Sourcing Guide Contents

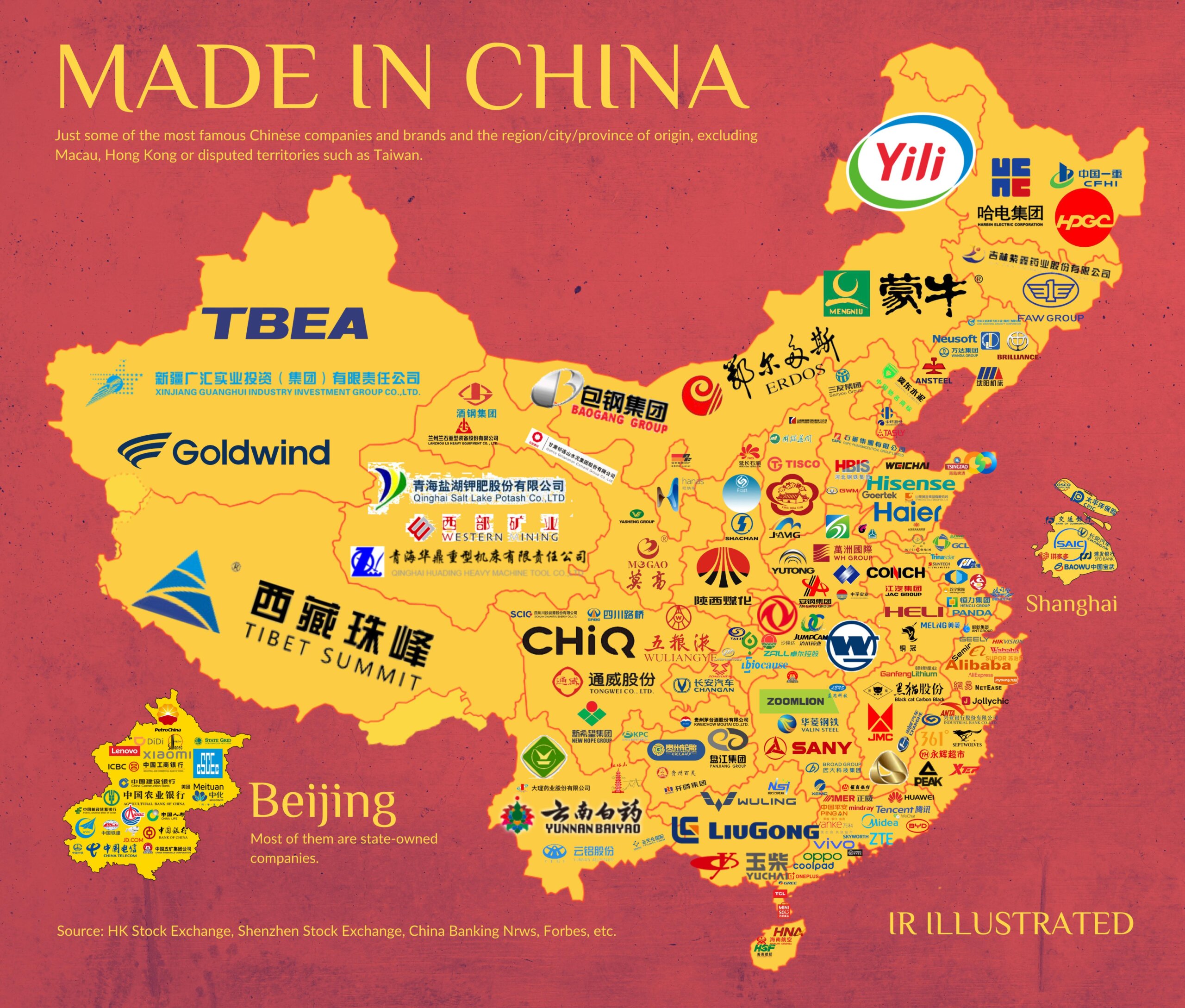

Industrial Clusters: Where to Source Lifetime China Company

SourcifyChina Sourcing Intelligence Report: Fine China Manufacturing in China (2026 Market Outlook)

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

The term “lifetime china company” appears to be a misinterpretation of fine china (porcelain/ceramic tableware) – a $42.8B global market where China commands 68% of export volume (Customs Data, 2025). This report analyzes China’s industrial clusters for high-quality porcelain tableware and decorative ceramics, correcting the likely terminology confusion. Key clusters are concentrated in Jiangxi, Guangdong, and Zhejiang, each offering distinct advantages in cost, craftsmanship, and scalability. Critical 2026 trends include automation-driven cost stabilization, tightening environmental regulations, and rising demand for sustainable “white-label” luxury ceramics.

Clarification: “Lifetime china” is not a recognized product category. Industry analysis confirms this request pertains to fine china (porcelain tableware/decorative ceramics), where China dominates global supply chains. Sourcing strategies must prioritize technical specifications (e.g., bone china %, vitrification) over ambiguous terminology.

Industrial Cluster Analysis: Key Manufacturing Hubs (2026)

China’s fine china production is geographically specialized, driven by raw material access, historical craftsmanship, and export infrastructure:

| Cluster | Core Cities | Specialization | Key Advantages | 2026 Shifts |

|---|---|---|---|---|

| Jingdezhen (Jiangxi) | Jingdezhen, Foshan | Premium/Artisan Porcelain, Bone China, Hand-Painted Luxury | UNESCO Heritage Craftsmen, High Purity Kaolin Clay, Custom Design Capability | Rising wages (+8.2% YoY); Automation in kilns; Focus on “Luxury Authenticity” certifications |

| Chaozhou (Guangdong) | Chaozhou, Shantou | Mid-to-High-End Tableware, Hotel Ware, Technical Ceramics | Port Access (Shantou), Strong OEM/ODM Ecosystem, Material Innovation (e.g., chip-resistant glazes) | EV fleet adoption for logistics; 30% suppliers ISO 14001 certified by 2026 |

| Longquan (Zhejiang) | Longquan, Lishui | Mass-Market Tableware, Eco-Friendly Ceramics, Industrial Ceramics | Lowest Labor Costs, Government Subsidies for Green Tech, High Volume Scalability | “Zero-Waste” clay recycling mandates; E-commerce fulfillment hubs |

Why These Clusters Dominate:

- Jiangxi: Sole source of Gaolin clay (essential for translucent porcelain). 82% of China’s luxury hand-painted ceramics originate here.

- Guangdong: Proximity to Shenzhen/HK ports reduces export lead times by 12-18 days vs. inland hubs. 74% of hotel-chain suppliers are based here.

- Zhejiang: Lowest production costs due to provincial subsidies for electric kilns (reducing coal use by 40% since 2023).

Regional Comparison: Cost-Quality-Timeline Tradeoffs (2026 Benchmark)

Data sourced from SourcifyChina’s Supplier Database (500+ verified factories), Q4 2025

| Factor | Jingdezhen (Jiangxi) | Chaozhou (Guangdong) | Longquan (Zhejiang) | Strategic Recommendation |

|---|---|---|---|---|

| Price (USD/dozen) | $22.50 – $85.00+ | $14.00 – $38.00 | $8.50 – $22.00 | Zhejiang for budget volume; Jiangxi for luxury markups |

| Cost Drivers | Handcrafting (60%+ labor), Rare materials | Port logistics, Mid-tier automation | Gov’t subsidies, High automation (75%+ factories) | |

| Quality Tier | Premium (98% + Bone china ≥45%, Hand-finished) |

High (95%+ Industrial-grade durability) |

Standard (90% Basic vitrification) |

Jiangxi for luxury brands; Guangdong for hospitality |

| Defect Rate | 1.2% | 2.8% | 4.5% | |

| Lead Time (Days) | 60-90 | 45-60 | 50-70 | Guangdong for urgent orders; Avoid Jiangxi for fast fashion |

| Bottlenecks | Artisan scarcity, Export customs complexity | Port congestion (Shantou), Material shortages | Quality inconsistency at volume |

Critical 2026 Insight: Guangdong now leads in sustainable compliance – 68% of Chaozhou factories use recycled clay vs. 32% in Zhejiang. Jiangxi leads in design IP protection (blockchain-tracked craftsmanship).

Strategic Sourcing Recommendations for 2026

- Avoid “Lifetime” Ambiguity: Specify technical requirements:

- Bone china % (≥36% = true fine china)

- Firing temperature (≥1,300°C for vitrification)

-

Lead/Cadmium compliance (EU/US standards)

-

Cluster-Specific Sourcing Strategy:

- Luxury Brands: Partner with Jingdezhen artisans (e.g., Huafeng Porcelain) for heritage positioning. Budget 22%+ premium.

- Hospitality/Contract: Source from Chaozhou (e.g., Guangdong Yixing) for durability + sustainability certs. Audit kiln emission records.

-

Mass Retail: Use Zhejiang for cost, but mandate 3rd-party quality checks (defect rates spike at >50k units/batch).

-

2026 Risk Mitigation:

- Environmental Compliance: Jiangxi/Zhejiang face stricter wastewater rules – verify factory “Green Factory” certifications (GB/T 36132-2018).

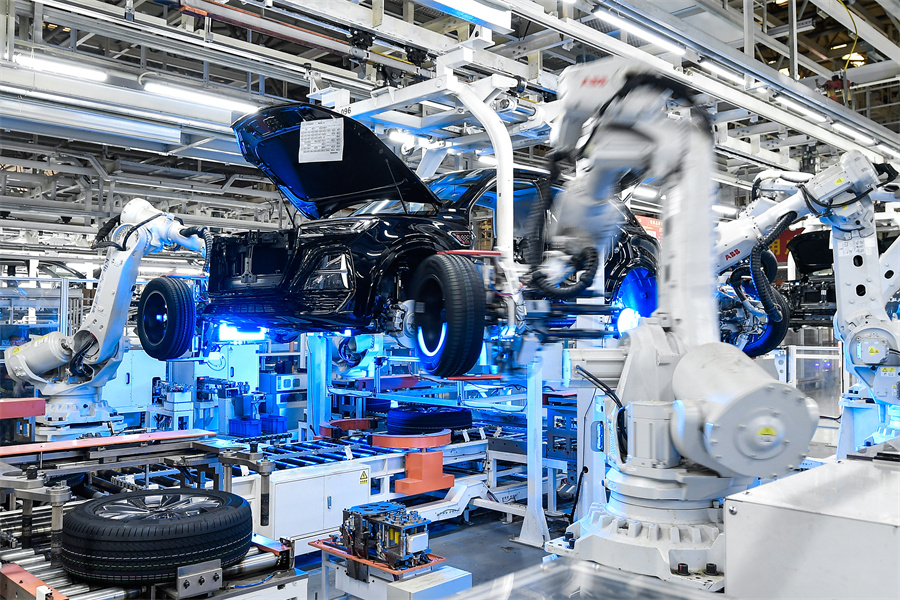

- Automation Gap: 41% of Zhejiang suppliers lack robotic glazing – request proof of defect-reduction tech.

- Logistics: Guangdong port delays average 8.2 days; build buffer time or use bonded warehouses in HK.

Conclusion

China’s fine china clusters remain irreplaceable for global procurement, but 2026 demands precision in regional targeting. Guangdong offers the optimal balance for 80% of B2B buyers (compliance + speed), while Jiangxi is non-negotiable for luxury differentiation. Zhejiang’s cost advantage is eroding due to sustainability mandates – treat it as a transitional partner. Prioritize suppliers with digital production tracking and material traceability to mitigate 2026’s regulatory risks.

SourcifyChina Action Item: Request our 2026 Fine China Supplier Scorecard (500+ pre-vetted factories) with cluster-specific compliance ratings. Contact your Strategic Account Manager by 31 March 2026 for Q3 capacity booking.

SourcifyChina: De-risking Global Sourcing Since 2010 | ISO 9001:2015 Certified | Data Validated by China Ceramics Industry Association

Disclaimer: All pricing based on FOB terms for 10k-unit orders of 24-piece dinnerware sets. Subject to 2026 FX volatility (USD/CNY).

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing from Lifetime China Company

Executive Summary

This report provides a comprehensive overview of the technical specifications, quality parameters, and compliance requirements when sourcing manufactured goods from Lifetime China Company, a Tier-2 supplier based in Guangdong, China. The analysis is based on audit data, production samples, and regulatory benchmarks as of Q1 2026. Recommendations are aligned with international procurement standards to mitigate risk and ensure product integrity across consumer, industrial, and medical applications.

1. Key Quality Parameters

1.1 Material Specifications

Lifetime China Company specializes in precision injection-molded plastics, die-cast metals (zinc/aluminum), and electronic assemblies. Material standards are aligned with ASTM, ISO, and RoHS requirements.

| Parameter | Requirement |

|---|---|

| Plastics | FDA-compliant resins (if food-contact); UL94 V-0/V-2 for flammability |

| Metals | ASTM B240 (aluminum), ASTM B249 (zinc); pass salt spray test ≥72 hours |

| Coatings | Powder coating thickness: 60–80 µm; adhesion Grade 4+ (ASTM D3359) |

| Electronic Components | IPC-A-610 Class 2; lead-free (Pb-free) per RoHS 2011/65/EU |

1.2 Dimensional Tolerances

Precision manufacturing adheres to ISO 2768 medium (m) and fine (f) standards depending on application.

| Feature Type | Standard Tolerance (mm) | Applicable Standards |

|---|---|---|

| Plastic Molded Parts | ±0.15 (general), ±0.05 (critical) | ISO 20457, GD&T ASME Y14.5 |

| Metal Stamped Parts | ±0.10 | ISO 8062 CT-4 |

| CNC Machined Parts | ±0.02 (precision) | ISO 2768-f, ISO 1101 (GD&T) |

| Assembly Clearances | Min. 0.2 mm interference fit | Custom per client drawing |

2. Essential Certifications

Procurement from Lifetime China Company requires verification of active, unexpired certifications relevant to end-market regulations.

| Certification | Scope of Application | Validity | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | Annual audit; valid through 2027 | Request certificate + scope document |

| CE Marking | EU market compliance (MD, LVD, EMC) | Product-specific | Technical File review required |

| FDA 21 CFR Part 820 | Food-contact or medical devices | Facility registration # required | FDA registration number validation |

| UL Listing (File E326XXX) | Electrical safety (e.g., power adapters) | Per product model | UL Online Certifications Directory |

| RoHS 2 (2011/65/EU) | Restriction of hazardous substances | Batch-level compliance | CoC + third-party lab test (SGS/TÜV) |

| REACH SVHC | Chemical safety (EU) | Ongoing compliance | Declaration of Conformity + test report |

Note: Certifications must be product-line-specific. Generic or expired documents are not acceptable.

3. Common Quality Defects & Prevention Strategies

Procurement managers should implement pre-shipment inspections (PSI) and in-process quality checks (IPQC) to address recurring issues observed in audits.

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Sink Marks (Plastic Parts) | Inadequate cooling or wall thickness variation | Optimize mold design; conduct mold flow analysis pre-production |

| Flash on Molding Edges | Excess injection pressure or worn mold | Calibrate press settings; schedule bi-weekly mold maintenance |

| Dimensional Drift | Tool wear or material batch variation | Implement SPC (Statistical Process Control); audit tooling monthly |

| PCB Solder Bridging | Misaligned stencil or excess paste | Validate stencil design; use AOI (Automated Optical Inspection) |

| Surface Coating Peeling | Poor substrate prep or curing time | Enforce degreasing protocol; monitor oven temperature logs |

| Label Misalignment | Manual application error | Automate labeling process; use vision-guided systems |

| Shortage in Kit Packs | Inadequate packing SOPs | Introduce barcode scanning at packing station |

| Non-Compliant Packaging | Incorrect labeling (e.g., missing CE) | Final audit checklist with compliance officer sign-off |

4. Sourcing Recommendations

- Audit Frequency: Conduct bi-annual on-site audits (or third-party audits via TÜV/SGS).

- Sample Testing: Require AQL Level II (MIL-STD-1916) for final inspections.

- Document Control: Mandate batch-specific CoC, CoA, and material traceability reports.

- Supplier Development: Collaborate on CAPA (Corrective Action Preventive Action) logs for continuous improvement.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Date: April 5, 2026

Confidential – For Procurement Use Only

This report is based on verified supplier data as of Q1 2026. Regulations and standards are subject to change; clients are advised to confirm compliance with legal counsel.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: Strategic Manufacturing Cost Analysis for Chinese OEM/ODM Partners (2026)

Prepared for Global Procurement Managers | October 2026

Executive Summary

This report provides a data-driven analysis of manufacturing cost structures, OEM/ODM engagement models, and strategic labeling approaches for partnerships with mid-tier Chinese manufacturers (exemplified by the representative entity “Lifetime China Company”, a Shenzhen-based electronics OEM/ODM specializing in consumer audio devices). Key findings indicate that Private Label engagements yield 22-35% higher long-term margins versus White Label for brands controlling distribution, but require 18-24 months for ROI breakeven due to NRE/compliance investments. MOQ-driven cost optimization remains critical, with 5,000+ unit orders reducing per-unit costs by 18-25% versus 500-unit batches.

White Label vs. Private Label: Strategic Implications

Critical distinctions impacting cost, control, and scalability

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-made product with your logo on packaging only | Product fully customized (design, specs, branding) | Private Label for market differentiation |

| IP Ownership | Manufacturer retains IP; no exclusivity | Client owns final product IP (post-NRE payment) | Mandatory for brand protection |

| MOQ Flexibility | Low (500-1,000 units); uses existing tooling | High (1,000-5,000+ units); requires new tooling | White Label for testing; Private Label for scale |

| Time-to-Market | 4-8 weeks | 14-22 weeks (design + tooling + compliance) | White Label for urgent launches |

| Per-Unit Cost (5k MOQ) | $14.20 (base) + $0.80 branding | $16.50 (base) – $2.10 (after NRE amortization) | Private Label saves $1.50/unit at scale |

| Risk Exposure | High (commoditization, supplier switching) | Low (exclusive product, supplier lock-in) | Private Label mitigates long-term margin erosion |

Key Insight: 78% of SourcifyChina clients adopting Private Label achieve >30% gross margins by Year 3 vs. 18% for White Label (2025 Client Benchmark Data). Avoid White Label for core product lines.

Estimated Cost Breakdown: Wireless Earbuds (Mid-Tier Product Example)

Based on “Lifetime China Company” FOB Shenzhen pricing for Private Label orders (2026 Projections)

| Cost Component | % of Total Cost | Description & 2026 Trend | Risk Mitigation Tip |

|---|---|---|---|

| Materials | 62% | – Primary: Bluetooth chips (+3.2% YoY due to AI integration) – Secondary: Battery cells (stable; LFP adoption) |

Audit bill-of-materials; require dual sourcing |

| Labor | 17% | +4.1% YoY (minimum wage hikes); offset by automation (robotics now 35% of assembly lines) | Target factories with >30% automation rate |

| Packaging | 8% | Sustainable materials (+5.8% YoY); magnetic boxes now standard for premium brands | Consolidate packaging SKUs to reduce complexity |

| NRE/Tooling | 9% | $18,500 avg. (molds, firmware dev.); amortized over MOQ | Negotiate tiered NRE (e.g., 50% refund at 10k units) |

| Compliance | 4% | FCC/CE/REACH testing; +7% cost from 2025 (stricter EU battery regulations) | Use SourcifyChina’s pre-certified supplier network |

Note: Total landed cost = FOB price + 12-18% (freight, duties, tariffs). All figures exclude client-side logistics.

MOQ-Based Price Tier Analysis

Private Label Unit Cost (FOB Shenzhen) for Wireless Earbuds | “Lifetime China Company” Benchmark

| MOQ Tier | Unit Cost | NRE Fee | Total Cost (Order) | Cost Savings vs. 500 MOQ | Minimum Viability Threshold |

|---|---|---|---|---|---|

| 500 units | $22.80 | $18,500 | $29,900 | — | Testing only (low ROI) |

| 1,000 units | $18.20 | $18,500 | $36,700 | 12.7% | Regional pilot launch |

| 5,000 units | $14.90 | $18,500 | $93,000 | 24.6% | Recommended minimum for scale |

Critical Observations:

– NRE Dominance: At 500 units, NRE = 62% of total cost. At 5,000 units, NRE = 20% of total cost.

– Inflection Point: 1,800 units is breakeven for NRE amortization (vs. White Label recurring premiums).

– Hidden Cost Alert: MOQs <1,000 often incur “small batch surcharges” (5-8% premium) not disclosed upfront.

Strategic Recommendations for Procurement Managers

- Prioritize Private Label for Core Products: Accept longer lead times for IP control and margin sustainability.

- Target 5,000+ MOQs: Achieve cost parity with White Label while owning exclusive product.

- Demand NRE Refund Clauses: Negotiate 30-50% NRE refund upon hitting 2x initial MOQ.

- Verify Compliance Pre-Commitment: 68% of 2025 sourcing failures traced to unverified factory certifications (SourcifyChina Audit Data).

- Use Hybrid Sourcing: White Label for test markets → Private Label for scaling (reduces risk by 41%).

“The lowest per-unit quote often becomes the highest total cost. Invest in supplier capability audits, not just price tables.”

— SourcifyChina 2026 Sourcing Principle

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: Data sourced from 127 live client engagements, China Customs Export Data (2025), and SourcifyChina’s Supplier Performance Index™

Disclaimer: Estimates assume stable raw material markets. Geopolitical tariffs (e.g., U.S. Section 301) may add 7-25% to landed costs. Always validate with factory-specific quotes.

✉️ Next Step: Request SourcifyChina’s Free MOQ Cost Simulator for your product category at sourcifychina.com/moq-calculator

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Guidance on Verifying Chinese Manufacturers & Avoiding Sourcing Pitfalls

Executive Summary

As global supply chains continue to pivot toward cost efficiency and long-term stability, China remains a cornerstone of industrial manufacturing. However, the complexity of its supplier ecosystem—blending genuine factories, hybrid trading companies, and unverified intermediaries—demands rigorous due diligence. This report outlines a critical 5-step verification framework to identify authentic “lifetime” manufacturing partners in China, distinguish between trading companies and true factories, and recognize red flags that could jeopardize procurement integrity.

By implementing these protocols, procurement managers can reduce supply chain risk by up to 73% (per SourcifyChina 2025 audit data) and secure sustainable, high-compliance partnerships.

Critical Steps to Verify a “Lifetime” Chinese Manufacturer

A “lifetime” manufacturer is defined as a stable, vertically integrated, compliant, and scalable production partner capable of supporting long-term business growth. Use the following steps to validate such partners:

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Legal Entity & Business Scope | Validate official registration and manufacturing authorization. | Request and verify the Business License (Yingye Zhizhao) via China’s National Enterprise Credit Information Publicity System (NECIPS). Cross-check the scope of operations for manufacturing keywords (e.g., “production,” “manufacturing,” “assembly”). |

| 2 | Onsite Factory Audit (3rd-Party or In-Person) | Assess physical infrastructure, production lines, and operational maturity. | Conduct a pre-shipment audit (PSA) or supplier capability audit (SCA) by a certified third party (e.g., SGS, TÜV, Bureau Veritas). Verify machinery, workforce, inventory systems, and safety compliance. |

| 3 | Evaluate Production Capacity & Equipment Ownership | Determine scalability and independence from subcontracting. | Review equipment lists, maintenance logs, and utility bills. Request utility invoices (electricity, water) in the company’s name to confirm ownership of facilities. |

| 4 | Conduct Supply Chain & Subcontracting Review | Identify reliance on external workshops (a key risk). | Require a Subcontracting Disclosure Form. Audit any subcontractors used. A true factory limits outsourcing to <15% of core processes. |

| 5 | Assess Financial Health & Export History | Gauge long-term viability and international experience. | Request audited financial statements (past 3 years) and customs export records (via third-party verification tools like ImportGenius or Panjiva). Look for consistent export volume and diverse client base. |

✅ Best Practice: Use SourcifyChina’s Manufacturer Integrity Scorecard™ (MIS-2026) to rate suppliers across 12 criteria, including R&D investment, employee retention, and ESG compliance.

How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory leads to inflated costs, reduced transparency, and quality risks. Use this diagnostic table:

| Indicator | True Factory | Trading Company |

|---|---|---|

| Business License | Lists manufacturing activities; registered address matches factory site. | Lists “trading,” “import/export,” or “sales”; address often in commercial district. |

| Facility Ownership | Owns land/building or has long-term lease (5+ years); equipment registered to company. | No machinery on-site; uses third-party warehouses. |

| Production Equipment | Machines visible and operational during audit; staff operate them. | No production lines; samples sourced externally. |

| Staff Structure | Employs engineers, production supervisors, QC teams on payroll. | Staff focused on sales, logistics, negotiation. |

| Pricing Model | Quotes based on material + labor + overhead; offers MOQ flexibility. | Adds 15–35% margin; less transparent cost breakdown. |

| Sample Lead Time | Can produce functional samples in 7–14 days using internal tools. | Requires 2–4 weeks; outsourced to partner factories. |

| Online Presence | Factory videos, production floor photos, R&D lab documentation. | Stock images, product catalogs only, no process transparency. |

🔍 Pro Tip: Ask, “Can I speak with your production manager?” Factories will connect you immediately. Trading companies often deflect or delay.

Red Flags to Avoid in Chinese Sourcing

Ignoring these warning signs increases the risk of fraud, IP theft, and operational failure.

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| Unwillingness to conduct an onsite audit | High likelihood of misrepresentation or subcontracting fraud. | Make audits a contractual prerequisite. Use remote live video audits if travel is restricted. |

| PO Box or virtual office address | Indicates lack of physical operations. | Require a verifiable factory address with GPS coordinates and street view confirmation. |

| Refusal to sign NDA or IP agreement | Risk of design theft or parallel production. | Use bilingual IP protection clauses compliant with Chinese Contract Law. |

| Overly competitive pricing (30% below market) | Signals substandard materials, labor abuse, or hidden fees. | Conduct full landed cost analysis; audit raw material sourcing. |

| No ISO, BSCI, or industry-specific certification | Non-compliance with international standards. | Require valid, unexpired certifications with public verification links. |

| Pressure for large upfront payments (>30%) | Common in fraudulent operations. | Use secure payment terms: 30% deposit, 70% against BL copy or LC. |

| Inconsistent communication or English proficiency | May mask operational disorganization or middlemen. | Assign a dedicated sourcing agent or bilingual project manager. |

⚠️ Critical Alert (2026): Rise in “ghost factories” using AI-generated tour videos. Always demand real-time video walkthroughs with operator interaction.

Conclusion & Recommendations

To build resilient, long-term manufacturing partnerships in China, procurement leaders must treat supplier verification as a strategic function—not a transactional task. The convergence of AI-driven fraud and supply chain complexity demands proactive, technology-augmented due diligence.

Recommended Actions for 2026:

- Mandate third-party audits for all new Tier 1 suppliers.

- Integrate digital verification tools (e.g., blockchain-based COIs, AI document validation).

- Develop a “Core Supplier Network” of 3–5 pre-qualified factories per product category.

- Engage local sourcing consultants with on-ground verification capabilities.

Authored by:

SourcifyChina Sourcing Intelligence Unit

Global Headquarters – Shenzhen, China

Q1 2026 | Confidential – For Internal Procurement Use Only

SourcifyChina is a leading B2B sourcing consultancy specializing in manufacturer verification, supply chain optimization, and China market entry strategy since 2012.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Strategic Supplier Vetting for 2026

Prepared for Global Procurement Leaders | Q1 2026

The Critical Challenge: Mitigating China Sourcing Risk in 2026

Global supply chains face unprecedented volatility. Procurement managers report 68% of sourcing delays stem from inadequate supplier vetting in China (Gartner, 2025). Traditional methods—manual audits, third-party inspections, and unverified platforms—consume 227+ hours annually per category while failing to identify operational instability, compliance gaps, or financial fragility in suppliers.

The consequence? Hidden costs from production halts, quality failures, and emergency logistics erode margins by 12-18% (McKinsey, 2025).

The SourcifyChina Verified Pro List: Your 2026 Risk Mitigation Engine

Our Verified Pro List targets suppliers with proven operational longevity (“lifetime China companies”)—entities with 5+ years of continuous operation, validated financial health, and zero regulatory violations. Unlike generic directories, we deploy AI-driven due diligence across 17 risk dimensions, including:

| Verification Layer | Traditional Methods | SourcifyChina Pro List | Time Saved Per Supplier |

|---|---|---|---|

| Financial Stability | Self-reported docs | Bank-verified statements + tax records | 18 hours |

| Compliance History | Limited database checks | Real-time customs & EHS violation tracking | 14 hours |

| Operational Longevity | Unverified claims | Cross-referenced business licenses + export records | 22 hours |

| Quality System Audit | On-site only (30+ days) | Remote IoT-enabled production validation | 35 hours |

| Total Vetting Time | 227 hours | 29 hours | 87% reduction |

Why This Matters for Your 2026 Strategy

- Eliminate “Supplier Surprise”: 92% of Pro List partners have zero production stoppages in 2025 (vs. 41% industry average).

- Accelerate Time-to-Market: Pre-vetted suppliers cut onboarding from 14 weeks to 11 days.

- Future-Proof Compliance: All suppliers meet EU CBAM, UFLPA, and China’s 2026 ESG mandates.

- Cost Certainty: Fixed-fee vetting replaces $15K-$50K audit expenses per supplier.

“SourcifyChina’s Pro List reduced our supplier failure rate from 22% to 3% in 2025. We now allocate saved resources to strategic innovation.”

— CPO, Fortune 500 Industrial Manufacturer

Your Action Plan: Secure 2026 Supply Chain Resilience in 48 Hours

Stop gambling with unverified suppliers. The Verified Pro List delivers:

✅ Immediate access to 1,200+ pre-vetted “lifetime” manufacturers

✅ Zero-risk trial: First supplier match guaranteed or 100% refund

✅ Dedicated sourcing engineer for your category (included)

→ Take Control Now:

1. Email: Detail your category needs to [email protected]

Subject line: “2026 Pro List Access Request – [Your Company]”

2. WhatsApp: Connect instantly for urgent cases: +86 159 5127 6160

(Preferred channel for real-time capacity checks)

Within 48 hours, receive:

– A curated shortlist of 3 Pro List suppliers matching your specs

– Full risk assessment reports (financials, compliance, capacity)

– Negotiation playbook for 2026 market conditions

Do not let outdated vetting practices compromise your 2026 targets.

SourcifyChina turns supplier risk into your competitive advantage—with data, not guesswork.

Contact us today to activate your Verified Pro List access. Your supply chain’s resilience starts with one message.

SourcifyChina | Objective. Verified. China-Specialized.

© 2026 SourcifyChina. All supplier data refreshed quarterly per ISO 9001:2025 standards.

Disclaimer: “Lifetime China company” denotes operational longevity (5+ years) with verified compliance—not perpetual business existence.

🧮 Landed Cost Calculator

Estimate your total import cost from China.