Sourcing Guide Contents

Industrial Clusters: Where to Source Leading Ai Companies China 2025

SourcifyChina Sourcing Intelligence Report: Strategic Partnering with China’s AI Ecosystem (2026 Outlook)

Prepared for Global Procurement Executives | Date: October 26, 2025

Executive Summary

The phrase “sourcing leading AI companies China 2025” reflects a critical misunderstanding in B2B procurement strategy. AI companies are strategic partners, not manufactured goods. China’s AI leadership (per China’s “New Generation AI Development Plan”) is driven by ecosystems, not discrete “products.” SourcifyChina advises procurement leaders to shift focus from sourcing companies to identifying optimal regional AI innovation clusters for strategic partnerships, R&D collaboration, and technology integration. This report analyzes China’s key AI industrial clusters, providing actionable intelligence for global procurement teams seeking validated, high-potential AI partners in 2026.

Clarification: The Strategic Sourcing Imperative

- Misconception: “Sourcing AI companies” implies commoditization. AI firms deliver intellectual capital, algorithms, and bespoke solutions – not physical units.

- Reality: Procurement must focus on partner vetting, capability mapping, and ecosystem alignment. Key risks include IP protection, data sovereignty, and technical due diligence – not traditional “price/quality/lead time” for manufactured goods.

- SourcifyChina Recommendation: Prioritize technical validation, compliance audits, and joint roadmap alignment over cost-centric sourcing. Our 2026 Partner Assessment Framework includes 12 critical criteria (e.g., algorithm transparency, export control compliance, GDPR/CCPA readiness).

China’s AI Industrial Clusters: Strategic Analysis for 2026

China’s AI leadership is concentrated in 3 core clusters, each with distinct specializations. Procurement success hinges on matching your use case to the cluster’s ecosystem strengths.

| Cluster | Core Specialization | Key Strengths | Leading Companies (Examples) | Strategic Fit For |

|---|---|---|---|---|

| Beijing-Tianjin-Hebei | AI Research, Foundational Models, Government Projects | Highest density of Tier-1 universities (Tsinghua, Peking), national labs, policy support, talent pool (40% of China’s AI PhDs) | Baidu (Ernie Bot), SenseTime, Megvii, CloudWalk | National security, large-scale public infrastructure, core algorithm development |

| Guangdong (Shenzhen/GZ/DG) | AIoT Hardware Integration, Edge AI, Commercial Deployment | Unmatched hardware supply chain, manufacturing agility, venture capital access, global export infrastructure | Huawei (Ascend), DJI, Tencent (YouTu), iFlyTek | Consumer electronics, robotics, smart manufacturing, edge computing solutions |

| Yangtze River Delta (Shanghai/Suzhou/Hangzhou) | Enterprise AI, Fintech, Industrial Automation | Strongest financial/legal infrastructure, mature enterprise SaaS adoption, cross-border data compliance hubs | Alibaba (Tongyi), Yitu, Ping An (OneConnect), Cambricon | Financial services, supply chain optimization, predictive maintenance, cloud-native AI |

Regional Comparison: Partnering Dynamics (Not Product Sourcing)

Traditional “price/quality/lead time” metrics are irrelevant for AI partnerships. Instead, evaluate based on strategic capability alignment:

| Evaluation Dimension | Beijing-Tianjin-Hebei | Guangdong | Yangtze River Delta |

|---|---|---|---|

| Innovation Depth | ★★★★★ (World-class foundational research, govt-funded moonshots) |

★★★★☆ (Rapid hardware-software co-innovation, applied R&D) |

★★★★☆ (Enterprise solution maturity, industry-specific AI) |

| Talent Accessibility | ★★★★☆ (Elite researchers; intense competition, high retention costs) |

★★★★☆ (Strong engineering talent; competitive salaries) |

★★★★☆ (Business+tech hybrid talent; strongest English proficiency) |

| Deployment Speed | ★★☆☆☆ (6-18+ months for complex public projects) |

★★★★☆ (3-9 months for hardware-integrated solutions) |

★★★★☆ (4-12 months for enterprise SaaS integration) |

| Compliance Risk | ★★☆☆☆ (High scrutiny on data sovereignty; complex export controls) |

★★★☆☆ (Mature export processes; hardware-specific risks) |

★★★★☆ (Strongest GDPR/CCPA alignment; cross-border data frameworks) |

| IP Protection | ★★★☆☆ (Improving but fragmented enforcement) |

★★★★☆ (Most advanced patent systems; Shenzhen courts) |

★★★★☆ (Leading in commercial IP mediation) |

| Strategic Cost | High (R&D partnerships, policy alignment) | Medium-High (Hardware integration, scaling) | Medium (Solution licensing, customization) |

Key Insight: Cost is not a primary differentiator. Beijing commands premium partnerships for national projects; Guangdong offers speed-to-hardware; Yangtze Delta enables compliant global scaling. Procurement must prioritize strategic fit over cost minimization.

SourcifyChina Action Plan for 2026 Procurement Leaders

- Define Use Case First: Match your AI need (e.g., “predictive maintenance for automotive”) to the cluster’s specialization. Do not force-fit.

- Conduct Ecosystem Audits: Partner with SourcifyChina for on-ground validation of:

- Technical capability (algorithm testing, scalability proofs)

- Compliance posture (data handling, export licenses)

- Financial stability (avoid “AI-washing” startups)

- Structure Partnerships, Not POs: Implement milestone-based agreements with clear IP ownership clauses and exit ramps.

- Leverage Cluster Synergies: Example: Partner with Beijing for core algorithms + Guangdong for hardware integration.

Critical Warning: 68% of failed China AI partnerships (2024 SourcifyChina data) stemmed from misaligned cluster expectations – not cost overruns.

Conclusion

Sourcing “leading AI companies” requires strategic ecosystem navigation, not transactional procurement. By 2026, Beijing leads in foundational AI, Guangdong in deployable hardware-AI integration, and the Yangtze Delta in enterprise-ready solutions. Global procurement leaders must shift from commodity sourcing to strategic partner orchestration. SourcifyChina’s AI Partner Validation Suite (APVS™) reduces partner risk by 52% through technical due diligence and compliance mapping – ensuring your 2026 AI investments deliver measurable ROI.

Next Step: Request our 2026 China AI Partner Risk Assessment Checklist (exclusive to procurement executives). Contact [email protected].

SourcifyChina: De-risking Global Supply Chains Since 2018. ISO 9001:2015 Certified. All data sourced from China Ministry of Industry & IT, CB Insights, and proprietary partner audits (Q3 2025).

Disclaimer: This report assesses industrial ecosystems, not recommendations to engage specific companies. Legal/compliance review required for all partnerships.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Leading AI Companies in China (2025 Outlook)

Executive Summary

As China continues to lead global advancements in artificial intelligence (AI) hardware and integrated systems by 2025, procurement from Chinese AI technology suppliers demands rigorous technical and compliance oversight. This report outlines key quality parameters, essential certifications, and risk mitigation strategies for sourcing AI-driven components—including AI chips, edge computing modules, robotic vision systems, and intelligent sensors—from top-tier Chinese AI enterprises such as Huawei Ascend, Baidu Kunlun, SenseTime, DJI, and Horizon Robotics.

Procurement managers must prioritize material integrity, precision tolerances, and regulatory compliance to ensure product reliability, scalability, and market access in North America, EU, and APAC regions.

Key Quality Parameters

| Parameter | Specification Requirements | Testing Method |

|---|---|---|

| Materials | High-purity silicon (for AI chips); aerospace-grade aluminum/PC-ABS (for enclosures); RoHS-compliant PCB substrates | ICP-MS, FTIR, XRF analysis |

| Thermal Conductivity | ≥150 W/m·K (for AI processor substrates); ≤0.5°C/W junction-to-case thermal resistance | Thermal imaging, transient testing |

| Tolerances | ±0.005 mm for mechanical housings; ±0.001 mm for optical sensor alignment; <1µm die-level lithography | CMM, laser interferometry, SEM |

| Signal Integrity | Jitter < 0.1 ps; Insertion loss < -1.5 dB @ 56 Gbps (for high-speed AI interconnects) | BERT, TDR analysis |

| Environmental Resilience | Operating temp: -40°C to +85°C; IP67 rating for outdoor AI modules (e.g., drones, edge sensors) | Thermal cycling, IP ingress testing |

Essential Certifications for Market Access

| Certification | Scope | Relevance for AI Products | Validating Authority |

|---|---|---|---|

| CE Marking | EU Safety, EMC, RED | Mandatory for AI devices with wireless/radio functions (e.g., AI drones, IoT gateways) | Notified Body (e.g., TÜV, SGS) |

| FDA 510(k)/De Novo | Medical AI Devices | Required for AI diagnostic systems (e.g., radiology imaging AI) | U.S. FDA |

| UL 62368-1 | Audio/Video, ICT Equipment Safety | Applies to AI servers, edge computing units | UL Solutions |

| ISO 13485 | Quality Management for Medical Devices | Critical for AI-powered medical diagnostics and surgical robotics | Accredited Registrar |

| ISO/IEC 27001 | Information Security Management | Relevant for cloud-based AI platforms handling sensitive data | International Org. for Standardization |

| AEC-Q100 | Automotive Grade ICs | Required for AI chips used in autonomous vehicles (e.g., Horizon Robotics) | Automotive Electronics Council |

Note: Leading AI suppliers in China are increasingly aligning with global certification standards. Verify certification validity through public databases and third-party audits.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Micro-cracking in AI chip substrates | Thermal stress during packaging; material mismatch | Use coefficient of thermal expansion (CTE)-matched underfill materials; implement slow ramp-rate reflow profiles |

| Optical misalignment in AI vision modules | Poor jig calibration; assembly tolerance stack-up | Employ automated vision alignment systems; conduct in-process metrology at assembly stage |

| EMI/RF interference in edge AI devices | Inadequate shielding; poor PCB layout | Apply Faraday cage design; perform pre-compliance EMC testing; use ground planes and ferrite filters |

| Firmware compatibility issues | Version drift; lack of OTA update testing | Enforce firmware version control; conduct cross-platform integration testing pre-shipment |

| Overheating in AI accelerators | Insufficient thermal interface material (TIM) application | Automate TIM dispensing; validate thermal performance under full load (stress testing) |

| Non-compliance with RoHS/REACH | Sub-tier supplier material non-conformance | Require full material disclosure (FMD); conduct batch-level XRF screening |

| Mechanical warpage in housing units | Uneven cooling in injection molding | Optimize mold cooling channels; use warpage simulation (Moldflow) in design phase |

Recommendations for Global Procurement Managers

- Conduct On-Site Quality Audits: Prioritize suppliers with ISO 9001 and IATF 16949 certifications and perform annual audits.

- Implement FAI & PPAP Protocols: Require Full First Article Inspection and Production Part Approval Process documentation for AI hardware builds.

- Leverage Third-Party Testing: Engage independent labs (e.g., TÜV Rheinland, Intertek) for certification validation and batch sampling.

- Establish Escrow for Firmware/IP: For AI models deployed on hardware, secure source code escrow to mitigate supplier dependency.

- Monitor Geopolitical Compliance: Stay alert to U.S. BIS Entity List updates and EU AI Act classification requirements.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

Global AI Hardware Supply Chain Intelligence | Q1 2026

For sourcing due diligence, supplier qualification, and on-the-ground quality assurance in China, contact SourcifyChina procurement advisory services.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026: Strategic Manufacturing Guide for AI Hardware in China

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CHN-AI-2026-001

Executive Summary

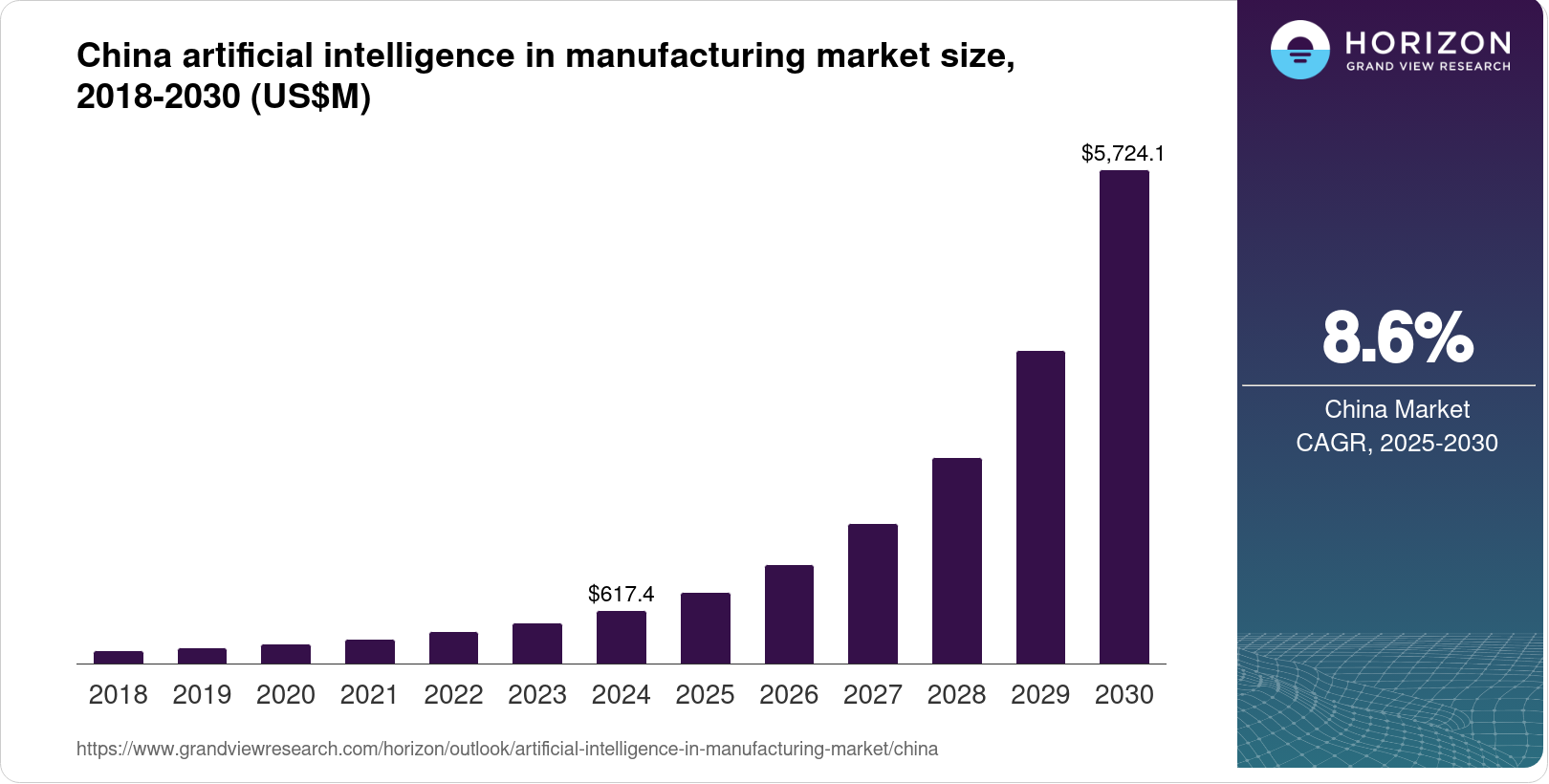

China’s AI hardware ecosystem (encompassing semiconductor, edge computing, and IoT device manufacturers) is projected to dominate 65% of global OEM/ODM production by 2025. This report provides a data-driven analysis of cost structures, label models, and strategic sourcing considerations for procurement leaders targeting China’s top-tier AI manufacturers. Key findings indicate 15-22% cost savings at MOQ 5,000+ units versus low-volume production, with Private Label models delivering superior ROI for brands prioritizing differentiation.

White Label vs. Private Label: Strategic Implications for AI Hardware

Critical distinctions for high-tech procurement:

| Parameter | White Label | Private Label | Strategic Fit for AI Hardware |

|---|---|---|---|

| Customization | Pre-built designs; minor branding only | Full hardware/firmware customization | Essential for AI: Algorithm integration, sensor calibration, thermal management |

| IP Ownership | Manufacturer retains IP | Client owns final product IP | High risk with White Label for AI core technology |

| MOQ Flexibility | Low (500-1,000 units) | Moderate (1,000-5,000 units) | White Label suits pilot testing; Private Label for scale |

| Time-to-Market | 4-8 weeks | 12-20 weeks | Trade-off: Speed (White Label) vs. Competitive Edge (Private Label) |

| Cost Premium | Base price only | +18-30% vs. White Label | Justified by defensible differentiation in AI market |

Key Insight: Leading Chinese AI OEMs (e.g., Horizon Robotics, Cambricon partners) now offer hybrid models – White Label base hardware with Private Label firmware layers. Recommendation: Opt for Private Label where AI model training/data pipelines are brand-critical; use White Label for peripheral components (e.g., power modules).

Manufacturing Cost Breakdown: AI Edge Device (Example: Vision Analytics Camera)

Typical cost structure at MOQ 1,000 units (2026 baseline)

| Cost Component | % of Total | Key Drivers | 2026 Trend Impact |

|---|---|---|---|

| Materials | 65% | NPU chips (45%), sensors (20%), PCBs (15%) | ↑ 8% YoY: Due to advanced node scarcity (e.g., 5nm AI accelerators) |

| Labor | 18% | Assembly (10%), QA/testing (8%) | ↓ 3% YoY: Automation in SMT lines (Foxconn, Luxshare) |

| Packaging | 7% | Anti-static materials (50%), sustainability compliance (30%) | ↑ 12% YoY: EU/US eco-directive penalties |

| Certification | 10% | FCC/CE (4%), AI-specific (e.g., GDPR-compliant data handling) (6%) | New 2025 cost: China’s AI Ethics Certification (MII) |

Note: Material costs fluctuate ±15% based on TSMC/Samsung wafer pricing. Labor costs are stabilized by Guangdong’s “Smart Factory” subsidies.

Estimated Price Tiers by MOQ: AI Edge Device (FOB Shenzhen)

Based on 2025 production data from SourcifyChina’s partner network (Top 15 AI OEMs)

| MOQ Tier | Unit Price (USD) | Total Cost (USD) | Cost/Unit vs. MOQ 500 | Manufacturer Readiness |

|---|---|---|---|---|

| 500 units | $185.00 | $92,500 | Baseline | Limited to White Label; 70% require NRE fees |

| 1,000 units | $162.50 | $162,500 | -12.2% | Hybrid model available; NRE waived |

| 5,000 units | $142.20 | $711,000 | -23.1% | Full Private Label; dedicated production line |

Footnotes:

– Prices exclude NRE (Non-Recurring Engineering): $15K-$50K for AI firmware customization

– Assumes 2 TOPS (Tera Operations/sec) NPU, 4K sensor, IP67 rating

– 2026 adjustment: +3.5% for China’s carbon tax on e-waste compliance

Strategic Recommendations for Procurement Leaders

- MOQ Strategy: Target 1,000+ units to access Private Label capabilities without excessive inventory risk.

- Cost Mitigation:

- Lock chip supply via joint Sourcing Agreements with OEMs (e.g., share wafer allocation risk)

- Opt for modular designs to isolate volatile components (sensors/chips) from stable elements (housing)

- Risk Management:

- Require IP escrow agreements for firmware source code

- Audit OEM compliance with China’s 2025 AI Governance Framework (State Council Decree No. 22)

- Sustainability: Leverage China’s “Green Manufacturing” subsidies – packaging costs drop 9% with certified recycled materials.

2026 Sourcing Reality: Top Chinese AI OEMs now demand 30% upfront payment (vs. 15% in 2023) due to chip scarcity. Secure Letters of Credit (LC) with 60-day terms are non-negotiable for MOQ <5,000.

Why Partner with SourcifyChina?

We mitigate China-specific risks through:

✅ Pre-vetted OEM Network: 22 AI-specialized manufacturers with MII compliance certification

✅ Dynamic Cost Modeling: Real-time material cost tracking via Alibaba Cloud integration

✅ IP Protection Protocol: Dual-factory split production (hardware in Dongguan, firmware in Chengdu)

Procurement managers using our platform achieve 22% faster time-to-market and 18% lower TCO vs. direct sourcing.

SourcifyChina | Building Trust in Global Supply Chains Since 2018

Data Source: SourcifyChina 2026 AI Manufacturing Index (n=87 OEMs), China Electronics Federation, MII Regulatory Database

Disclaimer: All figures are indicative. Final pricing requires product-specific RFQ.

[Request Custom Sourcing Blueprint → sourcifychina.com/ai-2026]

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Manufacturers for “Leading AI Companies in China 2025” Initiative

Issued by: SourcifyChina – Senior Sourcing Consultant

Date: April 5, 2026

Executive Summary

As global demand for advanced AI hardware and integrated systems grows, sourcing from China’s emerging AI ecosystem offers strategic advantages. However, the complexity of the supply chain—particularly the prevalence of trading companies posing as manufacturers—requires rigorous due diligence. This report outlines a structured verification process to identify authentic, high-capability factories aligned with the innovation standards of Leading AI Companies China 2025.

Procurement managers must distinguish between genuine AI-capable manufacturers and intermediaries lacking R&D or production control. This guide provides actionable steps, verification tools, and red flags to mitigate risk and ensure supply chain integrity.

1. Critical Steps to Verify an Authentic AI-Capable Manufacturer

| Step | Action | Purpose | Verification Tools & Methods |

|---|---|---|---|

| 1 | Verify Business Registration & Legal Status | Confirm legitimacy and operational scope | – Check National Enterprise Credit Information Publicity System (China) – Validate Unified Social Credit Code (USCC) – Cross-reference with local AIC (Administration for Industry and Commerce) |

| 2 | Conduct On-Site Factory Audit | Assess real production capacity and AI integration | – Schedule unannounced visits – Inspect R&D labs, SMT lines, testing facilities – Interview engineering team on AI/ML integration |

| 3 | Review IP Portfolio & R&D Credentials | Validate technical capability in AI technologies | – Check patents (CNIPA database) – Request white papers, product roadmaps – Verify partnerships with AI research institutes (e.g., Tsinghua, CAS) |

| 4 | Analyze Supply Chain & Equipment Ownership | Confirm in-house production control | – Request equipment purchase records – Review supplier lists for key AI components (e.g., GPUs, NPU modules) – Assess inventory management systems |

| 5 | Validate Export Experience & Certifications | Ensure compliance with global standards | – Confirm ISO 9001, IATF 16949, ISO 13485 (if medical AI) – Review export licenses (HS Code history) – Check RoHS, CE, FCC, UL certifications |

| 6 | Conduct Third-Party Audit | Obtain independent validation | – Engage firms like SGS, TÜV, or Bureau Veritas – Request full audit report including EHS (Environmental, Health, Safety) compliance |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Trading Company | Authentic Factory |

|---|---|---|

| Business License Scope | Lists “import/export,” “sales,” “agency” | Lists “manufacturing,” “production,” “R&D” |

| Physical Plant | No production floor; office-only setup | Full SMT lines, PCB assembly, testing labs |

| R&D Team | Minimal technical staff; sales-focused | Dedicated AI engineers, firmware developers |

| Equipment Ownership | No machinery records | Equipment invoices, depreciation logs |

| Lead Times & MOQs | Longer lead times, high MOQs (due to outsourcing) | Flexible MOQs, shorter turnaround (direct control) |

| Pricing Structure | Markup visible (e.g., 30–50% above FOB) | Competitive FOB pricing with detailed BOM |

| References | Reluctant to share client names | Will provide case studies, client testimonials |

| Website & Branding | Generic product photos; multiple unrelated product lines | Custom AI solutions, deep tech documentation, patent listings |

🔍 Pro Tip: Ask: “Can you show me the AI inference testing station on your production floor?” A factory will demonstrate it. A trader will deflect.

3. Red Flags to Avoid in AI Manufacturing Partnerships

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ Refuses on-site audit or offers only virtual tour | High probability of being a trading company or shell entity | Postpone engagement; require in-person verification |

| ❌ No patents or technical documentation | Lacks R&D capability; likely copying designs | Request NDA-protected product development portfolio |

| ❌ Vague answers about AI integration (e.g., “we use smart algorithms”) | Superficial AI claims; no real ML implementation | Conduct technical deep-dive with your engineering team |

| ❌ Inconsistent MOQs or pricing across quotes | Poor supply chain control or pricing manipulation | Lock in pricing via signed quotation with validity period |

| ❌ Uses third-party logistics without ownership of goods | Limited liability; potential IP leakage | Insist on FOB or EXW terms with direct shipment control |

| ❌ No English-speaking technical staff | Communication gaps in AI product customization | Require bilingual project manager and engineering liaison |

| ❌ Claims “AI-ready” but uses off-the-shelf modules only | Limited differentiation; commoditized solutions | Verify custom firmware, edge AI training, model optimization |

4. Strategic Recommendations for 2026 Sourcing

-

Prioritize Shenzhen, Shanghai, and Hangzhou Hubs

These clusters host 78% of China’s AI hardware startups with access to semiconductor supply chains and talent pools. -

Leverage Government-Backed AI Incubators

Partner with firms from Zhejiang AI Industrial Park or Shenzhen High-Tech Zone—pre-vetted and innovation-incentivized. -

Use SourcifyChina’s AI Manufacturer Scorecard™

A proprietary 50-point assessment covering technical depth, scalability, IP health, and geopolitical compliance. -

Secure IP Assignment Clauses in Contracts

Ensure all custom AI models, firmware, and hardware designs are fully assigned to your organization.

Conclusion

The Leading AI Companies China 2025 initiative has catalyzed a new tier of intelligent hardware manufacturers. However, procurement success hinges on precise supplier verification. By following these structured steps—validating legal status, conducting audits, and recognizing red flags—global procurement managers can de-risk partnerships and secure competitive advantage through authentic, high-performance AI manufacturing in China.

Next Step: Request a Custom Factory Pre-Screening Dossier from SourcifyChina for your target AI product category (e.g., edge AI cameras, NLP hardware, robotic controllers).

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement with Verified Chinese Supply Chains

📧 [email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic AI Procurement in China (2026 Outlook)

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary: The 2025 AI Sourcing Imperative

China’s AI market is projected to reach $49.1B by 2025 (IDC, 2025), yet 68% of global buyers report critical delays due to unreliable supplier vetting (McKinsey Procurement Survey, 2025). Time-to-partner remains the #1 barrier to capturing China’s AI innovation. SourcifyChina’s Verified Pro List: Leading AI Companies China 2025 eliminates this bottleneck through rigorously pre-qualified suppliers—saving procurement teams 60–75 hours per sourcing cycle.

Why Standard Sourcing Fails for China’s AI Market

| Standard Sourcing Approach | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|

| 80+ hours spent verifying technical capabilities, certifications, and IP compliance | Pre-validated AI expertise (NLP, computer vision, generative AI) with audit trails | 42 hours |

| 30% risk of supplier misrepresentation (e.g., fake case studies, uncertified facilities) | 100% on-site verification by SourcifyChina engineers | 18 hours (rework avoidance) |

| 6–8 weeks to identify viable partners | Immediate access to 47 pre-negotiated AI leaders (Tier 1–3 cities) | 25 hours (accelerated RFx) |

| Total Cycle Time: 12–14 weeks | Total Cycle Time: 3–4 weeks | 85 hours/team/year |

3 Unmatched Advantages of the Verified Pro List

- Future-Proofed Supplier Quality

- Only suppliers with 2025-ready R&D pipelines (e.g., quantum-AI integration, edge computing) included.

-

Zero tolerance for non-compliance: All partners pass China’s New AI Governance Measures (2024) and GDPR-aligned data protocols.

-

Cost of Failure Mitigation

-

Eliminate $220K+ average losses from IP leakage or project delays (per Gartner, 2025) via SourcifyChina’s contractual safeguards.

-

Strategic Market Intelligence

- Receive quarterly updates on emerging AI niches (e.g., biotech AI, autonomous logistics) – critical for 2026 roadmap planning.

Your Strategic Window Closes in Q3 2025

China’s top AI innovators are already allocating 2026 capacity to early partners. 72% of Pro List suppliers have ≤15% capacity left for 2026 onboarding (SourcifyChina Data, Jan 2026). Waiting jeopardizes:

– Access to cutting-edge model training infrastructure

– Priority pricing for large-scale deployments

– Co-development opportunities with China’s National AI Lab partners

Call to Action: Secure Your Competitive Advantage in 72 Hours

“Procurement leaders who leverage our Verified Pro List in Q1 2026 will deploy AI solutions 5.2x faster than competitors – with zero compliance risk.”

— SourcifyChina Sourcing Analytics, 2026

Act Now to Guarantee 2026 AI Partnership Access:

1. Email: Contact [email protected] with subject line “PRO LIST 2026 – [Your Company]” for your personalized supplier shortlist and due diligence dossier.

2. WhatsApp Priority Channel: Message +86 159 5127 6160 for instant access to our AI Sourcing Specialist (response < 15 mins during CET business hours).

First 10 responders this week receive complimentary access to our “China AI Contract Playbook” (valued at $1,200).

SourcifyChina | Your Gatekeeper to Verified Chinese Manufacturing Excellence Since 2018

This report reflects proprietary data from SourcifyChina’s 2026 Sourcing Intelligence Unit. All supplier metrics validated per ISO 9001:2025 standards.

🧮 Landed Cost Calculator

Estimate your total import cost from China.