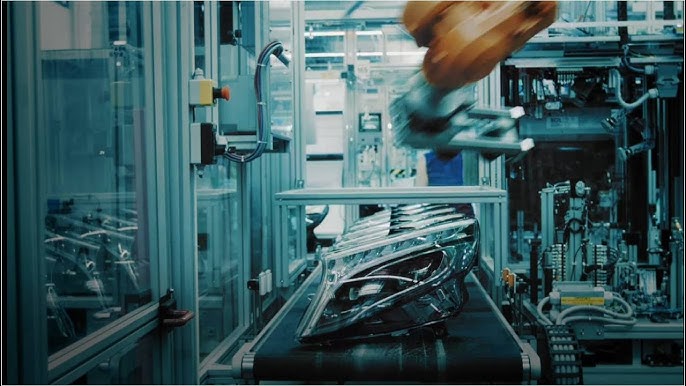

The global laser cutting equipment market is experiencing robust expansion, driven by rising demand for precision manufacturing across industries such as automotive, aerospace, and electronics. According to Mordor Intelligence, the laser cutting machine market was valued at USD 4.7 billion in 2023 and is projected to grow at a CAGR of over 7.5% from 2024 to 2029. This growth is fueled by advancements in fiber laser technology, increased automation in production processes, and the superior accuracy and speed of laser cutting compared to traditional methods. As industrial adoption accelerates, the role of reliable, high-performance laser torch manufacturers becomes increasingly critical. In this landscape, a select group of companies are leading innovation and market share. Here are the top 10 laser torch manufacturers shaping the future of precision manufacturing.

Top 10 Laser Torch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Laser Technology

Domain Est. 2018

Website: luxinar.com

Key Highlights: Luxinar develops, manufactures and sells industrial laser sources. The company has been at the forefront of laser technology for over 25 years….

#2 Laser light show technology

Domain Est. 2013

Website: kvantlasers.sk

Key Highlights: Manufacturer of world-class laser show projectors, laser technology and laser display accessories – Club and Festival lasers | High-power outdoor and Sky ……

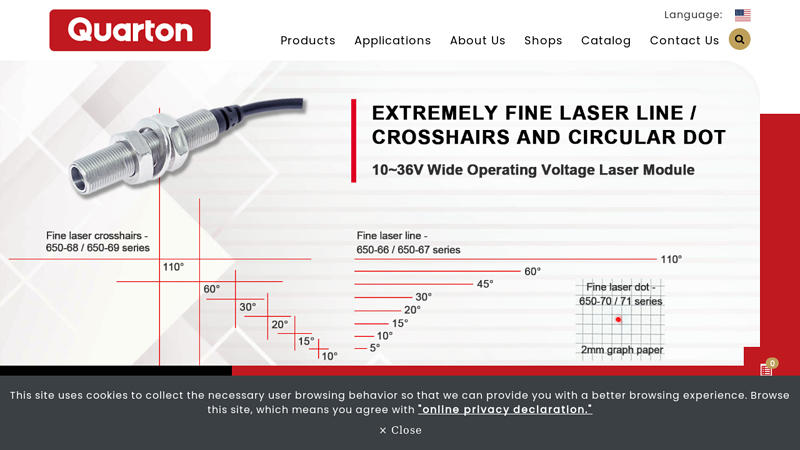

#3 Quarton

Domain Est. 1997

Website: quarton.com

Key Highlights: Quarton Inc. has more than 30 years of experience in laser related industries. Provides lasers and laser modules from IR, visible, and UV wavelengths, ……

#4 Erchonia: The World Leader in Low

Domain Est. 2000

Website: erchonia.com

Key Highlights: Erchonia is the world leader in LLLT technology dedicated to producing safe, effective solutions for chiropractors, physical therapists, & vets worldwide….

#5 Laser Tech

Domain Est. 1994

Website: lasertech.com

Key Highlights: Laser Tech is a global leader in innovative laser speed & distance measurement equipment bringing efficiency & improved safety to your industry….

#6 Lasers

Domain Est. 1994

Website: coherent.com

Key Highlights: Coherent is a recognized leader in the laser industry, bringing technical innovation and superior reliability to the broadest spectrum of applications….

#7 IPG Photonics

Domain Est. 1999

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#8 Laser Systems and Laser Show by Laserworld

Domain Est. 2003

Website: laserworld.com

Key Highlights: Buy Show Laser Light Systems. Laserworld is a world leader in the field of manufacturing and distribution of show laser light systems….

#9 BeamQ Laser, DFB Laser, Solid State Laser, Gaussian Laser and …

Domain Est. 2008

#10 Nuburu Blue Laser Company

Domain Est. 2015

Website: nuburu.net

Key Highlights: NUBURU’s blue lasers uniquely deliver kW-class power with galvo scanner compatibility, enabling high speed welding with a large process window and micron-scale ……

Expert Sourcing Insights for Laser Torch

H2: Market Trends for Laser Torches in 2026

As we approach 2026, the laser torch market is experiencing transformative growth driven by technological innovation, expanding applications, and increasing demand across industrial, defense, and consumer sectors. Below is an analysis of key market trends shaping the laser torch industry in 2026:

-

Advancements in Solid-State and Fiber Laser Technology

By 2026, solid-state and fiber laser torches dominate the market due to their superior efficiency, precision, and durability compared to traditional CO₂ lasers. Continued miniaturization and improvements in thermal management enable more compact, portable laser torches with higher output power, making them ideal for field applications in construction, automotive repair, and aerospace maintenance. -

Rise of Portable and Handheld Laser Tools

There is a growing shift toward handheld laser torches for cutting, welding, and engraving in both professional and DIY markets. Enhanced battery technology and ergonomic designs have made portable laser torches more accessible and user-friendly. These tools are increasingly adopted in emergency response, metal fabrication, and artistic applications. -

Integration with Smart Systems and IoT

Laser torches in 2026 are increasingly integrated with smart sensors, AI-driven diagnostics, and IoT connectivity. Real-time monitoring of beam quality, temperature, and material feedback allows for adaptive control, reducing human error and improving safety. Cloud-based platforms enable remote operation and predictive maintenance, particularly in industrial automation settings. -

Growth in Defense and Security Applications

Military and law enforcement sectors are adopting laser torches for precision cutting in breaching operations, explosive ordnance disposal (EOD), and vehicle extraction. Directed energy applications, such as non-lethal disabling tools, are also under development, accelerating R&D investment in high-power, compact laser systems. -

Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop energy-efficient laser torches with reduced carbon footprints. The use of recyclable materials in construction and energy recovery systems during operation are becoming standard features, especially in Europe and North America. -

Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, is witnessing rapid adoption of laser torch technology due to expanding manufacturing sectors and infrastructure development. Local production and decreasing component costs are making laser torches more affordable, driving market penetration. -

Regulatory and Safety Developments

With increased use of high-power lasers, regulatory bodies are tightening safety standards. In 2026, laser torches are required to include advanced safety features such as automatic shut-off, beam containment, and real-time hazard detection, aligning with ISO and IEC standards. -

Competitive Landscape and Innovation

The market is seeing consolidation among key players (e.g., IPG Photonics, TRUMPF, Han’s Laser) and increased competition from startups focusing on niche applications. Innovation in beam delivery systems, multi-functional tools (e.g., combined cutting/welding torches), and AI-assisted operation is fueling product differentiation.

Conclusion:

By 2026, the laser torch market is poised for sustained growth, shaped by technological convergence, diversification of applications, and global industrial digitization. Companies that prioritize innovation, safety, and sustainability are likely to lead the next phase of market evolution.

Common Pitfalls When Sourcing Laser Torches: Quality and Intellectual Property Risks

Sourcing laser torches—especially high-powered handheld units—can present significant challenges related to both product quality and intellectual property (IP) compliance. Buyers, distributors, and integrators must be vigilant to avoid costly mistakes, safety hazards, and legal exposure. Below are key pitfalls to watch for in both areas.

Quality-Related Pitfalls

1. Inconsistent or Exaggerated Power Output

Many low-cost laser torches, particularly from unverified suppliers, advertise misleading power ratings (e.g., claiming 5,000mW when actual output is far lower). Poor calibration and lack of third-party testing can result in unreliable performance and safety risks.

2. Substandard Build and Materials

Inferior heat dissipation, fragile housings, and cheap lenses increase the risk of overheating, beam misalignment, or premature failure. Units lacking proper heat sinks or quality thermal management may degrade rapidly during use.

3. Absence of Safety Certifications

Reputable laser torches should comply with international safety standards such as IEC 60825 (laser safety) and FDA/CDRH regulations (in the U.S.). Sourcing from manufacturers without verifiable certifications can expose users to legal liability and safety incidents.

4. Poor Beam Quality and Stability

Low-quality diodes and optics lead to unstable or divergent beams, reducing effectiveness for precision tasks. This is common in budget models that cut corners on optical components and driver electronics.

5. Inadequate Cooling and Duty Cycle Management

Many budget lasers lack active cooling or proper thermal throttling, leading to frequent shutdowns or permanent damage. Buyers may overlook duty cycle limitations, assuming continuous operation is safe.

Intellectual Property-Related Pitfalls

1. Unauthorized Replication of Branded Designs

Some suppliers sell laser torches that closely mimic patented designs from established brands (e.g., shape, button layout, heatsink design). These clones may infringe on design patents or utility models, exposing importers and resellers to IP litigation.

2. Use of Unlicensed Core Technology

Key components such as laser diodes or driver circuits may incorporate patented technology. Sourcing from manufacturers that use unlicensed or reverse-engineered components can result in supply chain IP violations.

3. Misuse of Trademarks and Branding

Counterfeit products often feature misleading branding or logos that resemble well-known brands, increasing consumer confusion and legal risk. Even subtle visual similarities can trigger trademark infringement claims.

4. Lack of IP Due Diligence in Contracts

Purchase agreements that fail to include IP indemnification clauses leave buyers exposed if the product is later found to infringe third-party rights. Always require suppliers to warrant that their products do not violate existing patents or trademarks.

5. Export/Import Compliance Risks

Certain high-powered lasers are regulated or restricted in various jurisdictions (e.g., U.S. ITAR or EU export controls). Sourcing without verifying compliance can lead to seized shipments or penalties, especially if the product incorporates controlled technology.

Conclusion

To mitigate these risks, conduct thorough due diligence: verify technical specifications with independent testing, audit supplier certifications, and perform IP landscape assessments. Engage legal counsel to review contracts and ensure compliance with regional regulations. Prioritizing reputable suppliers with transparent manufacturing and IP practices is essential for long-term success and liability protection.

Logistics & Compliance Guide for Laser Torch

Product Classification and Regulatory Overview

Laser torches are classified as laser products and are subject to international and national safety regulations due to their potential hazards. Proper classification under relevant standards is essential for legal import, export, distribution, and use. Most laser torches fall under Class 2, Class 3R, or higher categories based on output power and wavelength. Understanding these classifications determines compliance requirements across jurisdictions.

International Standards and Certification Requirements

Laser torches must comply with international standards such as the International Electrotechnical Commission (IEC) 60825-1, which specifies safety requirements for laser products. Key certification marks include:

– CE Marking (Europe): Required for sale in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

– FDA/CDRH (USA): The U.S. Food and Drug Administration’s Center for Devices and Radiological Health mandates reporting and compliance for laser products. Manufacturers must submit a product report and comply with variance requirements if applicable.

– RoHS and REACH (EU): Ensure restriction of hazardous substances and chemical safety in electrical equipment.

Export and Import Regulations

Shipping laser torches internationally requires adherence to export control laws and import regulations:

– Export Controls: Some high-powered laser torches may be subject to export restrictions under regimes like the Wassenaar Arrangement or the U.S. Export Administration Regulations (EAR). Verify if the product requires an export license.

– Customs Documentation: Accurate Harmonized System (HS) codes are essential. Laser torches typically fall under HS code 9013.20 (other optical appliances and instruments). Include detailed product descriptions, power output, and classification in shipping documents.

– Restricted Destinations: Certain countries restrict or ban the import of handheld lasers. Verify destination country regulations before shipment.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for compliance and safety:

– Warning Labels: Must include the laser class, wavelength, maximum output power, and caution statements (e.g., “Do not stare into beam” or “Avoid direct eye exposure”).

– Compliant Markings: Include manufacturer information, serial number, and applicable certification marks (CE, FDA, etc.).

– Secure Packaging: Use tamper-evident, shock-resistant packaging to prevent damage and unauthorized access during transit.

Transportation and Handling

Laser torches must be shipped in accordance with dangerous goods regulations if they meet certain criteria (e.g., high-powered batteries or laser components):

– Battery Regulations: If the torch includes lithium-ion batteries, comply with IATA Dangerous Goods Regulations for air transport (e.g., UN38.3 testing, proper packaging, and labeling).

– Ground and Sea Transport: Follow IMDG (for sea) and ADR (for road in Europe) guidelines as applicable.

– Temperature and Humidity: Store and ship in controlled environments to prevent damage to electronic components.

End-User Compliance and Documentation

Ensure end users are informed of safe usage and regulatory obligations:

– User Manuals: Provide multilingual instructions including safety warnings, operating procedures, and compliance information.

– Declaration of Conformity (DoC): Supply a DoC for CE-marked products, confirming compliance with relevant EU directives.

– Record Keeping: Maintain records of certifications, test reports, and shipment documentation for at least 10 years as required by some regulatory bodies.

Compliance Monitoring and Updates

Regulations may change; implement a compliance monitoring system:

– Regularly review updates from regulatory agencies (e.g., FDA, European Commission, national standards bodies).

– Audit supply chain partners to ensure ongoing compliance.

– Recertify products if design or components change significantly.

Adhering to this guide ensures safe, legal, and efficient global logistics for laser torches while minimizing regulatory risks.

Conclusion for Sourcing Laser Torch:

Sourcing a laser torch requires a careful evaluation of quality, technical specifications, safety standards, and supplier reliability. It is essential to select a supplier that offers durable, high-performance laser torches compliant with international safety regulations such as FDA, CE, or RoHS, depending on the region of operation. Factors such as laser power, beam accuracy, battery life, build quality, and ease of use should align with the intended application—whether for industrial alignment, construction, presentations, or outdoor use.

Cost-effectiveness should not compromise performance or safety. Establishing long-term partnerships with reputable suppliers ensures consistent product quality, timely delivery, and access to technical support. Additionally, considering warranties, after-sales service, and scalability of supply helps mitigate risks and supports business continuity.

In conclusion, a strategic sourcing approach—balancing performance, compliance, and supplier credibility—will ensure the acquisition of reliable laser torches that meet operational needs efficiently and safely.