The global loading bay equipment market is experiencing steady expansion, driven by rising e-commerce activity, warehouse automation, and increasing demand for efficient logistics operations. According to a 2023 report by Mordor Intelligence, the global loading dock equipment market was valued at USD 2.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028. A critical yet often overlooked component of this ecosystem is the loading bay dock light—a safety and efficiency essential that ensures clear visibility during cargo transfer, reducing error rates and improving operational throughput. With over 250,000 loading docks in North America alone, and increasing regulatory focus on workplace safety, demand for high-visibility, durable, and energy-efficient dock lights is surging. In response to these trends, manufacturers are innovating rapidly with LED technology, impact-resistant designs, and smart lighting integration. Based on market presence, product innovation, global reach, and customer reviews, here are the top 9 loading bay dock light manufacturers shaping the modern logistics landscape.

Top 9 Loading Bay Dock Lights Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rite

Domain Est. 1995

Website: ritehite.com

Key Highlights: Rite-Hite is the world leader in the manufacture and sale of loading dock … Loading Dock Lights · Flex Neck LED · HD LED · Cool Head™ · Loading Dock Bumpers….

#2 Poweramp

Domain Est. 1997

Website: poweramp.com

Key Highlights: Poweramp has been a leading manufacturer of loading dock equipment for over 60 years. With a focus on quality, all products are proudly Made in the USA!…

#3 Loading Dock Lights

Domain Est. 1998

Website: loading-systems.com

Key Highlights: Dock lights are the point of light in the darkness. They illuminate the entire inside of a trailer. ✓ Increased safety ✓ Durable choice….

#4 Category: Loading Lights

Domain Est. 1998

Website: vestil.com

Key Highlights: Dock Loading Lights are designed to illuminate your docking area during loading and unloading operations, ensuring optimal visibility even in low-light ……

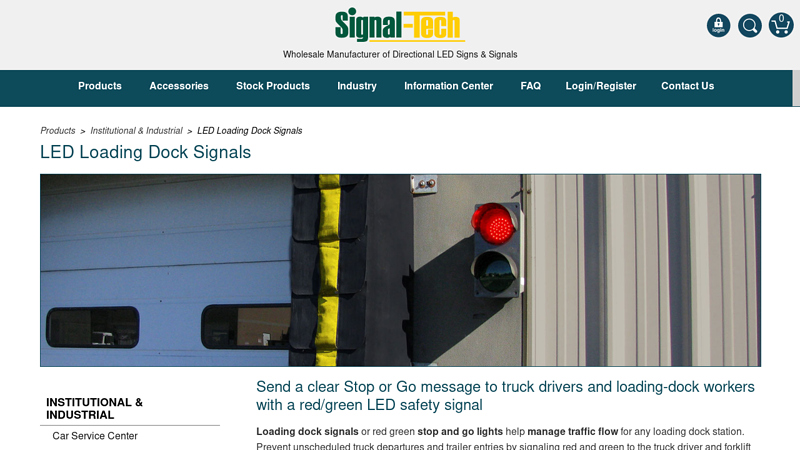

#5 LED Loading Dock Signals

Domain Est. 1999

Website: signal-tech.com

Key Highlights: Loading dock signals or red green stop and go lights help manage traffic flow for any loading dock station. Prevent unscheduled truck departures and trailer ……

#6 Loading Dock Lights Archives

Domain Est. 2000

Website: triliteinc.com

Key Highlights: Tri Lite’s Loading Dock Lights provide reliable, durable illumination for warehouses, loading bays, and truck docks. Our dock lights improve visibility ……

#7 ASSA ABLOY DE6090DL dock light

Domain Est. 2012

Website: assaabloyentrance.com

Key Highlights: The virtually indestructible ASSA ABLOY DE6090DL dock light heavy-duty LED is the perfect solution to bring light in the truck and docking area….

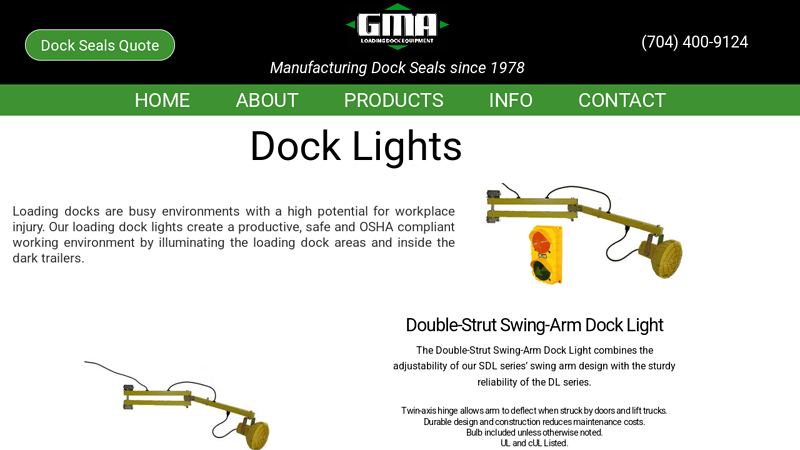

#8 Dock Lights

Domain Est. 2016

Website: gmadock.com

Key Highlights: Our loading dock lights create a productive, safe and OSHA compliant working environment by illuminating the loading dock areas and inside the dark trailers….

#9 LED Loading Dock Light with Wattage and CCT Selectable

Domain Est. 2016

Website: zledlighting.com

Key Highlights: This high-performance LED Loading Dock Light, engineered for safety, durability, and flexibility. Featuring selectable wattage (30W / 50W) and adjustable color ……

Expert Sourcing Insights for Loading Bay Dock Lights

H2: 2026 Market Trends for Loading Bay Dock Lights

The global market for loading bay dock lights is poised for significant transformation by 2026, driven by advancements in technology, growing emphasis on energy efficiency, and the expansion of logistics and cold chain infrastructure. Key trends shaping the industry include:

-

Shift Toward LED Technology

LED lighting is becoming the standard in loading bay applications due to its energy efficiency, longevity, and low maintenance requirements. By 2026, the majority of new dock light installations are expected to utilize LED systems, replacing outdated halogen and fluorescent fixtures. This transition is supported by stricter energy regulations and corporate sustainability goals. -

Smart and Connected Lighting Solutions

Integration with IoT (Internet of Things) platforms is emerging as a major trend. Smart dock lights equipped with motion sensors, daylight harvesting, and remote monitoring capabilities allow warehouse operators to optimize energy use and improve safety. By 2026, demand for connected lighting systems that integrate with warehouse management systems (WMS) is projected to rise, especially in automated distribution centers. -

Focus on Worker Safety and Visibility

Enhanced visibility during loading and unloading operations remains a top priority. Manufacturers are developing high-lumen, glare-reduced dock lights with improved beam angles to illuminate trailers more effectively. Regulatory standards and OSHA guidelines are pushing facilities to adopt lighting solutions that minimize blind spots and reduce accident risks. -

Growth in E-Commerce and Cold Chain Logistics

The rapid expansion of e-commerce and temperature-sensitive supply chains—especially for pharmaceuticals and perishable goods—is driving demand for reliable dock lighting in refrigerated warehouses. Lights designed for cold environments with durable, condensation-resistant housings are expected to see increased adoption. -

Sustainability and Regulatory Compliance

Environmental regulations, such as the EU’s Ecodesign Directive and U.S. ENERGY STAR standards, are influencing product design and performance benchmarks. By 2026, manufacturers will need to ensure compliance with energy efficiency and recyclability requirements, accelerating innovation in eco-friendly materials and low-carbon manufacturing. -

Regional Market Expansion

While North America and Europe remain mature markets, Asia-Pacific—particularly China, India, and Southeast Asia—is expected to witness the highest growth due to industrialization, urbanization, and infrastructure development. Investments in smart warehouses and logistics parks will fuel demand for modern dock lighting systems. -

Customization and Modular Designs

Facility operators are increasingly seeking customizable lighting solutions tailored to specific dock configurations and operational needs. Modular designs that allow for easy installation, maintenance, and retrofitting are gaining traction, reducing downtime and lifecycle costs.

In summary, the 2026 loading bay dock light market will be defined by intelligent, energy-efficient, and safety-focused lighting solutions. Companies that prioritize innovation, sustainability, and integration with digital logistics ecosystems will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Loading Bay Dock Lights (Quality, IP)

Sourcing loading bay dock lights requires careful attention to both quality and Ingress Protection (IP) ratings to ensure durability, safety, and long-term performance. Overlooking key factors can lead to premature failures, safety hazards, and increased maintenance costs. Below are common pitfalls to avoid:

Choosing Low-Quality Materials and Construction

Many suppliers offer dock lights made with substandard materials such as thin-gauge steel, low-grade plastics, or poor-quality wiring. These components degrade quickly under the harsh conditions of loading docks—frequent impacts, temperature fluctuations, and exposure to moisture and dust. Opting for lights with robust housings (e.g., die-cast aluminum or heavy-duty polycarbonate) and reinforced impact-resistant lenses helps prevent damage and extends service life.

Ignoring Adequate IP Ratings for the Environment

One of the most frequent mistakes is selecting dock lights with insufficient Ingress Protection (IP) ratings. Loading bays are exposed to dust, dirt, water spray, and even high-pressure washdowns. A minimum rating of IP65 is recommended to ensure complete dust protection and resistance to low-pressure water jets. For harsher environments or outdoor installations, IP66 or IP67 may be necessary. Using lights rated below IP65 can result in moisture ingress, electrical faults, and premature failure.

Overlooking Impact Resistance (IK Rating)

While IP ratings address environmental protection, IK ratings measure resistance to mechanical impacts—crucial in busy loading zones where forklifts and trailers frequently collide with dock infrastructure. Dock lights should typically have an IK10 rating (highest level of impact protection) to withstand accidental bumps and knocks. Failing to verify IK ratings can lead to cracked housings, broken lenses, and exposed electrical components.

Selecting Inadequate LED Quality and Lumen Output

Not all LED lights deliver consistent brightness or longevity. Some low-cost options use inferior LED chips that degrade quickly, resulting in diminished light output over time. Poor thermal management can also shorten LED lifespan. Ensure the lights use high-quality, long-life LEDs with sufficient lumen output (typically 3,000–5,000 lumens) and proper heat dissipation design to maintain visibility and reduce replacement frequency.

Neglecting Proper Mounting and Adjustability

Fixed or poorly designed mounting systems limit flexibility and reduce lighting effectiveness. Dock lights should be easily adjustable to accommodate various trailer heights and positions. Non-adjustable or flimsy mounts can lead to misalignment, shadows, and unsafe working conditions. Choose models with durable, multi-axis adjustment mechanisms and secure mounting hardware.

Skipping Compliance with Industry Standards and Certifications

Using non-compliant lighting can pose safety and legal risks. Ensure the dock lights meet relevant regional safety and performance standards such as CE, UL, or ETL certifications. In hazardous or outdoor zones, compliance with ATEX or IECEx (for explosive atmospheres) may also be required. Lack of certification can void insurance and result in regulatory penalties.

Underestimating Maintenance and Serviceability

Some dock lights are difficult to service or require complete replacement when a component fails. Choose designs that allow quick access to internal components, such as tool-less lens removal or modular LED drivers. Lights that are hard to maintain increase downtime and long-term costs.

By addressing these common pitfalls—focusing on build quality, appropriate IP and IK ratings, LED performance, adjustability, and compliance—facilities can ensure reliable, safe, and cost-effective lighting solutions for their loading bay operations.

Logistics & Compliance Guide for Loading Bay Dock Lights

Product Overview

Loading bay dock lights are essential safety and visibility tools used in warehouses, distribution centers, and shipping facilities. They illuminate the interior of trailers during loading and unloading operations, enhancing worker safety and operational efficiency. This guide outlines key logistics considerations and compliance requirements for the procurement, installation, and use of dock lights.

Regulatory & Safety Compliance

Dock lights must comply with relevant electrical and safety standards to ensure safe operation in industrial environments. Key compliance requirements include:

– UL 508 Certification: Required for industrial control equipment in the United States.

– CE Marking: Mandatory for sale within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

– IP Rating: Look for a minimum of IP65 (dust-tight and protected against water jets) for durability in harsh loading dock conditions.

– OSHA Guidelines: While OSHA does not specify dock light standards, general lighting requirements under 29 CFR 1910.136 apply to ensure safe working conditions.

– NEC (National Electrical Code): Installation must comply with Article 511 (Commercial Garages) and relevant sections for wet/damp location wiring methods.

Electrical & Installation Standards

Proper installation is critical to ensure safety and code compliance:

– Voltage Compatibility: Confirm dock lights are compatible with facility voltage (typically 120V or 277V).

– Wiring & Conduit: Use weather-resistant wiring and conduit suitable for outdoor or semi-outdoor environments.

– Mounting Height & Positioning: Install lights at optimal height (usually 8–10 feet) to illuminate trailer interiors without glare or obstruction.

– Emergency Backup: Consider models with battery backup or integration into emergency power systems for uninterrupted operation during outages.

Environmental & Durability Requirements

Dock lights are exposed to extreme conditions, including temperature fluctuations, moisture, and physical impact:

– Operating Temperature Range: Ensure lights function in expected facility climates (e.g., -30°C to +50°C).

– Impact Resistance: Choose models with rugged housings (e.g., polycarbonate lenses, aluminum or steel bodies).

– Corrosion Protection: Stainless steel or powder-coated fixtures recommended for coastal or high-humidity areas.

Logistics & Supply Chain Considerations

Efficient delivery and handling are critical to project timelines:

– Lead Times: Confirm standard and expedited shipping options with suppliers.

– Packaging: Units should be shipped in protective packaging to prevent damage during transit.

– Quantity & Configuration: Order based on dock door count and trailer types (e.g., dry van, refrigerated).

– Spare Parts: Maintain inventory of common replacement parts (lenses, bulbs, gaskets) to minimize downtime.

Maintenance & Inspection Protocol

Regular maintenance ensures long-term performance and compliance:

– Scheduled Inspections: Conduct monthly visual checks for damage, loose wiring, or lens clouding.

– Cleaning: Clean lenses and reflectors every 3–6 months to maintain illumination levels.

– Record Keeping: Document inspections and repairs to support safety audits and warranty claims.

Training & Operational Safety

Personnel should be trained on proper use and hazards:

– Avoid Physical Contact: Warn staff not to touch lights during operation (risk of heat or electrical shock).

– Reporting Malfunctions: Establish procedures for reporting flickering, dimming, or non-operational units.

– Lockout/Tagout (LOTO): Follow LOTO procedures during maintenance to prevent accidental energizing.

Sustainability & Energy Efficiency

Modern dock lights should align with energy-saving initiatives:

– LED Technology: Preferred for long life (50,000+ hours), low energy use, and minimal maintenance.

– Motion Sensors or Timers: Optional features to reduce energy consumption when docks are idle.

– RoHS Compliance: Ensure lights are free of hazardous substances like lead and mercury.

Documentation & Warranty

Ensure all documentation is retained for compliance and service:

– Product Manuals: Include installation, operation, and maintenance instructions.

– Certifications: Keep copies of UL, CE, IP, and other compliance certificates on file.

– Warranty Terms: Register products and understand coverage duration and service response times.

Conclusion

Proper selection, installation, and maintenance of loading bay dock lights are essential for safety, regulatory compliance, and operational efficiency. By following this guide, facilities can ensure reliable lighting performance while meeting all logistical and compliance requirements.

In conclusion, sourcing loading bay dock lights requires careful consideration of several key factors including energy efficiency, durability, brightness, safety compliance, and ease of maintenance. LED lighting has emerged as the preferred choice due to its long lifespan, low energy consumption, and superior visibility, which enhances safety and operational efficiency in loading environments. When selecting suppliers, it is important to evaluate product quality, certifications (such as IP ratings and impact resistance), warranty terms, and after-sales support. Additionally, considering smart lighting options with motion sensors or daylight harvesting can further optimize energy use. A well-informed sourcing decision not only improves functionality and safety within the loading bay but also contributes to long-term cost savings and sustainability goals.