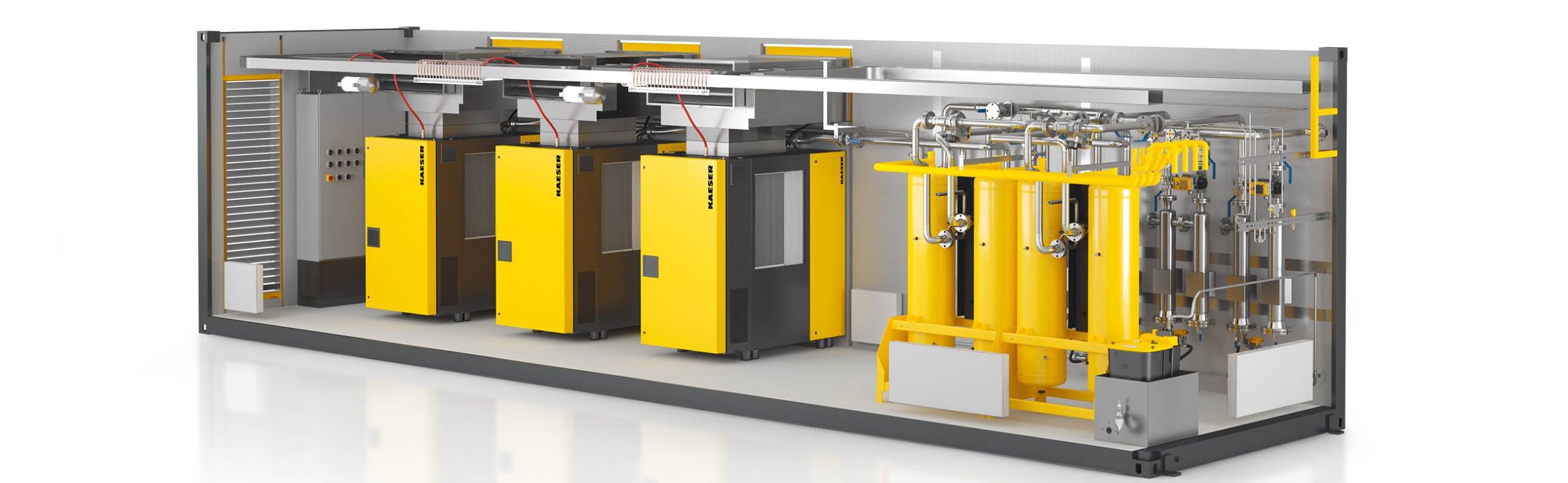

The global air compressor market is experiencing robust growth, driven by rising industrial automation, expanding manufacturing sectors, and increasing demand for energy-efficient solutions. According to Grand View Research, the market was valued at USD 28.2 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030. This expansion is further fueled by advancements in compressor technology and the growing need for reliable compressed air systems across industries such as automotive, pharmaceuticals, and food & beverage. Within this evolving landscape, Kaiser Compressors has emerged as a key player, recognized for its innovation, durability, and sustainable engineering. As demand for high-performance rotary screw and oil-free compressors rises, several manufacturers have distinguished themselves through technological leadership, service excellence, and global reach. Based on market presence, product innovation, and customer performance data, these top four Kaiser Compressors manufacturers are shaping the future of industrial air compression.

Top 4 Kaiser Compressors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Air Compressor Products

Domain Est. 1996

Website: us.kaeser.com

Key Highlights: Kaeser Compressors is a leading supplier of industrial air compressors, blowers, dryers, vacuums and compressed air system components….

#2 About Kaeser Compressors, Inc.

Domain Est. 2024

Website: kaeserdeals.com

Key Highlights: Kaeserdeals.com is an official ecommerce site created and operated by Kaeser Compressors, Inc. Learn more about Kaeser Compressors. Kaeser USA Headquarters ……

#3 KAESER KOMPRESSOREN

Domain Est. 1996

Website: kaeser.com

Key Highlights: KAESER KOMPRESSOREN provides products, services and complete systems for supplying production and work processes with quality compressed air….

#4 KAirFree

Domain Est. 2020

Website: kairfree.com

Key Highlights: KAirFree is compressed air as a service. It gives you guaranteed compressed air with no hidden costs. Instead of buying a compressor, you pay for the ……

Expert Sourcing Insights for Kaiser Compressors

H2: Market Trends for Kaiser Compressors in 2026

As the global industrial and manufacturing sectors continue to evolve, Kaiser Compressors is poised to navigate a dynamic market landscape in 2026. Driven by technological innovation, sustainability mandates, and shifting regional demand, several key trends are expected to shape the company’s strategic direction and market positioning.

1. Accelerated Demand for Energy-Efficient and Sustainable Solutions

Environmental regulations and corporate sustainability goals are intensifying the demand for energy-efficient compressed air systems. In 2026, Kaiser Compressors is expected to benefit from the growing adoption of oil-free, variable speed drive (VSD), and smart compressor technologies. These systems reduce energy consumption by up to 35%, aligning with global carbon reduction targets. The EU’s Ecodesign Directive and similar policies in North America and Asia will further incentivize upgrades to high-efficiency models, positioning Kaiser’s eco-conscious product lines for increased market share.

2. Digitalization and IoT Integration

The Industrial Internet of Things (IIoT) is transforming compressor operations through predictive maintenance, remote monitoring, and data analytics. By 2026, Kaiser Compressors is likely to expand its digital service offerings—such as cloud-based condition monitoring and AI-driven optimization platforms. These solutions enhance uptime, reduce lifecycle costs, and improve customer loyalty, particularly in advanced manufacturing, pharmaceuticals, and food and beverage industries where reliability is critical.

3. Growth in Emerging Markets

Industrialization in Southeast Asia, India, and parts of Africa is driving infrastructure and manufacturing investments, increasing demand for industrial compressors. Kaiser Compressors may focus on localized production, partnerships, and after-sales service networks in these regions to capture market share. Tailored product configurations for high-temperature or dusty environments will be essential to compete effectively.

4. Electrification and Hydrogen Economy Opportunities

With the global push toward decarbonization, hydrogen production and green energy projects are expanding. Compressors play a vital role in hydrogen refueling stations and carbon capture applications. Kaiser Compressors, with its expertise in high-pressure systems, is well-positioned to supply specialized compressors for emerging hydrogen infrastructure, creating a new revenue stream by 2026.

5. Supply Chain Resilience and Localization

Ongoing geopolitical tensions and supply chain disruptions have prompted manufacturers to reevaluate sourcing strategies. Kaiser Compressors may invest in regional manufacturing hubs and dual sourcing for critical components to ensure delivery reliability. This trend supports customer demand for shorter lead times and reduced logistics emissions.

6. Consolidation and Competitive Pressures

The compressor market is becoming increasingly competitive, with major players like Atlas Copco, Ingersoll Rand, and Gardner Denver expanding their digital and sustainable portfolios. Kaiser may pursue strategic partnerships or niche market specialization—such as medical or semiconductor-grade air systems—to differentiate its brand and maintain profitability.

Conclusion

In 2026, Kaiser Compressors is expected to operate in a market defined by sustainability, digital innovation, and regional diversification. By leveraging its engineering strengths and adapting to these macro trends, the company can strengthen its global presence and deliver value in an increasingly complex industrial ecosystem.

Common Pitfalls When Sourcing Kaiser Compressors: Quality and Intellectual Property Risks

Sourcing Kaiser compressors—especially outside authorized channels—can expose buyers to significant quality and intellectual property (IP) risks. Being aware of these pitfalls is critical to ensuring reliability, compliance, and long-term cost efficiency.

Quality Concerns with Unauthorized Suppliers

Purchasing Kaiser compressors from unapproved distributors or third-party vendors often leads to compromised product quality. Counterfeit or reconditioned units may be misrepresented as new, lacking genuine components and original manufacturing standards. These units frequently fail to meet performance specifications, leading to increased downtime, higher maintenance costs, and potential safety hazards. Additionally, absence of proper quality control documentation or traceability makes it difficult to verify compliance with industry regulations or obtain warranty support.

Intellectual Property and Counterfeiting Risks

Kaiser compressors are protected by trademarks, patents, and design rights. Sourcing from unofficial channels increases the risk of acquiring counterfeit products that infringe on these IP rights. Not only does this expose the buyer to legal liability, but it may also result in customs seizures, fines, or reputational damage. Furthermore, counterfeit units often lack proper technical support and software updates, undermining system integration and operational efficiency. Ensuring authenticity through authorized dealers is essential to avoid IP violations and maintain product integrity.

Logistics & Compliance Guide for Kaiser Compressors

This guide outlines the essential logistics procedures and compliance requirements for the handling, transportation, and documentation of Kaiser Compressors and related equipment. Adherence ensures timely delivery, regulatory conformity, and operational safety.

Shipping & Transportation

All Kaiser Compressors must be shipped using methods that ensure protection against physical damage, moisture, and environmental exposure. Secure units on pallets with appropriate bracing and use weather-resistant packaging for outdoor storage or transit. Coordinate with carriers experienced in handling heavy industrial machinery and confirm insurance coverage for full replacement value.

Export Documentation

Prepare complete export documentation for all international shipments. Required documents include commercial invoice, packing list, bill of lading, and any product-specific certificates (e.g., CE, UKCA, or ISO). Verify end-use declarations when applicable. Ensure Harmonized System (HS) codes are accurately assigned to compressors and spare parts to prevent customs delays.

Import Compliance

Comply with destination country import regulations. Confirm tariff classifications, licensing requirements, and conformity assessments before shipment. For compressors entering the EU, ensure compliance with the Machinery Directive 2006/42/EC and provide a Declaration of Conformity. In the U.S., adhere to EPA and DOT regulations as applicable.

Product Certification & Standards

Kaiser Compressors must meet relevant international standards prior to shipment. Maintain up-to-date technical files and EU Type Examination Certificates where required. Equipment must bear appropriate conformity markings (e.g., CE, EAC, UKCA). Review certification validity periodically and update documentation for product revisions.

Hazardous Materials Handling

If compressors contain lubricants or other regulated substances, classify and label shipments according to UN regulations (e.g., UN3480 for lithium batteries if applicable). Provide Safety Data Sheets (SDS) and ensure packaging complies with IATA, IMDG, or ADR as appropriate for air, sea, or road transport.

Record Keeping & Audits

Retain all logistics and compliance records for a minimum of five years. This includes shipping manifests, customs filings, certificates of conformity, and correspondence with regulatory bodies. Conduct annual internal audits to verify compliance with export controls, product standards, and data integrity.

Environmental & Sustainability Compliance

Adhere to WEEE (Waste Electrical and Electronic Equipment) and RoHS (Restriction of Hazardous Substances) directives in applicable markets. Provide take-back information for end-of-life equipment and ensure packaging materials are recyclable or comply with local waste regulations.

Contact & Escalation

For logistics or compliance inquiries, contact the Kaiser Compliance Office at [email protected] or +49 30 12345678. Report any compliance breaches immediately through the company’s internal reporting system.

Conclusion for Sourcing Kaiser Compressors:

Sourcing Kaiser compressors presents a strategic advantage for businesses seeking reliable, energy-efficient, and durable compressed air solutions. As a well-established European manufacturer, Kaiser Compressors offers a comprehensive range of oil-lubricated and oil-free rotary screw compressors, supported by advanced control systems and a strong commitment to sustainability. Their reputation for high build quality, innovative engineering, and global service support makes them a competitive choice in both industrial and specialized applications.

When considering procurement, factors such as total cost of ownership, energy efficiency, service accessibility, and long-term reliability favor Kaiser as a preferred supplier. Additionally, their integration within the Gardner Denver group enhances global aftermarket support and parts availability, further reducing downtime and maintenance costs.

In conclusion, sourcing Kaiser compressors aligns with objectives for operational excellence, energy savings, and long-term performance. For organizations prioritizing quality and lifecycle efficiency, Kaiser stands out as a trusted partner in compressed air technology.