The global knife gate valve market is experiencing steady growth, driven by increasing demand across industries such as water and wastewater treatment, mining, pulp and paper, and chemical processing. According to Mordor Intelligence, the Knife Gate Valve Market was valued at USD 2.1 billion in 2023 and is projected to reach USD 2.9 billion by 2029, growing at a CAGR of approximately 5.4% during the forecast period. This expansion is fueled by infrastructure development, stringent environmental regulations requiring reliable flow control solutions, and the need for corrosion-resistant and high-performance valves in abrasive service conditions. As industrial automation and process efficiency become priorities, leading manufacturers are investing in R&D to enhance valve durability, sealing performance, and operational longevity. In this competitive landscape, a select group of manufacturers have emerged as key players, setting industry benchmarks in innovation, quality, and global reach—making them the top nine knife gate valve suppliers worldwide.

Top 9 Knife Gate Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Knife Gate Valves

Domain Est. 1995

Website: emerson.com

Key Highlights: We manufacture knife gate valves for light to heavy slurry service in the mining and mineral processing, power, pulp and paper, waste water and chemical ……

#2 Knife Gate Valves

Domain Est. 1996

Website: dezurik.com

Key Highlights: DeZURIK manufactures a wide variety of both cast and fabricated Knife Gate Valves for liquids, paper stock, slurries, chemicals, and dry materials….

#3 Knife Gate Valve

Domain Est. 1996

Website: metso.com

Key Highlights: The Metso Knife Gate Valve is made for the toughest and most abrasive shut off applications involving slurries, powders or granular substances….

#4 Knife Gate Valves

Domain Est. 1996

Website: henrypratt.com

Key Highlights: We specialize in custom knife gate valves from 2″ to 96” and above, utilizing carbon steel to stainless steels and other weldable alloys….

#5 Wey knife gate valves

Domain Est. 1997

Website: weyvalve.com

Key Highlights: KNIFE GATE VALVES. Equipped with the unique Wey sealing system, our knife gate valves are suitable for the most demanding of applications….

#6 Fabri

Domain Est. 1997

Website: engvalves.com

Key Highlights: ITT Engineered Valves offers solutions for abrasive, corrosive, and hygienic applications within many industries….

#7 ORBINOX

Domain Est. 1997

Website: orbinox.com

Key Highlights: More than 50 years’ experience designing, manufacturing and marketing knife gate valves, penstocks, dampers, and valves for hydraulic work….

#8 Knife Gate Valves

Domain Est. 2003

Website: craneengineering.net

Key Highlights: Crane Engineering is a leading distributor for knife gate valves. Ideal for on/off isolation services in systems with heavy suspended solids….

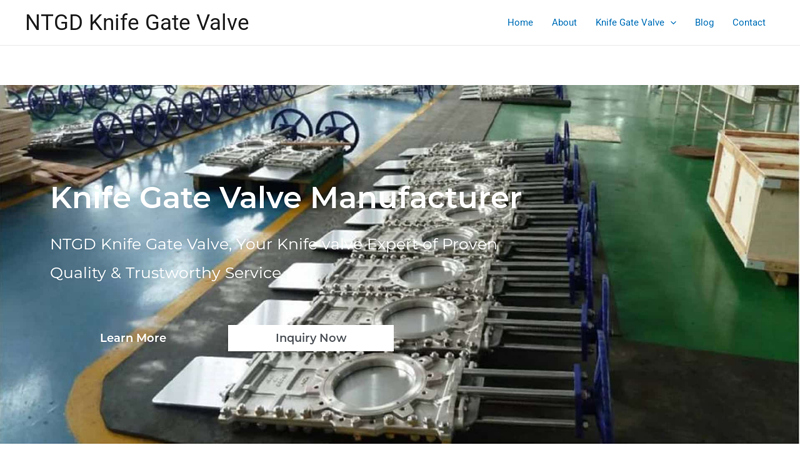

#9 NTGD Knife Gate Valve

Domain Est. 2021

Website: knifevalve.net

Key Highlights: NTGD specialized in manufacturing knife gate valve, including pneumatic knife gate valve, manual knife gate valve, through conduit knife gate valve….

Expert Sourcing Insights for Knife Gate Valve

H2: 2026 Market Trends for Knife Gate Valves

The global knife gate valve market is poised for steady growth through 2026, driven by increasing demand across key industrial sectors and technological advancements in valve design. As industries prioritize efficiency, durability, and minimal maintenance, knife gate valves are becoming a preferred choice in applications involving slurry, viscous, and abrasive media.

One of the primary drivers shaping the 2026 market landscape is the expansion of infrastructure and water treatment projects, particularly in emerging economies. Governments in Asia-Pacific, Latin America, and Africa are investing heavily in wastewater management and municipal water systems—sectors where knife gate valves are extensively used due to their ability to handle high-solids content and provide tight shutoff.

Additionally, the mining and mineral processing industries continue to adopt knife gate valves for their reliability in handling abrasive slurries. With commodity demand projected to remain strong through 2026, mining operations are upgrading equipment to improve uptime, further boosting valve demand. The oil and gas sector, particularly in downstream processing and refining, is also integrating more durable and corrosion-resistant knife gate valves to manage heavy residues and byproducts.

Technological innovations are another critical trend. Manufacturers are focusing on enhanced materials such as duplex stainless steel, super alloys, and advanced elastomers to improve valve longevity and performance in harsh environments. Smart valve integration—featuring condition monitoring, remote actuation, and predictive maintenance capabilities—is gaining traction, especially in automated industrial plants. These smart solutions are expected to account for a growing share of the market by 2026.

Sustainability and regulatory compliance are influencing product development as well. Stricter environmental regulations are pushing industries to reduce leaks and improve system efficiency. Knife gate valves with zero leakage designs and lower fugitive emissions are becoming standard requirements, prompting manufacturers to redesign sealing mechanisms and actuation systems.

Regionally, the Asia-Pacific market is expected to lead in growth due to rapid industrialization, urbanization, and government-led environmental initiatives. North America and Europe will see moderate growth, supported by aging infrastructure upgrades and the adoption of smart industrial technologies.

In summary, the 2026 knife gate valve market will be characterized by rising demand from water, mining, and energy sectors, innovation in materials and digital integration, and a regional shift toward Asia-Pacific dominance. Companies that invest in R&D, sustainability, and smart valve solutions are likely to gain a competitive edge in this evolving market.

Common Pitfalls When Sourcing Knife Gate Valves (Quality and Intellectual Property)

Sourcing knife gate valves, especially for critical industrial applications, involves navigating several potential pitfalls related to quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to operational failures, safety hazards, legal disputes, and financial losses. Below are the most common challenges buyers face:

Quality-Related Pitfalls

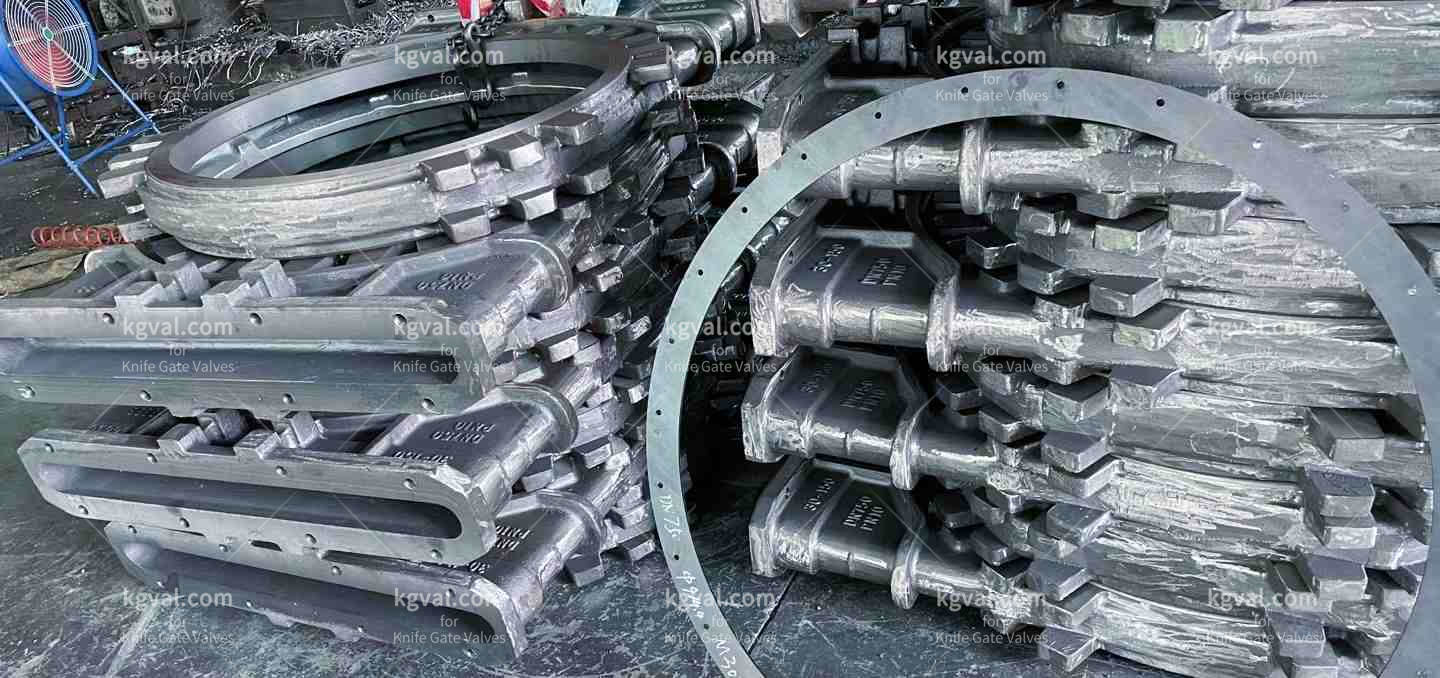

1. Inadequate Material Certification and Traceability

A frequent issue is receiving valves without proper material test reports (MTRs) or with falsified certifications. Buyers may assume supplied valves meet ASTM, API, or ISO standards, only to discover later that materials (e.g., stainless steel grades, elastomers) do not comply. Lack of full traceability from raw material to finished product increases the risk of using substandard components prone to corrosion or mechanical failure.

2. Poor Manufacturing Tolerances and Workmanship

Low-cost suppliers may cut corners in precision machining, leading to misaligned blades, uneven sealing surfaces, or improper gate alignment. These defects result in leakage, premature wear, and reduced valve lifespan. Visual inspection alone may not detect internal flaws such as porosity in cast bodies or inadequate weld integrity.

3. Insufficient Testing and Performance Validation

Some suppliers conduct only basic pressure tests or skip performance testing altogether. Without proper factory acceptance testing (FAT), including seat leakage tests per API 598 or fugitive emissions testing (e.g., ISO 15848), buyers risk deploying valves that fail under real operating conditions—especially in high-pressure, abrasive, or corrosive environments.

4. Misrepresentation of Design Standards and Ratings

Suppliers may falsely claim compliance with API 6D, MSS SP-81, or other industry standards without third-party verification. Valves might be labeled as “API-style” without actual certification. This misrepresentation can lead to incompatibility with system requirements and non-compliance during audits or inspections.

Intellectual Property-Related Pitfalls

1. Counterfeit or Replica Valves

Reputable brands (e.g., Bray, Tyco, Flowserve) are often counterfeited, with suppliers offering “look-alike” valves that mimic design and branding. These replicas may infringe on registered designs, trademarks, or patented technologies (e.g., specific blade geometries, sealing mechanisms), exposing the buyer to legal liability, especially in regulated industries.

2. Unauthorized OEM Replicas and Grey Market Goods

Some suppliers produce or distribute valves that replicate original equipment manufacturer (OEM) designs without licensing. While not always counterfeit, these “compatible” or “replacement” valves may violate IP rights. Purchasing such products can lead to warranty voidance, lack of technical support, and enforcement actions from IP holders.

3. Lack of IP Due Diligence in Supplier Contracts

Buyers often fail to include IP warranties and indemnification clauses in procurement agreements. Without contractual safeguards, the buyer assumes the risk if the valve design or branding is later found to infringe on third-party patents or trademarks. This can result in costly recalls, litigation, or supply chain disruptions.

4. Ambiguity in Custom or Engineered Valve Designs

When sourcing custom knife gate valves, unclear ownership of design specifications, CAD files, or modifications can lead to IP disputes. Suppliers may claim ownership of design improvements or reuse proprietary configurations for other clients, undermining the buyer’s competitive advantage.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Require full material traceability and third-party certification (e.g., CE, API Monogram).

– Conduct factory audits or use independent inspection agencies (e.g., SGS, Bureau Veritas).

– Specify testing protocols in purchase orders and witness critical tests when possible.

– Verify supplier credentials and check for genuine OEM partnerships or licenses.

– Include IP indemnification clauses and design ownership terms in contracts.

– Source from authorized distributors or directly from OEMs when brand authenticity is critical.

By proactively addressing quality and IP concerns, organizations can ensure reliable valve performance and mitigate legal and operational risks in their sourcing process.

Logistics & Compliance Guide for Knife Gate Valve

Overview

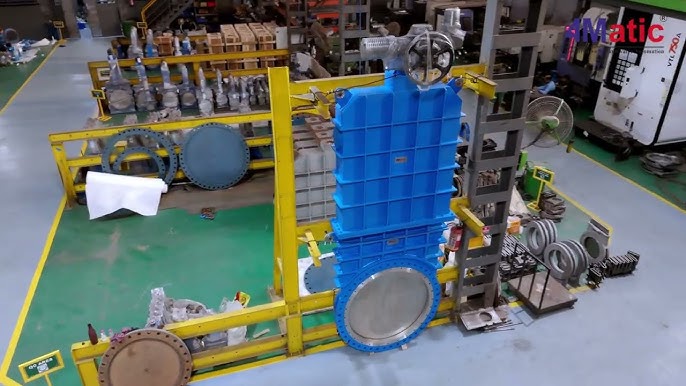

Knife Gate Valves are widely used in industries such as mining, pulp and paper, wastewater treatment, and chemical processing due to their ability to handle slurry, viscous, and abrasive media. Ensuring proper logistics and compliance during manufacturing, transportation, and installation is critical to performance, safety, and regulatory adherence.

Classification and HS Code

- Product Type: Industrial Valve – Knife Gate Valve

- Common HS Code: 8481.80 (Valves for pipes, boiler shells, tanks, or reservoirs)

Note: Exact HS code may vary by country and valve specifications (e.g., material, size, actuation). Confirm with local customs authority.

- Subcategories: Manual, Pneumatic, Electric, or Hydraulic actuated; lined (e.g., rubber, PTFE) or unlined.

Material Compliance and Certifications

- Material Standards:

- ASTM A126 (Cast Iron Valves)

- ASTM A216 WCB (Carbon Steel)

- ASTM A351 CF8/CF8M (Stainless Steel)

- Certifications Required:

- ISO 5208: Valve leakage classification

- API 598: Inspection and testing of valves

- CE Marking (for EU markets)

- ATEX (if used in explosive environments)

- NACE MR0175/ISO 15156 (for sour service applications)

- PED 2014/68/EU (Pressure Equipment Directive – EU)

Packaging and Handling

- Packaging Requirements:

- Valves must be securely crated or palletized to prevent damage.

- Use protective end caps on flanges and port openings to prevent debris ingress.

- Include desiccants in packaging for valves with internal linings (e.g., rubber, PTFE) to avoid moisture damage.

- Handling Instructions:

- Lift using lifting lugs only—never use handwheels or actuators.

- Avoid dropping or impact during loading/unloading.

- Store in dry, covered area; elevate off ground to prevent corrosion.

Transportation Considerations

- Mode of Transport:

- Road, sea, or air (based on size, weight, and urgency)

- Oversized valves may require special permits for road transport.

- Documentation:

- Commercial Invoice

- Packing List

- Certificate of Origin

- Test Reports (e.g., pressure test, material certificates)

- Material Safety Data Sheet (MSDS), if applicable

- International Shipping:

- Comply with IMDG Code (for sea freight)

- IATA regulations (for air freight) — especially for actuated valves with pneumatic components

- Ensure proper labeling: fragile, lifting points, orientation arrows.

Import and Export Regulations

- Export Controls:

- Check for dual-use regulations (e.g., EU Dual-Use Regulation) if valves are for oil & gas or nuclear applications.

- Validate ECCN (Export Control Classification Number) — typically EAR99 for standard industrial valves.

- Import Duties and Taxes:

- Duties vary by destination country; use HS code to determine rate.

- Preferential tariffs may apply under trade agreements (e.g., USMCA, ASEAN, EU free trade pacts).

- Customs Clearance:

- Provide accurate technical specifications (size, pressure rating, material, actuation type).

- Some countries require pre-shipment inspection (e.g., SABER for Saudi Arabia, SONCAP for Nigeria).

Installation and On-Site Compliance

- Alignment and Support:

- Ensure pipeline is properly supported to avoid stress on valve body.

- Install in correct orientation (flow direction marked on body).

- Actuator Safety:

- For pneumatic/electric actuators, comply with local electrical codes (e.g., NEC in USA, IEC in EU).

- Lockout/Tagout (LOTO) procedures during maintenance.

- Environmental Compliance:

- Follow local regulations for fugitive emissions (e.g., EPA Method 21 in USA).

- Ensure no leakage during operation, especially in hazardous fluid services.

Maintenance and Documentation

- Record Keeping:

- Maintain test certificates, material traceability (e.g., MTRs), and compliance documentation.

- Log maintenance and repairs per ISO 5752 or customer requirements.

- Disposal:

- Follow local environmental regulations for end-of-life disposal.

- Recycle metallic components where possible.

Summary

Adhering to logistics and compliance standards ensures knife gate valves perform reliably and meet international regulatory requirements. Always verify country-specific regulations, obtain necessary certifications, and use proper handling and documentation practices from manufacturing through installation.

Conclusion for Sourcing Knife Gate Valve:

In conclusion, sourcing knife gate valves requires a comprehensive evaluation of application requirements, material compatibility, operational conditions, and quality standards. Selecting the right supplier is critical to ensure reliable performance, longevity, and cost-efficiency. Key factors such as valve size, pressure rating, end connections, sealing material, and compliance with industry standards (e.g., API, ASME, ISO) must be carefully considered. Additionally, prioritizing suppliers with proven manufacturing capabilities, stringent quality control processes, and responsive after-sales support helps mitigate risks and ensures project success. By adopting a strategic sourcing approach—balancing cost, quality, and technical specifications—organizations can secure knife gate valves that meet operational demands and contribute to the overall efficiency and safety of their fluid handling systems.