

Plating thickness and quality (e.g., zinc, nickel, or passivation) are often inconsistent. Thin or uneven coatings reduce corrosion protection and can cause galling or seizing during assembly. Some suppliers may skip required post-treatment processes to cut costs.

4. Poor Dimensional Consistency Across Batches

Lack of rigorous quality control leads to variations in height, width across flats, and chamfering. This affects automation compatibility (e.g., in pick-and-place machines) and increases the risk of assembly errors in high-precision applications.

5. Insufficient Testing and Certification

Many low-cost suppliers fail to provide material test reports (MTRs), torque-tension test data, or compliance certifications (e.g., RoHS, REACH, ISO 898-2). Without these, verifying performance and regulatory compliance becomes difficult.

IP-Related Pitfalls

1. Unintentional Use of Proprietary or Patented Designs

Some specialized M2 nuts—such as flange nuts with integrated seals, locking features, or custom geometries—may be protected by patents. Sourcing generic versions without due diligence can result in IP infringement, leading to legal action or shipment seizures.

2. Counterfeit or Grey Market Components

Suppliers may offer branded nuts (e.g., from Stanley Engineered Fastening or Nord-Lock) at suspiciously low prices. These could be counterfeit products mislabeled with trademarked names or packaging, exposing your company to IP liability and reputational damage.

3. Lack of IP Clarity in Custom Designs

If you commission a custom M2 nut design (e.g., for a proprietary device), failure to establish clear IP ownership in the supplier contract may result in the manufacturer claiming rights or reselling the design to competitors.

4. Inadequate Supplier Agreements on IP Protection

Generic supply agreements often omit clauses on IP indemnification, confidentiality, and design ownership. This leaves your company vulnerable if the supplier leaks design specifications or replicates your proprietary fastener for other clients.

Mitigation Strategies

- Verify certifications (ISO 9001, IATF 16949) and request test reports.

- Conduct incoming inspections using calibrated gauges and material analysis.

- Audit suppliers—especially offshore manufacturers—on-site or through third parties.

- Conduct patent searches before adopting non-standard nut designs.

- Use legally-reviewed contracts that define IP ownership, confidentiality, and infringement liability.

Avoiding these pitfalls ensures reliable M2 nut performance and protects your innovation and supply chain integrity.

Certainly! Below is a Logistics & Compliance Guide for M2 Nuts, formatted using H2 headings as requested. This guide covers essential aspects of handling, transporting, and complying with regulations when dealing with M2 nuts—small but critical fasteners commonly used in electronics, precision instruments, and light machinery.

Product Overview: M2 Nut

The M2 nut is a metric fastener with a nominal thread diameter of 2mm. Typically made from materials such as steel, stainless steel, brass, or nylon, M2 nuts are used in low-torque applications requiring precision assembly. Common types include hex, square, flange, and lock nuts.

Material & Packaging Specifications

M2 nuts must be packaged to prevent contamination, corrosion, and physical damage. Use anti-static, moisture-resistant, or vacuum-sealed packaging depending on material. Common packaging includes:

– Plastic bags with desiccants (for metal nuts)

– Blister packs for retail

– Reusable plastic or metal bins for industrial bulk shipping

– ESD-safe packaging for use in electronics environments

Label packages with:

– Part number (e.g., ISO 4035 for hex nuts)

– Material type (e.g., A2-70 stainless steel)

– Quantity per package

– Lot/batch number

– Manufacturer and country of origin

Storage & Handling Requirements

Store M2 nuts in a dry, temperature-controlled environment (15–25°C, RH <60%). Avoid exposure to:

– Corrosive chemicals

– High humidity

– Direct sunlight (especially for plastic variants)

Use first-in, first-out (FIFO) inventory rotation. Handle with clean tools or gloves to prevent oil contamination, particularly in precision applications.

Transportation & Logistics

Domestic & International Shipping

- Classify under HS Code 7318.15 (Nuts, of iron or steel, metric threaded).

- Declare accurate weight, dimensions, and value for customs.

- Use UN-certified packaging if transporting hazardous materials (e.g., coated nuts with chemical treatments).

Mode of Transport

- Air freight: Acceptable for small, high-value shipments; ensure compliance with IATA regulations.

- Sea freight: Cost-effective for bulk orders; protect against saltwater corrosion using VCI (Vapor Corrosion Inhibitor) packaging.

- Ground transport: Ideal for regional distribution; secure loads to prevent vibration damage.

Regulatory Compliance

REACH & RoHS Compliance

- Ensure M2 nuts (especially metallic types) comply with:

- REACH (EC 1907/2006): Registration, Evaluation, Authorisation and Restriction of Chemicals

- RoHS (2011/65/EU): Restriction of Hazardous Substances in electrical equipment (lead, cadmium, etc.)

Provide compliance documentation (e.g., Declaration of Conformity) upon request.

Conflict Minerals

If sourced from regions like the DRC, verify supply chain compliance with:

– Dodd-Frank Act Section 1502 (U.S.)

– EU Conflict Minerals Regulation (Regulation (EU) 2017/821)

Use certified suppliers from conflict-free zones.

Import/Export Documentation

Required documents for international logistics:

– Commercial invoice

– Packing list

– Bill of Lading (for sea) or Air Waybill (for air)

– Certificate of Origin

– Material Test Report (MTR), if applicable

– REACH/RoHS compliance certificate

– Export declaration (if applicable under ECCN/NLR classification)

Note: M2 nuts typically fall under EAR99 (U.S. Export Administration Regulations), meaning no license is required for most destinations unless embargoed.

Quality Assurance & Traceability

Implement ISO 9001-compliant quality systems. Each batch should be traceable via:

– Unique batch/lot numbers

– Date of manufacture

– Supplier and material certifications

Perform periodic audits and sampling checks (e.g., thread fit, torque testing).

Environmental & Sustainability Practices

- Recycle metal scrap from production.

- Use recyclable or biodegradable packaging where possible.

- Partner with suppliers committed to carbon footprint reduction.

Summary & Best Practices

- Verify material and regulatory compliance before shipping.

- Package appropriately to prevent damage and contamination.

- Maintain full documentation for traceability and customs.

- Train logistics staff on handling small components and hazardous material protocols, if applicable.

This guide ensures safe, compliant, and efficient logistics for M2 nuts across global supply chains. Always consult local regulations and customer specifications for project-specific requirements.

Conclusion for Sourcing M2 Nuts:

After evaluating various suppliers, material options, and quality standards, sourcing M2 nuts requires a balanced approach focusing on cost-efficiency, material compatibility, and reliability. Key considerations include selecting the appropriate material (such as stainless steel, zinc-plated steel, or brass) based on the application’s environmental and mechanical requirements. It is essential to partner with reputable suppliers that adhere to international standards (e.g., ISO, DIN) to ensure consistent quality and thread precision.

Additionally, factors such as minimum order quantities, lead times, and compliance with industry-specific regulations should be assessed to support uninterrupted production. While cost is a significant factor, prioritizing quality and supplier reliability helps minimize risks related to product failure or downtime. In conclusion, a strategic sourcing approach—emphasizing quality assurance, supply chain stability, and long-term partnerships—will ensure successful procurement of M2 nuts that meet both performance and budgetary goals.