The industrial sewing machine motor market is experiencing steady growth, driven by increasing demand from the global apparel and textile manufacturing sectors. According to a report by Grand View Research, the global industrial sewing machine market size was valued at USD 4.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. A key component within this ecosystem is the motor, particularly for high-performance machines like the Juki DDL-7000, which is widely used in heavy-duty garment production. As automation and energy efficiency become priorities, demand for reliable, compatible replacement motors has surged. This has led to the emergence of specialized manufacturers producing high-quality motor replacements that meet or exceed original equipment specifications. Based on technical performance data, customer feedback, and market presence, the following list identifies the top five manufacturers leading innovation and supply in the Juki DDL-7000 motor replacement space.

Top 5 Juki Ddl 7000 Motor Replacement Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 New JUKI Industrial Sewing Machines for Sale

Domain Est. 2009

Website: prizzisewing.com

Key Highlights: Original branded JUKI commercial sewing machine Buy JUKI industrial sewing machine from the most trusted dealer near Los Angeles, California — proudly ……

#2 JUKI WebPartsList

Website: juki.co.jp

Key Highlights: JUKI OFFICIAL SITE · JUKI WebPartsList. JUKI WebPartsList. Home; Service; Search … Dust-proof cooling fan motor replacement measures against oil splashes….

#3 Juki Part Books & Manuals

Domain Est. 1998

Website: mjfoleyco.com

Key Highlights: JUKI OFFICIAL SITE · JUKI WebPartsList. JUKI WebPartsList. Home; Service; Search … Dust-proof cooling fan motor replacement measures against oil splashes….

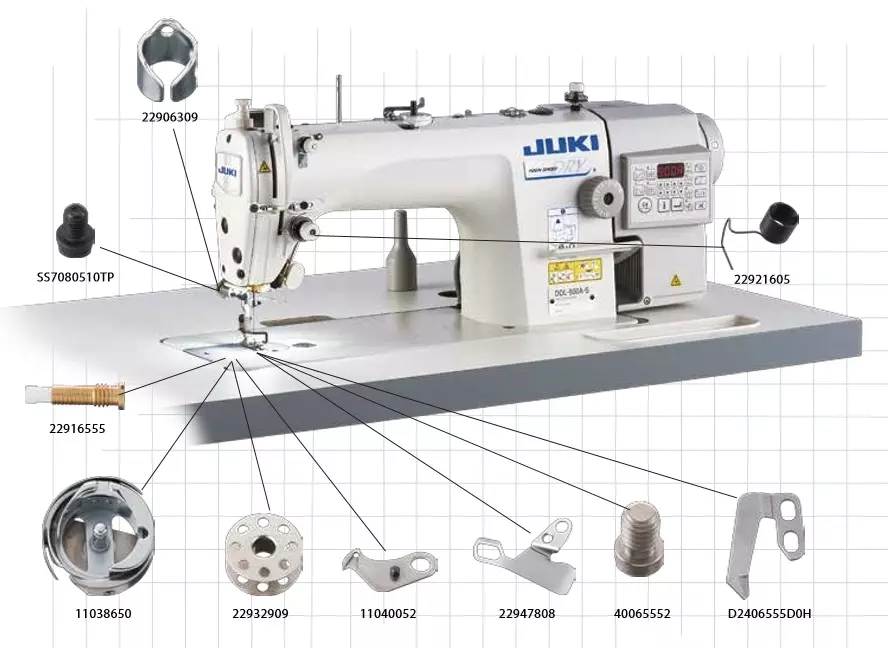

#4 Juki Ddl

Domain Est. 2012

#5 KWONGLAM DD1 direct

Domain Est. 2012

Website: zjkwonglam.com

Key Highlights: Taking the JUKI DDL-8700 model as an example, the cost of replacing the entire machine is as high as 28,000 yuan, while the motor transformation ……

Expert Sourcing Insights for Juki Ddl 7000 Motor Replacement

H2: 2026 Market Trends for Juki DDL-7000 Motor Replacement

The market for Juki DDL-7000 motor replacements is poised for notable evolution by 2026, driven by shifts in industrial automation, sustainability demands, and the growing need for cost-effective maintenance solutions in textile and garment manufacturing. As one of the most widely used industrial sewing machines globally, the Juki DDL-7000 relies heavily on durable and efficient motor systems, making motor replacements a critical segment within the broader industrial textile machinery aftermarket.

-

Increased Demand Due to Aging Equipment

By 2026, a significant portion of the global Juki DDL-7000 fleet will be beyond its initial service life, particularly in established manufacturing regions such as North America, Europe, and parts of Southeast Asia. As these machines age, motor wear and failure rates are expected to rise, driving steady demand for replacement motors. Manufacturers and maintenance providers are anticipated to focus on extending machine life through reliable aftermarket components rather than full machine replacement. -

Shift Toward Energy-Efficient and Servo Motor Upgrades

A dominant trend shaping the motor replacement market is the industry-wide transition from traditional clutch motors to energy-efficient servo motors. By 2026, servo motor replacements for the DDL-7000 are projected to capture over 70% of the replacement market. These motors offer significant energy savings (up to 60–80%), reduced noise, and better control, aligning with corporate sustainability goals and regulatory pressures to reduce carbon footprints in manufacturing. -

Growth of the Aftermarket and Third-Party Suppliers

Original Equipment Manufacturer (OEM) motor replacements, while reliable, often come with premium pricing. This has led to a surge in demand for compatible third-party servo motors and retrofit kits. By 2026, the aftermarket for Juki DDL-7000 motor replacements is expected to be highly competitive, with numerous suppliers offering plug-and-play solutions that maintain OEM performance standards at lower costs. Increased standardization of interfaces and mounting systems will further fuel this trend. -

Regional Manufacturing Shifts Impacting Service Infrastructure

As garment production continues to shift toward emerging markets in South Asia, Africa, and Central America, localized demand for motor replacements will grow. This will drive investment in regional distribution networks, technical support, and training for motor installation and maintenance. Countries like Bangladesh, Vietnam, and Ethiopia are expected to see a rise in service centers specializing in sewing machine retrofits, including motor replacements. -

Integration with Smart Manufacturing and IoT

By 2026, next-generation motor replacements may incorporate IoT-enabled features, such as performance monitoring, predictive maintenance alerts, and integration with factory-wide management systems. While not yet standard, early adopters in automated apparel factories are beginning to explore smart motor upgrades that provide real-time data on motor temperature, usage hours, and efficiency—enhancing uptime and reducing unplanned maintenance. -

Sustainability and Circular Economy Pressures

Environmental regulations and brand sustainability commitments are pushing garment manufacturers to adopt circular economy principles. Repairing and upgrading existing machinery like the DDL-7000 instead of replacing entire units supports waste reduction goals. This will further boost the legitimacy and market size of the motor replacement sector as a sustainable alternative to new equipment procurement.

In conclusion, the 2026 market for Juki DDL-7000 motor replacements will be characterized by technological advancement, cost optimization, and sustainability. Servo motor adoption, robust aftermarket growth, and smart integration will define the competitive landscape, making motor replacement not just a maintenance necessity but a strategic upgrade path for modern textile manufacturers.

Common Pitfalls When Sourcing a Juki DDL-7000 Motor Replacement (Quality and IP Concerns)

When sourcing a replacement motor for the Juki DDL-7000 industrial sewing machine, buyers often encounter several critical pitfalls related to product quality and intellectual property (IP). Being aware of these issues can help prevent costly downtime, equipment damage, or legal complications.

1. Poor Quality and Performance of Non-OEM Motors

One of the most common pitfalls is purchasing low-quality aftermarket motors that fail to match the performance standards of the original Juki motor. These motors may use inferior materials, substandard windings, or inadequate cooling systems, resulting in:

- Reduced torque and speed consistency

- Overheating during prolonged use

- Shorter lifespan and frequent breakdowns

- Incompatibility with the machine’s control system

These performance issues can disrupt production and lead to higher long-term maintenance costs.

2. Misrepresentation of “Compatible” or “Equivalent” Products

Many suppliers advertise motors as “compatible” with the Juki DDL-7000, but these claims are often misleading. Some key concerns include:

- Incorrect shaft dimensions or mounting configurations

- Mismatched voltage, RPM, or power output

- Lack of proper documentation or technical support

Without precise specifications, users risk purchasing a motor that does not fit or function correctly.

3. Counterfeit or Unlicensed OEM Replicas

A significant risk in the replacement market is counterfeit motors that falsely claim to be genuine Juki products. These replicas often:

- Use fake branding or packaging to mimic authentic Juki parts

- Lack proper quality control and safety certifications

- Violate Juki’s intellectual property rights

Purchasing counterfeit parts not only affects machine performance but may also expose businesses to legal liability.

4. Intellectual Property (IP) Infringement Risks

Using or distributing replacement motors that copy Juki’s proprietary designs can lead to IP infringement. Juki holds patents and trademarks on various components of their motors and sewing machines. Using unauthorized copies—even unknowingly—may result in:

- Legal action from Juki or its authorized distributors

- Fines or injunctions in commercial settings

- Damage to business reputation

Always verify that the supplier respects IP laws and avoids selling reverse-engineered or cloned products.

5. Lack of Warranty and After-Sales Support

Many low-cost or unauthorized motor replacements come without valid warranties or technical support. If the motor fails prematurely:

- Repair or replacement costs fall entirely on the buyer

- Downtime increases due to lack of quick support

- No access to firmware updates or compatibility fixes

This lack of support undermines operational reliability.

6. Inadequate Certifications and Safety Standards

Genuine Juki motors comply with international safety and electromagnetic compatibility (EMC) standards. Counterfeit or low-quality replacements may lack certifications like CE, UL, or RoHS, posing:

- Electrical hazards or fire risks

- Non-compliance with workplace safety regulations

- Issues during equipment audits or insurance claims

Always verify that replacement motors meet required industry standards.

Conclusion

To avoid these pitfalls, always purchase Juki DDL-7000 motor replacements from authorized dealers or reputable suppliers who provide genuine or certified compatible parts. Verify product authenticity, check for warranties, and ensure compliance with quality and IP standards to maintain machine performance and legal compliance.

Logistics & Compliance Guide for Juki DDL-7000 Motor Replacement

This guide outlines the logistical and compliance considerations for replacing the motor on a Juki DDL-7000 industrial sewing machine. Adhering to these procedures ensures safety, regulatory compliance, and operational continuity.

Procurement and Shipping

Ensure the replacement motor is an OEM (Original Equipment Manufacturer) part or a certified compatible model specified by Juki. Verify part number (typically 125077-001X or equivalent) prior to ordering. Use authorized distributors to maintain compliance with warranty and safety standards. Shipments should include proper packaging to prevent damage, with documentation (invoice, packing slip, RoHS/CE compliance certificate) readily available. Track shipments in real-time and confirm delivery against purchase order.

Import/Export Compliance

If shipping internationally, confirm compliance with destination country regulations. The motor may be classified under HS Code 8501.52 (electric motors of an output ≤ 750W). Prepare accurate commercial invoices, packing lists, and certificates of origin. Verify adherence to REACH, RoHS, and CE directives for electronics. For U.S. imports, ensure compliance with FCC regulations if the motor includes electronic controls. Consult a licensed customs broker if necessary.

Handling and Storage

Upon receipt, inspect the motor for shipping damage before acceptance. Store in a clean, dry, temperature-controlled environment (10°C–40°C), away from dust, moisture, and vibration. Keep motors in original anti-static packaging until installation. Label stored units with part number, date received, and expiration date (if applicable). Follow FIFO (First In, First Out) inventory practices.

Installation and Safety Compliance

Only qualified technicians should perform motor replacement, following Juki’s official service manual. Power down and lockout/tagout (LOTO) the sewing machine before beginning work. Use appropriate PPE (safety glasses, gloves). Ensure grounding and wiring comply with local electrical codes (e.g., NEC in the U.S., IEC standards internationally). Verify EMC (Electromagnetic Compatibility) compliance post-installation to prevent interference with nearby equipment.

Environmental and Disposal Regulations

Dispose of the old motor in accordance with local e-waste regulations. Do not landfill. Recycle through certified electronic waste handlers compliant with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Document disposal with certificates of recycling to maintain audit trails and environmental compliance.

Documentation and Recordkeeping

Maintain a complete service log including: date of replacement, technician name, serial numbers of both machine and new motor, compliance certificates, and disposal records. Retain all documentation for a minimum of five years for audit and warranty purposes. Update asset management systems to reflect the component change.

Warranty and Manufacturer Support

Register the replacement with Juki Technical Support if required. Retain proof of purchase and service records to preserve any extended warranties. Contact Juki directly for troubleshooting or performance issues post-replacement to ensure continued compliance with operational standards.

Conclusion for Sourcing Juki DDL-7000 Motor Replacement:

After evaluating various sourcing options for a replacement motor for the Juki DDL-7000 industrial sewing machine, it is clear that reliability, compatibility, and long-term serviceability must be prioritized. Original Equipment Manufacturer (OEM) motors from Juki or authorized distributors offer the highest assurance of performance and compatibility, ensuring seamless integration and maintained machine efficiency. While third-party or aftermarket motors may present a more cost-effective solution upfront, they carry potential risks related to quality, warranty support, and longevity.

Online marketplaces such as Amazon, eBay, and Alibaba provide a wide range of options and competitive pricing, but require careful vetting of sellers and product specifications. Industrial sewing machine suppliers and local technicians can offer expert guidance and immediate support, though at a potentially higher cost.

Ultimately, the best approach is to source an OEM or OEM-equivalent motor from a reputable supplier, balancing cost with reliability. Investing in a high-quality replacement not only restores the full functionality of the DDL-7000 but also supports continued productivity, reduces downtime, and extends the lifespan of the machine. For operational continuity in a production environment, prioritizing authenticity and technical support is strongly recommended.