The global joint roller market is experiencing robust growth, driven by rising demand in pharmaceutical, food & beverage, and industrial manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global sealing solutions market—of which joint rollers are a critical component—is projected to grow at a CAGR of 5.8% from 2023 to 2028. Similarly, Grand View Research estimated in 2022 that the global gasket and sealing materials market would expand at a CAGR of 5.2% over the same timeframe, citing advancements in material technology and increasing regulatory emphasis on leak prevention and operational efficiency. As industries prioritize precision, durability, and compliance, the role of high-performance joint rollers has become increasingly central in rotary equipment applications. This growing demand has spurred innovation and competition among manufacturers worldwide. Based on market presence, product quality, technological advancement, and global reach, the following ten companies stand out as leaders in the design and production of joint rollers.

Top 10 Joint Roller Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Jeeter: #1 Pre

Domain Est. 2001

Website: jeeter.com

Key Highlights: Check Point. You must be “21” or older to access the website. Are you over 21 years of age? NOYES. This site uses cookies and by entering you acknowledge ……

#2 RAWling • RAWthentic Rolling Accessories from RAW Rolling Papers

Domain Est. 2004

Website: rawthentic.com

Key Highlights: Products on rawthentic.com are for informational purposes only. Visit the Buy RAW page to find a recommended retailer near you….

#3 Smoking Accessories

Domain Est. 2005

Website: daysavers.com

Key Highlights: From the Tumbleweed to the Ace Roller, we have a variety of joint rolling machines designed to help you roll your own joints and blunts faster than ever….

#4 Cookies

Domain Est. 2010

Website: cookies.co

Key Highlights: Bred at Cookies One Log, Fried Bananas is Now Available in 10+ states. RESERVE YOUR BATCH. Get Fried. Fried Bananas Swag Giveaway….

#5 King Rollers

Domain Est. 2012

Website: kingrollers.com

Key Highlights: Every cigarette, cigar and joint rolling machine is proudly handcrafted in-house from beautiful hardwoods with natural finishes. Our rollers are made in the USA ……

#6 Commercial Pre Roll Machines

Domain Est. 2017

Website: stmcanna.com

Key Highlights: RocketBox 2.0, a cutting-edge pre-roll machine, produces up to 453 pre-rolls in three minutes – offering speed and reliability unparalleled in the industry….

#7 The BEED Machine

Domain Est. 2018

Website: beed.co

Key Highlights: The first and only fully-automated appliance for producing a single fresh joint in 20 seconds. The BEED Machine extracts the contents of each BEED Capsule….

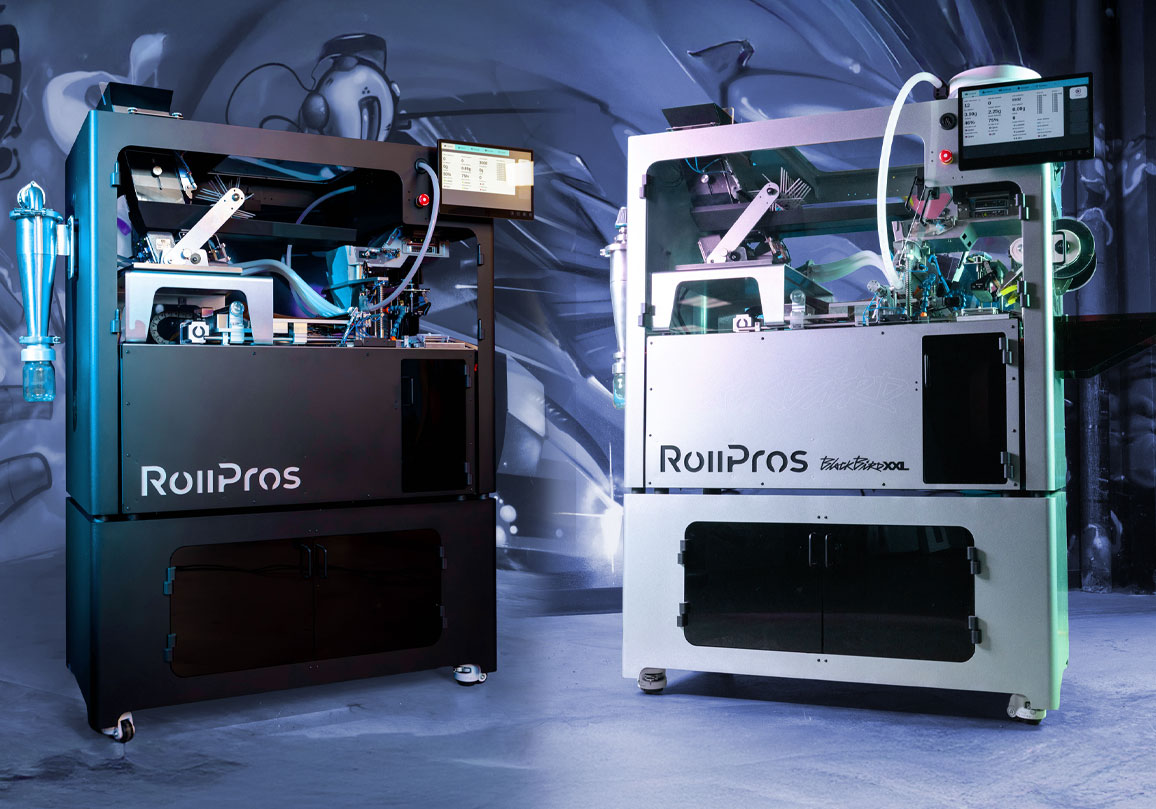

#8 RollPros: Automatic Pre Roll Machine

Domain Est. 2019

Website: rollpros.com

Key Highlights: The cannabis industry’s only automated pre-roll machine that rolls joints. See Our Complete Demo On-Demand. No sales, no hassle, just helpful….

#9 Modern Joint Roller Machine

Domain Est. 2021

Website: lacannapa.com

Key Highlights: Designed as an all-in-one joint roller and cone maker this vertical system lets you add in a pre-rolled cone and pack it tight with weed or tobacco seamlessly….

#10 DoinkRollerz Shop: DoinkRollerz™

Domain Est. 2022

Website: doinkrollerz.com

Key Highlights: Best joint roller machine & blunt roller machine. Rolls perfect joints & blunts in 8 seconds. Works with all rolling papers and wraps….

Expert Sourcing Insights for Joint Roller

H2 2026 Market Trends for Joint Roller

Based on current trajectories in health, wellness, and consumer behavior, the market for joint rollers (also known as massage guns, percussive therapy devices, or recovery tools) in the second half of 2026 is expected to be shaped by several key trends:

1. Mainstream Integration into Daily Wellness Routines

By H2 2026, joint rollers will have moved beyond fitness enthusiasts and athletes to become standard tools in general wellness regimens. Consumers will increasingly view them as essential for managing sedentary lifestyles, office-related stiffness, and age-related joint discomfort. Adoption will be driven by broader awareness of proactive pain management and musculoskeletal health.

2. Smart Technology and Personalization

Devices will feature advanced AI-driven personalization:

– Adaptive Intensity: Rollers will auto-adjust pressure and speed based on real-time muscle feedback via embedded sensors.

– App Integration: Enhanced companion apps will offer guided recovery programs, track usage patterns, and sync with wearables (e.g., Apple Watch, Whoop) to recommend sessions based on activity levels and recovery scores.

– Voice & Gesture Control: Integration with smart home systems and voice assistants for hands-free operation.

3. Focus on Ergonomics and Accessibility

Design innovation will prioritize usability for diverse populations:

– Ergonomic Redesigns: Lightweight, quieter models with improved grip and balance for easier use on hard-to-reach areas.

– Inclusivity: Devices tailored for seniors, individuals with arthritis, or limited mobility—featuring lower noise output, gentle modes, and simplified controls.

4. Sustainability and Ethical Manufacturing

Environmental consciousness will influence purchasing decisions:

– Eco-Materials: Use of recycled plastics, biodegradable packaging, and modular designs for easier repair and part replacement.

– Longevity & Repairability: Brands will emphasize durability and offer extended warranties, repair services, and software updates to reduce e-waste.

5. Expansion into Clinical and Therapeutic Settings

Joint rollers will gain credibility in medical and rehabilitation contexts:

– Partnerships with Physical Therapists: Devices may be prescribed or recommended as adjunct therapy for conditions like tendonitis, arthritis, or post-surgical recovery.

– Evidence-Based Marketing: Increased investment in clinical studies to validate efficacy, leading to stronger claims and insurance reimbursement potential in select markets.

6. Premiumization and Niche Market Growth

The market will segment into distinct tiers:

– Luxury Segment: High-end models with premium materials (e.g., wood finishes, custom engravings), silent motors, and concierge app support.

– Specialized Devices: Niche rollers designed for specific use cases—e.g., travel-friendly mini rollers, pet massage tools, or models optimized for facial/myofascial release.

7. Retail and Distribution Evolution

- Direct-to-Consumer (DTC) Dominance: Continued growth of DTC brands with subscription models (e.g., accessory bundles, guided therapy plans).

- Omnichannel Presence: Expansion into pharmacies, medical supply stores, and wellness boutiques, reflecting medical legitimacy.

Conclusion

By H2 2026, the joint roller market will be characterized by smarter, quieter, and more personalized devices integrated into holistic health ecosystems. Success will depend on innovation in tech, design, and sustainability, as well as expanded validation in clinical and everyday wellness contexts. Brands that prioritize user experience, inclusivity, and long-term health benefits will lead the market.

Common Pitfalls Sourcing Joint Roller (Quality, IP)

Sourcing a Joint Roller—particularly for applications in construction, manufacturing, or industrial maintenance—can present several challenges, especially concerning product quality and intellectual property (IP) considerations. Below are key pitfalls to avoid:

Quality-Related Pitfalls

Inconsistent Material Composition

Many low-cost Joint Rollers, especially those from unverified suppliers, use substandard materials such as low-grade steel or inferior rubber compounds. This leads to premature wear, reduced rolling efficiency, and potential failure under load. Always request material certifications and conduct third-party testing if volume sourcing.

Poor Manufacturing Tolerances

Joint Rollers require precise alignment and dimensional accuracy to function effectively. Suppliers from regions with lax quality control may deliver products with inconsistent diameters, misaligned bearings, or uneven surfaces. Insist on detailed engineering drawings and conduct incoming quality inspections.

Lack of Durability Testing

Reputable manufacturers perform load, fatigue, and environmental testing. Some suppliers may skip these steps to cut costs, resulting in rollers that degrade quickly under real-world conditions. Require test reports or conduct your own lifecycle assessments before large orders.

Inadequate Bearing Quality

The performance of a Joint Roller heavily depends on its internal bearings. Sourcing from suppliers who use counterfeit or low-grade bearings can result in increased friction, overheating, and early failure. Specify bearing standards (e.g., ISO, ABEC) and verify supplier sourcing practices.

Intellectual Property (IP) Pitfalls

Risk of IP Infringement

Some suppliers, particularly in regions with weak IP enforcement, may produce Joint Rollers that copy patented designs, logos, or proprietary engineering features. Sourcing such products—even unknowingly—can expose your company to legal liability, customs seizures, or reputational damage.

Counterfeit or “Clone” Products

Beware of suppliers offering “compatible” or “equivalent” Joint Rollers at suspiciously low prices. These may be illegal replicas of branded products. Always verify authenticity through trademarks, certification marks, and direct engagement with original equipment manufacturers (OEMs).

Lack of IP Documentation

Ensure suppliers can provide proof of IP ownership or licensing rights for the design and technology used. Absence of such documentation increases the risk of infringement and limits your ability to defend against third-party claims.

Grey Market Sourcing

Purchasing through unauthorized distributors may result in genuine products obtained through unofficial channels. While not always counterfeit, grey market items may lack warranty support and could still implicate your business in IP disputes if resale or integration into proprietary systems is involved.

Best Practices to Mitigate Risks

- Conduct thorough supplier audits, including on-site factory visits.

- Require material and performance certifications (e.g., ISO, RoHS, REACH).

- Include IP indemnification clauses in procurement contracts.

- Work with legal counsel to assess IP risks, especially when entering new markets.

- Establish long-term partnerships with transparent, certified manufacturers.

By addressing these quality and IP pitfalls proactively, businesses can ensure reliable performance, regulatory compliance, and legal protection when sourcing Joint Rollers.

Logistics & Compliance Guide for Joint Roller

Overview

This guide outlines the essential logistics and compliance considerations for the manufacturing, distribution, and sale of Joint Roller products. Adherence to these guidelines ensures regulatory compliance, supply chain efficiency, and consumer safety.

Regulatory Classification

Joint Roller products may be classified as dietary supplements, consumer goods, or medical devices depending on claims, ingredients, and intended use. Determine the appropriate regulatory category in each target market to ensure proper labeling, registration, and compliance.

Ingredient Sourcing & Quality Control

- Source raw materials from approved, audited suppliers adhering to Good Manufacturing Practices (GMP).

- Obtain Certificates of Analysis (CoA) for all ingredients to verify purity, potency, and absence of contaminants.

- Implement strict quality control protocols for incoming materials and finished goods.

Manufacturing Compliance

- Facilities must comply with relevant standards such as cGMP (current Good Manufacturing Practice) for dietary supplements (21 CFR Part 111) or ISO 13485 for medical devices.

- Maintain detailed batch records, production logs, and sanitation procedures.

- Conduct routine internal audits and facility inspections.

Labeling Requirements

- Ensure product labels include:

- Product name and brand

- Net quantity

- Ingredient list (in descending order)

- Manufacturer or distributor information

- Supplement facts panel (if applicable)

- Usage instructions and warnings

- Batch number and expiration date

- Avoid unsubstantiated health claims; comply with FDA, FTC, and local advertising regulations.

Packaging & Shelf Life

- Use tamper-evident, child-resistant packaging where required.

- Conduct stability testing to determine accurate expiration dates.

- Store products in climate-controlled environments to preserve integrity.

Import/Export Regulations

- Verify compliance with destination country regulations (e.g., FDA in the U.S., Health Canada, EU Novel Foods Regulation).

- Prepare accurate commercial invoices, packing lists, and certificates of origin.

- Ensure Harmonized System (HS) codes are correctly assigned for customs clearance.

Distribution & Inventory Management

- Partner with licensed, compliant logistics providers experienced in handling consumer health products.

- Implement a batch-tracking system for full traceability.

- Monitor inventory levels to prevent stockouts or expired goods.

Shipping & Transportation

- Use carriers compliant with temperature and handling requirements.

- Document shipping conditions (e.g., temperature logs) when necessary.

- Insure high-value shipments and maintain chain-of-custody records.

Recordkeeping & Documentation

- Retain manufacturing, testing, distribution, and complaint records for a minimum of 3–5 years (or as required by jurisdiction).

- Maintain up-to-date regulatory filings, licenses, and permits.

Adverse Event Reporting

- Establish a system to receive, document, and report adverse events related to product use.

- Comply with mandatory reporting timelines (e.g., FDA’s 15-day expedited reporting for serious events).

Recalls & Corrective Actions

- Develop a recall plan outlining procedures for product retrieval, notifications, and root cause analysis.

- Register with relevant authorities (e.g., FDA’s Reportable Food Registry) where applicable.

Training & Compliance Culture

- Train all staff on relevant regulations, GMP, and internal SOPs.

- Conduct regular compliance reviews and update policies as regulations evolve.

By following this guide, Joint Roller can ensure safe, legal, and efficient operations across its supply chain while maintaining consumer trust and regulatory compliance.

Conclusion for Sourcing a Joint Roller:

Sourcing a joint roller requires a balanced evaluation of product quality, cost-efficiency, supplier reliability, and compliance with industry standards. After assessing various suppliers and manufacturing options, it is evident that selecting a reputable manufacturer—whether domestic or international—should be based on consistent quality control, material safety, scalability, and after-sales support. Additionally, factors such as minimum order quantities, lead times, and customization capabilities play a crucial role in meeting specific business or operational needs.

Ultimately, establishing a long-term partnership with a trusted supplier ensures a steady supply of durable and efficient joint rollers, contributing to improved productivity, reduced downtime, and cost savings over time. Continuous monitoring of market trends and periodic supplier reviews will further enhance sourcing effectiveness and adaptability in a competitive environment.