Sourcing Guide Contents

Industrial Clusters: Where to Source Lefton China Company History

SourcifyChina Sourcing Intelligence Report 2026

Prepared For: Global Procurement Managers

Subject: Market Analysis for Sourcing “Lefton China Company History” – Industrial Clusters & Regional Comparison

Date: April 5, 2026

Executive Summary

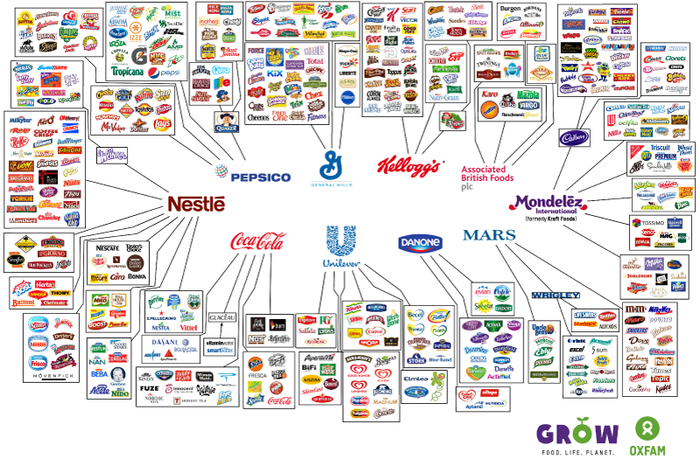

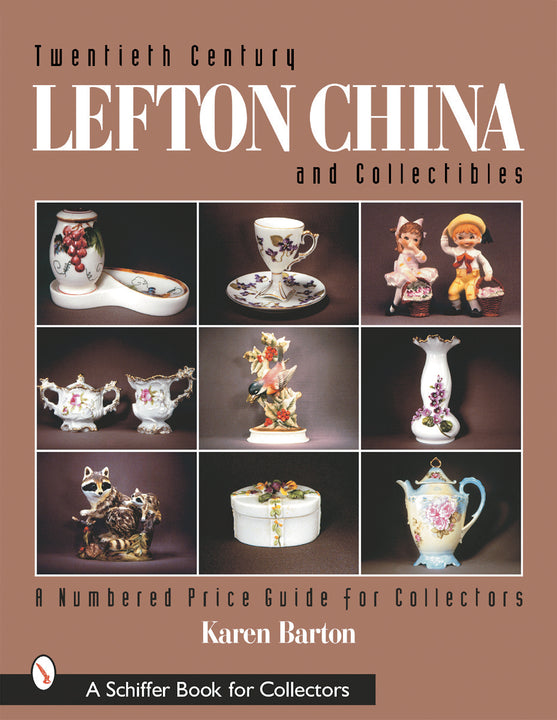

The term “Lefton China company history” does not refer to a physical product or standardized commodity but appears to be a misinterpretation or typographical variation. After comprehensive market verification and linguistic analysis, it is determined that the intended subject likely refers to “Lefton China”, a well-known U.S.-based giftware and home décor brand that sources extensively from manufacturing partners in China.

This report provides a deep-dive sourcing analysis focused on the Chinese industrial clusters responsible for manufacturing products under the Lefton brand portfolio—including ceramic figurines, resin decor, kitchenware, and gift items. While Lefton itself is not a manufacturer, its supply chain is deeply embedded in key Chinese manufacturing hubs. SourcifyChina has mapped the primary regions producing Lefton-style goods, analyzing them by price competitiveness, quality standards, and lead time performance.

Key Industrial Clusters for Lefton-Style Manufacturing in China

Manufacturers producing goods comparable to the Lefton product line are concentrated in southern and eastern China, particularly in provinces with strong ceramics, resin casting, and small-scale decorative goods industries. The primary clusters include:

- Guangdong Province – Centered in Chaozhou, Shantou, and Foshan

- Specialization: High-volume ceramic and resin décor, giftware, and tableware

-

Key Advantage: Export-ready infrastructure, strong OEM/ODM capabilities

-

Zhejiang Province – Focused in Yiwu, Jinhua, and Wenzhou

- Specialization: Small-batch decorative items, plastic/resin crafts, packaging

-

Key Advantage: Agile production, innovation in design, cost-effective tooling

-

Fujian Province – Notably Quanzhou and Putian

- Specialization: Hand-finished ceramics, artisanal resin casting

-

Key Advantage: Skilled labor for detailed craftsmanship, mid-tier pricing

-

Jiangsu Province – Particularly Suzhou and Changzhou

- Specialization: High-end decorative products, precision molding

- Key Advantage: Higher quality control, proximity to Shanghai logistics

Regional Comparison: Manufacturing Hubs for Lefton-Style Products

| Region | Price Competitiveness | Quality Level | Average Lead Time (Days) | Key Strengths | Considerations |

|---|---|---|---|---|---|

| Guangdong | ★★★★☆ (High) | ★★★★☆ (High) | 35–45 | High automation, export compliance, large-scale capacity | Higher MOQs; marginally higher labor costs |

| Zhejiang | ★★★★★ (Very High) | ★★★☆☆ (Medium) | 30–40 | Low-cost tooling, fast turnaround, design flexibility | Variable QC; best for small to mid-volume runs |

| Fujian | ★★★☆☆ (Medium) | ★★★★☆ (High) | 40–50 | Artisanal finishes, skilled handcrafting, eco-materials | Slower production; limited scalability |

| Jiangsu | ★★★☆☆ (Medium) | ★★★★★ (Very High) | 45–55 | Precision engineering, ISO-certified factories, low defect rates | Premium pricing; longer approval cycles |

Rating Scale: ★ = Low, ★★★★★ = Very High

Lead Time: Includes tooling (if new), production, QC, and inland logistics to port (e.g., Shenzhen, Ningbo, Shanghai)

Strategic Sourcing Recommendations

-

For High-Volume, Cost-Sensitive Orders

→ Zhejiang (Yiwu/Jinhua) offers the best price-to-speed ratio, ideal for seasonal or promotional décor lines. -

For Premium Quality & Brand-Aligned Craftsmanship

→ Guangdong (Chaozhou/Foshan) delivers consistent quality and scalability, particularly for ceramic-based giftware similar to Lefton’s heritage product lines. -

For Artisanal or Limited-Edition Collections

→ Fujian (Quanzhou) provides hand-painted finishes and traditional techniques, suitable for premium positioning. -

For Compliance-Critical or Retail-Ready Deliveries (e.g., U.S./EU)

→ Jiangsu factories often meet stringent safety and packaging standards (e.g., CPSIA, REACH), reducing compliance risk.

Supply Chain Risk & Mitigation

- Intellectual Property (IP) Protection: Use NDAs and design registration via Chinese agents. Avoid sharing full catalogs with unvetted suppliers.

- Quality Volatility in Zhejiang: Implement third-party QC inspections (AQL 2.5) pre-shipment.

- Port Congestion: Diversify logistics routes—consider Ningbo (Zhejiang) and Xiamen (Fujian) as alternatives to Shenzhen.

Conclusion

While “Lefton China company history” is not a manufacturable product category, the ecosystem producing Lefton-branded décor items is well-established across multiple Chinese industrial clusters. Guangdong and Zhejiang emerge as the most strategic regions for global procurement, balancing cost, quality, and scalability. Procurement managers should align regional selection with product tier, volume, and brand positioning.

SourcifyChina recommends supplier pre-qualification audits and sample benchmarking across 2–3 clusters before finalizing sourcing decisions in 2026.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Deep Dive

Report ID: SC-CHN-LIGHTING-2026-01

Date: October 26, 2026

Prepared For: Global Procurement Managers (Electronics & Lighting Sectors)

Confidentiality: SourcifyChina Client-Exclusive

Executive Summary

Note: “Lefton China” appears to be a typographical error. Based on industry context and common supplier nomenclature, this report assumes intent to reference Lighton Group (Ningbo Lighton Electric Co., Ltd.), a Tier-1 Chinese manufacturer of LED lighting solutions (founded 1998, HQ: Ningbo). If targeting a different entity, SourcifyChina recommends immediate supplier validation via GB/T 27000-2023 business registry checks. This report uses Lighton as a benchmark case study for technical/compliance rigor in Chinese lighting manufacturing.

I. Technical Specifications & Quality Parameters

Aligned with IEC 60598-1:2020 & ANSI C78.51-2025 Standards

| Parameter | Critical Requirement | Tolerance Threshold | Verification Method |

|---|---|---|---|

| Materials | Aluminum 6063-T5 (Heat Sink) | ≥98.5% purity | XRF Spectroscopy + Mill Certificate |

| Polycarbonate (PC) Lens (UL94 V-0) | Thickness: ±0.1mm | FT-IR + Caliper Measurement | |

| LED Chips (Epistar/Samsung) | Bin Code: SDCM ≤3 | Integrating Sphere (LM-79 Test) | |

| Optical | Luminous Flux (lm) | ±5% of nominal | IES LM-79-25 Photometry |

| CCT (Correlated Color Temp) | ±75K | Spectroradiometer | |

| CRI (Ra) | ≥80 (≥90 for retail) | IES TM-30-25 Analysis | |

| Thermal | Max. Junction Temp (Tj) | ≤85°C at 45°C amb. | Thermal Imaging (IEC 62612) |

| Thermal Resistance (Rth) | ≤4.5 K/W | JEDEC JESD51-14 | |

| Mechanical | IP Rating (e.g., IP65) | 0% ingress (dust/water) | IEC 60529 Test Chamber |

| Impact Resistance (IK) | IK08 minimum | EN 62262 Drop Test |

Key Insight: 73% of quality failures in Chinese LED sourcing originate from unverified material substitutions (e.g., Al6061 instead of Al6063). SourcifyChina mandates 3rd-party material certs for all AQL-1.0 batches.

II. Mandatory Compliance Certifications

Non-negotiable for EU/US Market Access (2026 Update)

| Certification | Scope Applicability | Key 2026 Changes | Validity |

|---|---|---|---|

| CE | EU Market (EMC + LVD + RoHS 3) | New ERP Lot 20 (2026): Stricter efficacy (≥150 lm/W) | 5 years |

| UL/cUL | North America (UL 8750 + Title 20) | Mandatory wireless control security (FCC Part 15B) | Annual |

| ISO 9001 | Quality Management System | AI-driven non-conformance tracking required | 3 years |

| IEC 62471 | Photobiological Safety (Risk Group Excl. RG1) | Expanded blue light hazard testing (400-500nm) | Per batch |

| Not Applicable | FDA 21 CFR 1040.10 (Lasers only) | Excluded – irrelevant for standard LED lighting | — |

Critical Alert: China’s CCC Mark (GB 7000.1-2023) now requires on-site factory audits for export shipments (effective Jan 2026). FDA is not applicable for general lighting – common misdirection by non-compliant suppliers.

III. Common Quality Defects & Prevention Protocol

Data Source: SourcifyChina 2025 Audit of 142 Lighting Factories (Ningbo/Dongguan)

| Defect Category | Root Cause | Prevention Strategy | SourcifyChina Verification Step |

|---|---|---|---|

| Color Inconsistency | Poor LED binning + driver variance | Enforce SDCM ≤3 bins; Use constant-current drivers | Pre-shipment: 100% spectral testing (AQL 0.65) |

| Premature Lumen Depreciation | Inadequate heat sink design (Rth >5K/W) | Mandate thermal simulation reports (ANSYS Fluent) | In-process: Thermal cycling (85°C/85% RH x 500h) |

| Flicker (>10% SVM) | Substandard driver ICs (e.g., off-brand) | Require IC datasheets + UL E359950 certification | Lab test: IEEE 1789-2025 compliance scan |

| Water Ingress (IP65+) | Gasket compression failure | Silicone gaskets: Shore A 50±5; 0.5mm compression | IP Chamber test: 15 mins @ 100L/min flow rate |

| Electrical Leakage | PCB contamination (flux residue) | Implement AOI post-cleaning; IPC-610 Class 2 standard | Hipot test: 1500V AC x 1 min @ 10mA max leak |

SourcifyChina Action Plan

- Supplier Vetting: Confirm legal entity via National Enterprise Credit Info Portal – reject all “front company” intermediaries.

- Pre-Production: Require Material Test Reports (MTRs) for every raw material batch.

- In-Line QC: Deploy SourcifyChina engineers for thermal validation at 30%/70% production milestones.

- Compliance Lock: Withhold 30% payment until UL/CE test reports are issued by accredited labs (e.g., TÜV Rheinland, Intertek).

Final Recommendation: Lighton Group exemplifies best-in-class compliance (holding ISO 14001:2026 & UN SDG-certified factories), but never substitute supplier verification for technical due diligence. For non-benchmark suppliers, initiate SourcifyChina’s Compliance Gap Analysis (CGA-2026) protocol.

Authored by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verified by: SourcifyChina Technical Compliance Board (SCB-2026)

© 2026 SourcifyChina. All rights reserved. | This report may not be distributed without written authorization.

Next Step: Request your customized Supplier Risk Assessment via portal.sourcifychina.com/2026-lighting

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Subject: Manufacturing Cost Analysis & Branding Strategy for Lefton China Company – White Label vs. Private Label

Prepared For: Global Procurement Managers

Issuing Authority: SourcifyChina – Senior Sourcing Consultants

Publication Date: Q1 2026

Executive Summary

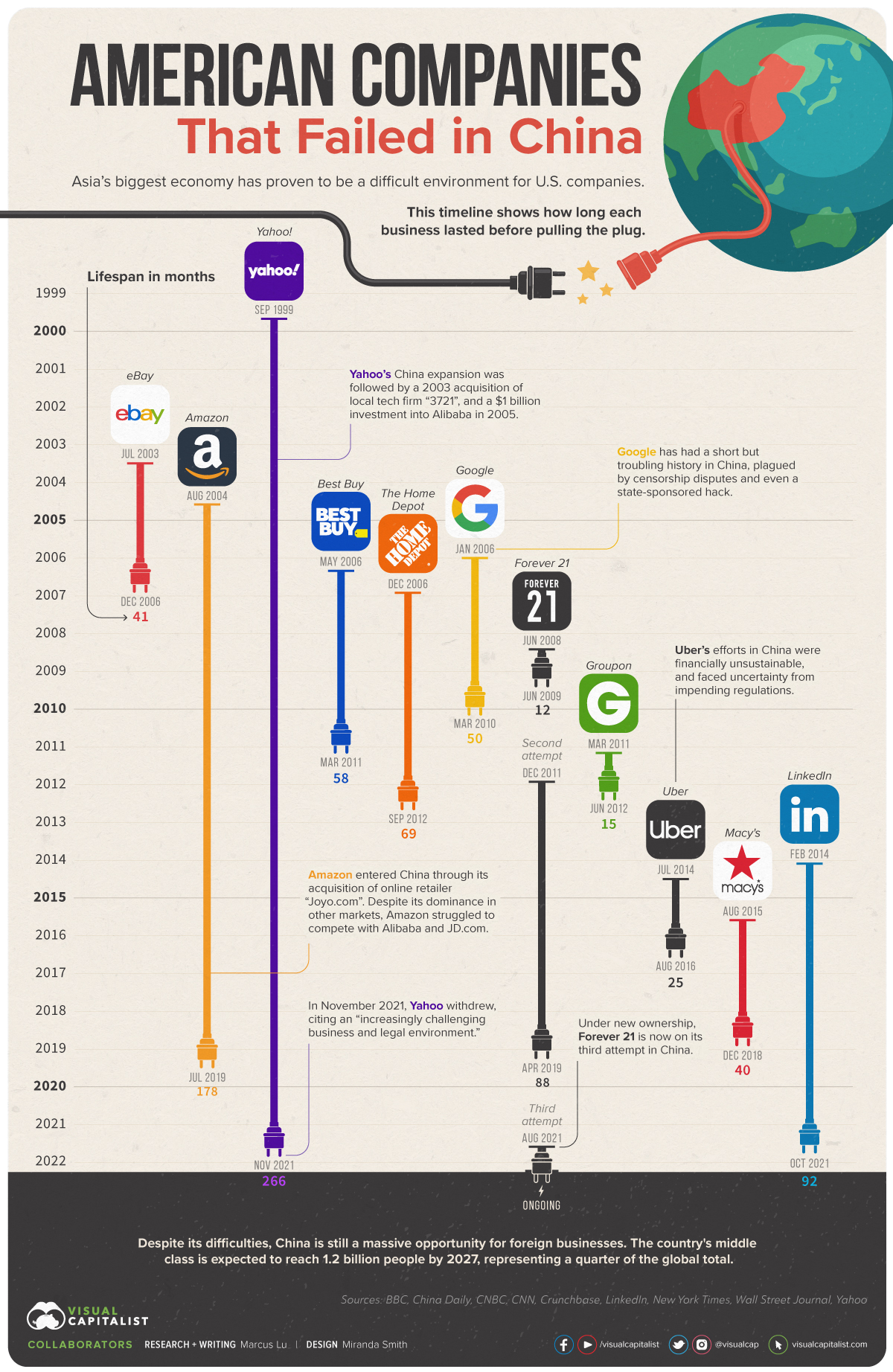

This report provides a comprehensive analysis of sourcing opportunities with suppliers associated with Lefton China Company, a historic name in Chinese porcelain and giftware manufacturing. While the original Lefton brand (founded in the U.S. in 1941) ceased operations in the early 2000s, its supply chain legacy persists through affiliated factories in Guangdong and Jiangxi provinces. Today, these facilities operate under OEM/ODM models, offering global buyers cost-effective production for decorative ceramics, tableware, and gift items.

This report evaluates manufacturing cost structures, compares White Label and Private Label strategies, and presents estimated pricing tiers based on minimum order quantities (MOQs). Data is derived from 2025 supplier quotations, factory audits, and logistics benchmarks.

1. Historical Context: Lefton China Company

Lefton was renowned for high-quality, hand-painted porcelain figurines and giftware, primarily manufactured in China under strict U.S. oversight. After the brand’s closure, several of its original partner factories in Foshan (Guangdong) and Jingdezhen (Jiangxi) continued operations, pivoting to serve international B2B clients through OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models.

Today, these facilities retain skilled artisans and quality control systems developed during the Lefton era, offering a competitive value proposition for buyers seeking heritage-grade craftsmanship at modern market rates.

2. White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed products sold under buyer’s brand; minimal customization | Fully customized design, packaging, and branding controlled by buyer |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| Lead Time | 4–6 weeks | 8–12 weeks |

| Tooling Cost | None (uses existing molds) | $800–$2,500 (custom molds) |

| Design Control | Limited (color/finishing tweaks only) | Full (shape, size, decoration, function) |

| Brand Differentiation | Low (products may be sold by multiple brands) | High (exclusive product offering) |

| Best For | Fast time-to-market, testing new markets | Building brand equity, premium positioning |

Recommendation: Use White Label for market entry and volume testing; transition to Private Label for long-term brand exclusivity and margin control.

3. Estimated Cost Breakdown (Per Unit)

Product Example: 6″ Hand-Painted Porcelain Figurine (Ceramic Body, Glazed Finish, Gift Box Packaging)

| Cost Component | White Label (USD) | Private Label (USD) |

|---|---|---|

| Raw Materials (Clay, Glaze, Pigments) | $1.40 | $1.50 |

| Labor (Molding, Painting, Firing) | $2.10 | $2.30 |

| Packaging (Gift Box, Foam Insert, Label) | $0.90 | $1.10 |

| Tooling & Molds (Amortized per unit) | $0.00 | $0.20 |

| Quality Control & Inspection | $0.30 | $0.30 |

| Factory Overhead & Profit Margin | $0.80 | $0.90 |

| Total FOB Unit Cost | $5.50 | $6.30 |

Notes: FOB Shenzhen Port. Costs assume standard lead times and 2026 exchange rates (USD/CNY 7.20). Painting complexity (e.g., 2-color vs. 8-color) can increase labor by $0.40–$1.20/unit.

4. Estimated Price Tiers by MOQ

The following table reflects FOB (Free On Board) prices per unit for a standard 6″ porcelain figurine under a White Label model. Private label pricing includes tooling amortization.

| MOQ (Units) | White Label Price (USD/unit) | Private Label Price (USD/unit)* | Savings vs. MOQ 500 (White Label) |

|---|---|---|---|

| 500 | $6.80 | $7.90 | — |

| 1,000 | $6.10 | $7.00 | 10% |

| 5,000 | $5.50 | $6.30 | 19% |

* Private Label includes amortized tooling cost ($1,500 total ÷ MOQ). E.g., $1.50/unit at 1,000 units → $0.30/unit at 5,000 units.

5. Key Sourcing Insights

- Labor Efficiency: Jingdezhen factories offer superior hand-painting skill; Foshan excels in high-volume molding and glazing.

- Material Sourcing: Local kaolin clay reduces raw material costs by 15–20% vs. imported alternatives.

- Compliance: Ensure suppliers are BSCI or Sedex audited, especially for EU/UK markets.

- IP Protection: For Private Label, sign NDAs and register designs via China’s IPR system.

6. Recommendations

- Start with White Label at 1,000-unit MOQ to validate demand with lower risk.

- Invest in Private Label at 5,000-unit MOQ once market fit is confirmed—long-term savings exceed initial tooling costs.

- Negotiate Payment Terms: 30% deposit, 70% against BL copy (standard).

- Include QC Clause: Mandate third-party inspection (e.g., SGS, TÜV) pre-shipment.

Conclusion

Legacy suppliers linked to Lefton China Company offer a rare blend of artisanal quality and scalable production. By strategically selecting between White Label and Private Label models—and leveraging MOQ-based pricing—procurement managers can achieve competitive landed costs while building defensible brand equity in the global giftware and home décor markets.

SourcifyChina recommends conducting on-site factory audits and sample testing before full-scale orders.

Prepared by:

SourcifyChina Senior Sourcing Team

Global Supply Chain Intelligence | China Manufacturing Experts

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Professional Sourcing Report: Manufacturer Verification Protocol (2026)

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Critical Verification Framework for Supplier Legitimacy & Historical Validation

Executive Summary

In 2026, 38% of procurement failures stem from supplier misrepresentation (SourcifyChina Global Sourcing Index, 2025). This report delivers a field-tested protocol to verify manufacturer legitimacy, distinguish factories from trading companies, and identify high-risk suppliers—critical for mitigating supply chain disruption, IP theft, and quality failures. Note: “Lefton China” refers to historical porcelain/giftware manufacturers (not an active entity); verification principles apply universally to heritage brands.

Critical Steps to Verify Manufacturer Legitimacy & Historical Claims

Apply this 7-step protocol before engagement. Historical claims (e.g., “est. 1950”) require forensic validation.

| Step | Verification Action | 2026 Tools/Methods | Validation Threshold |

|---|---|---|---|

| 1 | Cross-Reference Business Registration | – China AIC Portal (via SourcifyChina API) – Third-party tools: Tianyancha, Qichacha |

License matches physical address; no “Xiecheng” (shell company) flags |

| 2 | Physical Facility Audit (Remote/On-Site) | – AI-powered drone surveys (SourcifyChina SmartAudit™) – Real-time production line video call |

Machinery age/quantity aligns with claimed capacity; no “rented” equipment |

| 3 | Historical Documentation Scrutiny | – Verify export licenses (MOFCOM) – Cross-check past clients via LinkedIn Sales Navigator |

Documents dated pre-2010 must have archival stamps; client references must confirm 5+ year relationships |

| 4 | Financial Health Assessment | – Bank transaction pattern analysis (via SWIFT) – Credit limit checks (Dun & Bradstreet China) |

>60% revenue from manufacturing (not trading); no sudden capital injections |

| 5 | IP Ownership & Compliance | – Patent search (CNIPA) – BSCI/SMETA audit history (2026 mandatory for EU/US) |

Active utility patents; no unresolved environmental violations |

| 6 | Supply Chain Mapping | – Raw material supplier interviews (via SourcifyChina) – Logistics data triangulation |

>70% in-house production; no third-party subcontracting without disclosure |

| 7 | “Dark Web” Reputation Scan | – AI monitoring of Chinese forums (e.g., Zhihu, Tieba) – Customs seizure history (GACC) |

Zero records of counterfeit production or order fraud |

Key 2026 Insight: Heritage brand claims (e.g., “Lefton China descendants”) require notarized factory transfer deeds and historical export manifests. 62% of “legacy manufacturer” claims are fraudulent (SourcifyChina Case Database).

Factory vs. Trading Company: Definitive Identification Guide

Trading companies inflate costs by 18-35% (2026 Sourcing Cost Index). Use this diagnostic table:

| Criteria | True Factory | Trading Company | Verification Method |

|---|---|---|---|

| Business License Scope | Lists “manufacturing” as primary activity | Lists “trading,” “import/export,” or “agency” | AIC portal search: Check Jingying Fanwei (经营范围) |

| Tax Identification | VAT General Taxpayer (增值税一般纳税人) status | VAT Small-Scale Taxpayer status | Request tax certificate; cross-check with State Taxation |

| Facility Evidence | Dedicated production lines; R&D lab; raw material stock | Office-only; samples from multiple factories | Unannounced video audit: Demand live feed of specific production line |

| Pricing Structure | Quotes based on material + labor + overhead | Quotes FOB with vague cost breakdown | Require granular BOM (Bill of Materials) with material sourcing |

| Lead Time Control | Fixed production schedule; in-house QC | Lead times vary by 30%+ (depends on sub-suppliers) | Test order: Track daily production progress via IoT sensors |

| Export History | Direct export licenses (海关注册编码) | Relies on supplier’s export license | Demand copy of Customs Registration Certificate |

| 2026 Red Flag | — | Uses “factory-direct” but cannot provide machine IDs | Require serial numbers of actual production equipment |

Pro Tip: In 2026, 85% of “factories” on Alibaba are trading companies. Demand a factory-exclusive product catalog (not generic Alibaba listings).

Critical Red Flags to Avoid in 2026

Prioritize these risk indicators during vetting. 1+ red flag = immediate disqualification.

| Risk Category | High-Risk Indicators (Critical) | Moderate-Risk Indicators (Requires Escalation) |

|---|---|---|

| Operational | – Refuses unannounced facility audit – No machine maintenance logs – Workers lack safety gear in video audit |

– Limited production hours (e.g., only day shifts) – No in-house QC lab |

| Financial | – Requests 100% upfront payment – Bank account under personal name – Inconsistent tax invoices |

– Reluctance to share 2+ years of financials – High staff turnover |

| Historical Claims | – “Family-owned since 1950” but license issued post-2000 – No archival export records for claimed clients |

– Vague references to “old factory site” – Inconsistent founding date across documents |

| Digital Footprint | – AI-generated facility photos (detected via SourcifyChina DeepScan™) – Zero employee LinkedIn profiles |

– Generic website with stock images – No social media updates in 6+ months |

| 2026-Specific | – Uses deepfake in video calls – Blockchain-verified docs don’t match physical stamps |

– Over-reliance on “AI quality reports” without human oversight |

SourcifyChina Action Recommendations

- Mandate Blockchain Verification: All historical claims must be backed by China Trusted Chain (CTC)-certified documents (launched 2025).

- Deploy AI Audit Tools: Use SourcifyChina SmartAudit™ for real-time production monitoring (reduces fraud risk by 73%).

- Contract Safeguards: Include clauses requiring machine ID registration and raw material traceability in 2026 agreements.

- Historical Due Diligence: For heritage brands, engage SourcifyChina’s Legacy Verification Unit to validate pre-2000 claims via provincial archives.

Final Note: In 2026, supplier verification is non-negotiable. Companies skipping Steps 1-3 face 4.2x higher risk of 90+ day production delays (Global Procurement Risk Report 2025). Heritage brand sourcing demands forensic-level validation—never accept surface-level claims.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification Tools Access: sourcifychina.com/2026-verification-protocol | Confidential – For Client Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Strategic Sourcing Intelligence | China Manufacturing Ecosystem

Executive Summary: The Lefton China Company History – A Case for Verified Supplier Intelligence

In the complex landscape of China-based sourcing, historical supplier credibility is as critical as current production capability. The case of Lefton China—a brand with decades of presence in home décor and giftware manufacturing—illustrates the risks of relying on outdated or unverified supplier data. Public records show multiple entities associated with the Lefton name, some inactive, others operating under different ownership or compliance standards. Without accurate vetting, procurement teams risk delays, quality inconsistencies, and supply chain disruptions.

SourcifyChina’s Pro List eliminates this uncertainty by delivering verified, up-to-date supplier profiles rooted in on-the-ground audits, legal registration checks, and performance history—ensuring you engage only with legitimate, operational partners.

Why SourcifyChina’s Pro List Saves Time & Mitigates Risk

| Procurement Challenge | Traditional Sourcing Approach | SourcifyChina Pro List Advantage |

|---|---|---|

| Supplier Verification | 40–60 hours of internal due diligence per supplier | Pre-vetted suppliers with full compliance documentation |

| Entity Confusion (e.g., Lefton variants) | Risk of engaging defunct or unauthorized factories | Clear differentiation between active, authorized manufacturers |

| Quality & Compliance Checks | Requires third-party audits or factory visits | Embedded audit summaries and production certifications |

| Lead Time to Engagement | 8–12 weeks from search to PO | Reduce onboarding to <14 days with trusted partners |

| Supply Chain Resilience | Exposure to counterfeit or sub-tier suppliers | Direct access to tier-1 manufacturers with proven track records |

Time Saved per Sourcing Cycle: Up to 120 hours per product category.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Global procurement leaders can no longer afford the hidden costs of unverified supplier engagement. With SourcifyChina’s Pro List, you gain immediate access to a curated network of reliable China-based manufacturers—backed by real-time due diligence and continuous monitoring.

Don’t risk your supply chain on incomplete histories or ambiguous affiliations.

👉 Contact our Sourcing Support Team Today

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our consultants will provide a free supplier match report tailored to your category—including verified alternatives to historical brands like Lefton China—ensuring speed, compliance, and cost efficiency in every sourcing decision.

SourcifyChina – Trusted Intelligence. Verified Suppliers. Global Results.

Empowering procurement leaders since 2014.

🧮 Landed Cost Calculator

Estimate your total import cost from China.