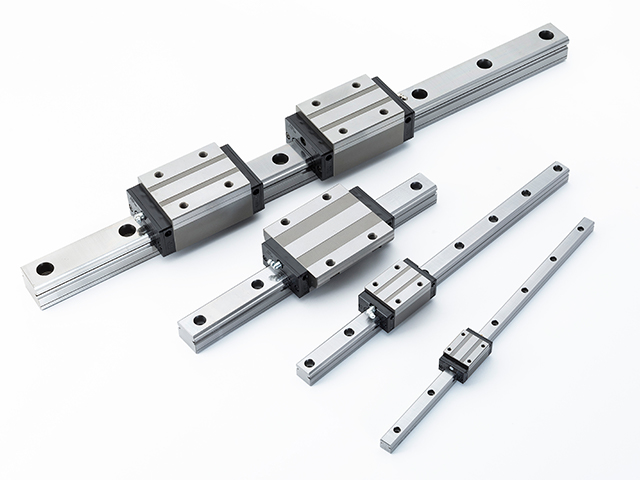

The global linear rail slides market is experiencing steady expansion, driven by rising automation across industrial manufacturing, semiconductor production, and electric vehicle assembly. According to a 2023 report by Mordor Intelligence, the linear motion components market—including linear rails—is projected to grow at a CAGR of over 5.8% from 2023 to 2028, fueled by demand for high-precision guidance systems in advanced machinery. This growth is further supported by Grand View Research, which highlights increasing adoption of Industry 4.0 technologies and factory automation as key drivers accelerating the need for reliable, high-performance linear guide systems. As competition intensifies among suppliers to meet stringent performance standards, several manufacturers have emerged as leaders in innovation, precision engineering, and global reach. Below is an overview of the top 9 linear rail slide manufacturers shaping the future of motion control.

Top 9 Linear Rail Slides Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Chambrelan

Domain Est. 1999 | Founded: 1956

Website: chambrelan.com

Key Highlights: Chambrelan, Manufacturer of heavy duty drawer slides and linear ball bearing guide rails for industrial professionals since 1956….

#2 SCHNEEBERGER

Domain Est. 1996

Website: schneeberger.com

Key Highlights: SCHNEEBERGER stands for pioneering innovations in the field of linear motion technology. The product and manufacturing program includes linear bearings and ……

#3 Linear Slide Manufacturers

Domain Est. 2015

Website: linearslides.net

Key Highlights: Del-Tron is a linear slide manufacturer/distributor of ball bearing slides, crossed roller tables, roller slides, multi-axis positioning stages, xy tables….

#4 Slide Rail

Domain Est. 1995

Website: thk.com

Key Highlights: The Slide Rail is a low-priced limited-type linear guide made of steel plate precision-formed by rolling. Thin, compact and easy to install….

#5 Linear Rail and Track Systems

Domain Est. 1995

#6 Del

Domain Est. 1996

Website: deltron.com

Key Highlights: Del-Tron Precision manufactures high-performance linear motion slides and precision slides for automation, medical, and aerospace applications….

#7 Rollon

Domain Est. 1996

Website: rollon.com

Key Highlights: myRollon is Rollon’s digital working platform designed to simplify the selection and configuration of linear and rotary motion solutions….

#8 Linear Slide, Guide Rail and Motion Systems Product Catalog

Domain Est. 1997

Website: nbcorporation.com

Key Highlights: Browse our line of products for all your linear motion needs. We manufacture products that provide the best linear motion solutions for our customers….

#9 PM

Domain Est. 1997

Website: pm.nl

Key Highlights: Discover PM’s high-precision linear guides, linear slides, and positioning systems for tailored solutions to meet your specific requirements….

Expert Sourcing Insights for Linear Rail Slides

2026 Market Trends for Linear Rail Slides

The linear rail slides market is poised for significant evolution by 2026, driven by advancements in automation, precision engineering, and shifting industrial demands. Key trends shaping the landscape include:

Rising Automation and Industry 4.0 Integration

Manufacturers are increasingly adopting smart linear rail systems embedded with sensors and IoT connectivity. By 2026, demand will grow for linear rails that support predictive maintenance, real-time monitoring, and seamless integration into digital factory ecosystems. This shift enhances operational efficiency and reduces downtime in applications across automotive, electronics, and logistics.

Demand for Miniaturization and High Precision

As industries like semiconductor manufacturing and medical devices push for smaller, more precise components, linear rail slides must deliver micron-level accuracy in compact form factors. Expect innovation in materials and design—such as ceramic-coated rails and lightweight composites—to meet these stringent requirements without sacrificing load capacity or durability.

Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are driving demand for energy-efficient motion systems. Linear rail manufacturers are focusing on low-friction coatings, optimized preloading, and recyclable materials. By 2026, eco-conscious procurement will influence buying decisions, especially in European and North American markets.

Expansion in E-Mobility and Renewable Energy

The booming electric vehicle (EV) and renewable energy sectors require robust automation for battery production, solar panel assembly, and wind turbine manufacturing. Linear rail slides with high load capacity, corrosion resistance, and reliability in harsh environments will see heightened demand in these high-growth industries.

Regional Market Shifts and Supply Chain Resilience

Post-pandemic supply chain disruptions have prompted companies to diversify sourcing and localize production. By 2026, Asia-Pacific will remain a dominant manufacturing hub, but North America and Europe are expected to increase regional production of high-end linear systems to reduce dependency and improve delivery times.

In summary, the 2026 linear rail slides market will be defined by smarter, smaller, and more sustainable solutions, with growth fueled by automation across advanced industries and strategic shifts in global manufacturing.

Common Pitfalls When Sourcing Linear Rail Slides (Quality, IP)

Inadequate Quality Control and Material Standards

One of the most frequent issues when sourcing linear rail slides—especially from low-cost manufacturers—is inconsistent quality control. Poor heat treatment, substandard steel (e.g., incorrect grade or improper hardening), and imprecise grinding processes can lead to premature wear, reduced load capacity, and inconsistent motion performance. Buyers may receive rails with surface defects, dimensional inaccuracies, or inconsistent preloading, resulting in system failure and costly downtime.

Misrepresentation of Load and Precision Ratings

Some suppliers exaggerate performance specifications such as dynamic load capacity, static load ratings, or precision class (e.g., claiming C3 or C5 accuracy without certification). These inflated ratings can mislead engineers into selecting undersized components, leading to system instability, reduced lifespan, or outright mechanical failure under real operating conditions.

Lack of Traceability and Certification

Reputable linear rail manufacturers provide material certifications, heat treatment records, and quality inspection reports. When sourcing from unknown or unqualified suppliers, these documents are often missing or falsified. Without traceability, it becomes impossible to verify compliance with industry standards (like ISO or JIS), increasing the risk of component failure and compromising product liability.

Intellectual Property (IP) Infringement Risks

Sourcing low-cost linear rails from certain regions may expose companies to IP infringement. Many budget rails are reverse-engineered copies of designs from major brands like THK, HIWIN, or Bosch Rexroth. Using counterfeit or cloned components can lead to legal liability, especially in regulated industries or international markets where IP enforcement is strict.

Compatibility and Interchangeability Issues

Even if a slide appears dimensionally identical, subtle differences in rail profile, ball recirculation design, or mounting hole placement can prevent true interchangeability. This can cause assembly problems, alignment errors, and performance degradation when replacing branded components with generic alternatives.

Poor Corrosion Resistance and Environmental Suitability

Low-cost rails often use inferior surface treatments or lack proper seals, making them susceptible to corrosion in humid or industrial environments. This is especially problematic in food processing, medical, or outdoor applications where stainless steel or enhanced sealing is required but not properly implemented.

Inadequate Technical Support and Documentation

Generic suppliers may not provide detailed installation guides, preload adjustment instructions, or technical support. This lack of documentation increases the risk of improper installation, misalignment, and premature failure—especially in high-precision applications.

Hidden Costs from Downtime and Maintenance

While initial cost savings are attractive, poor-quality rails often require more frequent maintenance, lubrication, or replacement. The hidden costs of unplanned downtime, rework, and reduced machine uptime can far exceed the price difference compared to high-quality, reliable components.

Supply Chain and Long-Term Availability Risks

Smaller or unproven suppliers may go out of business or discontinue product lines without notice. This jeopardizes long-term maintenance and spare parts availability, particularly for custom or high-volume applications where continuity is critical.

Conclusion

To avoid these pitfalls, buyers should prioritize suppliers with verifiable quality systems (e.g., ISO 9001), transparent documentation, genuine IP compliance, and a proven track record. Investing in trusted brands or certified manufacturers—though initially more expensive—often results in lower total cost of ownership and reduced risk.

Logistics & Compliance Guide for Linear Rail Slides

Overview

Linear rail slides are precision motion components used in automation, manufacturing, and industrial equipment. Proper logistics handling and regulatory compliance are essential to ensure product integrity, safety, and adherence to international and regional standards.

Packaging and Handling

- Protective Packaging: Linear rail slides must be packaged in anti-corrosion materials (e.g., VCI paper or plastic) and enclosed in rigid containers to prevent mechanical damage during transit.

- Labeling: Clearly label packages with “Fragile,” “Do Not Stack,” and orientation indicators (e.g., “This Side Up”) to prevent mis-handling.

- Environmental Protection: Store and ship in dry, temperature-controlled environments to avoid condensation and rust. Avoid exposure to dust, moisture, and harsh chemicals.

- Handling Precautions: Use appropriate lifting equipment for heavy assemblies. Never grip or apply force directly on the rail or carriage bearing surfaces.

Transportation Requirements

- Domestic Shipments (e.g., U.S., EU): Comply with carrier-specific guidelines for dimension and weight limits. Use shock and tilt monitoring devices for high-value or sensitive shipments.

- International Shipments:

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, DDP).

- Customs Documentation: Include commercial invoice, packing list, bill of lading, and certificate of origin.

- HS Codes: Use appropriate Harmonized System (HS) code (e.g., 8483.10 or 8482.80, depending on design and application) for customs classification.

- Air vs. Sea Freight: Prioritize air freight for time-sensitive deliveries; sea freight for bulk shipments with longer lead times. Ensure packaging meets IATA (air) or IMDG (sea) standards if hazardous materials (e.g., lubricants) are present.

Regulatory Compliance

- RoHS (EU): Ensure linear rail slides comply with Restriction of Hazardous Substances (RoHS) directives. Confirm absence of lead, cadmium, mercury, and other restricted substances in materials and coatings.

- REACH (EU): Comply with Registration, Evaluation, Authorization, and Restriction of Chemicals. Provide SVHC (Substances of Very High Concern) declarations if applicable.

- Proposition 65 (California, USA): Provide warnings if components contain listed chemicals (e.g., certain lubricants or metal alloys).

- CE Marking: Required for products sold in the European Economic Area. Indicates conformity with health, safety, and environmental protection standards.

- UKCA Marking: Required for goods placed on the market in Great Britain (England, Wales, Scotland) post-Brexit.

- ISO Standards: Adhere to relevant ISO standards such as ISO 14122 (safety of machinery) or ISO 2378 (linear motion bearings) for design and performance.

Export Controls

- Dual-Use Regulations: Evaluate whether linear rail slides fall under dual-use export control regimes (e.g., EU Dual-Use Regulation, U.S. EAR). High-precision components may be subject to licensing if used in military or aerospace applications.

- Destination Restrictions: Screen end-users and destinations against denied party lists (e.g., U.S. BIS, EU Consolidated List). Avoid shipments to embargoed countries without proper authorization.

Documentation and Traceability

- Certificates of Conformity (CoC): Provide CoC for each batch or shipment to certify compliance with applicable standards.

- Material Declarations: Supply material composition data (e.g., RoHS, REACH) upon request.

- Serial Number Tracking: For critical applications, implement traceability through serial numbers or batch codes for quality control and recalls.

End-of-Life and Recycling

- WEEE Directive (EU): If integrated into electrical equipment, ensure disposal follows Waste Electrical and Electronic Equipment (WEEE) guidelines.

- Recycling Recommendations: Provide guidance on disassembly and recycling of metal components (steel, aluminum) and separation of lubricants.

Best Practices

- Conduct periodic audits of logistics providers for compliance with handling and storage protocols.

- Train staff on proper handling, packaging, and regulatory requirements.

- Maintain up-to-date compliance documentation and certifications accessible to customers and regulators.

By adhering to this guide, manufacturers, distributors, and end-users can ensure safe, compliant, and efficient logistics for linear rail slide products across global markets.

Conclusion for Sourcing Linear Rail Slides

In conclusion, sourcing the right linear rail slides is a critical step in ensuring the performance, precision, and longevity of motion systems across various industrial and automation applications. Careful consideration of load capacity, accuracy, rigidity, environmental conditions, and compatibility with existing components is essential to select the most suitable linear rail system. Working with reputable suppliers and manufacturers helps guarantee product quality, consistency, and technical support throughout the procurement and integration process. Additionally, balancing cost-efficiency with performance requirements ensures a reliable and cost-effective solution. By conducting thorough research, evaluating multiple sourcing options, and prioritizing quality and specifications aligned with the application needs, businesses can optimize their operations, enhance machine efficiency, and reduce long-term maintenance costs. Ultimately, strategic sourcing of linear rail slides contributes significantly to the overall success and reliability of motion control systems.