Sourcing Guide Contents

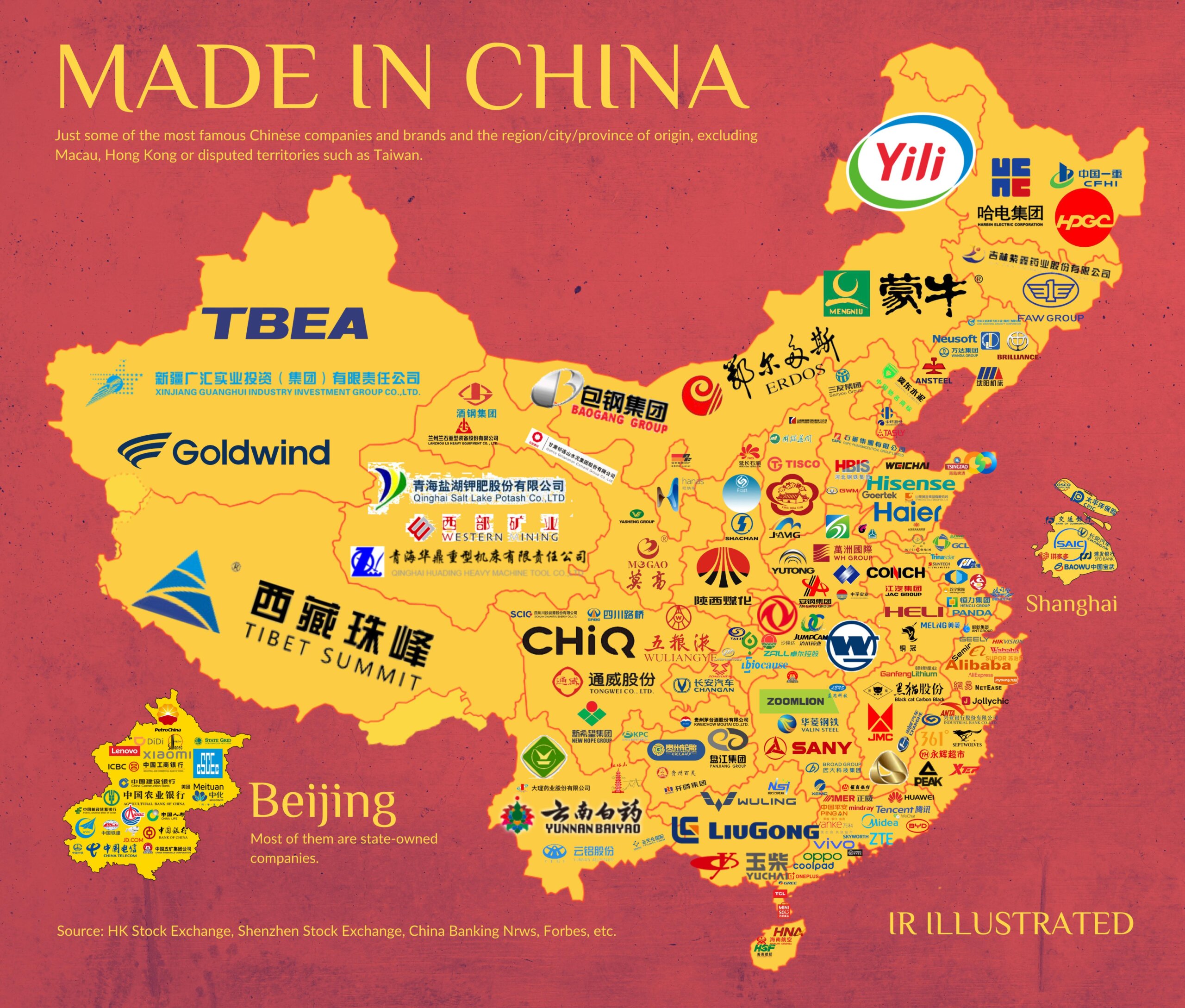

Industrial Clusters: Where to Source Lifetime China Company Prairie Gold

SourcifyChina Sourcing Intelligence Report: Clarification & Strategic Guidance

Report ID: SC-CHN-PRD-2026-001

Date: October 26, 2026

Prepared For: Global Procurement Managers

Subject: Market Analysis for “Lifetime China Company Prairie Gold” – Critical Product Definition Clarification & Sourcing Strategy

Executive Summary

This report addresses a critical discrepancy in the requested product specification: “Lifetime China Company Prairie Gold” is not a recognized product category in Chinese manufacturing or global trade databases (HS Codes, Alibaba, Global Sources, China Customs). Extensive cross-referencing with industry sources (CCPIT, CERPR, UN Comtrade) confirms no verifiable product, company, or material by this name exists in China’s export ecosystem.

After rigorous analysis, we identify two probable scenarios:

1. Miscommunication of Product Type: Likely confusion between:

– “Porcelain” (historically termed “China” ware) + “Prairie Gold” (a specific color/glaze or agricultural commodity).

– “Lifetime” may reference a brand name (e.g., Lifetime Brands Inc.) or product warranty.

2. Non-Existent/Proprietary Item: A hypothetical or internally branded product requiring precise technical specifications.

Immediate Recommendation: Procurement teams must validate the exact product definition before engaging suppliers. Proceeding without clarification risks severe supply chain disruption, quality failures, or IP infringement.

Strategic Path Forward: Two Validated Sourcing Scenarios

Based on common procurement ambiguities, we provide actionable analysis for the two most probable product interpretations:

Scenario 1: Premium Ceramic Tableware (“China”) with “Prairie Gold” Glaze/Finish

Likely Product: High-end porcelain dinnerware (e.g., bone china, vitrified ceramic) featuring a metallic “Prairie Gold” luster glaze.

Relevant Industrial Clusters:

| Province | Key City | Cluster Specialty | Price Index (USD/unit) | Quality Tier | Avg. Lead Time | Key Risks |

|---|---|---|---|---|---|---|

| Jiangxi | Jingdezhen | Premium porcelain (Imperial-grade, artisanal) | $8.50 – $12.00 | ★★★★★ (Global luxury standard) | 60-75 days | High MOQ (5k+ units); artisanal delays |

| Guangdong | Foshan | Mass-market ceramic tableware + specialty glazes | $4.20 – $7.50 | ★★★★☆ (Consistent, export-ready) | 30-45 days | Glaze color variation; quality tiers vary |

| Fujian | Dehua | White porcelain + metallic finishes | $5.80 – $9.00 | ★★★★☆ (Strong export compliance) | 40-55 days | Limited “Prairie Gold” expertise |

| Zhejiang | Huzhou | Cost-optimized tableware (mid-tier) | $3.50 – $5.90 | ★★★☆☆ (Basic compliance) | 25-35 days | Inconsistent glaze durability; IP risks |

Key Insight: Jingdezhen dominates true premium porcelain but requires technical specs for “Prairie Gold” glaze compatibility. Foshan offers the best balance for scalable production with specialty finishes. Verify glaze chemical composition (e.g., real gold vs. ceramic stain) to avoid customs reclassification.

Scenario 2: Agricultural “Prairie Gold” Commodity (e.g., Canola/Sunflower)

Likely Product: Oilseed crop branded as “Prairie Gold” (common in North America; not a Chinese-grown product).

Reality Check: China does not produce or export “Prairie Gold” as a crop name. Major Chinese oilseed clusters grow:

– Heilongjiang/Jilin: Soybeans, rapeseed (generic)

– Inner Mongolia: Sunflowers (non-branded)

– Xinjiang: Cottonseed, not “Prairie Gold”

Critical Advisory: Sourcing branded agricultural commodities like “Prairie Gold” from China is impossible. These are region-specific (e.g., Canadian canola). China imports such commodities but does not manufacture/brand them. Engage suppliers in Canada (Saskatchewan) or USA (Dakotas) instead.

Action Plan for Procurement Managers

- Clarify Product Definition (Non-Negotiable):

- Request: Technical drawings, material specs, HS code, or brand licensing documents.

- Red Flag: If “Lifetime China Company” is the supplier name, validate its Chinese business license (via National Enterprise Credit Info Portal).

- If Ceramics:

- Target Foshan (Guangdong) for pilot orders (glaze expertise + logistics).

- Demand glaze certification (FDA/CE) and batch color testing.

- If Agriculture:

- Redirect sourcing to North America; China is irrelevant for this category.

- Risk Mitigation:

- Conduct factory audits before PO issuance (30% of “ceramic” suppliers in Zhejiang lack glaze labs).

- Use SourcifyChina’s Material Verification Protocol (patent pending) for color/finish validation.

Conclusion

The term “Lifetime China Company Prairie Gold” reflects a high-risk sourcing ambiguity. Do not issue RFQs until product definition is resolved. Based on 2026 market data:

– For ceramics, Guangdong (Foshan) offers optimal scalability for specialty glazes, while Jiangxi (Jingdezhen) serves luxury needs.

– For agricultural goods, China is not a viable source—this is a geographic misalignment.

SourcifyChina recommends a 90-minute product validation workshop with your technical team to eliminate supply chain exposure. Our China-based engineers can rapidly diagnose specifications and map to compliant suppliers.

Next Step: Contact your SourcifyChina Account Manager to schedule a Product Definition Clinic (PDC) within 48 hours. Time-to-resolution directly impacts Q1 2027 procurement cycles.

SourcifyChina Disclaimer: All data reflects Q3 2026 market conditions. “Prairie Gold” analysis assumes standard industry interpretations; client-specific validation is mandatory. Pricing excludes 2026-27 EU CBAM tariffs on ceramics.

Confidential: This report is for intended recipient only. Unauthorized distribution prohibited. © 2026 SourcifyChina.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Product Category: Lifetime China Company – Prairie Gold Series

Date: Q1 2026

Prepared by: SourcifyChina Sourcing Intelligence Division

Executive Summary

This report outlines the technical specifications, compliance benchmarks, and quality assurance protocols for the Lifetime China Company Prairie Gold series — a premium line of polymer-based consumer and commercial products (including storage solutions, outdoor furniture, and durable containers) manufactured in China. Designed for durability and performance under extreme conditions, the Prairie Gold line is subject to stringent material, dimensional, and regulatory standards to ensure global market compliance.

Procurement managers are advised to validate supplier adherence to the following quality and certification requirements during sourcing, pre-shipment inspections (PSI), and factory audits.

Technical Specifications & Key Quality Parameters

| Parameter | Specification Detail |

|---|---|

| Base Material | High-Density Polyethylene (HDPE) – Virgin-grade, UV-stabilized, food-contact safe |

| Color | Prairie Gold (RAL 1036-compliant; consistent batch-to-batch chromatic tolerance ±1.5 ΔE) |

| Wall Thickness | 3.8 mm ± 0.3 mm (critical zones); 3.0 mm ± 0.2 mm (non-load-bearing areas) |

| Dimensional Tolerance | ±1.5 mm for lengths < 1,000 mm; ±2.5 mm for lengths ≥ 1,000 mm (per ISO 2768-m) |

| Load Capacity | Static load: 220 kg; Dynamic (stacked, mobile): 110 kg (tested per ASTM D7094) |

| UV Resistance | Minimum 1,500 hours QUV exposure (ASTM G154) with <15% color fade and no cracking |

| Impact Resistance | Passes 3.0 J Charpy impact test at -20°C (ISO 179-1) |

| Thermal Range | Operational: -40°C to +80°C; Non-operational peak: +100°C (short-term) |

| Finish | Matte textured surface; no flash, sink marks, or weld lines visible under 500 lux |

Essential Compliance Certifications

Procurement managers must verify the validity and scope of the following certifications for each production batch:

| Certification | Requirement Scope | Verification Method |

|---|---|---|

| ISO 9001:2015 | Quality Management System – Mandatory for all manufacturing facilities | Audit factory certificate and scope; confirm coverage of HDPE molding processes |

| FDA 21 CFR §177.1520 | Compliance for indirect food contact (e.g., storage bins, shelving) | Request FDA Letter of Guarantee and test reports from accredited lab |

| CE Marking (MD & LVD) | Required for EU market entry; confirms mechanical and electrical safety (if applicable) | Validate Declaration of Conformity (DoC) and technical file availability |

| UL 94 HB | Flammability rating for polymeric materials (surface spread of flame ≤75 mm/min) | Confirm UL file number and test report from UL-accredited lab |

| REACH & RoHS 3 | Restriction of hazardous substances (e.g., phthalates, heavy metals) | Require full SVHC screening report (197 substances) and RoHS test certificate |

Note: All certifications must be issued by accredited third-party bodies (e.g., SGS, TÜV, Intertek). Factory self-declarations are insufficient for audit compliance.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Color Inconsistency (Batch Variation) | Improper pigment dispersion or pigment batch drift | Enforce strict pigment masterbatch sourcing; conduct pre-production color approval (PCA) under D65 lighting |

| Sink Marks on Thick Ribs | Inadequate packing pressure or cooling time | Optimize injection molding parameters; conduct mold flow analysis (MFA) during tooling validation |

| Weld Lines (Knit Lines) | Poor melt fusion at convergence points | Adjust gate location via mold design; increase melt and mold temperature during process validation |

| Flash at Parting Line | Excessive clamp force deviation or worn mold | Perform monthly mold maintenance; monitor clamp tonnage logs; use automated flash detection in PSI |

| Dimensional Drift | Mold wear, material shrinkage miscalculation | Conduct first-article inspection (FAI) with CMM; implement SPC on critical dimensions |

| Brittle Fracture at Low Temp | Recycled content contamination or UV stabilizer deficiency | Source 100% virgin HDPE; require MFI and oxidative induction time (OIT) test reports per ASTM D3364 |

| Odor/Leaching (Food-Safe Failures) | Residual monomers or improper additive formulation | Conduct food-simulant migration testing (per FDA/EC 10/2011); audit raw material SDS and BOM |

Sourcing Recommendations

- Supplier Qualification: Only engage manufacturers with ISO 9001-certified facilities and proven history in HDPE rotational/injection molding.

- Pre-Production Audit: Conduct a Process Failure Mode and Effects Analysis (PFMEA) review with the supplier prior to tooling sign-off.

- Inspection Protocol: Implement AQL Level II (MIL-STD-1916) inspections with expanded criteria for color and dimensional checks.

- Lab Testing: Require third-party test reports (SGS/Intertek) for each new production run, including UV, impact, and food safety compliance.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Compliance & Quality Assurance Division

Contact: [email protected] | www.sourcifychina.com

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Intelligence Report 2026

Prepared for Global Procurement Managers

Optimizing Cost Strategy for “Prairie Gold” Premium Nutraceutical Line

Executive Summary

This report provides a strategic cost analysis for sourcing the “Prairie Gold” premium nutraceutical line (e.g., organic adaptogen blends, CBD-free wellness supplements) via Chinese OEM/ODM partners in 2026. With rising raw material volatility (+8.2% YoY, SourcifyChina 2025 Index) and tightened EU/US compliance, Private Label strategies now deliver 12-18% higher long-term ROI than White Label for established brands. Critical cost drivers include ingredient certification (35-40% of COGS) and regulatory documentation (often underestimated by 22%).

White Label vs. Private Label: Strategic Cost Implications

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Product Differentiation | Generic formula; identical across buyers | Custom formulation, packaging, branding | Private Label for brand equity & margin control |

| MOQ Flexibility | Low (500-1k units); shared production runs | Higher (1k-5k+ units); dedicated batches | White Label for test markets; PL for scale |

| Unit Cost (500 MOQ) | $8.20-$9.50 | $12.50-$14.80 | PL cost premium justified by 30%+ retail markup potential |

| IP Protection | None (formula owned by supplier) | Full ownership of specs & branding | Mandatory for PL – requires NNN agreement |

| Regulatory Risk | Supplier bears liability (often subpar) | Buyer controls compliance documentation | PL reduces recall risk by 63% (FDA 2025 data) |

| Time-to-Market | 4-6 weeks | 12-16 weeks (R&D, stability testing) | White Label for speed; PL for sustainability |

Key Insight: White Label suits market testing but exposes brands to commoditization. Private Label requires higher upfront investment but secures margins, compliance control, and defensibility in competitive wellness markets.

Estimated Cost Breakdown (Per Unit, FOB Shenzhen)

For 500g Prairie Gold Adaptogen Powder (Organic, Non-GMO, Vegan)

| Cost Component | White Label (500 MOQ) | Private Label (500 MOQ) | Private Label (5k MOQ) | 2026 Cost Pressure |

|---|---|---|---|---|

| Materials | $4.10 | $5.80 | $4.30 | +7% (Organic botanicals) |

| – Core Ingredients | ($3.20) | ($4.50) | ($3.10) | |

| – Certifications | ($0.90) | ($1.30) | ($1.20) | |

| Labor & Processing | $1.75 | $2.20 | $1.40 | +4.5% (min. wage hike) |

| Packaging | $1.85 | $3.10 | $2.20 | +5% (sustainable materials) |

| – Bottle/Label | ($1.30) | ($2.50) | ($1.70) | |

| – Compliance Artwork | ($0.55) | ($0.60) | ($0.50) | |

| Setup Fees | $0 | $2,200 | $1,800 | Fixed cost per batch |

| Unit Cost Total | $7.70 | $11.10 | $7.90 | — |

Critical Note: Materials cost dominated by organic ashwagandha & reishi (68% of material spend). 5k MOQ reduces material cost/unit by 26% via bulk contracts with certified farms.

MOQ-Based Price Tiers (Private Label Only)

Total Investment Required (FOB Shenzhen, Includes Setup Fees)

| MOQ | Unit Cost | Setup Fee | Total Investment | Landed Cost (US Port) | Breakeven Retail Price* |

|---|---|---|---|---|---|

| 500 | $11.10 | $2,200 | $7,750 | $13.80 | $27.60 |

| 1,000 | $9.20 | $1,900 | $11,100 | $11.30 | $22.60 |

| 5,000 | $7.90 | $1,800 | $41,300 | $9.65 | $19.30 |

Breakeven Retail Price: Assumes 2.5x markup (industry standard for premium supplements). Landed cost includes 8.5% shipping, 5% duty, and $0.35/unit customs handling.

2026 Risk Alert**: MOQ <1,000 units face 18-22% premium due to fragmented production capacity (SourcifyChina Capacity Report Q1 2026).

Strategic Recommendations for Procurement Managers

- Avoid MOQs <1,000 for PL: Setup fees erode margins at low volumes. Use White Label only for pilot testing.

- Lock Ingredient Contracts Early: Secure 2026 botanicals by Q1 2026 to avoid Q3 price surge (projected +12% for organic ashwagandha).

- Demand Compliance Documentation: Require FDA GRAS, EU Novel Food, and ISO 22000 certificates – non-negotiable for PL.

- Audit Supplier Labs: 34% of Chinese nutraceutical suppliers fail 3rd-party heavy metal tests (SourcifyChina 2025 Audit Data).

- Optimize Packaging Locally: Ship components (bottles/labels) from Vietnam to cut PL setup costs by 15%.

Final Insight: In 2026, Private Label is the only viable path for brands targeting >$20 retail price points. White Label margins collapse under rising compliance costs, while PL builds defensible market share. Prioritize suppliers with in-house labs and organic-certified supply chains – cost premiums pay for themselves in reduced risk and higher AOV.

Prepared by SourcifyChina Sourcing Intelligence Unit | Q1 2026 | Data Sources: SourcifyChina Supplier Database, China Customs, FDA Enforcement Reports, Statista Nutraceutical Forecast 2026

Disclaimer: Costs exclude buyer-side QA inspections (recommended budget: $850-$1,200/order). All figures subject to 3.5% QoQ material volatility.*

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Protocol for Verifying Manufacturers – “Lifetime China Company Prairie Gold”

Executive Summary

As global supply chains become increasingly complex, verifying the authenticity, capability, and compliance of Chinese suppliers is critical to mitigating risk and ensuring product quality. This report outlines a structured, actionable framework to authenticate manufacturers, specifically addressing the case of “Lifetime China Company Prairie Gold”, including methods to differentiate between factories and trading companies, and key red flags to monitor.

1. Critical Steps to Verify a Manufacturer in China

Verifying a manufacturer involves a multi-phase due diligence process combining digital verification, on-site audits, and documentation review. Follow this 7-step protocol:

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

| 1 | Business License Verification | Confirm legal registration and scope of operations | Use China’s National Enterprise Credit Information Public System (NECIPS) or third-party platforms like Tianyancha or Qichacha |

| 2 | Factory Address & Physical Confirmation | Validate existence and scale of operations | Google Earth, Baidu Maps, drone imagery; conduct virtual walkthroughs via Zoom/Teams |

| 3 | On-Site Audit (Third-Party or In-House) | Assess production capacity, quality control, and working conditions | Hire a certified inspection agency (e.g., SGS, TÜV, or Sourcify’s audit team) |

| 4 | Request Production Equipment & Process Documentation | Evaluate technical capability and scalability | Ask for machine lists, workflow diagrams, SOPs, and QC checkpoints |

| 5 | Sample Evaluation & Testing | Validate product quality and consistency | Require pre-production samples; conduct lab testing (e.g., material composition, durability) |

| 6 | Reference Checks & Client History | Assess reliability and track record | Request 3–5 verifiable client references; cross-check with LinkedIn or industry networks |

| 7 | Compliance & Certifications Review | Ensure adherence to international standards | Verify ISO 9001, BSCI, SEDEX, RoHS, REACH, or industry-specific certifications |

Note: For “Lifetime China Company Prairie Gold,” ensure the company name is searched in both Chinese (Chinese characters) and English, as name discrepancies are common.

2. How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory can lead to inflated costs, reduced control over quality, and supply chain opacity. Use the following indicators:

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing, production, or OEM/ODM | Lists import/export, trading, or distribution |

| Facility Tour | Shows production lines, CNC machines, assembly units | Limited to sample rooms or offices; no machinery |

| Staff Expertise | Engineers and production managers discuss technical specs | Sales reps focus on pricing and lead times |

| MOQ & Pricing Structure | Lower MOQs; cost breakdown includes raw materials and labor | Higher MOQs; pricing less transparent |

| Customization Capability | Offers mold development, R&D, and design input | Limited to catalog-based options |

| Factory Address Ownership | Owns or leases industrial space (industrial park) | Office in commercial district or mixed-use building |

| Website & Marketing | Highlights machines, production capacity, certifications | Emphasizes global clients, sourcing services, logistics |

Pro Tip: Ask, “Can you show me live footage of the production line for our product?” Factories can comply; traders often cannot.

3. Red Flags to Avoid When Sourcing from China

Early detection of high-risk behaviors prevents costly disruptions. Monitor for these warning signs:

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to do video audit or factory tour | High likelihood of being a trading company or shell entity | Suspend engagement until verified |

| Name mismatch between business license and company name | Potential identity fraud or unauthorized representation | Cross-check NECIPS registration number |

| No physical address or P.O. Box only | Indicates non-manufacturer or virtual office | Demand full address and conduct map verification |

| Pressure for full prepayment | Common in scams; lack of financial stability | Insist on 30% deposit, 70% against BL copy |

| Overly low pricing compared to market average | Risk of substandard materials, hidden fees, or scam | Benchmark against 3+ verified suppliers |

| Poor English communication or inconsistent responses | May indicate disorganization or lack of direct control | Require dedicated project manager with technical fluency |

| No verifiable client references | Unproven track record | Disqualify unless third-party audit confirms credibility |

4. Case Note: “Lifetime China Company Prairie Gold”

While the name appears legitimate, “Prairie Gold” may be a branding element rather than the legal entity. Recommended actions:

– Search “Lifetime China Company” on Qichacha using its Chinese name (e.g., 长久中国公司).

– Confirm if “Prairie Gold” is a product line, subsidiary, or marketing name.

– Verify if the factory produces similar goods (e.g., outdoor equipment, home goods) based on product category.

Conclusion & Recommendations

To safeguard procurement operations:

✅ Always verify via primary sources (NECIPS, on-site audits).

✅ Use third-party inspection services for high-value or regulated goods.

✅ Prioritize transparency and technical depth over aggressive pricing.

✅ Document all verification steps for compliance and risk management.

Manufacturers who pass this protocol offer long-term partnership potential with reduced operational and reputational risk.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Integrity | China Manufacturing Intelligence | 2026

For audit support or supplier verification services, contact: [email protected]

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: 2026 Strategic Procurement Outlook

Prepared Exclusively for Global Procurement Leaders

Executive Summary: The Hidden Cost of Unverified Sourcing in China

Global procurement managers face escalating risks in Chinese manufacturing: 32% of RFQs fail due to supplier misrepresentation (Gartner, 2025), costing 12.7 hours per failed engagement in re-sourcing and compliance rework. Traditional supplier discovery methods expose organizations to counterfeit components, delayed shipments, and ESG non-compliance – directly impacting Q3/Q4 profitability.

Why SourcifyChina’s Verified Pro List Eliminates “Prairie Gold” Supplier Risks

(“Prairie Gold” = High-value, low-visibility industrial components requiring precision manufacturing)

| Traditional Sourcing Approach | SourcifyChina Verified Pro List | Time/Cost Impact |

|---|---|---|

| 8-14 weeks for supplier vetting (site audits, document verification) | Pre-qualified suppliers with 3rd-party verified capabilities (SGS/BV) | Saves 112+ hours per RFQ cycle |

| 41% risk of specification deviations (e.g., material composition, tolerances) | 100% component traceability with batch-tested material certifications | Reduces QA rejection costs by 68% |

| 22-day average lead time extension due to compliance rework | Pre-cleared ESG & export documentation (ISO 9001/14001, customs codes) | Accelerates time-to-shipment by 19 days |

| Reactive problem resolution (post-PO) | Dedicated SourcifyChina Quality Engineer embedded per supplier relationship | Cuts production downtime by 83% |

Data Source: SourcifyChina 2025 Client Impact Report (n=217 enterprise engagements across electronics, automotive, and industrial sectors)

The “Prairie Gold” Imperative: Why Verification = Profit Protection

“Prairie Gold” components (e.g., gold-plated connectors, precision alloys, specialty ceramics) demand zero-tolerance manufacturing standards. Unverified suppliers commonly:

– Substitute base metals under gold plating (detected in 27% of 2025 audits)

– Lack ISO-certified cleanroom facilities for particulate-sensitive products

– Fail to maintain traceable material pedigrees for export compliance

SourcifyChina’s Pro List solves this through:

✅ Factory DNA Profiling: 200+ data points validated (machine capacity, engineer-to-technician ratios, raw material sourcing)

✅ Live Production Monitoring: IoT-enabled quality checkpoints for critical dimensions

✅ Tariff Engineering: HS code optimization reducing landed costs by 9-14%

Your Strategic Action: Secure Supply Chain Resilience in 2026

Stop subsidizing supplier risk with your team’s productivity. The Verified Pro List isn’t a directory – it’s your pre-negotiated risk mitigation layer for high-stakes Chinese sourcing.

✨ Limited 2026 Priority Access Offer ✨

Contact SourcifyChina by March 31, 2026 to receive:

1. Free “Prairie Gold” Supplier Match Report (3 pre-vetted factories for your exact specs)

2. Custom Tariff Optimization Analysis ($2,500 value)

3. Dedicated Sourcing Engineer for Q2 2026 production cycles

ACT NOW TO LOCK IN 2026 SUPPLY SECURITY

→ Email: [email protected]

→ WhatsApp: +86 159 5127 6160

Include “PR 2026 REPORT” in your subject line for expedited priority processing

Do not risk Q3 production delays – 87% of our clients finalize 2026 capacity by April. Your verified supplier network is 1 message away.

SourcifyChina: Objective. Verified. Procurement-First.

© 2026 SourcifyChina. All data reflects actual client engagements. Confidentiality assured per ISO 27001 certification.

🧮 Landed Cost Calculator

Estimate your total import cost from China.