The global latch barrel market is experiencing steady growth, driven by rising demand across automotive, residential, and commercial security applications. According to Mordor Intelligence, the global door locks and latches market was valued at USD 11.8 billion in 2022 and is projected to grow at a CAGR of 6.3% from 2023 to 2028, fueled by advancements in smart lock technology and increased construction activity. As a core component in locking mechanisms, latch barrels benefit from this upward trajectory, with manufacturers focusing on precision engineering, durability, and integration capabilities. With both residential and industrial sectors prioritizing enhanced security solutions, the need for high-quality, reliable latch barrels has intensified. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining innovation, scalability, and strict quality control to meet evolving global standards. Here are the top 9 latch barrel manufacturers shaping the industry’s future.

Top 9 Latch Barrel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cylinder Lock Manufacturer

Domain Est. 2004

Website: luter.com.tw

Key Highlights: Luter is one of the most professional cylinder lock manufacturers and suppliers in Taiwan. We focus on different cylinder manufacture including euro profile ……

#2 Wholesale Lock Hardware Suppliers

Domain Est. 2008

Website: tai-sam.com

Key Highlights: At present, we are supplying our lock hardware to more than 80% of the industrial enclosure makers in Taiwan and we have entered the global market for 20 years….

#3 Door cylinder

Domain Est. 1995

Website: abus.com

Key Highlights: Door cylinders The heart of every door. We have the right length and the right cylinder model for almost every door and every private locking system….

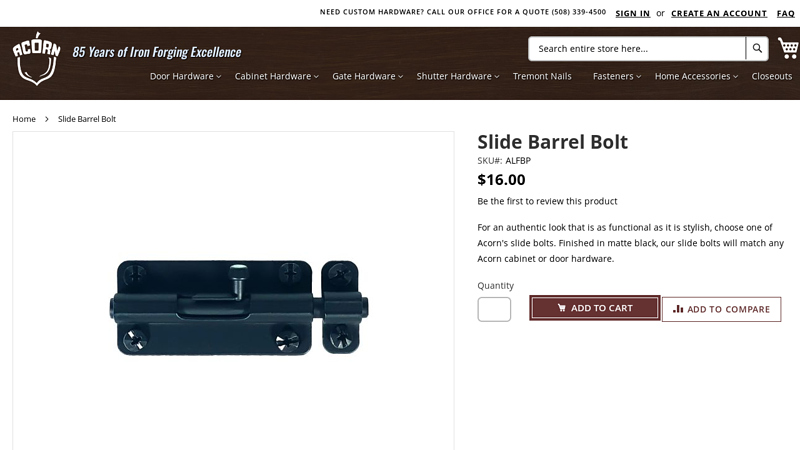

#4 Slide Barrel Bolt

Domain Est. 1996

Website: acornmfg.com

Key Highlights: Slide Barrel Bolt · Made of steel with a matte black finish · 15/16″ throw · Main body pad , 3″ wide, 1-1/2″ height · 4″ bolt · 1/4″ diameter bolt · 1/2″ projection ……

#5 Page – HOPPE

Domain Est. 1997

Website: hoppe.com

Key Highlights: Handle of excellence. HOPPE Brand Quality · HOPPE Innovations · Product Lines · Door Hardware · Products · Door Hardware Finishes · Support….

#6 Baldwin Hardware

Domain Est. 1998

Website: baldwinhardware.com

Key Highlights: Baldwin Hardware is a leading provider of high-quality, stylish and durable door and cabinet hardware for both residential and commercial applications….

#7 Barrels for Locks

Domain Est. 2000

Website: euro-locks.com

Key Highlights: Barrels for locks are the part of the lock that house tumblers and receive the key. Contact us today for more information….

#8 Latch Barrel Assembly for Chute Intake Doors, 1

Domain Est. 2001

Website: chutedr.com

Key Highlights: Out of stockThe latch barrel assembly is made up of the barrel case tube, latch plunger and main spring and has a 1-23/32″ set back from the inside face of the latch tube….

#9 Bolt Latch (Barrel) 4″ x 1

Domain Est. 2008

Expert Sourcing Insights for Latch Barrel

H2: Market Trends for Latch Barrel in 2026

As we approach 2026, the global market for latch barrels—mechanical components used primarily in door locking systems, cabinets, furniture, and automotive applications—is undergoing transformation driven by technological advancements, evolving consumer preferences, and broader industrial shifts. Below is an analysis of key market trends expected to shape the latch barrel industry in 2026.

1. Increased Demand for Smart and Secure Locking Systems

The integration of smart home technology is a dominant driver in the latch barrel market. By 2026, traditional mechanical latch barrels are being increasingly redesigned or replaced with smart-enabled variants compatible with electronic access systems, IoT-connected locks, and biometric authentication. This shift is particularly evident in residential and commercial construction sectors in North America and Europe, where demand for keyless entry and remote access control is rising. As a result, manufacturers are adapting by developing hybrid latch barrels that support both mechanical and electronic operation.

2. Growth in Construction and Furniture Sectors

Global construction activity, especially in emerging markets such as India, Southeast Asia, and parts of Africa, is fueling demand for hardware components, including latch barrels. Urbanization and infrastructure development projects are boosting residential and commercial real estate, increasing the need for durable and reliable door hardware. Additionally, the furniture industry—particularly modular and ready-to-assemble (RTA) furniture—is adopting standardized latch barrel systems for ease of manufacturing and assembly, further expanding market opportunities.

3. Emphasis on Sustainability and Material Innovation

Environmental regulations and consumer demand for sustainable products are influencing material choices in latch barrel production. By 2026, there is a noticeable shift toward using recycled metals, zinc alloys with lower carbon footprints, and corrosion-resistant coatings that extend product life. Manufacturers are also investing in energy-efficient production processes and exploring biodegradable or recyclable packaging solutions to align with ESG (Environmental, Social, and Governance) standards.

4. Automation and Precision Engineering in Manufacturing

The adoption of automation, CNC machining, and precision engineering is enhancing the quality and consistency of latch barrels. Automated production lines reduce human error, improve scalability, and lower unit costs—critical factors in a competitive, cost-sensitive market. These advancements also support the customization trend, allowing manufacturers to produce latch barrels tailored to specific dimensions, torque requirements, or aesthetic finishes for niche applications.

5. Rising Adoption in Automotive and Industrial Applications

Beyond traditional uses in doors and cabinets, latch barrels are finding growing applications in automotive interiors (e.g., glove compartments, center consoles) and industrial enclosures. The push for lightweight, durable components in electric vehicles (EVs) is prompting redesigns of internal latching mechanisms, where compact and reliable latch barrels play a critical role. This diversification is opening new revenue streams for suppliers and encouraging innovation in miniaturization and performance under extreme conditions.

6. Supply Chain Resilience and Regionalization

Ongoing geopolitical tensions and supply chain disruptions have prompted companies to regionalize production. By 2026, many latch barrel manufacturers are establishing localized supply chains to reduce dependency on single-source suppliers, particularly in Asia. Nearshoring in regions like Eastern Europe, Mexico, and Turkey is gaining momentum, supported by favorable trade agreements and lower logistics costs.

7. Competitive Landscape and Consolidation

The market is experiencing consolidation, with larger players acquiring niche manufacturers to expand product portfolios and geographic reach. At the same time, smaller firms are focusing on differentiation through design innovation, faster delivery times, and specialized applications (e.g., fire-rated or marine-grade latch barrels). Price competition remains intense, especially in commodity segments, pushing companies to add value through service and integration support.

Conclusion

By 2026, the latch barrel market is evolving from a commodity-driven sector into a technology- and application-integrated industry. Success will depend on manufacturers’ ability to innovate, respond to smart technology integration, meet sustainability demands, and adapt to shifting global supply dynamics. Companies that embrace digital transformation, invest in R&D, and align with broader trends in construction, automotive, and smart living will be best positioned to capture growth in this mature yet dynamic market.

Common Pitfalls When Sourcing Latch Barrels (Quality, IP)

Sourcing latch barrels—especially for high-security or specialized applications—can present significant challenges related to both product quality and intellectual property (IP) protection. Overlooking these aspects can lead to compromised performance, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Material and Manufacturing Quality

Many low-cost suppliers use substandard materials (e.g., low-grade zinc alloys or plastics) that degrade quickly under stress or environmental exposure. Inadequate heat treatment or imprecise machining can result in weak springs, misaligned components, or premature wear. This compromises the latch barrel’s durability, security, and smooth operation, leading to customer dissatisfaction and increased warranty claims.

Inconsistent Tolerances and Fitment Issues

Latch barrels must meet exact dimensional specifications to function properly within locking mechanisms. Sourcing from manufacturers with inconsistent quality control often leads to variations in diameter, length, or cam orientation. These inconsistencies can cause installation problems, poor alignment with strike plates, or failure to engage locks reliably—especially in high-volume or automated assembly environments.

Lack of Security Certification and Testing

High-security applications (e.g., commercial, government, or smart locks) require latch barrels that meet specific standards (e.g., ANSI, EN, or BHMA). Sourcing components without proper certifications exposes buyers to liability and security vulnerabilities. Unverified barrels may not withstand forced entry, tampering, or environmental stress, undermining the overall security system.

Intellectual Property Infringement Risks

Latch barrel designs—particularly those with unique cam profiles, anti-pick features, or patented mechanisms—are often protected by IP rights. Sourcing from suppliers who replicate branded or patented designs without authorization exposes the buyer to legal action, product seizures, and reputational harm. This is especially common when sourcing from regions with weak IP enforcement.

Inadequate Documentation and Traceability

Reputable suppliers provide full material certifications, test reports, and traceability data. Many budget suppliers lack these, making it difficult to validate quality or respond to audits and compliance inquiries. Missing documentation can also hinder root cause analysis during field failures or product recalls.

Hidden Tooling and Setup Costs

While unit pricing may appear attractive, some suppliers charge high, often non-negotiable, tooling fees for custom designs. Without clear contracts, buyers may find themselves locked into a single supplier for replacements or spare parts—especially if the supplier retains ownership of the tooling or design files.

Supply Chain and Long-Term Availability Risks

Latch barrels with proprietary designs may become obsolete if the supplier discontinues production or goes out of business. Sourcing without securing design rights or backup manufacturing agreements can leave buyers stranded without replacement parts, disrupting maintenance and after-sales service.

To mitigate these risks, conduct thorough due diligence on suppliers, verify certifications, perform independent quality audits, and ensure all IP rights are clearly defined and protected in contracts.

Logistics & Compliance Guide for Latch Barrel

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legally compliant handling, transportation, and storage of latch barrels. Latch barrels, which may contain pressurized or hazardous contents (depending on application), require careful management throughout their lifecycle.

Definition and Product Overview

A latch barrel typically refers to a cylindrical container—often used in industrial, automotive, or manufacturing settings—that features a latching closure mechanism. These barrels may store or transport gases, liquids, or specialized components. The compliance and logistics protocols depend heavily on the barrel’s contents, materials, pressure rating, and applicable regulations.

Regulatory Compliance Requirements

Latch barrels must comply with regional and international regulations depending on their contents and use. Key compliance standards include:

- DOT (Department of Transportation) – USA: If transporting hazardous materials, barrels must meet DOT 4BW or equivalent specifications for pressure vessels. Certification includes periodic requalification every 5 years.

- ADR – Europe: For road transport of dangerous goods, latch barrels must conform to ADR Chapter 6.2 standards, including UN certification markings and proper labeling.

- ISO Standards: ISO 9809 governs the design and testing of seamless steel gas cylinders, which may apply if the latch barrel stores compressed gas.

- Pressure Equipment Directive (PED) 2014/68/EU: Required in the EU for pressure-containing equipment above specified thresholds.

- OSHA & GHS Compliance: For workplace safety, barrels must be labeled with GHS-compliant hazard pictograms, signal words, and safety data sheets (SDS) must be accessible.

Ensure all latch barrels have visible certification marks, test dates, and manufacturer information.

Packaging and Handling Guidelines

Proper handling prevents damage, leaks, and safety incidents:

- Use appropriate lifting equipment (e.g., drum handlers, forklift attachments) to avoid dropping or rolling barrels.

- Always secure latch barrels upright during storage and transport to prevent leakage or valve damage.

- Inspect latches, seals, and valves before and after each use for wear, corrosion, or deformation.

- Never tamper with safety valves or pressure relief mechanisms.

- Use protective caps on valves when not in use to prevent contamination or impact damage.

Transportation Best Practices

Safe transport minimizes risk and ensures regulatory adherence:

- Secure barrels in vehicles using straps, chocks, or containment racks to prevent movement.

- Segregate incompatible materials (e.g., oxidizers from flammables) as per transport regulations.

- Clearly label vehicles transporting hazardous latch barrels with appropriate placards (e.g., Class 2.1 for flammable gas).

- Maintain transport documentation, including shipping papers, emergency response information, and manifests.

- Train drivers and handlers in hazardous materials (HAZMAT) protocols if applicable.

Storage Requirements

Store latch barrels in compliance with safety and environmental standards:

- Keep in a well-ventilated, dry, and temperature-controlled area away from direct sunlight and ignition sources.

- Store upright on level surfaces with latches securely closed.

- Separate full and empty barrels; clearly mark status.

- Implement a first-in, first-out (FIFO) inventory system to prevent aging or over-storage.

- Conduct regular inspections for corrosion, leakage, or pressure loss.

Inspection and Maintenance Schedule

Regular maintenance ensures ongoing compliance and safety:

- Perform visual inspections before each use.

- Conduct hydrostatic testing at intervals specified by regulation (typically every 5 years).

- Keep a maintenance log with test dates, repairs, and personnel responsible.

- Retire or requalify barrels that fail inspection or exceed service life.

Emergency Response and Spill Management

Prepare for potential incidents:

- Maintain spill kits appropriate for barrel contents (absorbents, neutralizers, PPE).

- Train personnel in emergency shutdown, evacuation, and containment procedures.

- Post emergency contact numbers and SDS access points in storage and handling areas.

- Report leaks, ruptures, or exposure incidents immediately per local and federal requirements.

Documentation and Recordkeeping

Maintain accurate records to demonstrate compliance:

- Retain certificates of compliance, test reports, and requalification documents.

- Keep logs of inspections, maintenance, and staff training.

- Store SDS for all substances contained in latch barrels.

- Ensure transport documents are archived for the required retention period (typically 2 years).

Training and Personnel Certification

Only trained personnel should handle latch barrels:

- Provide HAZMAT, pressure vessel safety, and emergency response training.

- Certify staff in the use of PPE, handling tools, and spill control equipment.

- Conduct annual refresher courses and document all training activities.

Environmental and Sustainability Considerations

Minimize environmental impact:

- Recycle or properly dispose of damaged or obsolete barrels through certified vendors.

- Prevent leaks and emissions through rigorous maintenance.

- Optimize logistics routes to reduce fuel use and emissions.

By following this guide, organizations can ensure the safe, compliant, and efficient management of latch barrels across all stages of operation.

Conclusion for Sourcing Latch Barrel:

Sourcing the appropriate latch barrel requires careful consideration of specifications such as diameter, length, key type, and compatibility with existing locking mechanisms. After evaluating multiple suppliers, quality, cost, and lead time must be balanced to ensure reliability and operational efficiency. Standardization where possible can simplify procurement and maintenance, while sourcing from reputable manufacturers ensures durability and security compliance. In conclusion, a strategic approach to sourcing latch barrels—prioritizing precision, supplier reliability, and long-term performance—will enhance security, reduce downtime, and support cost-effective facility or product management.