The global cable connectors market, driven by rising demand in automotive, industrial machinery, and consumer electronics, is projected to grow at a CAGR of approximately 5.8% from 2023 to 2030, according to Grand View Research. With JST cable connectors playing a critical role in compact power and signal transmission applications, the need for reliable manufacturers has intensified. As of 2024, Asia-Pacific remains the largest producer and consumer of electronic connectors, bolstered by robust electronics manufacturing in countries like Japan, China, and South Korea. Mordor Intelligence highlights that technological advancements in miniaturization and an increasing shift toward automation are key factors fueling market expansion. Within this competitive landscape, a select group of manufacturers has emerged as leaders in product quality, innovation, and global market reach—setting the standard for JST connector performance across industries.

Top 4 Jst Cable Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

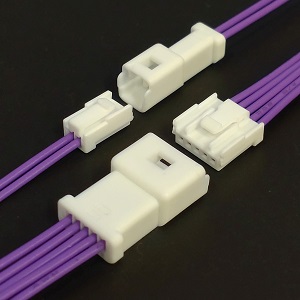

#1 J.S.T. Mfg. Co., Ltd.

Domain Est. 1997

Website: jst-mfg.com

Key Highlights: YL connector (Meets glow wire testing standards) This is a 4.5 mm pitch, wire-to-wire connector that comes with glow-wire compliant housing material and allows ……

#2 JST Sales America: Cutting

Domain Est. 1998

Website: jst.com

Key Highlights: Discover how our product line of over 100000 electrical connectors provides our customers with the tools they need for endless innovation….

#3 JST

Domain Est. 2007

Website: jst-india.com

Key Highlights: JST is your ‘Full Service’ supplier for the design, manufacture and supply of electrical / electronic terminals, connectors and associated application tooling ……

#4 JST Belgium

Domain Est. 2007

Website: jst-belgium.be

Key Highlights: Your connection to service and quality. JST is your supplier for the design, manufacture and supply of electrical / electronic terminals, connectors and ……

Expert Sourcing Insights for Jst Cable Connector

2026 Market Trends for JST Cable Connectors

Growing Demand in Consumer Electronics and IoT

By 2026, the market for JST cable connectors is expected to experience steady growth, primarily driven by the expanding consumer electronics and Internet of Things (IoT) sectors. JST connectors, known for their compact design and reliability, are widely used in smartphones, wearables, smart home devices, and portable electronics. As IoT device deployment continues to accelerate globally—especially in smart sensors, home automation, and edge computing—the need for small-form-factor, high-reliability connectors like those from JST will rise significantly.

Expansion in Electric Vehicles and E-Mobility Applications

The automotive industry, particularly electric vehicles (EVs) and e-mobility solutions such as e-bikes and scooters, will represent a key growth area for JST connectors by 2026. These connectors are increasingly adopted in battery management systems (BMS), onboard chargers, and control modules due to their durability and secure locking mechanisms. With global EV production projected to grow at a CAGR of over 20% through 2026, demand for JST’s high-current and low-profile connector variants, such as the JST-XH and JST-VH series, is expected to surge.

Emphasis on Miniaturization and High-Density Designs

As electronic devices become smaller and more powerful, the trend toward miniaturization will intensify. JST’s expertise in producing micro and ultra-micro connectors positions the company well for future demand. By 2026, markets will favor connectors with higher pin density, improved current ratings, and enhanced thermal performance—all areas in which JST has consistently innovated. The SH and PH series, for example, are likely to see increased adoption in medical devices, drones, and advanced robotics.

Regional Growth and Supply Chain Diversification

Asia-Pacific will remain the dominant market for JST connectors due to its robust electronics manufacturing base, especially in China, Japan, and Southeast Asia. However, growing geopolitical tensions and supply chain disruptions may prompt JST and its clients to diversify production and sourcing. By 2026, we may see increased manufacturing partnerships or localized distribution in North America and Europe to reduce dependency on single-region supply chains.

Sustainability and Regulatory Compliance

Environmental regulations and sustainability initiatives will influence connector design and materials. By 2026, JST is expected to further expand its range of RoHS-compliant, lead-free, and recyclable connectors. Energy efficiency and reduced material waste in production processes will become competitive differentiators, aligning with global ESG (Environmental, Social, and Governance) goals.

Competitive Landscape and Innovation Pressure

While JST remains a leader in the niche connector market, increasing competition from Chinese and Korean manufacturers offering lower-cost alternatives may pressure pricing. To maintain its market position, JST will likely continue focusing on R&D, quality assurance, and expanding its intellectual property portfolio. Patented locking mechanisms and proprietary contact technologies will be crucial in differentiating JST from generic clones.

In summary, by 2026, the JST cable connector market will be shaped by rising demand in high-growth tech sectors, ongoing miniaturization, and the need for supply chain resilience. JST’s strong brand reputation and engineering excellence will support continued success, provided it adapts swiftly to evolving technological and regulatory landscapes.

Common Pitfalls When Sourcing JST Cable Connectors: Quality and Intellectual Property Issues

Logistics & Compliance Guide for JST Cable Connectors

This guide outlines key logistics and compliance considerations when sourcing, shipping, and using JST cable connectors in electronic products. Adhering to these guidelines ensures smooth operations and regulatory compliance.

Product Identification and Specifications

Ensure accurate identification of the JST connector model (e.g., XH, PH, SH, EH series) and its specifications, including pitch, number of positions, gender (plug/receptacle), wire gauge compatibility, and mating cycle rating. Proper documentation and labeling are essential for traceability and quality control.

Regulatory Compliance Standards

JST connectors and their applications must comply with relevant international and regional standards, including:

- RoHS (Restriction of Hazardous Substances) – Ensures connectors are free from lead, mercury, cadmium, and other restricted materials.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) – Requires disclosure of SVHCs (Substances of Very High Concern).

- UL/CSA Recognition – Applies when connectors are used in UL-listed end products; verify UL file number and recognition status.

- IEC 60320 and IEC 60601 – Relevant for medical and industrial equipment applications.

- IPC/WHMA-A-620 – Standard for cable and wire harness assembly, important for quality assurance.

Packaging and Labeling Requirements

Use anti-static packaging for ESD-sensitive connectors. Label packages with:

- Part number and revision

- Quantity

- Lot/batch number

- Date of manufacture

- Compliance markings (e.g., RoHS, REACH)

- Handling symbols (e.g., ESD-sensitive)

Ensure labels are durable and legible throughout the supply chain.

Import and Export Documentation

When shipping internationally, prepare the following:

- Commercial Invoice

- Packing List

- Certificate of Origin

- Bill of Lading or Air Waybill

- RoHS/REACH Compliance Declaration

- Any required import permits or certifications (e.g., for EU or UK markets)

Verify tariff classifications (HS Code) — typically under 8536.90 or 8544.42 — to ensure correct duties and taxes.

Customs Clearance and Duties

Work with customs brokers to ensure smooth clearance. Confirm:

- Correct HS code for JST connectors

- Applicable duty rates and trade agreements (e.g., USMCA, ASEAN)

- Import restrictions or quotas (rare for connectors, but verify)

Maintain records of all compliance documentation for at least five years.

Storage and Handling

Store connectors in a clean, dry, temperature-controlled environment (10–30°C, 30–70% RH). Avoid exposure to dust, moisture, and direct sunlight. Handle with ESD-safe tools and grounding procedures to prevent damage.

Quality Assurance and Traceability

Implement a traceability system linking each batch of connectors to supplier records, inspection reports, and compliance certificates. Conduct incoming inspections to verify:

- Mechanical fit and dimensions

- Plating quality

- Correct polarity and pin configuration

- Absence of physical defects

Supplier and Supply Chain Management

Source JST connectors only from authorized distributors or certified suppliers to avoid counterfeits. Require suppliers to provide:

- Material Declarations (IMDS, if applicable)

- Test reports (e.g., insertion/withdrawal force, temperature rating)

- Conflict Minerals Reporting (per Dodd-Frank Act Section 1502, if applicable)

Regularly audit supplier compliance practices.

End-of-Life and Environmental Responsibility

Ensure connectors and associated products are designed for recyclability. Follow WEEE (Waste Electrical and Electronic Equipment) directives for proper disposal. Provide take-back or recycling options where required by law.

Summary

Proper logistics and compliance management for JST cable connectors ensures product reliability, regulatory adherence, and supply chain resilience. Maintain detailed documentation, choose reputable suppliers, and stay updated on evolving global standards.

Conclusion for Sourcing JST Cable Connectors:

After evaluating various suppliers, product specifications, pricing, and quality standards, it is evident that sourcing JST cable connectors requires a balanced approach focusing on reliability, compatibility, and cost-efficiency. JST connectors are critical components in many electronic applications due to their secure fit, durability, and standardized design. To ensure long-term performance and seamless integration, it is recommended to source connectors from reputable manufacturers or authorized distributors that adhere to international quality certifications (such as RoHS and UL).

Key considerations include matching the correct series (e.g., JST XH, PH, SH) to the application requirements, verifying pin count and pitch accuracy, and ensuring consistent material quality. While cost is a factor, compromising on quality can lead to higher failure rates and increased maintenance costs. Establishing relationships with reliable suppliers offering consistent lead times and strong technical support will contribute to supply chain stability.

In conclusion, a strategic sourcing approach—prioritizing quality, compatibility, and supplier credibility—will ensure optimal performance of JST cable connectors in end-use applications, supporting product reliability and customer satisfaction.