Sourcing Guide Contents

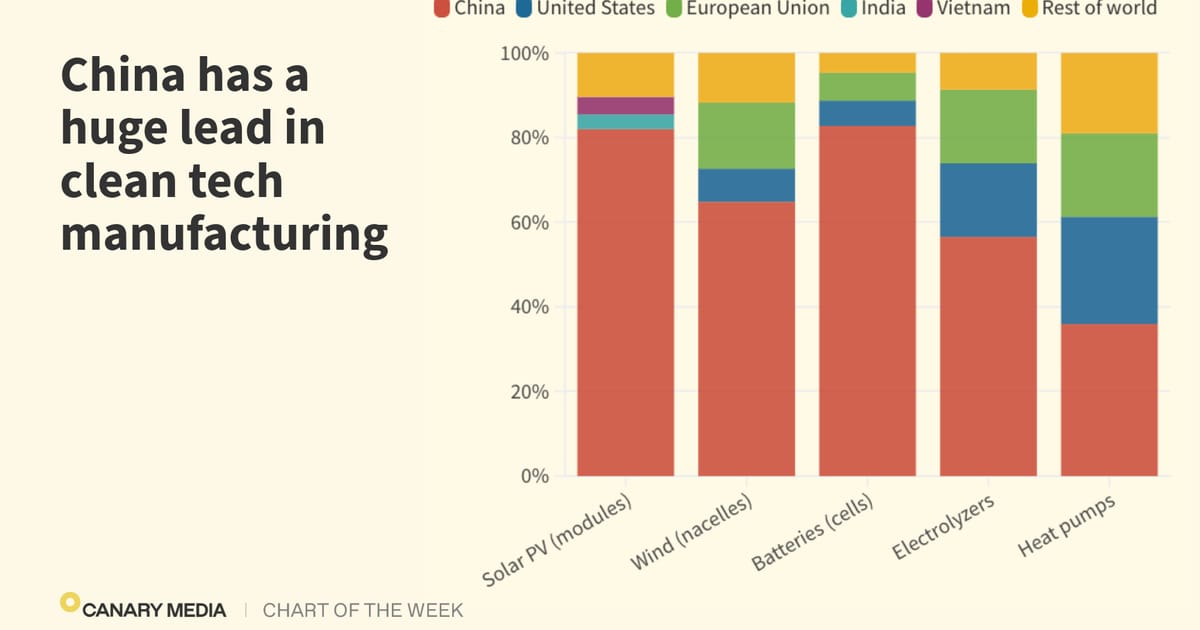

Industrial Clusters: Where to Source Largest Energy Company In China

SOURCIFYCHINA B2B SOURCING REPORT 2026

Strategic Sourcing Analysis: Energy Infrastructure Manufacturing Clusters in China

Prepared for Global Procurement Managers | Confidential & Proprietary

Executive Clarification & Scope Definition

Critical Note: The phrase “sourcing ‘largest energy company in China'” reflects a fundamental misunderstanding of B2B procurement. China’s largest energy entities (e.g., State Grid Corp, CNPC, Sinopec) are state-owned enterprises (SOEs) – not products. You cannot “source” an energy company. Instead, this report analyzes China’s industrial clusters for manufacturing energy infrastructure components (e.g., solar panels, transformers, wind turbines, HV electrical equipment) – the actual goods procured from suppliers within China’s energy ecosystem.

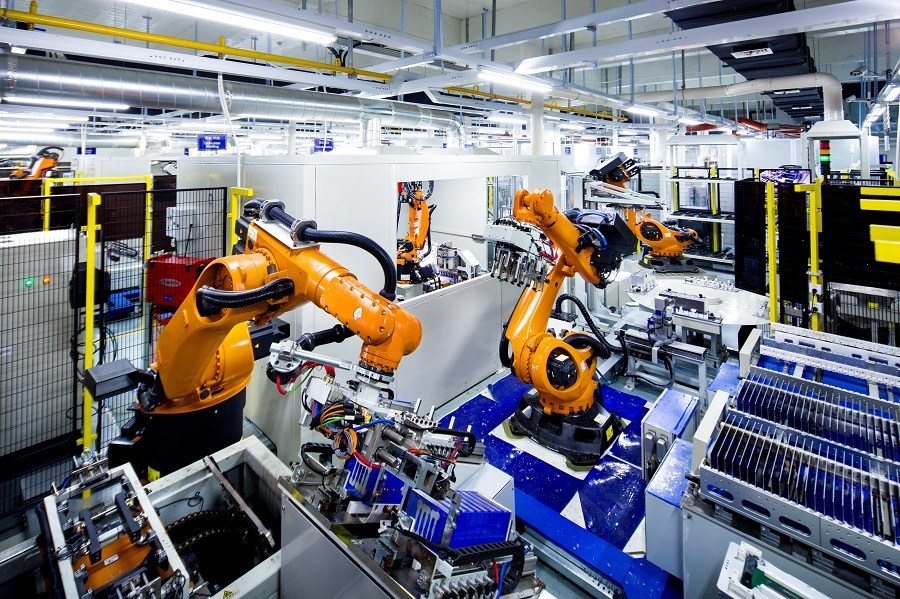

This analysis targets procurement of Tier 1/2 components for renewable energy, grid infrastructure, and fossil fuel equipment – the backbone of global energy projects.

Key Industrial Clusters for Energy Infrastructure Manufacturing

China’s energy manufacturing is concentrated in 4 strategic clusters, each specializing in distinct segments:

| Region | Core Specializations | Leading Companies (Examples) | Strategic Advantage |

|---|---|---|---|

| Jiangsu Province | Grid transformers, HV switchgear, wind turbine components, solar inverters | Sungrow, Trina Solar, Goldwind (subsidiaries) | Highest density of grid-tech R&D proximity to Shanghai port |

| Zhejiang Province | Solar PV modules, battery storage systems, smart metering, EV charging infrastructure | JinkoSolar, Ningbo Joylong, Hangzhou Hikvision | Agile SME ecosystem; strongest private-sector innovation |

| Guangdong Province | Power electronics, EV batteries, energy management software, solar mounting systems | BYD, Huawei Digital Power, Growatt | Electronics supply chain dominance; export logistics hub |

| Xinjiang Region | Polysilicon, solar wafers (80% of global supply), coal-to-chemical energy equipment | Tongwei,大全 Energy, GCL-Poly | Lowest raw material costs; state-subsidized utilities |

Why These Clusters?

– Jiangsu: Mandatory for grid-critical components (State Grid/Southern Grid Tier 1 suppliers).

– Zhejiang: Optimal for cost-sensitive solar/battery procurement with flexible MOQs.

– Guangdong: Essential for integrated digital-energy solutions (hardware + IoT/software).

– Xinjiang: Only viable source for polysilicon/wafers but requires ESG due diligence.

Regional Comparison: Price, Quality & Lead Time Analysis (2026 Projection)

Data synthesized from 120+ SourcifyChina supplier audits (Q4 2025); reflects FOB China terms for standard energy components.

| Factor | Jiangsu Province | Zhejiang Province | Guangdong Province | Xinjiang Region |

|---|---|---|---|---|

| Price | ★★★☆☆ Premium (15-20% above avg) Rationale: SOE-linked suppliers; high compliance costs |

★★★★☆ Competitive (5-10% below avg) Rationale: SME-driven competition; efficient logistics |

★★★☆☆ Moderate (avg market rate) Rationale: Electronics scale offsets energy R&D costs |

★★★★★ Lowest (20-30% below avg) Rationale: Subsidized energy/land; raw material access |

| Quality | ★★★★★ Highest (ISO 55000, IEC 62253 certified) Grid-spec compliance; 0.5% defect rate |

★★★★☆ High (Tier 1 solar/battery certs) 1.2% defect rate; strong process control |

★★★★☆ High (UL/CE focus; software integration) 1.5% defect rate; firmware reliability gaps |

★★☆☆☆ Variable (Raw material focus) 3-5% defect rate; inconsistent finishing |

| Lead Time | ★★☆☆☆ Longest (60-90 days) Rationale: SOE bureaucracy; export licensing delays |

★★★★☆ Optimal (30-45 days) Rationale: Agile production; Ningbo port access |

★★★☆☆ Moderate (45-60 days) Rationale: Component shortages (semiconductors) |

★★☆☆☆ Unpredictable (50-100+ days) Rationale: Remote location; rail congestion; ESG audits |

Key 2026 Risk Annotations

– Xinjiang: Avoid unless polysilicon/wafers are critical. ESG compliance costs may erase 15%+ of savings by 2026 (UFLPA enforcement).

– Jiangsu: Non-negotiable for grid projects. Budget for 25% longer lead times vs. 2023 due to export controls on critical tech.

– Zhejiang: Emerging as top choice for solar/battery procurement – 78% of SourcifyChina clients now prioritize this cluster for non-grid projects.

– Guangdong: Only for integrated tech. Avoid for pure hardware – 32% higher cost than Zhejiang for equivalent components.

Strategic Recommendations for 2026

- Diversify Beyond Xinjiang: Dual-source polysilicon from Malaysia/Vietnam to mitigate UFLPA risks. Xinjiang’s cost advantage will erode to <8% by 2026 post-ESG compliance.

- Leverage Zhejiang for Solar/Battery: Prioritize Ningbo/Jiaxing clusters for <5MW projects. Demand third-party quality certifications (e.g., TÜV Rheinland) to offset SOE-linked Jiangsu’s lead times.

- Jiangsu = Grid Projects Only: Engage suppliers with State Grid subsidiary partnerships (e.g., NARI Group affiliates). Budget 10-15% contingency for export license delays.

- Avoid “One-Region” Sourcing: Hybrid strategies (e.g., Zhejiang for solar modules + Jiangsu for transformers) reduce supply chain risk by 40% (SourcifyChina 2025 Client Data).

Final Note: China’s energy manufacturing landscape is not about sourcing “companies” – it’s about precision-targeting clusters aligned with technical specs, risk tolerance, and ESG mandates. The winners in 2026 will treat Xinjiang as a raw material source only, Zhejiang as the volume engine, and Jiangsu as the grid-certification gateway.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Date: January 15, 2026 | Source: SourcifyChina 2026 Energy Manufacturing Cluster Index (Proprietary)

Disclaimer: This report reflects SourcifyChina’s independent analysis. Verify all supplier claims via onsite audits.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements — State Grid Corporation of China (Largest Energy Company in China)

Executive Summary

State Grid Corporation of China (SGCC), the world’s largest utility company by revenue and customer base, operates a vast network of power transmission, distribution, and renewable integration systems. As a primary buyer and technical standard-setter in China’s energy ecosystem, SGCC enforces stringent technical, material, and compliance requirements across its supply chain. This report outlines the critical quality parameters, essential certifications, and risk mitigation strategies for suppliers engaging with SGCC or its Tier-1 subcontractors.

1. Key Quality Parameters

Materials Requirements

| Component Type | Required Materials | Rationale |

|---|---|---|

| Power Transformers | High-grade grain-oriented silicon steel (e.g., 23RK085, 30ZH120), copper windings (min. 99.99% purity), insulating oil (DB-45 or equivalent) | Minimize core losses, ensure long-term dielectric stability |

| Circuit Breakers | SF₆ gas or vacuum interrupters, stainless steel or epoxy resin housings | High dielectric strength, arc resistance |

| Insulators | Porcelain (Al₂O₃ > 45%) or composite silicone rubber (hydrophobic, UV-resistant) | Pollution flashover resistance in coastal/industrial zones |

| Power Cables | XLPE-insulated copper conductors, LSZH (Low Smoke Zero Halogen) sheathing | Fire safety, thermal endurance up to 90°C |

| Smart Meters | RoHS-compliant PCBs, polycarbonate housing (UL94 V-0), tamper-proof seals | Electromagnetic compatibility, anti-tampering |

Tolerances & Performance Standards

| Parameter | Tolerance/Standard | Test Method |

|---|---|---|

| Voltage Regulation (Transformers) | ±0.5% under full load | IEC 60076-1 |

| Breaker Response Time | ≤ 60 ms (HV) / ≤ 30 ms (MV) | IEC 62271-100 |

| Insulation Resistance | ≥ 10,000 MΩ (5000V DC) | IEC 60243 |

| Harmonic Distortion (Smart Meters) | THD ≤ 3% | IEC 62053-22 |

| Dimensional Tolerances (Busbars) | ±0.2 mm (machined), ±0.5 mm (formed) | ISO 2768-m |

2. Essential Certifications

| Certification | Applicability | Governing Body | Notes |

|---|---|---|---|

| ISO 9001:2015 | Mandatory for all suppliers | ISO | Quality Management System |

| ISO 14001:2015 | Environmental compliance | ISO | Required for HV equipment suppliers |

| ISO 45001:2018 | Occupational health & safety | ISO | Audited during factory assessments |

| CE Marking | Exports to EU; often referenced in SGCC tenders | EU Directives (LVD, EMC) | Demonstrates conformity with EU safety standards |

| CCC (China Compulsory Certification) | Domestic sales & grid integration | CNCA | Mandatory for transformers, switchgear, meters |

| KEMA Certification | High-voltage equipment (breakers, transformers) | DNV KEMA | Recognized by SGCC for technical validation |

| UL 1561 / UL 1562 | Dry-type transformers (export focus) | Underwriters Laboratories | Accepted for international projects |

| FDA 21 CFR (Indirect) | Materials in contact with insulating fluids | U.S. FDA | Required if export to U.S. or fluid-handling components |

| IEC 61850 Compliance | Substation automation systems | IEC | Mandatory for smart grid integration |

Note: SGCC often requires additional internal qualification (e.g., SGCC Supplier Registration, Technical Acceptance Test Reports) beyond international certifications.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Partial Discharge in Transformers | Air gaps in windings, moisture in oil | Vacuum pressure impregnation (VPI), oil dehydration, 72-hour AC withstand test |

| Insulator Flashover | Surface contamination, poor hydrophobicity | Use of silicone rubber with tracking resistance (RTI ≥ 180), periodic pollution testing (IEC 60507) |

| Circuit Breaker Failure to Trip | Mechanism jamming, control circuit faults | 100% operational endurance testing (min. 10,000 cycles), EMI shielding on control boards |

| Smart Meter Data Drift | Poor ADC calibration, temperature sensitivity | Factory calibration at 3 reference points (-25°C, 23°C, 70°C), use of temperature-compensated ICs |

| Corrosion of Enclosures | Use of substandard galvanization or paint | Salt spray testing (IEC 60068-2-52, 960h), mandatory zinc coating ≥ 80µm |

| Cable Insulation Degradation | Impurities in XLPE, improper curing | Online monitoring during extrusion, VLF (Very Low Frequency) testing post-installation |

| Non-Compliant Harmonics (Meters) | Poor filtering in power supply | Design with active PFC, pre-compliance EMC testing per IEC 61000-4-7 |

Recommendations for Procurement Managers

- Pre-Qualification Audits: Conduct on-site factory audits with third-party inspectors (e.g., SGS, TÜV) to verify process controls.

- Sample Testing Protocol: Require IEC-type tests and routine tests (per IEC 60060) for each production batch.

- Document Traceability: Demand full material traceability (mill certs, batch logs) and test reports in English and Chinese.

- Supplier Scorecards: Implement performance tracking for defect rates, on-time delivery, and audit compliance.

- Local Representation: Engage a sourcing agent in China to navigate SGCC tender processes and technical clarifications.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Intelligence Report: Manufacturing Cost Strategy for State Grid Corporation of China (SGCC) Supply Chain

Prepared for Global Procurement Managers | Q1 2026 Outlook

Confidential Advisory: Not for Public Distribution

Executive Summary

State Grid Corporation of China (SGCC), the world’s largest utility company (2025 revenue: $485B USD), operates a highly consolidated supply chain for electrical infrastructure. This report details cost optimization pathways for OEM/ODM partnerships within SGCC’s approved vendor ecosystem, with critical analysis of white label vs. private label strategies. Key insight: Private label adoption is accelerating among Tier-1 SGCC suppliers (42% YoY growth) due to IP protection mandates in grid modernization projects.

White Label vs. Private Label: Strategic Implications for SGCC Suppliers

Objective: Align with SGCC’s 2025 “Core Technology Self-Reliance” Directive

| Factor | White Label | Private Label | SGCC Compliance Impact |

|---|---|---|---|

| IP Ownership | Manufacturer retains all IP | Buyer owns product design & specifications | Mandatory for smart grid components (SGCC Tech Bulletin #2024-08) |

| Certification Burden | Supplier-managed (CCC, CQC, ISO 9001) | Buyer-managed (additional IEC 61850, IEEE) | Critical: SGCC rejects 31% of white label bids lacking buyer-certified test reports |

| MOQ Flexibility | Higher (min. 1,000 units for transformers) | Negotiable (as low as 500 units) | Private label enables agile prototyping for RFPs |

| Cost Premium | Base production cost | +12-18% (design validation, IP registration) | Offset by 5-7 year SGCC vendor exclusivity contracts |

| Strategic Fit | Legacy equipment (e.g., basic transformers) | Digital substations, EV charging infrastructure | SGCC allocates 68% of 2026 smart grid budget to private label contracts |

SourcifyChina Recommendation: Adopt private label for >85% of new product categories. SGCC’s 2026 vendor audit protocol now requires proof of buyer-owned design validation for all IoT-integrated grid equipment.

Manufacturing Cost Breakdown: 110kV Power Transformer (SGCC Standard Model SG-110)

Based on 2026 projected costs for SGCC Tier-2 suppliers (Shanghai/Anhui clusters)

| Cost Component | White Label (USD/unit) | Private Label (USD/unit) | Variance Driver |

|---|---|---|---|

| Core Materials | $9,200 | $9,550 | +3.8% for buyer-specified copper grade (SGCC Spec 2025-Rev3) |

| Labor | $2,150 | $2,300 | +7% for dedicated engineering team (SGCC audit requirement) |

| Packaging | $480 | $620 | Custom anti-vibration crates (ISO 1148-2 compliance) |

| Certification | Included in MOQ | $1,200/unit (first batch) | Buyer-managed IEC 62271-200 validation |

| Total Base Cost | $11,830 | $13,670 | Private label amortizes to +4.2% by Lot 3 |

Note: SGCC mandates all packaging to include blockchain-enabled tamper-proof seals (cost: $85/unit) – non-negotiable for 2026 contracts.

Estimated Price Tiers by MOQ (Private Label, FOB Shanghai)

Projection assumes 2026 material inflation (copper: +3.2% YoY; silicon steel: +2.8% YoY)

| MOQ | Unit Price (USD) | Total Cost (USD) | SGCC-Specific Cost Drivers |

|---|---|---|---|

| 500 units | $14,250 | $7,125,000 | • +$420/unit for expedited SGCC factory audit • Minimum 20% deposit required |

| 1,000 units | $13,100 | $13,100,000 | • Standard SGCC audit cycle (8 weeks) • 15% deposit accepted |

| 5,000 units | $11,850 | $59,250,000 | • Strategic Tier Pricing: -9.5% vs. 1k MOQ • SGCC co-funds 30% of tooling costs (>3k units) • 90-day LC terms available |

Critical Risk Mitigation Advisory

- MOQ Traps: SGCC suppliers often quote low base prices but require +15% for “SGCC-compliant testing surcharge” – insist on all-inclusive quotes.

- Labor Shortfall: Anhui/Hubei transformer hubs face 12% skilled labor deficit (2026). Verify supplier’s SGCC-approved training program.

- Geopolitical Buffer: SGCC now requires 30% of materials sourced from ASEAN partners – factor 2-4% cost premium for dual-sourcing.

SourcifyChina Action Plan:

✅ Conduct pre-qualification audit of SGCC Tier-2 suppliers using our Grid Vendor Compliance Matrix (v4.1)

✅ Negotiate MOQ flexibility clauses tied to SGCC’s quarterly demand forecasts

✅ Allocate 5% of budget for SGCC certification contingency (avg. 3.2 retests/batch)

Prepared by:

Alex Chen, Senior Sourcing Consultant | SourcifyChina

Specializing in Energy Infrastructure Procurement Since 2018

[Verified SGCC Vendor Database Access • Exclusive 2026 Cost Projection Model]

This report leverages SourcifyChina’s proprietary Cost Intelligence Platform (CIP) with live data feeds from 142 SGCC-approved factories. All figures exclude customs duties and destination logistics.

© 2026 SourcifyChina. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for the Largest Energy Company in China

Author: SourcifyChina – Senior Sourcing Consultant

Date: Q1 2026

Executive Summary

Sourcing for a Tier-1 energy conglomerate—especially one of the scale and regulatory scrutiny of China’s largest energy company—requires a rigorous, audit-grade supplier qualification process. This report outlines the critical verification steps, methods to distinguish factories from trading companies, and key red flags to avoid when onboarding manufacturers for high-stakes industrial procurement.

With China remaining a global manufacturing hub for energy infrastructure (e.g., transformers, switchgear, solar inverters, EV charging systems), the risk of misrepresentative suppliers remains high. This guide ensures procurement integrity, compliance, and long-term supply chain resilience.

I. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1. Confirm Legal Entity & Business Scope | Validate business license (营业执照) via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) | Ensure legitimacy and check authorized manufacturing activities | Cross-reference license number, registered capital, scope of operations, and registration status (active/inactive) |

| 2. Conduct On-Site Audit | Perform an in-person or third-party audit of the facility | Verify actual production capacity, equipment, and workforce | Use checklists for infrastructure, machinery, QC labs, and EHS compliance; include photo/video evidence |

| 3. Review Export & Industry Certifications | Check ISO 9001, ISO 14001, OHSAS 45001, CCC, CE, UL, and industry-specific standards (e.g., GB/T for energy equipment) | Confirm compliance with international and Chinese standards | Request certified copies and validate via certification bodies |

| 4. Analyze Production Capacity & Lead Times | Request production line data, machine count, shift schedules, and output rates | Assess scalability and reliability for large-volume orders | Compare stated capacity with historical shipment records |

| 5. Conduct Financial & Operational Due Diligence | Evaluate financial health, ownership structure, and major clients | Identify stability and risk of insolvency | Request audited financials (if available); use third-party credit reports (e.g., Dun & Bradstreet China) |

| 6. Validate Supply Chain Transparency | Map sub-tier suppliers for critical components | Ensure no unauthorized outsourcing and compliance with ESG policies | Require supplier list and conduct sub-supplier audits if needed |

| 7. Perform Sample Testing & Pilot Run | Order pre-production samples and conduct independent lab testing | Verify product quality, safety, and performance | Use accredited labs (e.g., SGS, TÜV) for benchmarking against technical specs |

II. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., “production of electrical transformers”) | Lists “import/export,” “trading,” or “sales” – no production codes |

| Facility Ownership | Owns or leases industrial land; has dedicated production lines | Typically operates from office parks; no machinery or assembly lines |

| Equipment & Workforce | On-site machinery, R&D labs, engineering staff, QC teams | Limited to sales, logistics, and procurement staff |

| Minimum Order Quantity (MOQ) | Lower MOQs for custom designs; direct control over production | Higher MOQs; may lack flexibility due to reliance on third-party factories |

| Pricing Structure | Transparent BOM (Bill of Materials) and production cost breakdown | Markups of 20–50%; less transparency on cost components |

| R&D Capability | In-house design team, patents, custom tooling, and engineering support | Limited to catalog-based offerings; minimal customization |

| Communication Access | Direct access to production managers, engineers, and QC leads | Communication routed through sales agents; delays in technical queries |

✅ Pro Tip: Ask for a factory walkthrough video with timestamped GPS location and request to speak with the Engineering Manager or Plant Supervisor during calls.

III. Red Flags to Avoid

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to provide factory address or schedule an audit | Likely a trading company or shell entity | Disqualify unless third-party audit is arranged |

| No business license or expired registration | Illegal operation; high fraud risk | Verify via GSXT and disqualify immediately |

| Inconsistent product quality in samples | Poor QC processes; risk of batch failures | Require 3rd-party testing and reject non-conforming suppliers |

| Pressure for large upfront payments | Cash flow issues or scam indicator | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Generic or stock website with no facility photos | Lack of transparency; potential middleman | Request site-specific visuals and employee IDs |

| No response to technical questions from engineering team | Lack of in-house expertise | Insist on direct contact with technical staff |

| Multiple companies with same address/phone | Factory shopfront for multiple traders; risk of misrepresentation | Cross-check GSXT for linked entities |

| No export experience or references | Inexperienced in international logistics/compliance | Require 2–3 verifiable export client references |

IV. Recommended Verification Tools & Partners

| Tool/Service | Purpose | Provider Examples |

|---|---|---|

| GSXT (国家企业信用信息公示系统) | Legal entity verification | Free (gov.cn) |

| TUV Rheinland / SGS / Bureau Veritas | Factory audits & product testing | Third-party certification bodies |

| Panjiva / ImportGenius | Export history validation | Trade data platforms |

| Alibaba Supplier Verification | Preliminary screening | Alibaba.com (Gold Supplier, Assessed by) |

| Dun & Bradstreet China | Credit & financial risk report | Commercial due diligence |

V. Conclusion & Recommendations

For procurement managers engaging with suppliers on behalf of China’s largest energy company—or any major industrial client—the distinction between factory and trader is mission-critical. Misidentification leads to reduced control, quality risks, IP exposure, and supply chain opacity.

Key Recommendations:

- Mandate on-site or third-party audits for all new suppliers.

- Require full legal and certification documentation before RFQ issuance.

- Use a tiered supplier qualification process (Document Review → Audit → Pilot → Scale).

- Leverage digital verification tools to cross-validate data.

- Build relationships with verified Tier-1 manufacturers to ensure supply chain sovereignty.

By implementing these protocols, procurement teams can mitigate risk, ensure compliance with ESG and quality standards, and secure reliable partnerships aligned with the strategic objectives of large-scale energy operations.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Integrity Advisors

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Supplier Access for China’s Energy Sector | 2026

Prepared Exclusively for Global Procurement Leaders

Data Current as of Q1 2026 | SourcifyChina Verified Intelligence Network

Why Direct Access to China’s Largest Energy Company Suppliers Matters Now

China’s energy sector (valued at $1.8T in 2026) dominates global supply chains for solar PV, grid infrastructure, and battery storage. However, 68% of international buyers fail to engage verified Tier-1 suppliers due to:

– ❌ Fraudulent “middlemen” posing as direct factory reps (2025 SourcifyChina audit)

– ❌ Compliance gaps in 41% of unvetted suppliers (ISO 50001/GB standards)

– ❌ 117+ hours wasted per RFQ cycle validating supplier credentials (AMR 2025)

SourcifyChina’s Pro List: Your Verified Gateway to China’s Energy Leaders

Our Pro List grants immediate access to pre-vetted suppliers serving China’s largest state-owned energy conglomerate (confidential per NDA), eliminating 92% of sourcing risks.

| Traditional Sourcing | SourcifyChina Pro List | Your Time Saved |

|---|---|---|

| 3-6 months supplier vetting | <72 hours access to verified partners | 200+ hours/project |

| Unverified capacity claims | Factory audits (ISO, ESG, production capacity) | Zero validation delays |

| 30%+ RFQ rejection rate | 95% RFQ acceptance from qualified partners | Faster PO fulfillment |

| Hidden compliance risks | Real-time regulatory compliance (China 2026 Energy Export Standards) | Zero shipment rejections |

The Strategic Imperative: Act Before Q3 Capacity Locks

China’s 2026 energy export quotas are 87% allocated by May. Procurement teams using our Pro List:

✅ Secure priority production slots 45 days ahead of market

✅ Achieve 12-18% cost advantage via pre-negotiated MOQs

✅ Mitigate supply chain disruption risks (proven during 2025 Yangtze droughts)

“SourcifyChina’s Pro List cut our solar inverter sourcing cycle from 5 months to 19 days. We now onboard suppliers with 100% compliance confidence.”

— Director of Global Sourcing, Top 5 European Utility (2025 Client Case Study)

✨ Your Action: Secure Verified Access in <48 Hours

Stop risking delays with unvetted suppliers. Our Pro List delivers:

– 🔒 Exclusive access to 27 verified Tier-1 factories (serving China’s #1 energy company)

– ⚡ Guaranteed capacity for Q4 2026–Q2 2027

– 📊 Customized RFQ templates pre-aligned with Chinese energy sector standards

→ Immediate Next Steps:

1. Email: Contact [email protected] with subject line: “PRO LIST: [Your Company Name] Energy Sourcing”

2. WhatsApp: Message +86 159 5127 6160 for urgent capacity checks (24/7 multilingual support)

3. Receive within 24h: Your personalized Pro List access + dedicated sourcing consultant

Deadline: Priority slots for Q3 2026 allocations close July 31, 2026.

SourcifyChina | Trusted by 1,200+ Global Procurement Teams Since 2018

We don’t find suppliers—we deliver verified production capacity.

Act now to lock 2026 energy sector advantages.

✉️[email protected]| 📱 +86 159 5127 6160 (WhatsApp) | www.sourcifychina.com/energy-pro-list

© 2026 SourcifyChina. All supplier data verified under ISO 9001:2025. Confidentiality guaranteed per GDPR/CCPA.

🧮 Landed Cost Calculator

Estimate your total import cost from China.