The global laboratory footwear market is experiencing steady expansion, driven by heightened safety regulations, increased R&D investments, and growing emphasis on contamination control across pharmaceutical, biotechnology, and healthcare sectors. According to Grand View Research, the global personal protective equipment (PPE) market, which includes lab footwear, was valued at USD 64.0 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.1% from 2023 to 2030. Mordor Intelligence further projects a robust CAGR of over 5.8% for the PPE market through 2029, citing rising industrial safety standards and expanding laboratory infrastructure in emerging economies. With demand surging for slip-resistant, chemical-resistant, and sterile footwear, manufacturers are intensifying innovation in materials and design. In this evolving landscape, identifying reliable lab shoe suppliers is critical for maintaining compliance and operational safety. Below is a data-informed overview of the top 10 lab shoe manufacturers shaping the industry’s future.

Top 10 Lab Shoes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Lab

Website: thelab.care

Key Highlights: Our probiotic biotechnology is engineered to clean, protect, and extend the life of sneakers, hats, apparel, denim, and accessories. Shop now….

#2 SureFitLab Homepage

Domain Est. 2000

Website: surefitlab.com

Key Highlights: Relief and Healing Shoes · Socks · Stirrups · Thigh · Torsion · Walkers · Upper Limb · Arm and Elbow · Fracture Bracing · Hand and Wrist · Shoulder · Spinal….

#3 Asphalt Shoes

Domain Est. 2001

Website: labmfg.com

Key Highlights: Free delivery over $100** FREE SHIPPING TODAY ON ORDERS OVER $100.00 *. CALL US: 1-800-776-5830….

#4 MASCOT workwear and safety footwear

Domain Est. 2006

Website: mascotworkwear.com

Key Highlights: MASCOT manufactures a broad range of high quality workwear and safety footwear. It doesn’t matter whether you are a retailer or a purchaser for a large company….

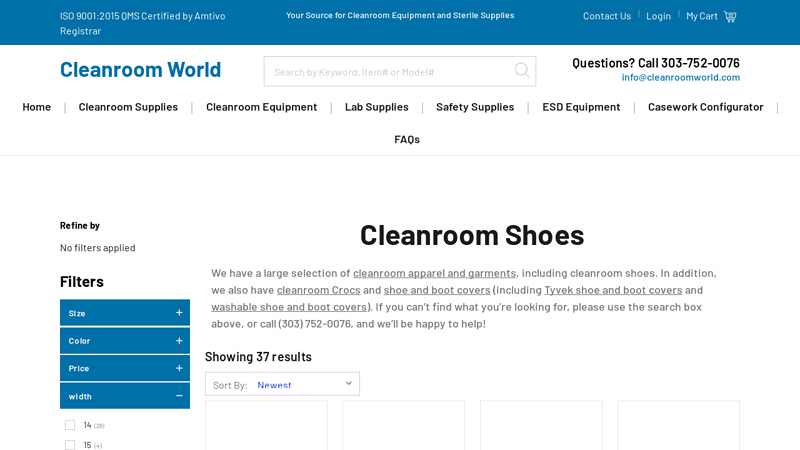

#5 ESD Cleanroom Shoes

Domain Est. 2007

Website: cleanroomworld.com

Key Highlights: Large selection of cleanroom shoes, including: ESD cleanroom shoes, safety shoes, washable shoes, autoclavable shoes, and slip resistant shoes….

#6 Athletic Propulsion Labs

Domain Est. 2009

Website: athleticpropulsionlabs.com

Key Highlights: $25 delivery · 10-day returns…

#7 Rope Laces, Reflective Laces, Shoe Laces & Accessories from Lace …

Domain Est. 2014

Website: lacelab.com

Key Highlights: 1–5 day delivery 30-day returnsAt Lace Lab, we make premium laces for your custom sneakers. From Rope Laces to 3M Reflectives to exclusive Roshe and Jordan XI laces, Lace Lab has y…

#8 Lab Milano Shoes Collection Made in Italy

Domain Est. 2016

Website: lab-milano.com

Key Highlights: Shoes of modern design, focused on details but also on a scrupolouse attention to the costs of production, becoming more competitive in the marketplace….

#9 BLUEVIEW • Shoes project

Domain Est. 2021

Website: algenesislabs.com

Key Highlights: The first fully biodegradable modern footwear brand. ‘Innovation in footwear: from polluting plastics to plant-based solutions’…

#10 Women’s Leather Shoes Online Store

Domain Est. 2022

Website: leatherlabstore.com

Key Highlights: Discover LEATHER LAB STORE – the official online women’s shoes store offering handcrafted, made-to-order women leather footwear. Shop loafers, Mary Janes, ……

Expert Sourcing Insights for Lab Shoes

2026 Market Trends for Lab Shoes

The global lab shoes market is poised for significant transformation by 2026, driven by advancements in material science, increasing health and safety regulations, and growing demand across healthcare, biotechnology, and research sectors. This analysis outlines key trends shaping the lab footwear industry in 2026.

Rising Demand for Safety and Compliance

In 2026, stringent occupational safety standards across North America, Europe, and parts of Asia-Pacific are pushing laboratories to adopt footwear that meets or exceeds ANSI, ASTM, and ISO safety certifications. Lab shoes are no longer seen as casual footwear but as critical personal protective equipment (PPE). Employers are investing in slip-resistant, chemical-resistant, and static-dissipative shoes to reduce workplace injuries and comply with evolving OSHA and EU PPE directives.

Innovation in Materials and Design

Material innovation is a dominant trend in the 2026 lab shoe market. Manufacturers are incorporating antimicrobial textiles, lightweight composites, and recyclable polymers to enhance durability, comfort, and sustainability. Closed-cell foams and moisture-wicking linings are becoming standard to prevent fungal growth and improve all-day wearability. Additionally, ergonomic designs with arch support and shock absorption are increasingly prioritized to reduce fatigue during long shifts.

Growth in Outsourced Research and CROs

The rise of contract research organizations (CROs) and outsourced laboratory services is expanding the user base for lab-specific footwear. As pharmaceutical and biotech firms outsource testing and development, the demand for standardized, professional lab attire—including footwear—increases. This trend drives bulk procurement and brand loyalty among suppliers offering scalable, certified solutions.

Sustainability and Eco-Conscious Manufacturing

Environmental sustainability is influencing purchasing decisions in 2026. Leading lab shoe brands are introducing eco-friendly product lines made from recycled plastics, natural rubber, and biodegradable components. Certifications like Cradle to Cradle and Bluesign are gaining traction, and institutional buyers are prioritizing vendors with transparent supply chains and low carbon footprints.

Expansion in Emerging Markets

Emerging economies in Southeast Asia, Latin America, and Africa are witnessing rapid growth in research infrastructure and healthcare investments. Governments and private institutions are modernizing laboratories, creating new demand for compliant lab footwear. Local manufacturing partnerships and affordable product tiers are enabling global brands to penetrate these markets effectively.

Integration with Smart Technology

While still in early adoption, smart lab shoes are emerging in high-security or precision research environments. In 2026, select models include embedded sensors to monitor foot pressure, detect contamination exposure, or track personnel movement within cleanrooms. Though niche, this segment is expected to grow with advancements in wearable tech and IoT integration.

Conclusion

By 2026, the lab shoes market will be characterized by heightened safety requirements, innovative materials, sustainability efforts, and geographic expansion. As laboratories become more specialized and regulated, lab footwear will evolve from a basic necessity to a high-performance, tech-enabled component of workplace safety and efficiency. Companies that prioritize compliance, comfort, and environmental responsibility will lead the market in this new era.

Common Pitfalls When Sourcing Lab Shoes (Quality, IP)

Sourcing lab shoes—specialized footwear designed for cleanroom, laboratory, or industrial environments—requires careful attention to both quality standards and intellectual property (IP) considerations. Overlooking these aspects can lead to compromised safety, non-compliance, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Quality Control and Inconsistent Materials

One of the most frequent issues is inconsistent product quality due to lax manufacturing standards. Lab shoes must meet specific requirements for static dissipation, chemical resistance, durability, and particle shedding. Sourcing from suppliers with inadequate quality assurance processes can result in substandard materials, such as non-compliant soles or fabrics that degrade quickly or fail ESD (electrostatic discharge) testing. Always verify certifications (e.g., ANSI, ISO, ASTM) and conduct independent batch testing.

Misrepresentation of Performance Specifications

Suppliers may exaggerate the technical capabilities of lab shoes—such as claiming ESD protection or chemical resistance without proper validation. This can lead to safety hazards in sensitive environments. Ensure that all performance claims are backed by third-party test reports and align with your operational requirements. Request documentation and conduct spot audits to verify compliance.

Lack of Traceability and Compliance Documentation

In regulated industries, traceability is critical. Poor documentation—such as missing batch numbers, material data sheets, or compliance certificates—can hinder audits and recalls. Always require full traceability from raw materials to finished goods and confirm that suppliers maintain robust quality management systems (e.g., ISO 13485 for medical device applications).

Intellectual Property Infringement Risks

Sourcing lab shoes, especially those with patented designs (e.g., unique sole patterns, anti-fatigue technology, or ventilation systems), carries IP risks. Using or importing shoes that replicate protected designs—even unintentionally—can result in legal action, shipment seizures, or forced recalls. Conduct thorough due diligence to ensure designs do not infringe on existing patents or trademarks. Work with legal counsel to review supplier designs and obtain IP indemnification clauses in contracts.

Copying Branded or Proprietary Designs

A common pitfall is sourcing “look-alike” lab shoes that mimic well-known brands. While cost-saving, this poses significant IP liability. Even subtle design similarities can trigger infringement claims. Avoid suppliers offering “compatible” or “equivalent” versions of branded lab footwear unless they have legitimate licensing agreements.

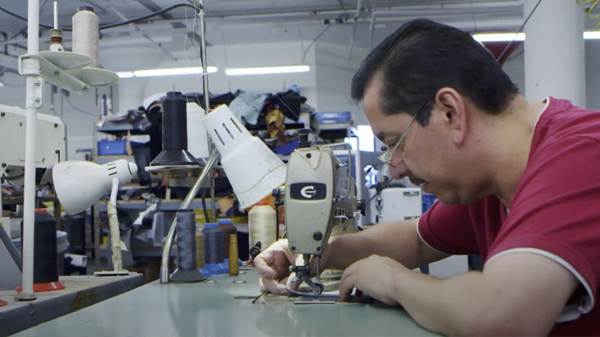

Inadequate Supplier Vetting and Transparency

Relying on intermediaries or uncertified manufacturers without onsite audits increases the risk of hidden quality lapses or IP violations. Poor supply chain transparency makes it difficult to verify ethical labor practices, material sourcing, and manufacturing authenticity. Establish direct relationships with vetted manufacturers and conduct regular factory assessments.

Overlooking Regional Regulatory Differences

Lab shoe standards vary by region and industry (e.g., EU’s EN standards vs. U.S. ASTM). Sourcing without considering local regulations can result in non-compliant products entering the market. Ensure your supplier understands and adheres to the target market’s regulatory framework.

By proactively addressing these quality and IP pitfalls, organizations can ensure they source reliable, compliant, and legally sound lab footwear that supports safety and operational integrity.

Logistics & Compliance Guide for Lab Shoes

Product Classification and Regulatory Requirements

Lab shoes, also known as laboratory safety footwear, are considered personal protective equipment (PPE) in most jurisdictions. As such, they are subject to specific regulatory standards. In the European Union, compliance with the Personal Protective Equipment Regulation (EU) 2016/425 is mandatory. In the United States, lab shoes must meet ASTM F2413 (Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear) and may require additional testing depending on workplace hazards (e.g., chemical resistance, slip resistance, static dissipation). Always verify the applicable standards based on the destination market and intended use.

Labeling and Documentation

All lab shoes must be properly labeled with essential information, including:

– Manufacturer name and address

– CE marking (for EU) or ASTM/ANSI compliance mark (for US)

– Size and model number

– Date of production or batch code

– Specific hazard protections (e.g., “ESD,” “SRC,” “CI”)

Accompanying documentation should include a Declaration of Conformity (DoC), user instructions in the local language, and technical data sheets outlining compliance with relevant standards. Export shipments require commercial invoices, packing lists, and certificates of origin where applicable.

Packaging and Shipping Requirements

Lab shoes must be packaged to prevent damage during transit. Use sturdy cartons with internal dividers to avoid scuffing or deformation. For international shipments, ensure packaging materials comply with ISPM 15 regulations if wood is used (e.g., pallets). Avoid excessive packaging to align with environmental regulations in regions such as the EU, which may impose packaging waste fees. Clearly label outer packaging with handling instructions (e.g., “Fragile,” “Keep Dry,” “This Side Up”) and include barcodes for inventory tracking.

Import and Customs Compliance

When importing lab shoes, confirm tariff classification codes (e.g., HS Code 6403 for footwear with outer soles of rubber, plastic, or leather) in the destination country. Duties and taxes vary by region and material composition. Provide accurate product descriptions and value declarations to avoid customs delays. Some countries may require pre-shipment inspections or conformity assessment certificates (e.g., SONCAP for Nigeria, SABER for Saudi Arabia). Maintain records of compliance documentation for at least five years for audit purposes.

Storage and Handling

Store lab shoes in a dry, well-ventilated area away from direct sunlight and extreme temperatures to prevent material degradation. Keep them off the floor using pallets or shelves to avoid moisture exposure. Implement a first-in, first-out (FIFO) inventory system to minimize shelf-life issues. For ESD (electrostatic discharge) lab shoes, maintain humidity levels between 40–60% to preserve performance characteristics.

End-of-Life and Environmental Compliance

Disposal of lab shoes must comply with local waste management regulations. In the EU, producers may be responsible under the Waste Electrical and Electronic Equipment (WEEE) directive if shoes include electronic components (e.g., smart sensors), or under extended producer responsibility (EPR) schemes for textiles and footwear. Encourage take-back programs or recycling partnerships where available. Avoid landfill disposal when possible and consider environmentally responsible manufacturing practices to support compliance with green procurement policies.

Training and User Compliance

Ensure end users receive proper training on the correct use, maintenance, and limitations of lab shoes. This includes inspection routines for wear and tear, cleaning procedures compatible with protective properties, and replacement schedules. Employers in regulated environments (e.g., pharmaceuticals, chemical labs) must document PPE compliance as part of their occupational health and safety programs.

Conclusion for Sourcing Lab Shoes:

In conclusion, sourcing the appropriate lab shoes is a critical step in ensuring safety, compliance, and efficiency within laboratory environments. After evaluating various suppliers, materials, safety standards (such as slip-resistance, chemical resistance, and anti-static properties), and cost-effectiveness, it is evident that prioritizing quality and protective features over initial cost leads to long-term benefits. The selected lab shoes meet or exceed industry safety standards, offer comfort for prolonged wear, and are suitable for the specific hazards present in the lab setting. Additionally, establishing a reliable supply chain with reputable vendors ensures consistent availability, timely delivery, and adherence to organizational requirements. Implementing a standardized lab footwear policy not only enhances workplace safety but also reinforces a culture of responsibility and professionalism. Therefore, the recommended sourcing strategy supports both employee well-being and operational excellence.