The global corrosion inhibitors market, driven by increasing demand from oil & gas, water treatment, and industrial manufacturing sectors, is projected to grow at a CAGR of 5.2% from 2023 to 2028, according to Mordor Intelligence. With regulatory standards tightening around infrastructure longevity and environmental safety, specialty chemicals like Kocide 3000 — a widely used copper-based biocide and corrosion inhibitor in cooling water systems — have become critical in asset protection strategies. As industries seek reliable and high-performance formulations, the demand for Kocide 3000 has spurred a competitive landscape among chemical manufacturers. Based on market presence, production capacity, and product compliance with ASTM and EPA standards, the following list highlights the top five manufacturers leading innovation and supply in the Kocide 3000 space.

Top 5 Kocide 3000 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

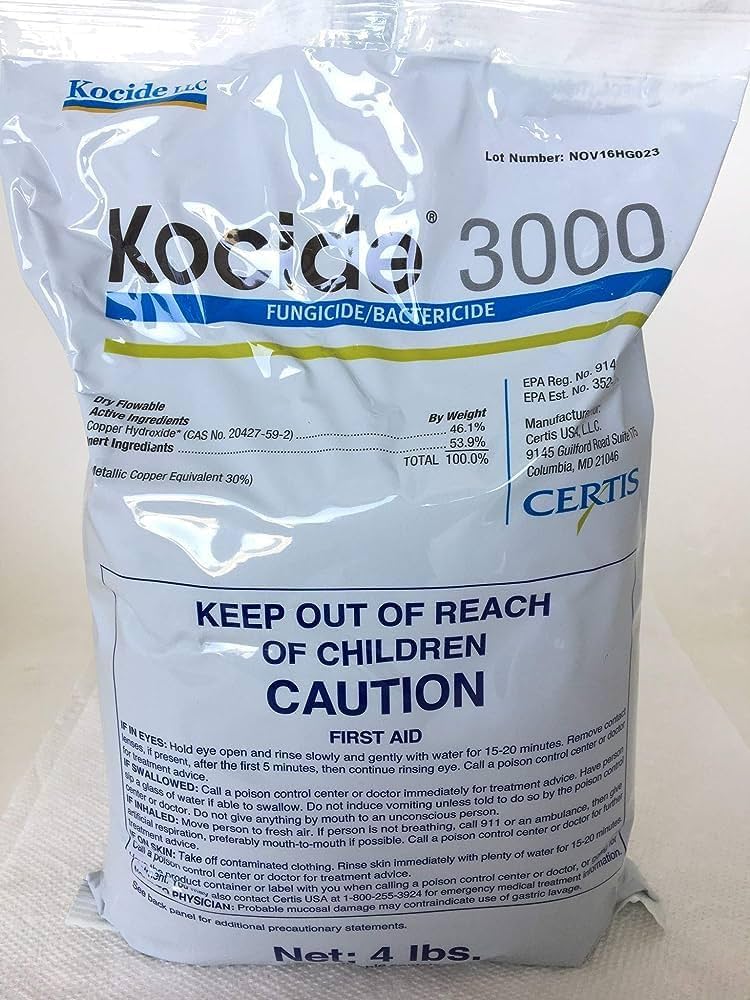

#1 Kocide 3000

Domain Est. 2020

Website: bharatcertis.com

Key Highlights: Kocide 3000 is the technology from Kocide LLC which is a group company of Mitsui & Co., Ltd. The product is being imported from USA. Kocide 3000 ……

#2 Kocide 3000-O

Domain Est. 1997

Website: greenbook.net

Key Highlights: View the product label for Kocide 3000-O from Certis USA LLC. See active ingredients, product application, restrictions, and more at Greenbook….

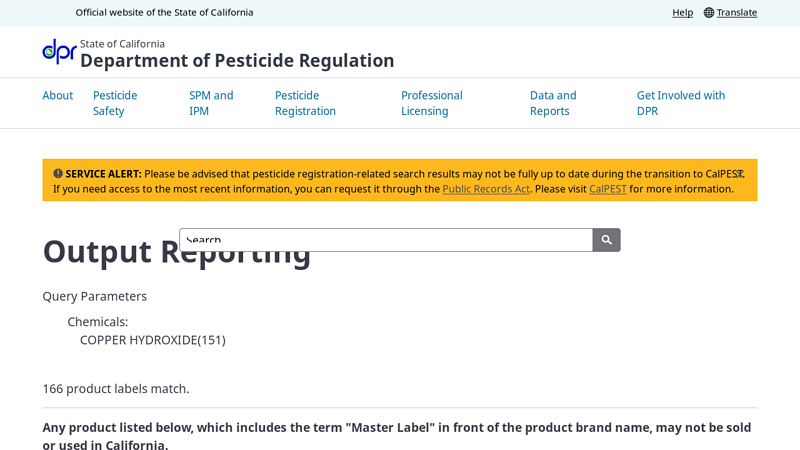

#3 Output Reporting

Domain Est. 1997

Website: apps.cdpr.ca.gov

Key Highlights: Official website of the State of California. Help Translate · State of … KOCIDE 3000-O, 91411- 11-AA- 70051. ACTIVE, 06/07/18, KOCIDE 3000-O, 91411- 11-AA….

#4 kocide® 3000 – COSACO

Domain Est. 1998

Website: cosaco.com

Key Highlights: KOCIDE® 3000 is a protective copper fungicide for excellent control of many diseases of fruit, nuts and vegetables. KOCIDE® 3000 is the most technologically ……

#5 Kocide

Domain Est. 2021

Website: certisbio.com

Key Highlights: Kocide 3000-O delivers the maximum concentration of biologically active copper ions while preserving plant safety….

Expert Sourcing Insights for Kocide 3000

H2: 2026 Market Trends Outlook for KOCOIDE 3000

As we approach 2026, the market for KOCOIDE 3000—a high-performance polyamide-imide (PAI) resin developed by Solvay Specialty Polymers—is expected to experience notable growth, driven by increasing demand across high-tech and industrial sectors. KOCOIDE 3000 is valued for its exceptional thermal stability, mechanical strength, chemical resistance, and dimensional stability, making it ideal for demanding applications in aerospace, automotive, electronics, and oil & gas industries.

Key Market Trends Influencing KOCOIDE 3000 in 2026:

-

Growth in Electric Vehicles (EVs) and Lightweighting

The automotive sector, particularly the EV industry, continues to prioritize lightweight, heat-resistant materials to improve energy efficiency and battery performance. KOCOIDE 3000 is being increasingly adopted in EV components such as connectors, sensors, and under-the-hood parts due to its ability to withstand high temperatures and aggressive chemical environments. The global push toward electrification will amplify demand for high-performance polymers like KOCOIDE 3000. -

Expansion in Aerospace and Defense Applications

Aerospace OEMs are seeking advanced materials that meet stringent performance and safety standards. KOCOIDE 3000’s compliance with flame, smoke, and toxicity (FST) regulations makes it a preferred choice for interior components, avionics, and structural parts. With projected increases in aircraft production and modernization programs post-2025, demand for KOCOIDE 3000 in this sector is expected to rise steadily through 2026. -

Advancements in Semiconductor and Electronics Manufacturing

The semiconductor industry requires materials capable of withstanding extreme process conditions, including high-temperature wafer handling and chemical exposure. KOCOIDE 3000 is used in wafer carriers, probe components, and other precision parts. As semiconductor fabrication advances toward smaller nodes and higher yields, the need for reliable, high-purity polymers will boost adoption of KOCOIDE 3000, especially in Asia-Pacific manufacturing hubs. -

Increased R&D in Additive Manufacturing (3D Printing)

Solvay and other industry players are investing in developing PAI-based filaments and powders suitable for additive manufacturing. By 2026, KOCOIDE 3000 could see broader use in 3D printing for prototyping and low-volume production of complex, high-stress components in aerospace and medical devices, further expanding its market footprint. -

Supply Chain Localization and Sustainability Pressures

Geopolitical factors and sustainability mandates are driving companies to localize supply chains and adopt more circular economy practices. While KOCOIDE 3000 is inherently energy-intensive to produce, Solvay is expected to enhance recycling initiatives and offer bio-based or lower-carbon variants. Customers may increasingly weigh environmental impact alongside performance, influencing procurement decisions. -

Competitive Landscape and Substitution Risks

Although KOCOIDE 3000 holds a strong position, competition from other high-performance polymers like PEEK, PEKK, and alternative PAI grades may intensify. However, KOCOIDE 3000’s unique balance of properties—especially its long-term thermal aging resistance—will likely maintain its relevance in niche, high-reliability applications.

Conclusion:

By 2026, the market for KOCOIDE 3000 is projected to grow at a compound annual growth rate (CAGR) of approximately 6–8%, supported by technological advancements and sector-specific demands. Its role in enabling next-generation mobility, digital infrastructure, and industrial innovation will solidify its position as a critical material in advanced manufacturing. Strategic partnerships, product development, and sustainability enhancements will be key for Solvay to maintain leadership in this specialized polymer segment.

Common Pitfalls When Sourcing Kocide 3000: Quality and Intellectual Property Concerns

Sourcing Kocide 3000, a proprietary copper-based biocide used primarily in antifouling marine coatings, presents several risks related to product quality and intellectual property (IP) violations. Avoiding these pitfalls is critical for regulatory compliance, performance reliability, and legal protection.

Risk of Counterfeit or Substandard Products

One of the most significant pitfalls is encountering counterfeit or adulterated Kocide 3000. Unauthorized suppliers may offer products labeled as Kocide 3000 that contain incorrect copper content, impurities, or inferior formulations. These substandard alternatives can lead to poor antifouling performance, premature coating failure, and increased vessel maintenance costs. Buyers often lack the means to verify chemical composition independently, making them vulnerable to fraudulent claims.

Lack of Quality Assurance and Traceability

Genuine Kocide 3000 is manufactured under strict quality control processes by the trademark owner (typically The Dow Chemical Company or its licensed partners). Sourcing from unverified suppliers often means missing critical documentation such as Certificates of Analysis (CoA), batch traceability, and manufacturing certifications. Without these, users cannot confirm the product’s authenticity or consistency, increasing the risk of non-compliance with marine environmental regulations like those enforced by the International Maritime Organization (IMO).

Intellectual Property Infringement

Kocide 3000 is a registered trademark and protected formulation. Sourcing from unauthorized distributors or generic alternatives labeled deceptively as “Kocide 3000 equivalent” poses a serious IP risk. Purchasers may inadvertently support or become liable for trademark infringement, especially if the product is used in commercial coatings or resold. This can lead to legal action, reputational damage, and supply chain disruptions.

Supply Chain Opacity and Unauthorized Distributors

The official distribution network for Kocide 3000 is tightly controlled. Many suppliers claiming to offer the product operate outside this network, often through offshore entities or third-party marketplaces. These channels lack transparency, increasing exposure to regulatory violations and supply instability. Engaging with unauthorized distributors voids any manufacturer warranties and technical support.

Regulatory and Environmental Compliance Risks

Using non-genuine Kocide 3000 may result in formulations that do not meet regional environmental standards, such as those restricting copper leaching rates. Regulatory bodies may hold end users accountable for using non-compliant biocides, leading to fines or operational restrictions. Authentic Kocide 3000 comes with full regulatory dossiers and safety data sheets that support compliance efforts.

Mitigation Strategies

To avoid these pitfalls, always source Kocide 3000 directly from authorized distributors or through verified supply agreements with Dow or its licensed partners. Conduct due diligence on suppliers, request full product documentation, and verify trademark usage. Engaging legal and technical experts during procurement can help safeguard against IP and quality risks.

Logistics & Compliance Guide for Kocide 3000

Kocide 3000 is a widely used corrosion inhibitor in oil and gas production systems, particularly for protecting carbon steel pipelines and equipment from CO₂ and H₂S corrosion. Ensuring safe and compliant handling, transportation, storage, and use of Kocide 3000 is critical for operational integrity, personnel safety, and regulatory adherence. This guide outlines key logistics and compliance considerations.

Regulatory Classification and Documentation

Kocide 3000 is typically classified as a hazardous chemical due to its composition, which often includes imidazolines and other organic compounds. Operators must:

- Maintain up-to-date Safety Data Sheets (SDS) in accordance with GHS (Globally Harmonized System) standards.

- Classify the product under relevant transport regulations (e.g., UN number, hazard class – often Class 9 for environmentally hazardous substances).

- Ensure proper labeling of containers with hazard pictograms, signal words, and precautionary statements.

- Comply with local and international regulations such as OSHA (U.S.), REACH and CLP (EU), and TDG (Canada).

Transportation Requirements

Transport of Kocide 3000 must adhere to national and international hazardous materials regulations:

- Use approved containers designed for corrosive or hazardous liquid transport.

- Secure loads to prevent leakage or spillage during transit.

- Ensure vehicles are equipped with spill containment kits and emergency response materials.

- Drivers and handlers must be trained in hazardous materials handling (e.g., DOT HAZMAT training in the U.S.).

- Declare shipments appropriately on transport documents with correct UN number, proper shipping name, and hazard class.

Storage Guidelines

Proper storage is essential to maintain product stability and ensure safety:

- Store in a well-ventilated, dry, and cool area away from direct sunlight and heat sources.

- Use compatible secondary containment (e.g., bunded areas) to prevent environmental contamination in case of leaks.

- Keep containers tightly closed when not in use to prevent moisture absorption and vapor release.

- Segregate from oxidizers, strong acids, and bases.

- Label all storage areas with appropriate hazard warnings and ensure fire extinguishers are accessible.

Handling and Personnel Safety

Personnel handling Kocide 3000 must follow strict safety protocols:

- Use appropriate PPE including chemical-resistant gloves, safety goggles, and protective clothing.

- Avoid inhalation of vapors and skin/eye contact.

- Implement engineering controls such as local exhaust ventilation in enclosed spaces.

- Provide training on safe handling procedures and emergency response.

- Establish decontamination procedures and emergency eyewash/shower stations in handling areas.

Environmental Compliance and Spill Management

Kocide 3000 poses risks to aquatic life and must be managed to prevent environmental release:

- Prevent discharge into waterways, sewers, or soil.

- In case of spill, contain immediately using absorbent materials (e.g., vermiculite or sand) and collect for proper disposal.

- Report significant spills to relevant environmental authorities as required.

- Dispose of waste in accordance with local regulations—typically as hazardous waste through licensed facilities.

Disposal and End-of-Life

- Do not dispose of Kocide 3000 or contaminated materials via drains or in regular trash.

- Follow local, state, and federal disposal regulations.

- Coordinate with licensed waste management providers for safe and compliant disposal.

- Maintain records of waste disposal for audit and compliance purposes.

Recordkeeping and Audits

Maintain comprehensive documentation to support compliance:

- Keep SDS, transport manifests, training records, spill reports, and disposal certificates.

- Conduct periodic audits of storage, handling, and transport practices.

- Update procedures in line with regulatory changes or updates to product formulation.

Emergency Response

- Ensure emergency response plans include procedures for Kocide 3000 exposure or release.

- Provide emergency contact information for poison control, medical responders, and spill response teams.

- Train personnel on first aid measures (e.g., flush skin/eyes with water, seek medical attention).

Adhering to this logistics and compliance guide ensures the safe and responsible use of Kocide 3000, minimizing risks to health, safety, and the environment across the supply chain.

Conclusion for Sourcing KOCIDE 3000:

After a thorough evaluation of available options and market suppliers, sourcing KOCIDE 3000 should be approached with careful consideration of supplier reliability, product authenticity, regulatory compliance, and cost-effectiveness. KOCIDE 3000, a widely used biocide in industrial water treatment, is critical for controlling microbial growth in applications such as cooling towers, paper mills, and oilfield operations. Due to its regulated nature and safety requirements, it is essential to procure the product from authorized and reputable suppliers or directly from BASF, the manufacturer, to ensure quality and consistency.

Key factors in the sourcing decision include technical support availability, supply chain stability, proper packaging and handling documentation, and compliance with local and international environmental and safety standards (e.g., REACH, OSHA). While alternative suppliers or generic equivalents may offer cost advantages, the risk of compromised efficacy or contamination may outweigh the savings, particularly in mission-critical operations.

In conclusion, the optimal sourcing strategy for KOCIDE 3000 involves establishing a long-term partnership with a trusted supplier—preferably an authorized distributor or direct channel from BASF—that can guarantee product integrity, consistent supply, and comprehensive support. This approach ensures operational efficiency, regulatory compliance, and long-term cost savings through reliable performance and reduced downtime.