The global cutlery market is experiencing steady growth, driven by rising demand for high-performance kitchen tools and increasing consumer interest in ergonomic, aesthetically pleasing designs. According to Grand View Research, the global cutlery market size was valued at USD 18.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. A notable trend within this expansion is the rising popularity of specialty blade designs, including leaf-shaped knives—renowned for their curved, tapering profile that combines precision with fluid cutting motion. These knives, often favored in both professional and home kitchens for tasks requiring dexterity and control, are being advanced by manufacturers integrating premium materials, such as high-carbon stainless steel and ergonomic composites. As demand grows, a select group of manufacturers has emerged at the forefront of innovation, blending traditional craftsmanship with data-informed design improvements to capture market share. This positions the leaf shape knife not just as a niche tool, but as a growing segment within the broader premium cutlery landscape.

Top 7 Leaf Shape Knife Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 History of Higonokami

Domain Est. 2017

Website: higonokami.jp

Key Highlights: Komataro Nagao, our founder, and Mr. Murakami started to produce knives in Hirata, Miki City for the first time. In those days, knives were all made manually….

#2 KUDU

Domain Est. 1996

Website: coldsteel.com

Key Highlights: The Cold Steel Kudu takes its inspiration from the classic ring lock folding knives of Africa. These highly functional blades are owned and carried by people ……

#3 Klotzli Knife Smithy

Domain Est. 2002

Website: klotzli.com

Key Highlights: The Klötzli kitchen knives are manufactured with care and craftsmanship in the Klötzli knife smithy in Burgdorf, Switzerland. The blades and shapes are inspired ……

#4 JACKSTONE

Domain Est. 2009

Website: montanaknifecompany.com

Key Highlights: The distinct leaf shape provides a strong tip and plenty of belly for detailed work — ideal for hunters and outdoorsmen. The drop point tip adds tremendous ……

#5 Leaf Blade Knives

Domain Est. 2018

Website: honeybadgerknives.com

Key Highlights: A leaf blade is a type of knife blade that is characterized by its elongated and curved shape, resembling the outline of a leaf, hence the name….

#6 Appeal of World Renowned Sakai Knives|Special Features

Website: sakai-tcb.or.jp

Key Highlights: Sakai is one of the three great knife and bladed tool producing regions in Japan. The knives individually hand-forged by craftspeople are particularly famous….

#7 Leafblade Viking Knife

Website: modernviking.com.au

Key Highlights: Introducing our latest masterpiece, the folding Leaf blade Viking Knife, handcrafted from Damascus steel and designed in the shape of a forest leaf….

Expert Sourcing Insights for Leaf Shape Knife

H2: Projected 2026 Market Trends for Leaf Shape Knives

The global market for specialized kitchen cutlery, including leaf shape knives, is expected to witness notable growth and transformation by 2026. The leaf shape knife—characterized by its broad, gently curved blade resembling a leaf, often used for lifting and transferring sliced foods—is gaining traction due to rising consumer interest in ergonomic, multipurpose, and aesthetically pleasing kitchen tools. Below is an analysis of key market trends projected for 2026:

1. Increasing Demand for Specialty Kitchen Tools

Home cooking and gourmet food preparation are on the rise, especially following sustained growth in culinary content on social media and streaming platforms. Consumers are investing in high-quality, specialized tools, and the leaf shape knife fits into this trend as a versatile utensil ideal for delicate tasks such as flipping fish, serving pastries, or transferring vegetables. By 2026, demand is expected to grow at a CAGR of approximately 6.8%, driven by urbanization and rising disposable incomes in emerging markets.

2. Premiumization and Aesthetic Appeal

Consumers are increasingly prioritizing design and craftsmanship in kitchenware. Leaf shape knives are being crafted with premium materials such as high-carbon stainless steel, Damascus steel, and ergonomic wooden or composite handles. Brands are leveraging artisanal aesthetics and eco-friendly packaging to appeal to environmentally conscious and design-savvy buyers. The integration of nature-inspired forms—like the leaf motif—resonates with biophilic design trends, expected to strengthen by 2026.

3. Growth of E-Commerce and Direct-to-Consumer Sales

Online retail channels are becoming the primary sales avenue for specialty kitchen knives. By 2026, it is projected that over 55% of leaf shape knife sales will occur through e-commerce platforms such as Amazon, Etsy, and brand-owned websites. This shift enables smaller, niche manufacturers to compete with established brands by offering personalized, hand-forged options directly to global customers.

4. Sustainability and Ethical Sourcing

Sustainability is a growing concern across consumer goods, and the cutlery market is no exception. By 2026, brands offering leaf shape knives made from recycled metals, sustainably harvested wood, or utilizing low-impact manufacturing processes are expected to capture increasing market share. Certifications such as FSC (Forest Stewardship Council) and B Corp status will likely serve as key differentiators.

5. Regional Market Expansion

While North America and Western Europe remain dominant markets, Asia-Pacific—particularly Japan, South Korea, and China—is expected to be the fastest-growing region for specialty knives by 2026. Japanese knife-making traditions, which often feature nature-inspired designs, provide a strong cultural foundation for the acceptance and appreciation of leaf-shaped utensils.

6. Innovation in Hybrid Designs

Manufacturers are increasingly combining the leaf shape with other functionalities—such as built-in portion guides, non-stick coatings, or antimicrobial properties. These hybrid innovations are expected to drive product differentiation and justify premium pricing, aligning with the broader trend of smart kitchenware.

In conclusion, the 2026 market for leaf shape knives will be shaped by evolving consumer preferences for design, functionality, and sustainability. Brands that embrace craftsmanship, digital reach, and environmental responsibility are poised to lead this niche yet expanding segment of the global kitchen tools industry.

Common Pitfalls When Sourcing Leaf Shape Knives (Quality and Intellectual Property)

1. Compromised Material Quality

One of the most frequent issues when sourcing leaf shape knives is receiving blades made from substandard materials. Some suppliers may use low-grade stainless steel or carbon steel that lacks proper hardness, corrosion resistance, or edge retention. This results in poor performance, premature dulling, and potential safety hazards. Always verify the steel grade (e.g., 420, 440C, or high-carbon variants) and request material certifications.

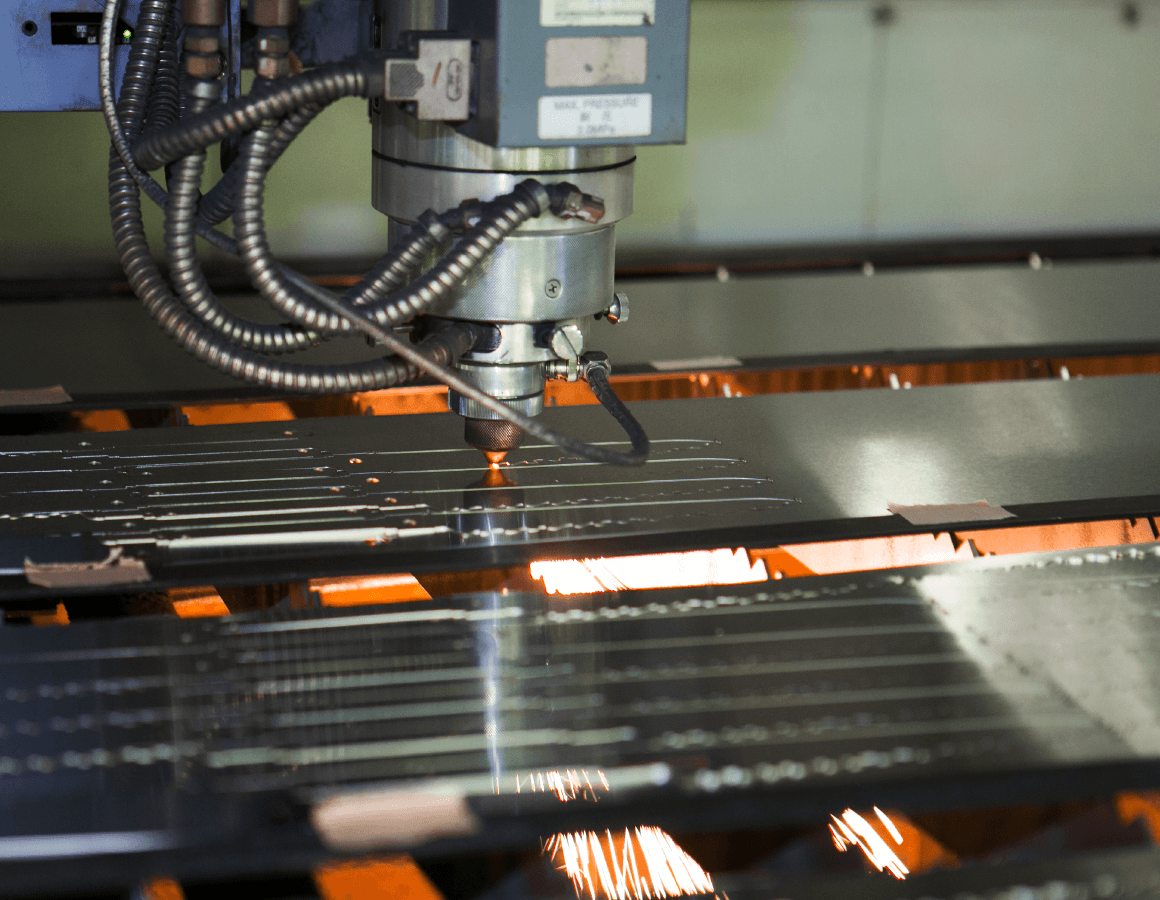

2. Inconsistent Heat Treatment

Even with high-quality steel, improper heat treatment can ruin a knife’s functionality. Poor tempering leads to brittle or overly soft blades that chip or bend easily. Many overseas manufacturers cut corners in this process to save costs. Ensure suppliers provide heat treatment specifications and conduct sample testing for hardness (e.g., Rockwell scale).

3. Poor Craftsmanship and Finishing

Leaf shape knives often feature intricate curves and detailed edges. Inexperienced or low-cost manufacturers may produce uneven grinds, rough edges, or misaligned handles. These flaws affect both aesthetics and performance. Conduct on-site factory audits or request detailed product samples before mass production.

4. Lack of Quality Control Standards

Suppliers without robust quality control (QC) systems may deliver inconsistent batches. Defects like loose handles, pitting, or incorrect blade geometry can go unnoticed without a structured inspection process. Require third-party QC checks or implement AQL (Acceptable Quality Level) inspections during production.

5. Intellectual Property (IP) Infringement Risks

Leaf shape knife designs—especially those resembling well-known patterns or branded products—can pose IP risks. Copying patented blade shapes, handle designs, or trademarks may lead to legal disputes, customs seizures, or forced product recalls. Always conduct an IP clearance search and ensure designs are either licensed or original.

6. Misrepresentation of Origin or Branding

Some suppliers falsely claim knives are made in specific countries (e.g., “Made in Japan” or “German Steel”) to increase perceived value. This mislabeling can violate import regulations and damage brand credibility. Verify certifications and request documentation to confirm material and manufacturing origins.

7. Inadequate Packaging and Corrosion Protection

Poor packaging can lead to scratches, moisture exposure, and rust during shipping. Especially for export, knives need proper anti-corrosion wrapping (e.g., VCI paper) and secure packaging. Overlooking this can result in damaged goods and customer dissatisfaction.

8. Overlooking Compliance and Safety Standards

Depending on the destination market, leaf shape knives may be subject to safety, labeling, or import regulations (e.g., FDA, CE, or UKCA). Non-compliant products can be rejected at customs. Confirm that the product meets blade length restrictions, safety labeling, and material safety standards for food contact if applicable.

9. Supplier Reliability and Communication Gaps

Working with unverified suppliers increases the risk of delays, unmet specifications, or disappearing vendors. Language barriers and time zone differences can exacerbate misunderstandings. Vet suppliers thoroughly via trade references, factory audits, and clear, written contracts.

10. Failure to Protect Your Own IP

When developing a unique leaf shape knife design, failing to patent or trademark it leaves your innovation vulnerable. Suppliers—especially in regions with lax IP enforcement—might replicate and sell your design to competitors. Secure IP rights early and use NDAs and manufacturing agreements with clear IP ownership clauses.

Logistics & Compliance Guide for Leaf Shape Knife

When importing, exporting, or distributing leaf shape knives—commonly used in kitchens, outdoor activities, or as collectibles—it is essential to adhere to international, national, and regional logistics and compliance regulations. This guide outlines key considerations to ensure legal and efficient handling of leaf shape knives across supply chains.

Classification & Harmonized System (HS) Code

Correct product classification is critical for customs clearance and duty assessment. Leaf shape knives may fall under various HS codes depending on their design, material, and intended use:

- HS 8211.92: Knives with cutting blades, other than pruning knives; knife blades – other.

- HS 8211.93: Knives with cutting blades, pruning knives.

- HS 8215.99: Other hand tools not elsewhere specified (may apply to specialty or multi-purpose tools).

Action: Verify the exact HS code with your customs broker based on blade length, handle material, locking mechanism, and primary use. Misclassification can lead to delays, fines, or seizure.

Import & Export Regulations

Compliance with trade laws is mandatory in both origin and destination countries.

- United States: Regulated by U.S. Customs and Border Protection (CBP). Most kitchen and utility knives are permitted, but switchblades and ballistic knives are prohibited under 15 U.S.C. § 1241–1245. Leaf shape knives are generally allowed if not classified as concealed or offensive weapons.

- European Union: Subject to Regulation (EU) No 952/2013 (UCC). Member states may impose additional restrictions. For example, the UK prohibits carrying bladed articles in public under the Criminal Justice Act 1988 unless there is “good reason.”

- Australia: Controlled by the Australian Border Force. Knives may be prohibited or require permits depending on blade length and locking features. Generally, blades over 6cm may be restricted.

- Canada: Regulated under the Criminal Code. Concealed knives or those with blade lengths over prescribed limits may be classified as prohibited weapons.

Action: Always consult destination country regulations before shipping. Use professional compliance software or legal counsel for high-risk markets.

Packaging & Labeling Requirements

Proper packaging and labeling reduce risks during transit and ensure regulatory compliance.

- Packaging: Knives must be securely packaged to prevent injury during handling. Use protective sheaths, blister packs, or rigid boxes. Avoid loose packing in mixed shipments.

- Labeling: Include product description, HS code, country of origin, blade length, and safety warnings (e.g., “Sharp Blade – Handle with Care”). For consumer sales, comply with local language requirements (e.g., CE marking in EU, FDA guidelines if marketed for food use in the U.S.).

Action: Implement standardized labeling protocols across all distribution channels.

Restricted Destinations & Carriers

Certain countries or carriers restrict the shipment of knives:

- Prohibited Destinations: UAE, Singapore, Japan, and India may restrict or ban certain types of knives.

- Carrier Policies: FedEx, UPS, and DHL have specific rules for shipping bladed products. Some require special labeling, documentation, or prohibit air shipment entirely.

Action: Confirm carrier policies and use ground shipping where air transport is restricted. Declare knives accurately on shipping manifests.

Safety & Product Compliance Standards

Ensure knives meet safety standards in the target market:

- EU: Must comply with General Product Safety Directive (2001/95/EC) and may require CE marking.

- U.S.: No federal certification required for most knives, but consumer product safety laws (CPSA) apply. Comply with ASTM F3267-17 for children’s folding knives if applicable.

- ISO Standards: Consider ISO 8442 (cutlery safety and performance) for quality assurance.

Action: Conduct third-party testing if entering regulated markets. Maintain compliance documentation for audits.

Storage & Handling Guidelines

During warehousing and distribution:

- Store knives in designated secure areas away from general inventory.

- Train staff in safe handling procedures.

- Use appropriate PPE (cut-resistant gloves) when unpacking or inspecting.

Action: Include knife handling protocols in warehouse safety manuals.

Recordkeeping & Documentation

Maintain comprehensive records for traceability and compliance:

- Commercial invoices

- Packing lists

- Certificates of origin

- Compliance declarations

- Safety data (if applicable)

Action: Retain documentation for a minimum of 5–7 years depending on jurisdiction.

Conclusion

Successfully managing the logistics and compliance of leaf shape knives requires attention to classification, legal restrictions, packaging, and carrier requirements. Proactive due diligence minimizes risks of delays, penalties, or confiscation. Always verify regulations with local authorities or trade experts before initiating shipments.

In conclusion, sourcing a leaf-shaped knife requires careful consideration of intended use, material quality, craftsmanship, and supplier reliability. Whether for culinary purposes, outdoor use, or decorative appeal, the unique curvature of the leaf-shaped blade offers both functional advantages and aesthetic distinction. By identifying reputable suppliers, verifying material durability (such as high-carbon steel or stainless steel), and ensuring proper handling and maintenance features, buyers can make informed decisions that balance performance, longevity, and value. Ultimately, successful sourcing hinges on aligning the knife’s design and construction with specific user needs while maintaining attention to safety, authenticity, and cost-effectiveness.