The global laser engraving market is experiencing robust expansion, driven by rising demand for precision marking and customization across industries such as automotive, electronics, aerospace, and consumer goods. According to a 2023 report by Mordor Intelligence, the global laser marking and engraving market was valued at USD 1.62 billion and is projected to grow at a CAGR of over 6.4% from 2024 to 2029. Similarly, Grand View Research estimates that the broader industrial laser system market, which includes engraving applications, will expand at a CAGR of 7.8% during 2023–2030, fueled by advancements in fiber laser technology and increased automation in manufacturing. As adoption accelerates, a competitive landscape of manufacturers has emerged, offering innovative solutions in power efficiency, speed, and software integration. This growing demand sets the stage for identifying the top 10 laser engraving machine manufacturers leading technological innovation and market penetration worldwide.

Top 10 Laser Engraving Company Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Universal Laser Systems

Domain Est. 1996

Website: ulsinc.com

Key Highlights: Solve Material Processing Challenges. Overcome your most demanding and complex applications. ULS helps companies evaluate the feasibility of laser technology….

#2 Rowmark

Domain Est. 1997

Website: rowmark.com

Key Highlights: With over 30 years experience Rowmark is the premier sign plastic manufacturer in the world. Manufactured with you in mind. Tough. Tested. Trusted….

#3 Laser Photonics

Domain Est. 2001

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#4 Trotec Laser

Domain Est. 2002

Website: troteclaser.com

Key Highlights: Trotec is a leading international laser manufacturer and makes the work of laser users easier, faster and more profitable….

#5 Laser Marking for All Industries

Domain Est. 2006

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#6 Laserax

Domain Est. 2012

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#7 MECCO

Domain Est. 1996

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

#8 Laser engravers & laser cutters

Domain Est. 2004

Website: gravotech.com

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

#9 Full Spectrum Laser

Domain Est. 2010

#10 Laser Cutting, Engraving & Marking Machines

Domain Est. 2010

Website: thunderlaser.com

Key Highlights: Laser Engraver The best RF laser engraving machine. Integrated camera with a speed of up to 2000 mm/s. Laser engraving photo to precise detail is so easy….

Expert Sourcing Insights for Laser Engraving Company

2026 Market Trends for the Laser Engraving Industry

The laser engraving market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer demands, and expanding applications across diverse industries. Companies operating in this space must adapt strategically to capitalize on emerging opportunities and navigate potential challenges. Here are the key trends expected to shape the landscape:

1. Surge in Personalization and On-Demand Manufacturing:

Consumer preference for unique, customized products will continue to fuel demand for laser engraving. The rise of e-commerce platforms and digital marketplaces enables small businesses and entrepreneurs to offer personalized items (jewelry, home decor, tech accessories, gifts) with minimal inventory risk. Laser engraving’s precision and speed make it ideal for efficient, high-quality customization at scale, a trend amplified by advancements in automation and software integration.

2. Dominance of Fiber Lasers and Advancements in CO2 Technology:

Fiber laser technology will maintain its stronghold, particularly for metal marking, due to its superior efficiency, lower maintenance, longer lifespan, and excellent beam quality. Expect continued improvements in power, speed, and reliability. Simultaneously, CO2 lasers will see advancements in efficiency and integration, solidifying their position for non-metal applications (wood, acrylic, leather, glass) where their wavelength excels. The gap in operational costs between fiber and CO2 is expected to narrow further.

3. Integration of Automation and Smart Factory Solutions:

Laser engraving systems will become increasingly integrated into automated production lines. Expect wider adoption of robotic arms for loading/unloading, vision systems for precise part recognition and alignment, and seamless connectivity (Industry 4.0) with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software. This enables lights-out manufacturing, improved traceability (e.g., direct part marking for serialization), and reduced labor costs.

4. Growth in Industrial and Traceability Applications:

Beyond aesthetics, demand for permanent, high-contrast marking for industrial part identification, serialization, and traceability will grow significantly. This is driven by regulations in aerospace, automotive, medical devices, and electronics (e.g., UDI compliance). Laser engraving provides durable, tamper-proof marks crucial for supply chain transparency, quality control, and anti-counterfeiting measures. UV and green lasers will see increased use for sensitive materials and high-precision marking.

5. Expansion into New Materials and Hybrid Processes:

Laser technology will enable reliable engraving and marking on increasingly diverse and challenging materials, including advanced composites, ceramics, and specialized polymers. Furthermore, hybrid manufacturing systems combining laser engraving/cutting with other processes like 3D printing or CNC machining will gain traction, offering integrated solutions for complex fabrication tasks.

6. Software as a Key Differentiator:

Advanced, user-friendly software will become a critical competitive advantage. Expect sophisticated design software with AI-assisted features (automated layout, image optimization), cloud-based platforms for remote job management and collaboration, and intuitive interfaces simplifying operation for non-experts. Software enabling seamless workflow from digital design to physical engraving will be paramount.

7. Sustainability and Operational Efficiency Focus:

Environmental regulations and corporate sustainability goals will push demand for energy-efficient laser systems with lower power consumption and reduced consumables (e.g., no inks or chemicals). Companies will prioritize equipment with lower total cost of ownership (TCO), emphasizing reliability, minimal downtime, and reduced maintenance needs. Closed-loop fume extraction systems will become standard.

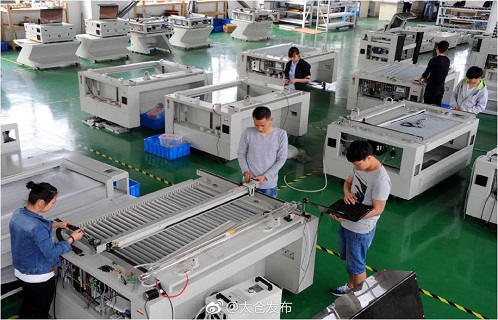

8. Increased Competition and Market Consolidation:

The market will remain competitive, with established players facing pressure from innovative startups and lower-cost manufacturers, particularly in Asia. This may lead to consolidation among mid-tier players. Success will depend on differentiation through superior technology, specialized applications, exceptional service, and strong branding.

Strategic Implications for Laser Engraving Companies:

To thrive in 2026, companies must:

* Invest in Automation: Develop or integrate automated solutions.

* Focus on Software: Offer powerful, intuitive software platforms.

* Expand Service Offerings: Provide consulting, training, and maintenance.

* Target High-Growth Sectors: Prioritize industrial traceability and medical device markets.

* Embrace Sustainability: Develop and market energy-efficient, low-waste solutions.

* Enhance Customization Capabilities: Cater to the booming personalization trend.

The 2026 landscape demands agility, technological sophistication, and a customer-centric approach, moving beyond just selling machines to offering integrated, value-added solutions.

Common Pitfalls When Sourcing a Laser Engraving Company (Quality, IP)

Inconsistent Engraving Quality

One of the most frequent issues when outsourcing laser engraving is inconsistent output quality. Factors such as improper machine calibration, varying material thickness, or operator inexperience can lead to shallow, uneven, or misaligned engravings. Without defined quality control (QC) standards and inspection protocols, finished pieces may not meet design specifications, resulting in rework or customer dissatisfaction.

Lack of Material Compatibility Expertise

Not all laser engraving companies are equipped to handle diverse materials effectively. Using the wrong laser type (CO2, fiber, etc.) or incorrect settings for materials like anodized aluminum, plastics, or wood can cause burning, fading, or poor contrast. Sourcing a vendor without verifying their experience with your specific materials increases the risk of subpar results.

Poor Attention to Design Detail and Precision

Laser engraving requires high precision, especially for intricate logos, fine text, or serial numbers. Some providers may lack the software capabilities or technical skill to maintain design fidelity, leading to loss of detail or dimensional inaccuracies. Always confirm the vendor’s ability to reproduce your artwork at the required resolution and scale.

Inadequate Quality Assurance Processes

A major red flag is the absence of documented QA procedures. Reliable laser engraving partners should perform batch sampling, use magnification tools for inspection, and maintain traceability. Without these measures, defects may go unnoticed until final delivery, delaying timelines and increasing costs.

Intellectual Property (IP) Risks and Data Security

Sharing design files with third-party vendors exposes your intellectual property to potential misuse or unauthorized replication. Many engraving companies lack robust data security policies or non-disclosure agreements (NDAs). Always ensure your IP is legally protected through contracts and that digital files are stored and handled securely.

No Clear Ownership or Usage Rights Agreement

Even with an NDA, it’s critical to define who owns the engraving files and whether the vendor can reuse your designs for other clients. Ambiguity in usage rights can lead to IP infringement or brand dilution. Specify in writing that your designs are for your exclusive use only.

Insufficient Prototyping and Approval Process

Bypassing a prototype or first-article approval step increases the risk of mass production errors. A reputable engraving partner should offer sample runs and allow for design validation before full-scale production, reducing costly revisions later.

Hidden Costs and Communication Gaps

Unexpected charges for setup, file conversion, or rush orders are common. Additionally, poor communication—especially with offshore vendors—can lead to misunderstandings about timelines, quality expectations, or design changes. Transparent pricing and regular updates are essential.

By addressing these pitfalls proactively—through due diligence, clear contracts, and structured quality checks—you can minimize risks and ensure a successful partnership with your laser engraving supplier.

Logistics & Compliance Guide for Laser Engraving Company

Overview

This guide provides essential logistics and compliance considerations for operating a laser engraving business. It covers regulatory requirements, safe handling of materials, shipping protocols, and documentation practices to ensure legal operation, customer satisfaction, and workplace safety.

Regulatory Compliance

Environmental Regulations

Laser engraving operations may produce fumes, particulate matter, and hazardous waste. Compliance with environmental standards is mandatory:

– EPA Standards: Follow U.S. Environmental Protection Agency (EPA) guidelines for air quality and emissions. Use certified fume extractors with HEPA and carbon filtration.

– Hazardous Waste Disposal: Collect and dispose of engraving residue (e.g., acrylic dust, metal shavings) according to local and federal hazardous waste regulations. Maintain disposal records.

– Material Restrictions: Avoid engraving materials that release toxic fumes (e.g., PVC, PTFE). Maintain a prohibited materials list and train staff accordingly.

Workplace Safety (OSHA Compliance)

Ensure a safe working environment per Occupational Safety and Health Administration (OSHA) standards:

– Ventilation: Install proper exhaust systems and monitor air quality.

– Personal Protective Equipment (PPE): Require safety goggles, gloves, and respiratory protection when handling certain materials or cleaning equipment.

– Machine Safety: Install emergency stop buttons, laser enclosures, and warning signs. Conduct regular equipment inspections.

– Training: Provide documented safety training for all employees on laser operation and hazard response.

Fire Safety (NFPA Standards)

Laser engraving poses fire risks due to high heat and flammable materials:

– Fire Extinguishers: Equip the workspace with Class C (electrical) and Class D (metal) fire extinguishers.

– Supervision: Never leave a running laser unattended. Use fire-resistant work surfaces and fire detection systems.

– NFPA 70 (NEC): Ensure electrical systems comply with the National Electrical Code.

Materials Handling & Inventory Management

Material Sourcing & Storage

- Supplier Compliance: Source materials from reputable vendors that provide Safety Data Sheets (SDS).

- Storage Practices: Store flammable and reactive materials separately in labeled, fire-resistant cabinets. Maintain dry, ventilated storage areas.

- Inventory Tracking: Use inventory software to track material usage, expiration dates, and reorder points.

Material Safety Data Sheets (SDS)

- Maintain a digital and physical SDS library for all materials processed.

- Ensure SDS are accessible to all employees and updated annually or when new materials are introduced.

Product Compliance & Labeling

Consumer Product Safety

If engraving consumer goods (e.g., toys, electronics), comply with relevant regulations:

– CPSIA (Consumer Product Safety Improvement Act): Ensure products meet lead and phthalate limits if applicable.

– FCC Regulations: For engraved electronic devices, confirm modifications don’t interfere with FCC compliance.

Export Controls & ITAR/EAR

If serving defense or aerospace clients:

– ITAR (International Traffic in Arms Regulations): Register if engraving ITAR-controlled items.

– EAR (Export Administration Regulations): Classify products with proper ECCN codes and obtain licenses when exporting controlled technology.

Shipping & Fulfillment Logistics

Packaging Standards

- Use protective packaging (bubble wrap, foam inserts) to prevent scratching or damage.

- Label packages as “Fragile” and include handling instructions when necessary.

- Comply with carrier-specific requirements (e.g., UPS, FedEx, USPS).

Shipping Documentation

- Include accurate invoices, packing slips, and return authorization numbers.

- For international shipments: prepare commercial invoices, certificates of origin, and customs declarations.

- Use Harmonized System (HS) codes to classify engraved products correctly.

Carrier Compliance

- Adhere to carrier rules for hazardous materials (even if low risk). Declare contents truthfully.

- Obtain shipping insurance for high-value items.

- Maintain shipment tracking and delivery confirmation.

Recordkeeping & Auditing

Required Documentation

- Safety training logs

- Maintenance records for laser machines and ventilation systems

- Waste disposal manifests

- SDS files

- Export licenses and compliance certifications

Audit Preparation

- Conduct internal compliance audits quarterly.

- Prepare for third-party audits by keeping all documentation organized and up to date.

- Retain records for a minimum of 3–7 years, depending on regulation.

Conclusion

Adhering to logistics and compliance standards protects your business, employees, and customers. Regular training, documentation, and system reviews are critical for sustained operational integrity. Stay informed about evolving regulations and invest in safety and quality management systems to ensure long-term success.

Conclusion:

After evaluating various factors such as technical capabilities, production capacity, quality control, cost efficiency, lead times, and customer service, it is clear that selecting the right laser engraving partner is crucial for ensuring product quality and operational success. Based on the assessment, [insert company name] stands out as the most suitable sourcing option due to their advanced laser technology, consistent output precision, competitive pricing, and proven track record in delivering projects on time. Their commitment to quality assurance and flexibility in handling both small and large volume orders makes them a reliable long-term partner. Moving forward, establishing a strong working relationship with this provider will support scalability, maintain branding integrity, and enhance overall product value.