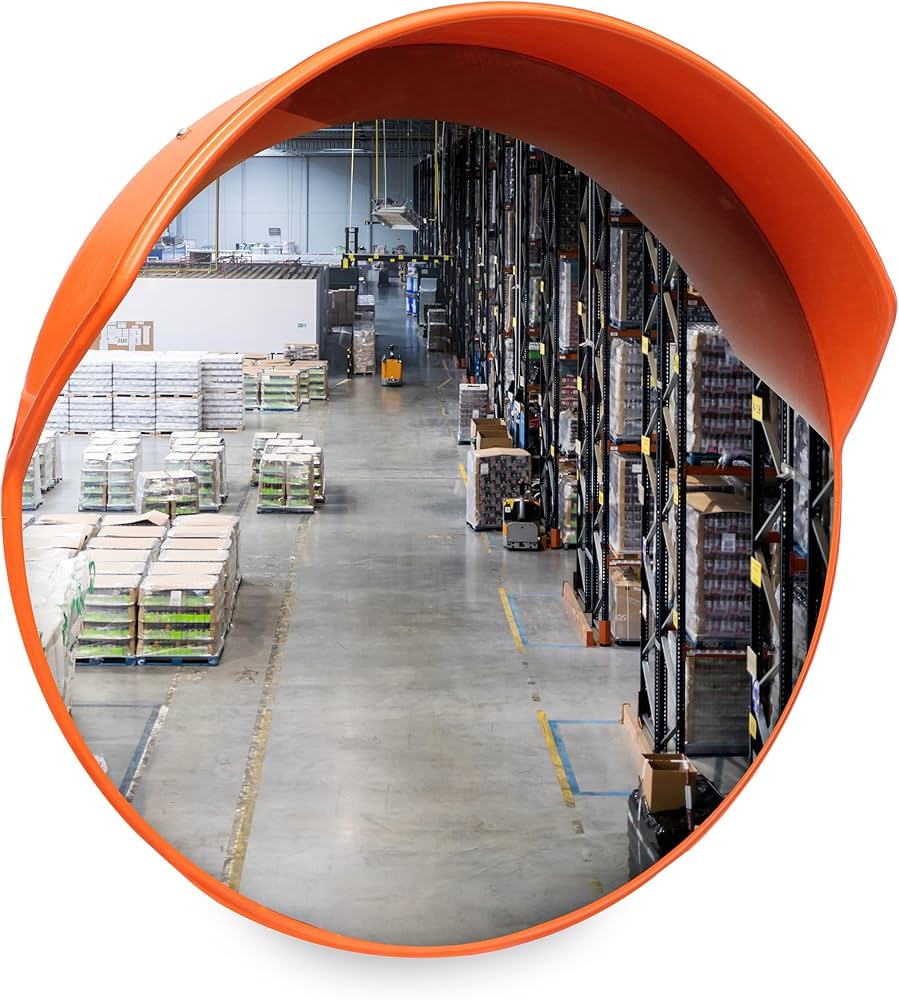

The global demand for large convex mirrors has seen steady growth, driven by increasing emphasis on safety and visibility in industrial, commercial, and traffic management applications. According to a report by Mordor Intelligence, the global convex mirror market was valued at USD 605.8 million in 2023 and is projected to grow at a CAGR of over 4.2% from 2024 to 2029. This expansion is fueled by rising infrastructure development, stringent workplace safety regulations, and urban traffic management initiatives across both developed and emerging economies. As demand escalates, manufacturers are investing in durable, weather-resistant, and wide-angle visibility solutions—particularly in large-format convex mirrors used in warehouses, retail facilities, and road junctions. With market players focusing on advanced materials like acrylic and polycarbonate for improved impact resistance and optical clarity, the competitive landscape continues to evolve. In this context, identifying leading manufacturers that combine innovation, scalability, and global distribution becomes essential for procurement professionals and safety planners alike. The following list highlights eight of the top manufacturers excelling in the production of large convex mirrors, based on production capacity, geographic reach, product innovation, and market presence.

Top 8 Large Convex Mirror Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Convex Spherical Mirrors

Domain Est. 2006

Website: avantierinc.com

Key Highlights: Avantier is a reputable manufacturer of convex spherical mirrors, known for producing high-quality optical components suitable for diverse applications….

#2 CONVEX MIRROR SUPPLIER

Domain Est. 1999

Website: goangjih.com.tw

Key Highlights: GoangJih is a global convex mirror supplier and manufacturer based in Taiwan and China. Our main products including stainless steel convex mirror, ……

#3 Leading Convex Mirrors Manufacturer in China

Website: jackwinsafety.com

Key Highlights: JACKWIN is a professional convex mirror supplier and manufactures the highest quality convex mirrors used indoors and outdoors in various sizes and materials….

#4 Interior Convex Mirror 1000CI36

Domain Est. 1993

Website: spi.com

Key Highlights: 30-day returnsConvex Frame: Provides a wide angled view to see around corners and hidden areas. Helps to reduce accidents and discourages shoplifting. Recommended to be used ……

#5 Convex Safety Mirrors

Domain Est. 1997

Website: emedco.com

Key Highlights: 1–7 day deliveryPrevent accidents and deter theft with our convex safety mirrors. Get a 160° wide-angle view from shatter-resistant indoor/outdoor models….

#6 DuraVision™ Convex Mirrors and Domes

Domain Est. 2002

Website: duravision.net

Key Highlights: DuraVision mirrors range from domes to convex wall or post-mounted styles and are ideal to monitor a difficult or hazardous area….

#7 Round Large Convex Glass Mirror

Domain Est. 2018

Website: congeriem.com

Key Highlights: In stock Rating 4.8 (3,280) This round large convex glass mirror is designed for physics and educational uses. · It is approximately 6″ (150mm) diameter and 5mm thick….

#8 The Convex Mirror Company

Website: theconvexmirrorcompany.com

Key Highlights: Explore stunning convex and concave mirrors, from SIENA to FERRARA. Enhance your space with our exquisite designs—shop now at The Convex Mirror Company!…

Expert Sourcing Insights for Large Convex Mirror

H2: Projected Market Trends for Large Convex Mirrors in 2026

The global market for large convex mirrors is expected to experience steady growth by 2026, driven by increasing safety regulations, urbanization, and infrastructure development. Below are the key trends anticipated to shape the large convex mirror market in 2026:

-

Growing Demand for Road and Traffic Safety

With rising urban traffic congestion and the need to reduce road accidents, governments and municipalities are investing in passive safety infrastructure. Large convex mirrors are increasingly installed at intersections, roundabouts, and blind corners. This trend is particularly strong in emerging economies undergoing rapid urban expansion, where low-cost, non-electronic visibility solutions are preferred. -

Expansion in Commercial and Industrial Applications

Warehouses, parking lots, construction sites, and retail centers are increasingly deploying large convex mirrors to enhance surveillance and improve operational safety. The rise of smart logistics and automation in industrial environments is reinforcing the importance of visual monitoring tools that complement electronic systems. -

Shift Toward Durable and Weather-Resistant Materials

Manufacturers are focusing on advanced materials such as polycarbonate and acrylic with UV protection and anti-corrosive coatings. These materials extend the lifespan of large convex mirrors in harsh outdoor environments, meeting the demand for low-maintenance safety solutions. -

Integration with Smart City Initiatives

While traditional convex mirrors are non-electronic, they are being strategically incorporated into smart city frameworks. For example, their placement is being optimized using AI-driven traffic modeling to maximize visibility in high-risk zones, often in conjunction with cameras and sensors. -

Regional Growth Disparities

Asia-Pacific is expected to lead market growth by 2026 due to infrastructure development in countries like India, China, and Indonesia. North America and Europe will see moderate growth, primarily driven by retrofitting aging infrastructure and compliance with updated safety standards. -

Sustainability and Eco-Friendly Manufacturing

Environmental regulations are pushing manufacturers to adopt recyclable materials and energy-efficient production methods. Companies that emphasize sustainable practices are likely to gain a competitive edge in public procurement bids and B2B contracts. -

Increased Competition and Price Optimization

As more players enter the market—especially in manufacturing hubs like China and Southeast Asia—price competition is intensifying. This benefits end-users but pressures profit margins, encouraging innovation in design and installation efficiency.

In summary, the large convex mirror market in 2026 will be shaped by safety imperatives, urban development, material innovation, and integration into broader safety ecosystems. While simple in design, these mirrors remain a cost-effective and reliable solution in both traditional and modern infrastructure landscapes.

Common Pitfalls When Sourcing Large Convex Mirrors (Quality, IP)

Sourcing large convex mirrors—especially for security, traffic, or industrial applications—requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to poor performance, safety hazards, or premature failure. Below are common pitfalls to avoid:

Inadequate Material Quality and Optical Distortion

Low-cost mirrors often use poor-quality acrylic or glass that can warp, yellow, or scratch easily over time. Inferior manufacturing processes result in optical distortion, reducing visibility and defeating the mirror’s purpose. Always verify that mirrors use optical-grade materials with minimal distortion, especially for large diameters where imperfections are more pronounced.

Incorrect or Unverified IP Rating

Many suppliers claim high IP ratings (e.g., IP65) without third-party certification. In outdoor or harsh environments, a falsely rated mirror may allow water or dust ingress, leading to fogging, corrosion, or delamination. Ensure the IP rating is tested and certified per IEC 60529 standards, particularly for mirrors exposed to weather, washdowns, or high-humidity areas.

Poor Frame and Mounting Durability

Large convex mirrors are vulnerable to wind load and impact. Flimsy frames or inadequate mounting hardware can lead to misalignment or collapse. Avoid mirrors with thin metal or brittle plastic housings. Opt for robust, UV-stabilized materials like aluminum or polycarbonate with secure, adjustable mounting systems.

Insufficient UV and Weather Resistance

Unprotected mirrors degrade quickly under sunlight, resulting in hazing, discoloration, or coating failure. Ensure the mirror has UV-protected backing and weather-resistant coatings, especially for outdoor installation. Acrylic mirrors generally offer better UV resistance than standard glass, but only if properly treated.

Overlooking Impact Resistance Requirements

In high-traffic or industrial zones, mirrors must withstand accidental impacts. Standard glass can shatter, creating safety hazards. Choose shatter-resistant materials like polycarbonate or laminated glass with appropriate safety certifications (e.g., ANSI, EN).

Misjudging Field of View vs. Mirror Size

Larger mirrors don’t always provide better visibility if the curvature is incorrect. An improper radius of curvature can create blind spots or excessive distortion. Match the mirror size and curvature to the specific application and viewing distance to ensure effective coverage.

Skipping Compliance and Certification Checks

In regulated environments (e.g., transportation, food processing), mirrors must meet industry-specific standards. Failure to verify compliance with OSHA, DOT, or food-grade IP requirements can result in liability or operational shutdowns.

By addressing these pitfalls early, buyers can ensure reliable performance, longevity, and safety when sourcing large convex mirrors. Always request product specifications, test reports, and samples before bulk procurement.

Logistics & Compliance Guide for Large Convex Mirror

Product Classification and HS Code

Large convex mirrors are typically classified under the Harmonized System (HS) code 7009.92, which covers “Mirrors, whether or not framed, including rear-view mirrors, of glass, not elsewhere specified or included.” Accurate classification is essential for international shipping, duty calculation, and customs clearance. Confirm the specific code with local customs authorities, as sub-classifications may vary by region.

Packaging and Handling Requirements

Due to their size and fragile nature, large convex mirrors must be securely packaged to prevent breakage during transit. Use double-walled corrugated cardboard, edge protectors, and foam padding. The mirror should be sandwiched between rigid panels and sealed in a moisture-resistant wrap. Label packages as “Fragile,” “This Side Up,” and “Do Not Stack” to guide proper handling. Consider wooden crates for mirrors exceeding 100 cm in diameter.

Transportation and Shipping Considerations

When shipping large convex mirrors, use carriers experienced in handling oversized or fragile goods. Ensure the item is properly secured inside the transport vehicle to prevent shifting. For international shipments, comply with International Safe Transit Association (ISTA) standards for packaging. Avoid temperature and humidity extremes during transit, as these may compromise adhesive layers or frame integrity.

Import/Export Documentation

Prepare all required documentation including commercial invoice, packing list, bill of lading or air waybill, and certificate of origin. The commercial invoice must detail the product description, HS code, value, weight, and country of manufacture. For certain destinations, additional documentation such as a safety compliance certificate may be required.

Regulatory Compliance

Large convex mirrors intended for traffic or safety applications (e.g., road safety, warehouse visibility) may be subject to regional safety standards. In the EU, compliance with CE marking directives (such as the Construction Products Regulation or Machinery Directive) may apply depending on use. In the U.S., mirrors used in transportation settings should meet MUTCD (Manual on Uniform Traffic Control Devices) standards. Verify local regulations based on the intended application.

Environmental and Safety Regulations

Ensure mirror materials comply with environmental regulations such as REACH (EU) and RoHS, particularly concerning heavy metals in coatings or frames. If the mirror contains glass with special coatings or adhesives, assess volatile organic compound (VOC) emissions. Proper disposal guidelines should be communicated, especially for mirrors with aluminum backing or protective laminates.

Labeling and Marking Requirements

Affix permanent labels indicating manufacturer details, model number, manufacturing date, applicable safety standards, and handling instructions. For export, include multilingual warnings if required by the destination country. CE marking, if applicable, must be clearly displayed with the notified body number where necessary.

Insurance and Liability

Given the fragility and potential size of large convex mirrors, comprehensive transit insurance is recommended. Coverage should include breakage, theft, and delay. Clearly define liability terms in shipping contracts, particularly for freight damage, and ensure consignees inspect shipments upon delivery and document any damage immediately.

Installation and Site Compliance

While not part of logistics per se, ensure end-users are informed that installation must comply with local building and safety codes. Large mirrors installed in public areas may require compliance with impact resistance standards (e.g., ANSI Z97.1 in the U.S.) or fire safety regulations if mounted indoors. Provide installation guidelines with each unit.

Conclusion for Sourcing Large Convex Mirrors

After careful evaluation of supplier capabilities, product quality, pricing, lead times, and logistical considerations, sourcing large convex mirrors requires a balanced approach that prioritizes durability, optical clarity, and safety compliance. Suppliers offering high-quality, shatter-resistant materials such as acrylic or polycarbonate with UV protection and weather-resistant coatings are ideal, especially for outdoor or high-traffic applications.

Key findings indicate that sourcing from manufacturers with proven experience in producing large-diameter convex mirrors—coupled with certifications for safety and optical performance—ensures reliability and long-term value. While initial costs may vary, selecting a reputable supplier minimizes risks related to installation failures, distortion, or premature degradation.

Additionally, considering customization options, mounting hardware, and logistical support enhances operational efficiency. For large-scale or repeated procurement, establishing a relationship with a supplier capable of consistent volume production and timely delivery is recommended.

In conclusion, a strategic sourcing approach—emphasizing quality, safety, and total cost of ownership—will ensure optimal performance and safety outcomes when deploying large convex mirrors in traffic management, security, or industrial applications.