The global LED flashlight market is experiencing robust growth, driven by rising demand for energy-efficient, durable, and portable lighting solutions across industrial, military, outdoor, and emergency sectors. According to Grand View Research, the global LED flashlights market size was valued at USD 2.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This expansion is fueled by advancements in LED technology, increased adoption in emerging economies, and growing emphasis on sustainable lighting. As demand surges, the need for reliable and high-performance LED flashlight circuits has intensified, positioning circuit manufacturers as critical enablers in the supply chain. Innovation in thermal management, driver efficiency, and compact design has become paramount. In this competitive landscape, a select group of manufacturers lead in R&D investment, production scalability, and technological integration—shaping the future of portable LED illumination.

Top 10 Led Flashlight Circuit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Torch Light Circuit Board Factories

Domain Est. 2011

Website: abiscircuits.com

Key Highlights: Torch Light Circuit Board Factories – Manufacturers, Suppliers, Factory from China. Our pursuit and company goal is to Always satisfy our customer requirements….

#2 China Led Flashlight Circuit Board Manufacturer and Supplier, Factory

Domain Est. 2023

Website: cnshenergy.com

Key Highlights: Looking for a reliable LED flashlight circuit board? Our China-based manufacturer is your trusted supplier and factory for top-quality products. Shop now!…

#3 Ushio America, Inc.

Domain Est. 1995

Website: ushio.com

Key Highlights: Ushio America, Inc. is a vertically integrated solutions company for lighting systems and components utilizing xenon short arc, Lasers, ultra high-pressure UV, ……

#4 LED PCBs – Amitron

Domain Est. 1995

Website: amitron.com

Key Highlights: Amitron manufactures high quality LED printed circuit boards (PCBs) at low prices with excellent customer service….

#5 PCB Assembly Manufacturer_PCB Prototype_China PCB …

Domain Est. 2011

Website: lzjpcb.com

Key Highlights: We own 8,000㎡ of High-Tech circuit board manufacturing that meets ROHS and REACH environmental standards. And we have passed ISO9001, ISO14001, ISO13485. More….

#6 China PCB Prototype & Fabrication Manufacturer

Domain Est. 2012

Website: pcbway.com

Key Highlights: $29 deliveryWhy Buy Printed Circuit Boards From us? 24 hours production lead-time*; Team supported by over 90 professionals & technical; 99% on-Time Shipping with great ……

#7

Domain Est. 2016

Website: cree-led.com

Key Highlights: Cree LED delivers best-in-class technology and one of the industry’s broadest portfolios of application-optimized LED chips and components….

#8 ams OSRAM is a global leader in innovative light and sensor …

Domain Est. 2019

Website: ams-osram.com

Key Highlights: We offer a distinct product and technology portfolio for sensing, illumination and visualization from high-performance LEDs and lasers to mixed-signal ……

#9 Kaidomain.com KD

Domain Est. 2006

Website: kaidomain.com

Key Highlights: Discover the latest and greatest consumer electronics items at Kaidomain KD today. Shop all newest arrivals to find awesome deals on LEDs, Flashlights and ……

#10 Machine Vision LED Lights Solutions for Printed Circuit Board

Domain Est. 2021

Website: 3amled.com

Key Highlights: 3AM provides machine vision lighting solutions for printed circuit board, ideal for outer surface inspection, alignment check, and dimensional measurement….

Expert Sourcing Insights for Led Flashlight Circuit

H2: Emerging Market Trends in LED Flashlight Circuits for 2026

As we approach 2026, the global market for LED flashlight circuits is undergoing significant transformation driven by advancements in semiconductor technology, growing demand for energy-efficient lighting, and increasing applications across consumer, industrial, and defense sectors. Key trends shaping the LED flashlight circuit landscape include miniaturization, integration of smart features, sustainability initiatives, and expansion into emerging markets.

-

Advancements in Circuit Efficiency and Miniaturization

LED flashlight circuits are becoming more compact and energy-efficient due to innovations in integrated circuit (IC) design and the use of advanced materials such as gallium nitride (GaN) and silicon carbide (SiC). These materials enable higher power density, improved thermal management, and reduced energy loss. In 2026, expect widespread adoption of micro-driver circuits that support ultra-compact flashlights without compromising brightness or battery life. -

Integration of Smart and Adaptive Lighting Features

Smart LED flashlight circuits are gaining traction, incorporating microcontrollers and sensors for adaptive brightness, motion detection, and user-configurable modes. Bluetooth and IoT connectivity are being embedded into high-end models, allowing users to control flashlights via smartphone apps. These features are particularly appealing in tactical, outdoor, and emergency response applications, boosting demand for programmable LED driver ICs. -

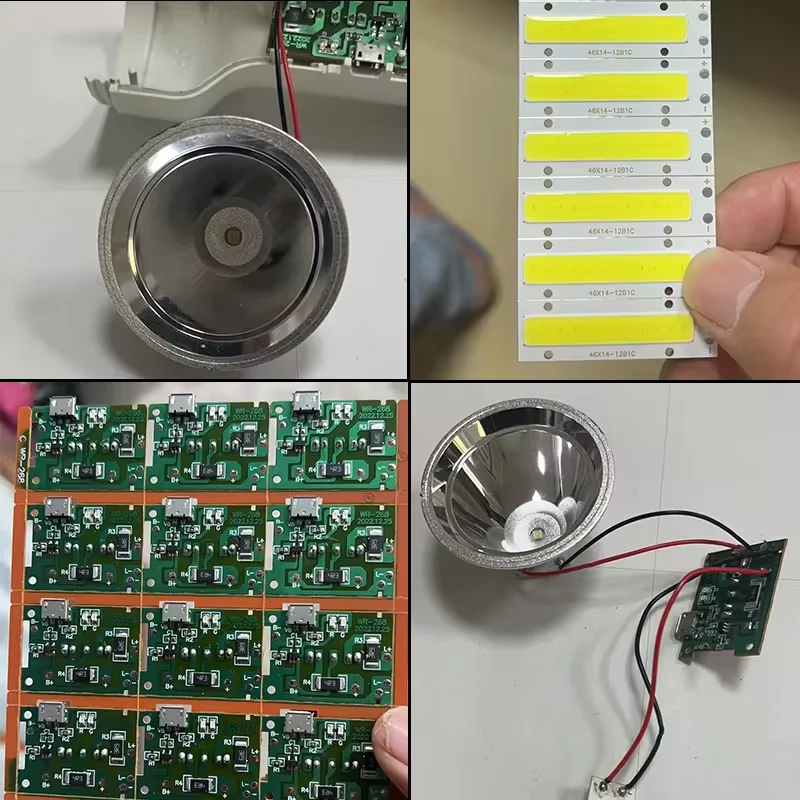

Rise of Rechargeable and Sustainable Designs

Environmental concerns and consumer preference for sustainable products are pushing manufacturers toward rechargeable flashlight systems using lithium-ion and solid-state batteries. In 2026, LED flashlight circuits will increasingly integrate efficient charging management systems, including USB-C and solar charging compatibility. Additionally, circuit designs will emphasize low standby power consumption and recyclable components to meet global energy efficiency standards. -

Growth in Tactical and Outdoor Markets

The tactical gear and outdoor recreation sectors are major drivers of innovation in LED flashlight circuits. Demand for rugged, waterproof, and high-lumen flashlights with long runtimes is fueling R&D in durable circuit layouts and thermal regulation systems. Military and law enforcement contracts are also contributing to growth, with requirements for circuits that support strobe, SOS, and infrared illumination modes. -

Expansion in Emerging Economies

Developing regions in Asia-Pacific, Africa, and Latin America are witnessing rising demand for affordable, reliable LED flashlights due to inconsistent power infrastructure. Localized manufacturing and cost-optimized circuit designs—such as those based on simple buck/boost converters—are enabling wider market penetration. By 2026, localized production and regional supply chain adaptations will play a crucial role in market expansion. -

Impact of AI and Predictive Maintenance

While still in early stages, AI-driven diagnostics are beginning to appear in commercial and industrial flashlight systems. Integrated circuits with embedded firmware can monitor battery health, usage patterns, and component wear, providing predictive maintenance alerts. This trend is expected to grow in sectors such as mining, construction, and utilities, where flashlight reliability is critical.

In conclusion, the 2026 market for LED flashlight circuits will be defined by smarter, smaller, and more sustainable technologies. Companies that invest in R&D for energy-efficient drivers, intelligent control systems, and scalable manufacturing solutions will be best positioned to capture value in this evolving landscape.

Common Pitfalls When Sourcing LED Flashlight Circuits (Quality and IP)

Sourcing LED flashlight circuits—especially for integration into larger products or private-label manufacturing—can present several challenges related to both quality assurance and intellectual property (IP) risks. Being aware of these pitfalls helps mitigate supply chain disruptions, legal exposure, and product performance issues.

Poor Component Quality and Inconsistent Performance

One of the most frequent issues when sourcing LED flashlight circuits is receiving substandard components. Low-cost suppliers may use inferior LEDs, resistors, or driver ICs that degrade quickly or fail under normal operating conditions. This results in inconsistent brightness, shortened battery life, or complete circuit failure. Additionally, poor PCB fabrication—such as inadequate copper traces or lack of conformal coating—can lead to overheating or corrosion, especially in outdoor or humid environments.

Lack of Compliance with Safety and Regulatory Standards

Many LED flashlight circuits sourced from unverified suppliers do not meet international safety standards such as CE, RoHS, or UL. This poses risks not only in terms of product safety (e.g., overheating, fire hazards) but also legal compliance. Importing non-compliant circuits into regulated markets can result in customs seizures, product recalls, or fines.

Inadequate or Missing Documentation

Reliable sourcing requires access to full technical documentation, including circuit schematics, BOMs (Bill of Materials), and test reports. However, many suppliers—particularly from less-regulated regions—fail to provide this information. Without proper documentation, it becomes difficult to verify design integrity, perform quality audits, or ensure compatibility with other system components.

Intellectual Property Infringement Risks

A major IP pitfall involves sourcing circuits that replicate patented designs without authorization. Some manufacturers produce near-identical copies of popular flashlight driver circuits (e.g., those using proprietary buck/boost or constant-current regulation technologies). Using such circuits may expose the buyer to legal liability, especially if the original IP holder enforces their patents in the target market.

Reverse Engineering and Hidden Design Flaws

Some circuits marketed as “compatible” or “equivalent” are reverse-engineered versions that may introduce hidden flaws—such as poor thermal management or inefficient power conversion. These flaws are not always apparent during initial testing but can lead to premature field failures. Moreover, reverse-engineered designs may inadvertently infringe on trade secrets or utility models protected under IP law.

No Assurance of Design Ownership or Licensing

When integrating a third-party circuit, it’s essential to confirm whether the supplier owns the design or has proper licensing rights. Without this clarity, businesses risk using circuits that could be pulled from the market due to IP disputes. This not only disrupts production but may also damage brand reputation.

Recommendations to Avoid Pitfalls

To mitigate these risks:

– Source from reputable suppliers with verifiable certifications.

– Request full technical and compliance documentation.

– Conduct independent testing for performance and reliability.

– Perform IP due diligence, including patent landscape reviews.

– Consider custom-designed circuits where IP ownership can be clearly assigned.

By addressing both quality and IP concerns proactively, companies can ensure reliable, legal, and high-performing LED flashlight circuit integration.

Logistics & Compliance Guide for LED Flashlight Circuit

Product Classification and HS Code

The LED flashlight circuit, as a component of a lighting device, typically falls under specific Harmonized System (HS) codes for international shipping and customs clearance. The most applicable HS code is 8543.70, which covers “Electrical apparatus for switching or protecting electrical circuits, or for making connections to or in electrical circuits… parts thereof.” Alternatively, if classified under lighting components, 9405.40 (“Electrical lamps and lighting fittings… parts and accessories thereof”) may apply. Confirm the exact classification with local customs authorities or a licensed customs broker, as variations exist by country.

Export Controls and Restrictions

LED flashlight circuits are generally not subject to stringent export controls unless they incorporate advanced technologies (e.g., encryption, military-grade components, or high-power laser integration). However, dual-use regulations such as the Export Administration Regulations (EAR) in the U.S. should be reviewed. Most standard LED circuit boards fall under EAR99, meaning they are low-risk and do not require an export license for most destinations. Always verify destination-specific restrictions, especially for countries under trade sanctions.

Safety and Electromagnetic Compliance

Ensure the LED flashlight circuit complies with relevant electrical safety and electromagnetic compatibility (EMC) standards for the target market:

– CE Marking (Europe): Comply with the Low Voltage Directive (LVD) 2014/35/EU and EMC Directive 2014/30/EU. Testing may include EN 61000-6-3 (EMI) and EN 61000-6-1 (immunity).

– FCC Certification (USA): If the circuit includes oscillating components or switching regulators, it may require FCC Part 15B compliance for unintentional radiators.

– PSE Mark (Japan): Required for electrical products under the DENAN Law. Apply for either Class A (industrial) or Class B (consumer) certification based on usage.

Environmental and Chemical Compliance

Adhere to environmental regulations governing hazardous substances:

– RoHS (EU): Ensure lead, mercury, cadmium, hexavalent chromium, PBB, and PBDE are below permissible levels. Applies to all electrical and electronic equipment.

– REACH (EU): Register and disclose Substances of Very High Concern (SVHCs) if present above threshold levels.

– China RoHS: Labeling requirements apply if the product is sold in China, indicating the presence of hazardous substances.

– WEEE (EU): While the circuit itself may not require direct labeling, it contributes to the recyclability obligations of the end product.

Packaging and Shipping Requirements

Use anti-static packaging for circuit boards to prevent electrostatic discharge (ESD) damage during transit. Clearly label packages with:

– Product description and part number

– Electrostatic-sensitive device (ESD) warning symbol

– Manufacturer/importer contact information

– Compliance marks (e.g., CE, FCC) as applicable

Ship via carriers experienced in handling electronic components, and ensure all commercial invoices and packing lists include accurate HS codes, value declarations, and country of origin.

Documentation and Recordkeeping

Maintain the following documentation for compliance and audit purposes:

– Bill of Materials (BOM) with component sourcing details

– Test reports from accredited laboratories (e.g., for EMC, safety)

– Declaration of Conformity (DoC) for each applicable regulation

– Conflict minerals reporting (if applicable under Dodd-Frank Act Section 1502)

– RoHS and REACH compliance certificates from suppliers

Retain records for a minimum of 5–10 years depending on jurisdiction.

Import Regulations by Key Markets

- United States: FDA does not regulate LED circuits, but customs may require entry filings (e.g., ISF for ocean freight). No import duty if classified under HTS 8543.70.9060 (duty-free for certain electronic components).

- European Union: Requires CE marking, EU Responsible Person designation, and customs declaration using TARIC codes. VAT applies upon import.

- Canada: Comply with ISED (Innovation, Science and Economic Development Canada) standards for electromagnetic compatibility. Use HS code 8543.70.00.

- Australia: Must meet RCM (Regulatory Compliance Mark) requirements under the EMC Framework and Electrical Equipment Safety System (EESS).

End-of-Life and Sustainability

Design the LED flashlight circuit to support recyclability. Avoid glued or non-separable components. Provide disassembly instructions if part of a larger product. Comply with producer responsibility schemes such as ERP (Energy-related Products Directive) in the EU, which promotes energy efficiency and eco-design.

Summary and Best Practices

To ensure smooth logistics and compliance:

1. Confirm correct HS code and country of origin.

2. Obtain necessary certifications (CE, FCC, PSE) before shipping.

3. Use ESD-safe packaging and accurate labeling.

4. Maintain full compliance documentation.

5. Partner with experienced freight forwarders and customs brokers.

6. Regularly monitor regulatory updates in target markets.

By following this guide, manufacturers and distributors can minimize delays, avoid penalties, and ensure global market access for LED flashlight circuits.

In conclusion, sourcing an LED flashlight circuit involves careful consideration of key factors such as component quality, power efficiency, circuit design (e.g., constant current regulation or basic resistor-limited setups), and compatibility with power sources like batteries. It is essential to evaluate suppliers based on reliability, cost-effectiveness, and adherence to technical specifications to ensure optimal performance and longevity of the flashlight. Whether sourcing individual components or pre-assembled circuit boards, attention to details like voltage requirements, thermal management, and durability will contribute to a successful and efficient lighting solution. Ultimately, a well-sourced LED flashlight circuit not only enhances product reliability but also supports energy efficiency and sustainability goals.