The global drywall screws market is experiencing steady growth, driven by rising construction activities and the increasing demand for efficient, durable interior wall solutions. According to Mordor Intelligence, the Drywall Screws Market was valued at approximately USD 1.4 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2028. This expansion is fueled by the shift toward lightweight construction materials and the preference for drywall systems in both residential and commercial buildings. As demand increases, manufacturers are optimizing product specifications—including screw length—to meet varying structural and application needs. From 1¼ inch screws for standard drywall to longer variants for metal studs or resilient channels, precision in length enhances holding power and installation efficiency. In this evolving landscape, leading manufacturers are differentiating themselves through innovation, quality control, and tailored product offerings. Below are the top 7 manufacturers recognized for their reliable and application-specific drywall screw lengths, backed by market presence and technical expertise.

Top 7 Length Of Screw For Drywall Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DWFSD Drywall

Domain Est. 1995

Website: strongtie.com

Key Highlights: This self-drilling screw is used for fastening drywall to cold-formed steel (recommended thicknesses: 43 mil / 18 ga. and 54 mil / 16 ga.)…

#2 What are the different types of drywall screws?

Domain Est. 1998

Website: home.howstuffworks.com

Key Highlights: Drywall screws are classified according to length and pitch. There are two common types of drywall screw lengths: S-type and W-type….

#3 What Screws Should You Use for 5/8

Domain Est. 2024

Website: sdrywallpro.com

Key Highlights: This means that as long as your screw penetrates 5/8-inch into the wood stud, you’re meeting code. For 5/8″ drywall, a 1 1/4″ screw typically does the job:…

#4 Step

Domain Est. 1998

Website: nationalgypsum.com

Key Highlights: Use bugle head drywall screws, spaced 12-16 inches apart on the framing. Use the GridMarX® guide marks as a reference for screw placement….

#5 Drywall Screw Spacing and Pattern Guide

Domain Est. 1998

Website: fastenersystems.com

Key Highlights: The optimal screw length for 1/2″ drywall is 1-1/4 inches. This length ensures that the screw can adequately penetrate the drywall and into ……

#6 2024 Comprehensive Guide to Drywall Screws for Wholesalers and …

Domain Est. 2013

Website: taiwan-screw.com

Key Highlights: Wood studs: 1-1/4-inch screws are common. Metal studs: Shorter screws, like 1-inch, may be better. 3. Aim for Stud Penetration. Choose a screw ……

#7 Drywall Screw Length Guide for Different Thicknesses

Domain Est. 2022

Website: donghefastener.com

Key Highlights: The standard and most universally used drywall screw length for interior home walls is 1-1/4 inches. This length is perfectly suited for the ……

Expert Sourcing Insights for Length Of Screw For Drywall

H2: 2026 Market Trends for Length of Screw for Drywall

The drywall screw market, particularly regarding screw length, is poised for notable shifts by 2026, driven by construction practices, material innovations, and regional dynamics. Key trends include:

1. Dominance of Standard Lengths with Niche Growth

The 1-5/8” screw will remain the dominant length for standard ½” drywall on wood and light-gauge steel studs, supported by code compliance and installer familiarity. However, demand for 2” and 2-½” screws is expected to rise, driven by thicker wall assemblies (e.g., double-layer drywall for soundproofing), resilient channels, and advanced framing techniques requiring deeper penetration into structural members.

2. Rise in Multi-Layer and Specialty Installations

Increased demand for improved acoustics, fire resistance, and durability in commercial and high-end residential projects will boost adoption of multi-layer drywall systems. This directly fuels demand for longer screws (2”–3”), especially in hospitality, healthcare, and multifamily housing, where building standards are more stringent.

3. Regional Construction Activity and Code Influence

North America, particularly the U.S., will remain a key market due to ongoing residential and commercial construction. Updated building codes emphasizing energy efficiency and structural integrity may indirectly influence screw length selection—e.g., thicker insulation or structural sheathing could require longer fasteners in certain framing configurations.

4. Shift Toward Lightweight and Composite Framing

Growth in light-gauge steel (LGS) and engineered wood framing systems favors screws with optimized thread design and length. While 1-5/8” remains standard, longer screws (2”) may be preferred in high-load or seismic zones for enhanced pull-out resistance. Compatibility with framing material will increasingly influence length choice.

5. Sustainability and Efficiency Pressures

Contractors will favor screws that reduce labor time and material waste. Longer, high-strength screws that secure multiple layers in one pass can improve efficiency, supporting their adoption despite higher per-unit cost. Manufacturers may promote dual-length packs or multi-application screws to meet diverse on-site needs.

6. Innovation in Coatings and Drive Types, Not Length

While screw length evolution will be incremental, innovation will focus on corrosion-resistant coatings (e.g., ceramic, zinc-aluminum) and drive systems (e.g., Phillips/Slot combo, square recess) to reduce cam-out. These improvements enhance performance but do not drastically alter optimal length standards.

Conclusion

By 2026, the drywall screw length market will remain anchored in established standards, with 1-5/8” commanding the largest share. However, growing demand for performance-driven wall systems will expand the niche for longer screws (2”–3”), particularly in commercial and code-sensitive applications. Market growth will be closely tied to construction volume, energy and acoustic regulations, and the adoption of advanced framing technologies.

Common Pitfalls When Sourcing Length of Screw for Drywall (Quality, IP)

When selecting the appropriate screw length for drywall installation, overlooking key quality and performance factors can lead to installation failures, compromised structural integrity, and long-term durability issues. Below are common pitfalls related to quality and mechanical performance (often associated with terms like “IP” — though IP typically refers to Ingress Protection in electronics, here interpreted as mechanical strength or performance):

Insufficient Penetration into Stud

One of the most frequent mistakes is choosing screws that are too short. A drywall screw must penetrate at least 3/4 inch (19 mm) into the wood or metal stud to ensure a secure hold. Screws that are too short may not anchor properly, leading to sagging drywall, loose panels, or nail pops over time.

Using Overly Long Screws

Conversely, using screws that are too long increases the risk of puncturing electrical wiring, plumbing lines, or HVAC ducts located within the wall cavity. Long screws can also compromise the structural integrity of metal studs by deforming them or creating stress points. Additionally, over-penetration can make finishing and taping more difficult.

Poor Screw Quality Leading to Stripping or Breakage

Low-quality screws often feature inferior head designs or weak materials that are prone to cam-out (stripping the screw head) during installation. This is especially common with Phillips-head screws that don’t maintain bit engagement. Poor tensile strength may also cause screws to snap under pressure, particularly when driven into dense framing or using power tools set at high torque.

Inadequate Corrosion Resistance

In high-moisture areas such as bathrooms or basements, using standard drywall screws without proper corrosion resistance can result in rust and eventual joint failure. Green-tag (mold-resistant) or blue-tag (moisture-resistant) drywall may require compatible corrosion-resistant screws (e.g., coated or stainless steel) to maintain long-term performance.

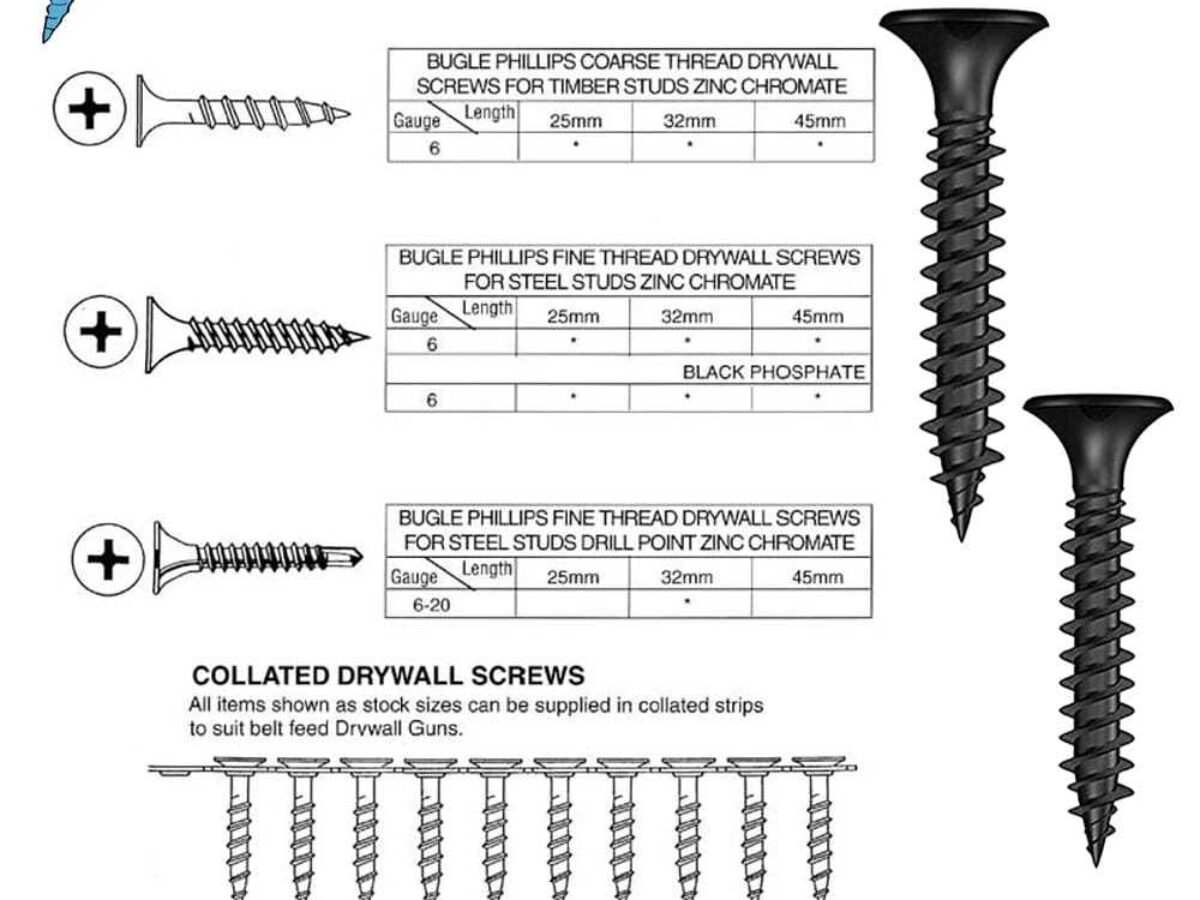

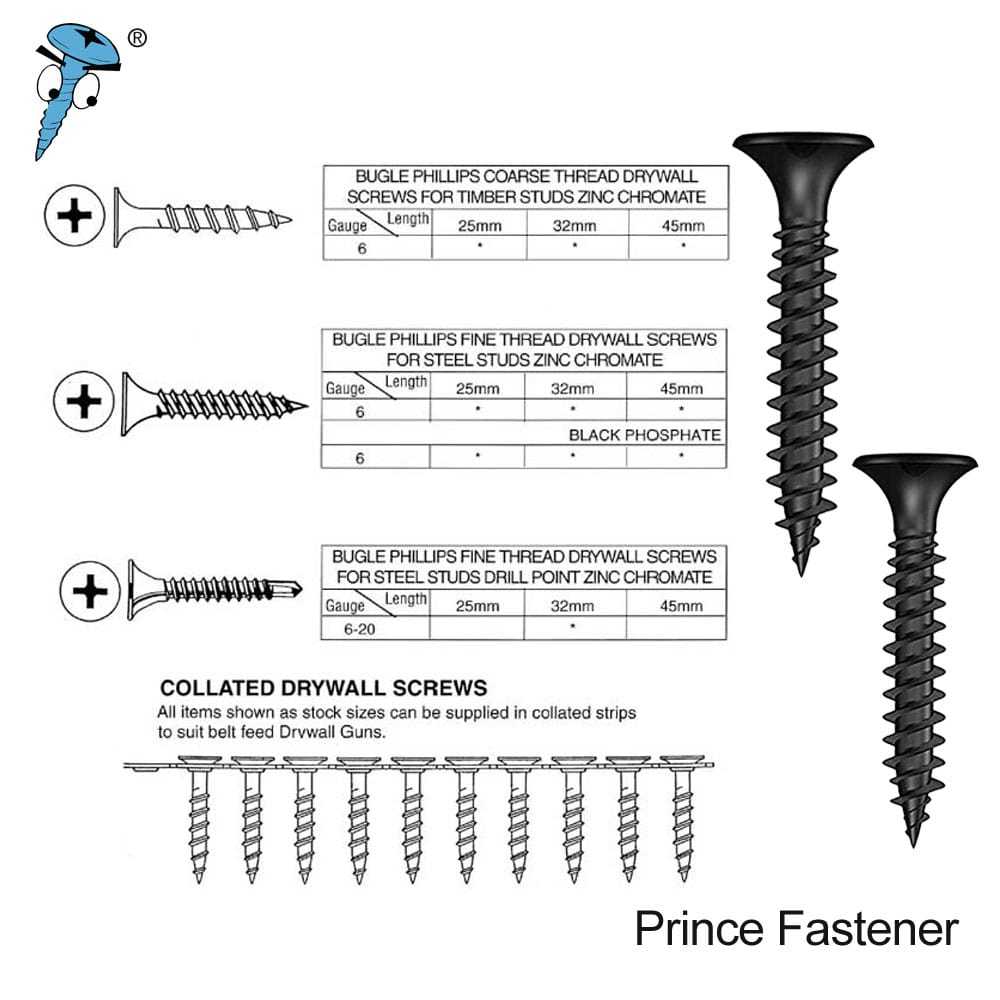

Mismatched Screw Type for Substrate

Using wood screws instead of proper drywall screws—or selecting coarse-thread screws for metal studs and vice versa—can impair holding power. Drywall screws are specifically designed with fine threads for metal studs and coarse threads for wood. Using the wrong type reduces grip strength and increases the risk of pull-through or stud damage.

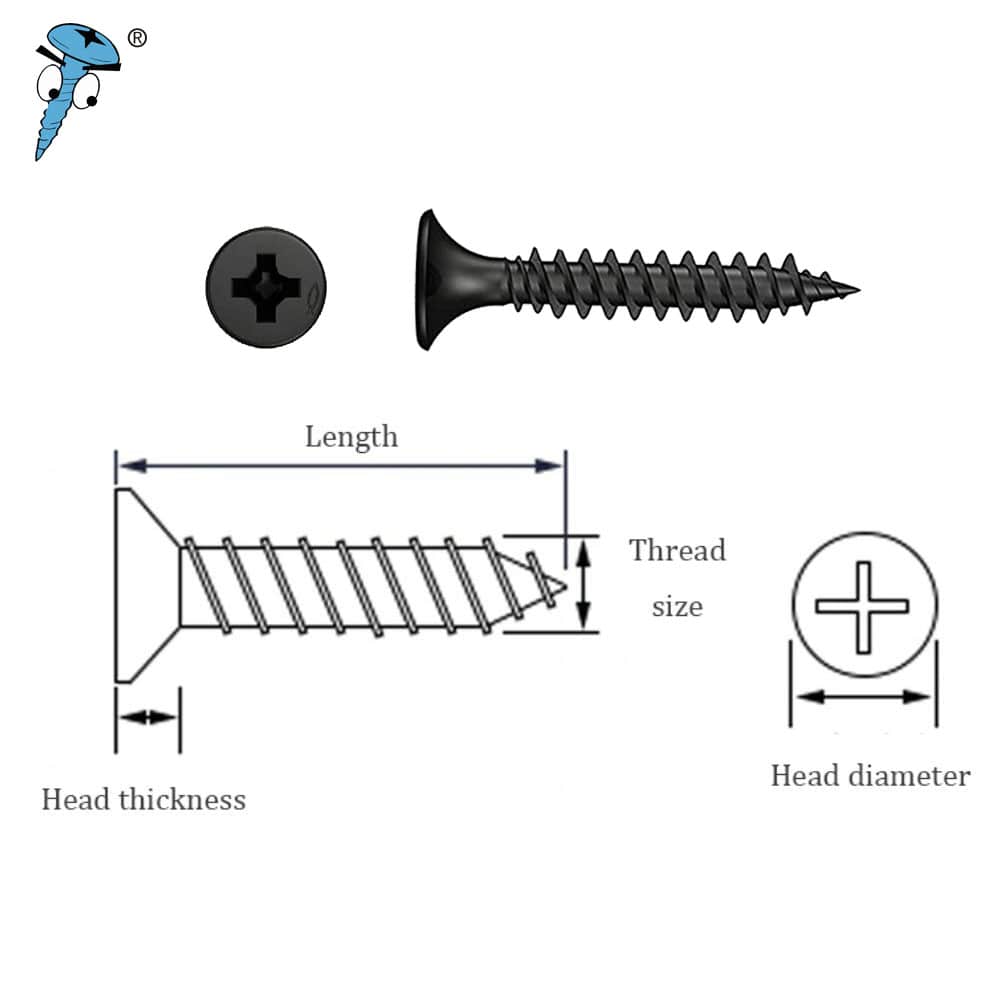

Ignoring Screw Head Design and Driving Depth

Screws with poorly designed heads may not seat properly, leading to under-driving (heads not recessed enough) or over-driving (breaking through the paper facing). Both scenarios compromise joint strength and finish quality. High-quality drywall screws feature optimized head geometry (e.g., bugle head) and recess types (e.g., square or combo drive) to reduce cam-out and ensure consistent depth control.

Lack of Compliance with Building Codes or Standards

Sourcing screws that do not meet local building codes or industry standards (such as ASTM C1002 for drywall screws) can result in failed inspections or liability issues. Always verify that the screw length, diameter, material, and performance characteristics are compliant with project requirements.

Avoiding these pitfalls requires careful selection based on stud material, drywall thickness, environmental conditions, and adherence to best installation practices—ensuring both quality and long-term performance.

Logistics & Compliance Guide for Length of Screw for Drywall

When installing drywall, selecting the correct screw length is essential for structural integrity, fire safety, and code compliance. This guide outlines key logistics and compliance considerations related to drywall screw length.

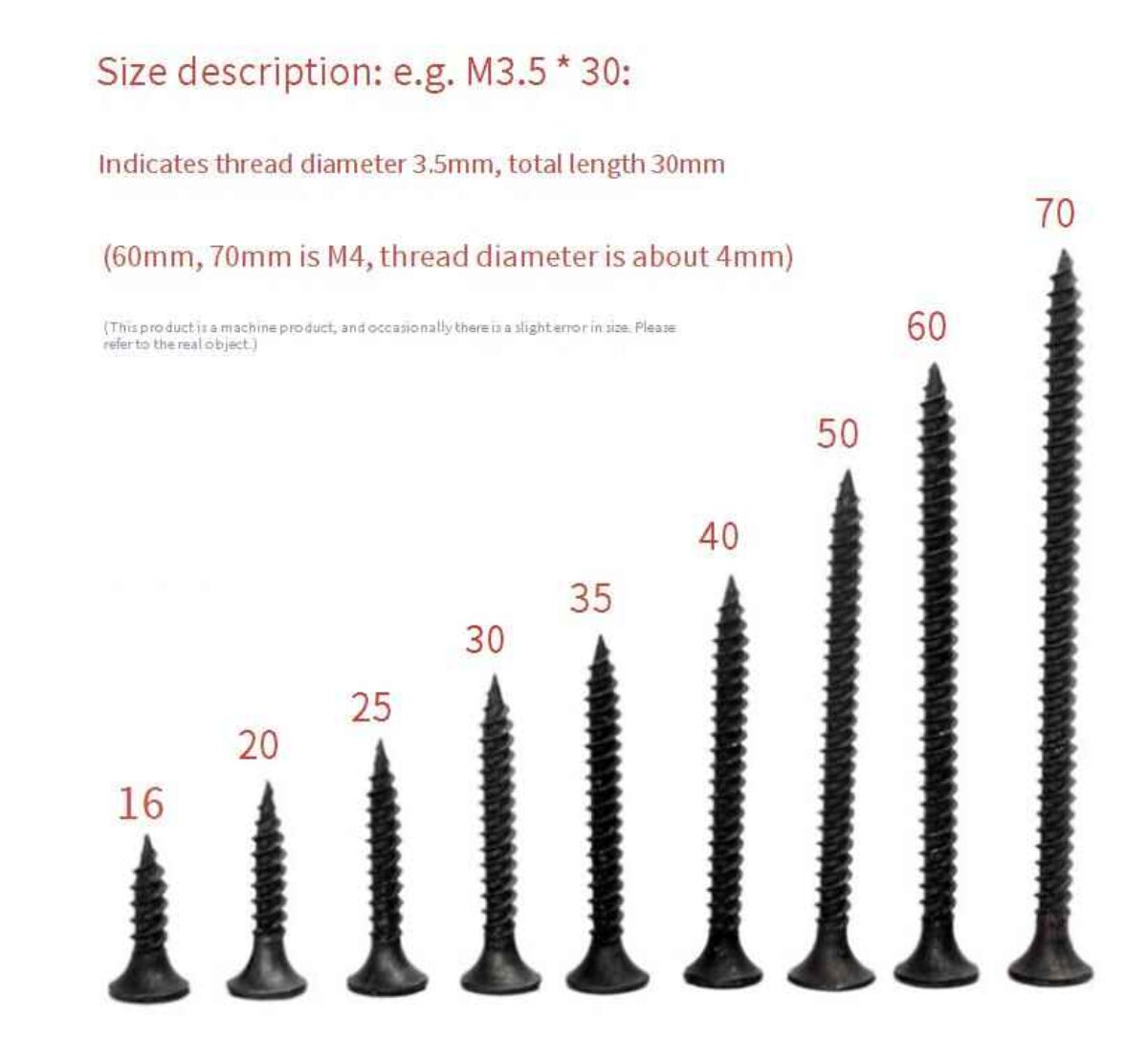

Understanding Standard Screw Lengths

The appropriate screw length depends on the thickness of the drywall and the type of framing (wood or steel). Common drywall thicknesses range from 1/4 inch to 5/8 inch. General guidelines for screw length include:

- 1/2-inch drywall on wood studs: Use 1¼-inch (32 mm) screws

- 5/8-inch drywall on wood studs: Use 1⅝-inch (41 mm) screws

- 1/2-inch drywall on steel studs: Use 1¼-inch (32 mm) screws

- 5/8-inch drywall on steel studs: Use 1⅝-inch (41 mm) screws

Using screws that are too short may result in poor holding power, while screws that are too long can puncture the opposite side of the stud or create safety hazards.

Compliance with Building Codes

Drywall installation must comply with local and national building codes, such as the International Building Code (IBC) and International Residential Code (IRC). Key compliance points include:

- IRC E3302.2 (Fastening Requirements): Specifies that fasteners (screws) must penetrate wood framing at least ¾ inch (19 mm) and steel framing at least 3/8 inch (10 mm) to ensure secure attachment.

- Fire-rated assemblies: In fire-rated walls (e.g., 1-hour firewalls), using incorrect screw length can compromise the fire rating. Screws must be installed per manufacturer specifications and tested assembly requirements (e.g., UL Design U300).

- Sound control assemblies: In STC-rated partitions, proper screw depth helps maintain acoustic performance; over-driving or under-driving screws can affect sound insulation.

Logistics and Handling Best Practices

Proper logistics ensure the correct screws are available at the job site and used appropriately:

- Inventory Management: Stock only the required screw lengths for the specific drywall and framing type to avoid installation errors. Clearly label packaging with length, type (e.g., coarse thread for wood, fine thread for steel), and application.

- Job Site Storage: Store screws in dry, secure containers to prevent rusting and damage. Moisture exposure can compromise corrosion-resistant coatings (e.g., phosphate or zinc-coated screws).

- Worker Training: Ensure installers are trained to identify drywall thickness and framing type, and to use the correct screw length and driving technique (screw heads should be dimpled but not breaking the paper facing).

Quality Control and Inspection

Regular inspections help ensure compliance and performance:

- Pre-Installation Check: Verify screw specifications against project plans and manufacturer guidelines.

- On-site Audits: Conduct random checks during installation to confirm proper screw depth and spacing (typically 12 inches on center along edges and 16 inches in the field).

- Documentation: Maintain records of screw type, length, and batch numbers for traceability, especially in commercial or multi-family projects subject to regulatory review.

Environmental and Safety Considerations

- Recycling and Waste: Collect and recycle unused or scrap screws. Avoid littering job sites.

- PPE Requirements: Workers should wear safety glasses when driving screws to protect against flying debris.

- Hazard Prevention: Over-driven screws can damage electrical wiring or plumbing within walls; ensure trades coordinate during rough-in phases.

Summary

Selecting the correct screw length for drywall is a critical component of safe, compliant, and durable construction. By adhering to building codes, managing materials effectively, and implementing quality control measures, contractors can ensure installations meet performance standards and pass inspection. Always consult project specifications, manufacturer guidelines, and local code requirements before beginning drywall installation.

When sourcing the appropriate length of screws for drywall installation, it is essential to match the screw length to the thickness of the drywall and the type of framing (wood or metal). As a general rule, use 1¼-inch screws for standard ½-inch drywall on wood studs, and 1⅝-inch screws when attaching drywall to steel studs or when installing double layers (e.g., in fire-rated assemblies or for veneer plaster). Screws that are too short may not penetrate sufficiently into the framing, leading to poor holding power, while screws that are too long risk damaging plumbing, electrical wiring, or protruding through the other side of the stud. Always ensure the screw head is properly recessed into the drywall surface without breaking the paper facing. Proper screw length ensures a secure, durable, and professional drywall finish.