The global laboratory blender market is experiencing steady expansion, driven by increasing demand for precision mixing in pharmaceutical, biotechnology, and research applications. According to Grand View Research, the global laboratory equipment market was valued at USD 58.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. A key segment within this landscape, lab blenders are critical for homogenization, cell disruption, and sample preparation, where reproducibility and contamination control are paramount. This rising need, coupled with advancements in automation and high-throughput processing, has intensified competition among manufacturers. Based on market presence, innovation, product reliability, and application versatility, the following eight companies have emerged as leading lab blender manufacturers shaping the future of laboratory workflows.

Top 8 Lab Blender Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lab Mixers & Blenders

Domain Est. 1994

Website: coleparmer.com

Key Highlights: 3-day delivery 30-day returnsDiscover Cole-Parmer’s mixers and blenders: overhead, laboratory, paddle, and industrial models engineered for precise, efficient mixing in demanding l…

#2 ROSS Mixers

Domain Est. 1999

Website: mixers.com

Key Highlights: ROSS manufactures a wide range of industrial mixing equipment, blenders, dispersers and dryers to meet specific processing requirements, with industry ……

#3 Lab Blenders – Laboratory Equipment

Domain Est. 1996

Website: interscience.com

Key Highlights: BagMixer laboratory blenders are easy to use and very effective, they ensure an optimal bacterial extraction in less than 60 seconds….

#4 Seward

Domain Est. 1996

Website: seward.co.uk

Key Highlights: For 50 years, Seward and our range of Stomacher® blenders, bags and accessories have been the gold standard in microbiology sample preparation….

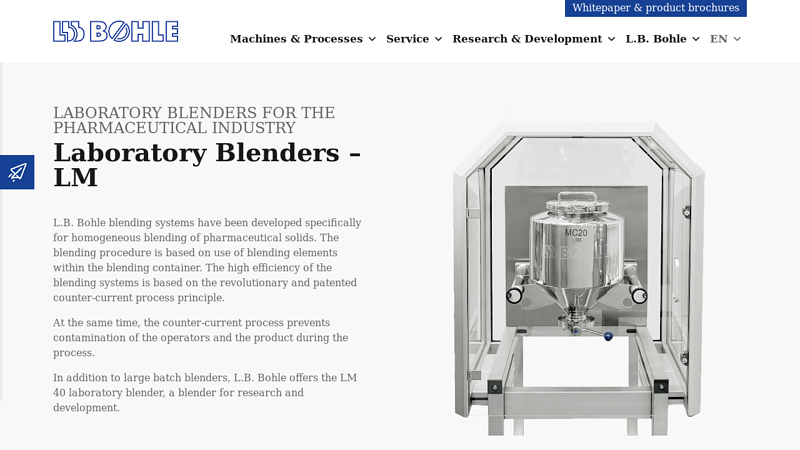

#5 Laboratory Blenders – LM

Domain Est. 1997

Website: lbbohle.com

Key Highlights: We offer our laboratory blenders in different sizes and technical designs. The following list provides an initial overview of our laboratory blender for your ……

#6 Blenders

Domain Est. 2006

Website: thermofisher.com

Key Highlights: Achieve powerful, reliable homogenization in your sample preparation with the Thermo Scientific™ Homogenizer Laboratory Blender….

#7 Laboratory Blenders

Domain Est. 2013

Website: nationalanalyticalcorp.com

Key Highlights: Explore high-performance Laboratory Blenders suitable for homogenizing, blending, and sample preparation. Built with precision and advanced safety features, ……

#8 Laboratory blender

Domain Est. 2015

Website: alliance-bio-expertise.com

Key Highlights: Laboratory blenders – The MIXWEL® range. lab blender. MIXWEL UP! (1) · lab blender accessories. Laboratory blender consumables and accessories (4). Filter….

Expert Sourcing Insights for Lab Blender

H2: 2026 Market Trends for Lab Blenders

The global laboratory blender market is poised for significant evolution by 2026, driven by advancements in research infrastructure, rising demand for precision in sample preparation, and a growing emphasis on automation and compliance in regulated industries. As laboratories across pharmaceuticals, biotechnology, food and beverage, and environmental testing sectors expand their capabilities, lab blenders are becoming increasingly essential for homogenizing, emulsifying, and cell disruption processes.

One of the key trends shaping the 2026 landscape is the integration of smart technologies into lab blender systems. IoT-enabled devices with remote monitoring, real-time data logging, and connectivity to laboratory information management systems (LIMS) are gaining traction. This shift supports the broader trend toward digitalization and data integrity in laboratories, particularly under Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) standards.

Another emerging trend is the demand for high-throughput and high-performance blenders capable of handling diverse sample types—from viscous biological tissues to dry powders—without cross-contamination. This has led to innovations in disposable blending chambers and sterile processing solutions, especially in the pharmaceutical and clinical diagnostics sectors.

Sustainability is also influencing design and material choices. By 2026, manufacturers are expected to prioritize energy-efficient motors, recyclable components, and reduced plastic waste in consumables, aligning with global sustainability goals and institutional procurement policies.

Geographically, North America and Europe will continue to dominate the lab blender market due to well-established research funding and advanced healthcare systems. However, the Asia-Pacific region is projected to exhibit the highest growth rate, fueled by increased investments in R&D, expansion of contract research organizations (CROs), and government initiatives to strengthen life sciences infrastructure.

In summary, by 2026, the lab blender market will be characterized by technological innovation, automation, regulatory compliance, and sustainability. Vendors that adapt to these trends—offering scalable, intelligent, and eco-conscious solutions—will be best positioned to capture market share in an increasingly competitive and specialized landscape.

Common Pitfalls When Sourcing Lab Blenders: Quality and Intellectual Property Concerns

Sourcing lab blenders—especially for regulated industries like pharmaceuticals, food, or biotechnology—requires careful evaluation to avoid critical setbacks. Two major areas of risk are product quality and intellectual property (IP) protection. Failing to address these can lead to compliance issues, failed validations, or legal disputes.

Quality-Related Pitfalls

Inconsistent Material Construction

A common issue is receiving lab blenders made from substandard materials. Some suppliers may claim compliance with standards like 316L stainless steel but deliver lower-grade alloys. This can lead to corrosion, contamination, and non-compliance with GMP (Good Manufacturing Practice) or FDA requirements.

Poor Manufacturing Tolerances

Low-cost manufacturers may overlook precision engineering. Inconsistent blade alignment, unbalanced motors, or poorly sealed housings can result in uneven mixing, equipment failure, or safety hazards during operation.

Lack of Validation Documentation

Many suppliers, especially smaller or offshore ones, fail to provide essential documentation such as Factory Acceptance Tests (FAT), calibration records, or material traceability. Without these, equipment cannot be validated for use in regulated environments.

Inadequate After-Sales Support and Spare Parts

Choosing a supplier with limited local presence can result in delayed repairs, long lead times for spare parts, and difficulty troubleshooting—disrupting lab operations and research timelines.

Intellectual Property (IP) Risks

Design Infringement and Counterfeit Products

Some manufacturers replicate patented designs from reputable brands without authorization. Purchasing such equipment may expose your organization to legal liability if the product is later deemed infringing.

Lack of IP Protection in Contracts

When customizing or co-developing a lab blender, failure to establish clear IP ownership in the supply agreement can result in disputes. Suppliers may claim rights to design improvements, limiting your freedom to use or modify the equipment.

Reverse Engineering by Suppliers

In regions with weak IP enforcement, suppliers may use your design specifications to produce and sell similar products to competitors. Without strong contractual clauses and non-disclosure agreements (NDAs), your innovations may be compromised.

Unclear Software and Firmware Rights

Modern lab blenders often include proprietary control software. Sourcing from vendors who don’t clearly license or assign software rights can restrict your ability to maintain, upgrade, or integrate the equipment into existing systems.

To mitigate these risks, conduct thorough due diligence: audit suppliers, request material certifications, review IP clauses in contracts, and involve legal and quality assurance teams early in the sourcing process.

Logistics & Compliance Guide for Lab Blender

This guide outlines the logistics handling, regulatory compliance, and safety considerations for the transportation, storage, and use of a laboratory blender. Adherence to these guidelines ensures operational safety, regulatory alignment, and equipment longevity.

Regulatory Classification and Documentation

Ensure the lab blender is classified correctly under applicable regulatory frameworks. Most lab blenders fall under scientific and laboratory equipment (HS Code 9027.80 or similar, depending on region). Maintain the following documentation:

– Manufacturer’s Certificate of Conformance

– Declaration of Compliance (e.g., CE, UKCA, or ANSI/UL standards)

– Technical data sheet and user manual

– Calibration and maintenance records

Verify that the equipment meets electromagnetic compatibility (EMC), low voltage (LVD), and RoHS directives where applicable.

Transportation and Shipping Requirements

Package the lab blender securely using manufacturer-recommended materials to prevent vibration, impact, or moisture damage. Use anti-static packaging if sensitive electronic components are present.

– Label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators

– Ship via carriers compliant with IATA, IMDG, or national transport regulations when moving internationally or across hazardous material zones (even if the blender itself is non-hazardous)

– Include a packing list and safety data sheet (SDS) if accessories contain regulated materials (e.g., stainless steel blades, plastic components)

Import/Export Compliance

For cross-border shipments:

– Confirm tariff classification and import duties based on destination country

– Complete necessary customs declarations (e.g., Commercial Invoice, Bill of Lading, Certificate of Origin)

– Comply with export control regulations (e.g., EAR in the U.S.) if the blender contains controlled technology

– Obtain import permits if required by local authorities (e.g., under metrology or electrical safety laws)

Storage and Handling Conditions

Store the lab blender in a clean, dry, temperature-controlled environment (typically 10°C to 30°C, 30–70% relative humidity, non-condensing).

– Keep packaging intact until deployment

– Store away from corrosive chemicals, dust, and direct sunlight

– Elevate units off the floor to prevent moisture absorption

– Ensure adequate ventilation if stored near heat sources

Installation and Operational Compliance

Install the blender on a stable, level surface in a well-ventilated laboratory area.

– Verify power supply compatibility (voltage, frequency, grounding)

– Use a dedicated circuit if high-power models are employed

– Follow manufacturer’s installation instructions for safety interlocks and blade assembly

– Perform initial calibration and function test per ISO/IEC 17025 or internal SOPs

Safety and Environmental Compliance

- Equip units with safety guards and interlock mechanisms to prevent operation when open

- Train personnel on proper operation, cleaning, and emergency shutdown

- Dispose of worn components (e.g., blades, seals) according to local waste regulations (may fall under WEEE or hazardous waste if contaminated)

- Conduct regular risk assessments under OSHA, COSHH, or equivalent workplace safety standards

Maintenance and Audit Readiness

Implement a preventive maintenance schedule per manufacturer guidelines. Document all servicing, repairs, and calibrations. Retain records for a minimum of five years or as required by accreditation bodies (e.g., ISO 17025, GLP). Audit readiness includes:

– Equipment logbook

– Calibration certificates traceable to national standards

– Proof of staff training and safety compliance

Adherence to this guide ensures safe, legal, and efficient use of the lab blender across its lifecycle.

Conclusion for Sourcing a Laboratory Blender

After a thorough evaluation of available options, stakeholder requirements, technical specifications, and supplier capabilities, sourcing a laboratory blender has been finalized based on the following key criteria: performance reliability, precision in sample homogenization, compatibility with various sample types (including viscous, solid, or temperature-sensitive materials), ease of cleaning and maintenance, and compliance with safety and regulatory standards.

The selected laboratory blender offers optimal speed control, durable construction (e.g., stainless steel or chemically resistant materials), and scalable processing capacity suitable for both small-scale research and repetitive testing applications. Furthermore, the chosen supplier demonstrates a strong reputation for after-sales support, technical training, and warranty coverage, ensuring long-term operational efficiency.

This procurement decision supports improved consistency in laboratory results, enhances workflow efficiency, and aligns with both current experimental needs and future scalability. The investment in a high-quality lab blender is expected to contribute significantly to data accuracy, reproducibility, and overall research integrity.