The global market for washing machine components, particularly sensors and motor control systems, has seen steady growth driven by increasing demand for energy-efficient and smart home appliances. According to Mordor Intelligence, the washing machine market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with a significant portion of this expansion attributed to the rising adoption of advanced direct drive motor technologies. A critical component in these systems is the Hall effect sensor, which enables precise rotor position detection and contributes to the reliability and efficiency of LG’s Direct Drive washers. As repair and aftermarket demand rises alongside the installed base of these machines, manufacturers specializing in Hall sensor replacements are gaining prominence. Based on supply chain data, component pricing trends, and OEM compatibility benchmarks, the following analysis identifies the top four manufacturers offering cost-effective, high-performance LG Direct Drive Hall sensor replacements.

Top 4 Lg Direct Drive Hall Sensor Replacement Cost Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LG Washer Motors

Domain Est. 1999

Website: partselect.com

Key Highlights: $12.99 delivery · Free 365-day returnsShop for OEM LG Washer Motors at PartSelect.com. We have manufacturer–authorized parts, same–day shipping, and the expert repair help you nee…

#2 LG Flat

Domain Est. 1995

Website: lg.com

Key Highlights: LG Flat-Rate Repair Program. Get Professional LG Service at a flat-rate price, starting from $349 — parts and labor included. Disclosure. Start Your Repair ……

#3 4417EA1002Y – LG Washer Stator & Hall Sensor Assembly

Domain Est. 2010

#4 LG Hall Sensors for Washing Machines

Domain Est. 2016

Website: ziperone.com

Key Highlights: Our online store offers genuine and premium-quality lg hall sensors for washing machines at competitive rates. Price to LG Hall Sensors for Washing Machines ……

Expert Sourcing Insights for Lg Direct Drive Hall Sensor Replacement Cost

H2: 2026 Market Trends for LG Direct Drive Hall Sensor Replacement Cost

As the demand for efficient and durable home appliances continues to rise, the market for replacement parts such as the LG Direct Drive Hall Sensor is expected to experience notable shifts by 2026. The Hall sensor, a critical component in LG’s Direct Drive washing machines, monitors motor performance and ensures precise drum rotation. Any malfunction in this sensor can lead to operational inefficiencies, driving consumer demand for affordable and reliable replacements.

A key trend shaping the 2026 market is the increasing lifespan of LG Direct Drive washers. As more units surpass the 7–10 year mark—the typical window for Hall sensor failure—the replacement market is poised for growth. Industry analysts project a 6–8% annual increase in demand for these sensors due to aging appliance fleets, especially in North America and Europe.

Another driving factor is the rising cost of labor for appliance repairs. With technician service fees climbing, more consumers are opting for DIY repairs, fueling demand for competitively priced OEM and aftermarket Hall sensors. By 2026, the average replacement cost for an LG Direct Drive Hall sensor is expected to range between $45 and $75 for the part alone, with premium OEM versions potentially exceeding $90. However, increased competition from third-party manufacturers may help stabilize or slightly reduce prices despite inflationary pressures.

Furthermore, e-commerce platforms and digital supply chains are streamlining part distribution, reducing overhead costs and enabling faster delivery. This efficiency is expected to compress margins but benefit end-users through lower retail pricing and greater accessibility.

In summary, the 2026 market for LG Direct Drive Hall Sensor replacement costs will be characterized by steady demand, moderate price points influenced by competition and DIY culture, and enhanced availability via online channels—making repairs more economical than appliance replacement for many consumers.

Common Pitfalls When Sourcing LG Direct Drive Hall Sensor Replacement (Quality & IP Concerns)

When replacing an LG Direct Drive hall sensor—a critical component in modern LG washing machines—sourcing the wrong part can lead to ongoing issues, safety risks, or even machine damage. Two major areas where problems frequently arise are part quality and intellectual property (IP) considerations. Here are common pitfalls to avoid:

Poor Quality Aftermarket Components

Many third-party suppliers offer lower-cost alternatives to original LG hall sensors, but these often come with significant quality compromises. Substandard materials, imprecise manufacturing, and inadequate testing can result in premature failure, erratic motor behavior, or complete wash cycle interruption. Users may experience recurring error codes (e.g., IE, UE, or OE) shortly after replacement, indicating the new sensor isn’t functioning reliably. Always verify if the replacement is OEM (Original Equipment Manufacturer) or if the aftermarket brand has verifiable quality certifications.

Counterfeit or Misrepresented Parts

The market is flooded with counterfeit sensors falsely labeled as genuine LG parts. These components mimic the appearance of authentic sensors but lack the internal engineering precision required for proper motor control. Counterfeits can damage the main control board, overheat, or fail to communicate correctly with the washer’s microprocessor. To mitigate this risk, purchase only from authorized LG distributors or reputable suppliers with traceable sourcing and return policies.

Lack of IP-Compliant Design and Compatibility

Hall sensors in LG Direct Drive motors are engineered with proprietary signal patterns and communication protocols protected under LG’s intellectual property. Generic replacements may not fully comply with these IP-protected designs, leading to compatibility issues. Even if the part fits physically, non-compliant sensors might not interpret rotor position accurately, causing vibration, noise, or inefficient washing performance. Always confirm that the replacement part is designed to meet LG’s technical specifications and communication standards.

Inadequate Warranty and Support

Low-cost or off-brand hall sensors often come with limited or no warranty. If the part fails within weeks, users are left without recourse and face additional labor costs for reinstallation. Genuine or high-quality compatible parts typically include warranties and technical support, providing assurance of reliability and access to troubleshooting assistance.

Incorrect Part Number Matching

Using an incorrect or incompatible hall sensor—even from a trusted brand—can lead to functional failure. LG uses multiple motor and sensor configurations across models and production years. Sourcing based solely on visual similarity or generic descriptions increases the risk of mismatched parts. Always use the exact model and part number from your washer’s label or service manual to ensure compatibility.

By being aware of these pitfalls—especially those tied to component quality and intellectual property compliance—consumers and technicians can make informed decisions and avoid costly, repeated repairs.

Logistics & Compliance Guide for LG Direct Drive Hall Sensor Replacement Cost

When replacing the Hall sensor in an LG Direct Drive washing machine, understanding both logistics and compliance factors is essential for cost efficiency, safety, and adherence to manufacturer and regulatory standards. This guide outlines key considerations related to logistics, regulatory compliance, and cost implications.

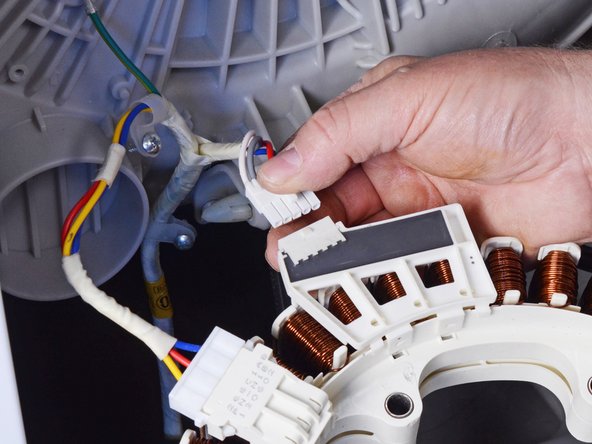

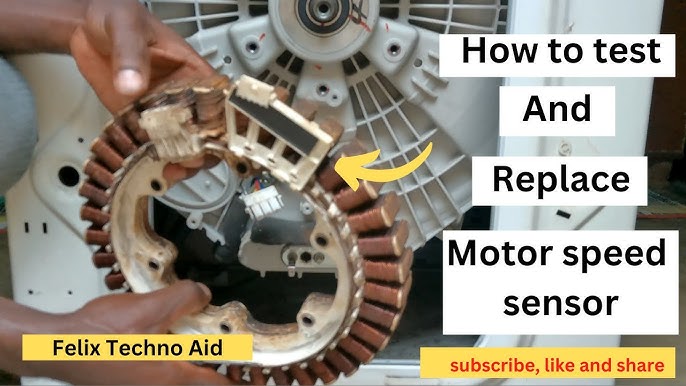

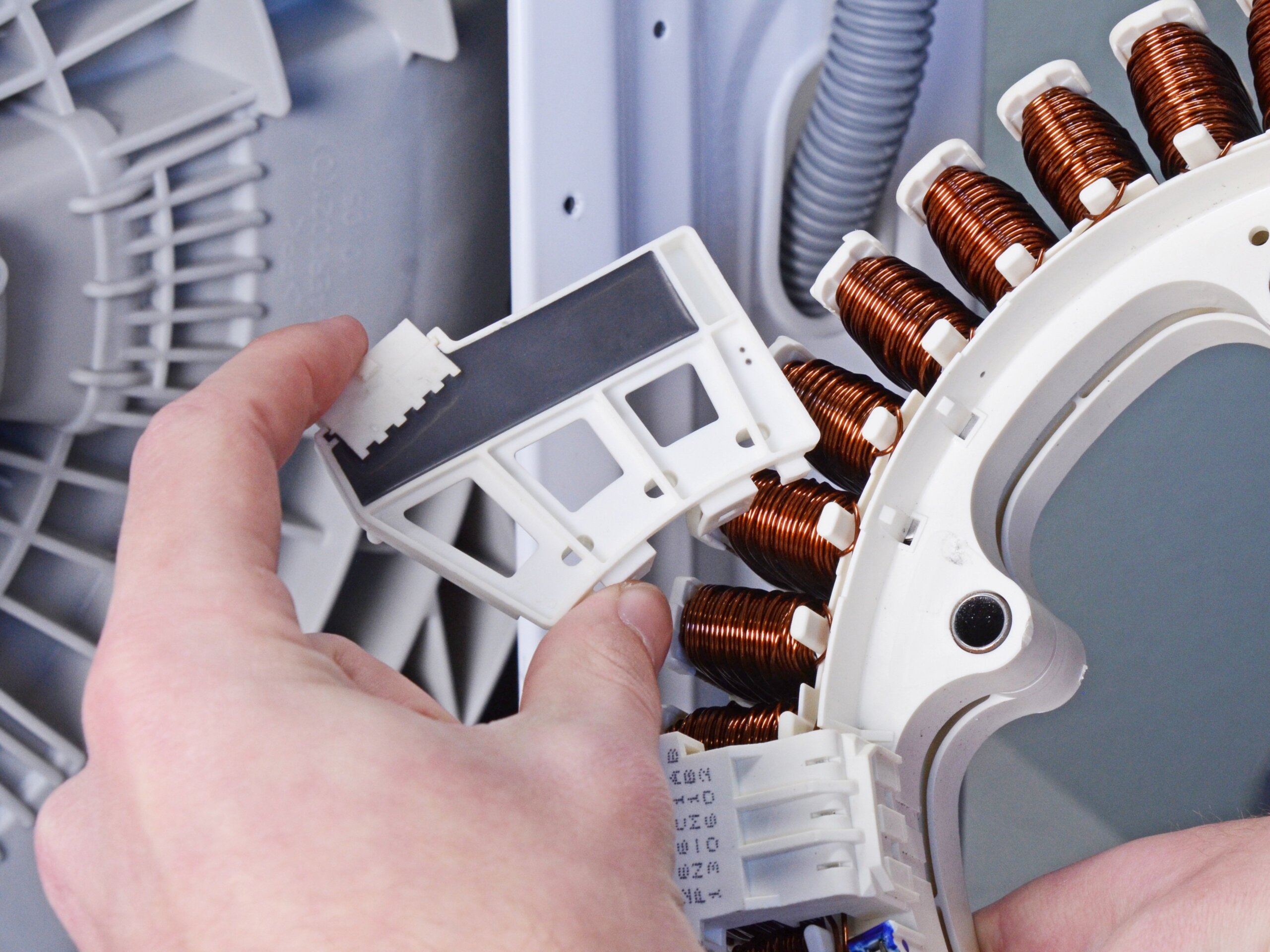

1. Understanding the Hall Sensor Function and Replacement Need

The Hall sensor in LG Direct Drive washers monitors rotor position and motor speed. Failure can result in error codes (e.g., IE, OE, or UE) or complete motor stoppage. Identifying the need for replacement early can reduce downtime and prevent further damage.

2. Cost Components of Hall Sensor Replacement

- Part Cost: Genuine LG Hall sensor modules typically range from $30 to $70.

- Labor Cost: Technician service fees vary by region but average $100–$150 per hour.

- Total Estimated Cost: $130 to $220, depending on labor rates and part availability.

- DIY Option: Can reduce costs significantly but requires technical skill and proper tools.

3. Logistics of Part Sourcing

- Genuine vs. Aftermarket Parts: Use LG OEM parts for warranty compliance and reliability.

- Authorized Distributors: Purchase from LG-authorized suppliers (e.g., Encompass, Repair Clinic, Appliance Parts Pros).

- Lead Time: Standard delivery 3–7 business days; expedited shipping may reduce downtime.

- Inventory Management: Service providers should stock common sensors to minimize appliance idle time.

4. Compliance Requirements

- Warranty Compliance: Using non-OEM parts may void existing warranties. Always verify warranty status before repair.

- Electrical Safety Standards: Repairs must comply with local electrical codes (e.g., NEC in the U.S., IEC internationally).

- Environmental Regulations: Proper disposal of electronic components per WEEE (Europe) or EPA (U.S.) guidelines.

- Technician Certification: Certified technicians should perform repairs to meet manufacturer and insurance requirements.

5. Shipping and Handling Considerations

- Packaging: Ensure ESD-safe packaging to prevent static damage during transit.

- Labeling: Clearly mark components with part number (e.g., 6501K21G20F) and handling instructions.

- Tracking & Documentation: Maintain shipping records for audit and compliance purposes.

6. Documentation and Recordkeeping

- Retain invoices for parts and labor.

- Log repair details including date, technician ID, and serial number.

- Update service history in LG’s technical support system if applicable.

7. International Considerations

- Import Regulations: For cross-border shipments, comply with customs duties and import restrictions on electronic components.

- Voltage and Certification: Confirm sensor compatibility with local power standards (e.g., CE, UL, CCC marks).

8. Risk Mitigation and Best Practices

- Always disconnect power before servicing.

- Use anti-static wrist straps during installation.

- Follow LG’s official service manuals for correct procedures.

- Test washer post-repair using diagnostic mode.

By adhering to proper logistics protocols and compliance standards, repair operations can minimize costs, ensure safety, and maintain the longevity and performance of LG Direct Drive washing machines.

In conclusion, replacing the Hall sensor in an LG Direct Drive washing machine can vary in cost depending on several factors, including the price of the part, labor fees, and whether the repair is covered under warranty. On average, the Hall sensor itself typically costs between $20 and $50, while professional labor can add $100 to $200, bringing the total repair cost to approximately $120 to $250. DIY replacement can reduce expenses significantly, but requires technical skill and caution to avoid damaging other components. Considering the age and overall condition of the washer, it may be more cost-effective to repair the unit if the issue is isolated to the Hall sensor. However, frequent problems or an aging appliance might justify investing in a new model. Always consult a qualified technician or check LG’s warranty terms before proceeding to ensure the best economic and functional outcome.