The global jig making materials market is experiencing robust growth, driven by increasing demand for precision tooling across automotive, aerospace, and industrial manufacturing sectors. According to a report by Mordor Intelligence, the global precision tooling market is projected to grow at a CAGR of over 6.2% from 2023 to 2028, with jig and fixture components forming a critical segment. This expansion is fueled by the rising need for improved manufacturing efficiency, reduced production downtime, and tighter tolerances in high-mix, low-volume production environments. As industries continue to adopt advanced materials that offer superior wear resistance, dimensional stability, and longer service life, the role of specialized jig making material manufacturers becomes increasingly vital. The following list highlights the top 8 manufacturers leading innovation and market share in this evolving landscape, selected based on product breadth, material performance, global footprint, and technological advancement.

Top 8 Jig Making Materials Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

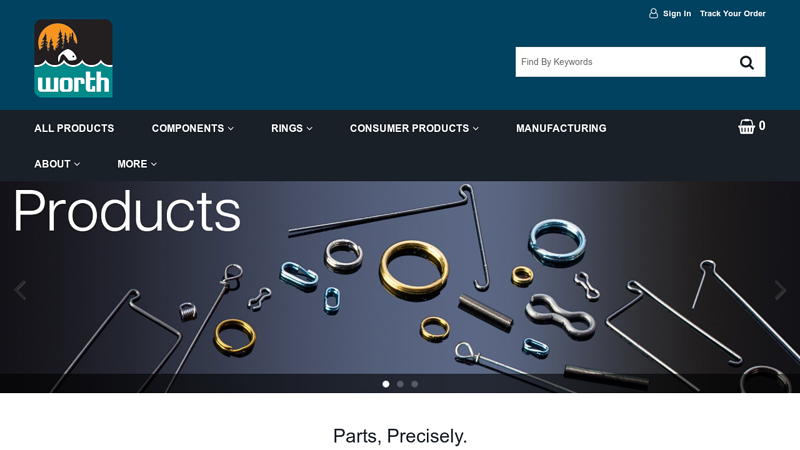

#1 The Worth Company

Domain Est. 1997

Website: worthco.com

Key Highlights: The leading original equipment manufacturer in fishing lure components and split rings. All of our components are made in the USA….

#2 Lure Making

Domain Est. 1997

#3 Lure Making Parts and Components Catalogue

Domain Est. 1998

Website: luremaking.com

Key Highlights: Canada’s only complete source for lure making components. Place your order during our business hours by calling 1-800-203-8427 orders only please!…

#4 Wholesale Tackle Supplies

Domain Est. 1999

Website: hagensfish.com

Key Highlights: Hagen’s Fish offers bulk baits, tackle, and fishing components for bait shops and DIY tackle makers. Discount fishing gear Made in the USA!…

#5 JB Lures

Domain Est. 2000

Website: jblures.com

Key Highlights: Free delivery over $75The Heavy Metal Tungsten Jig offers unmatched sensitivity and a fast fall rate, making it a top choice for anglers using live sonar. SHOP NOW….

#6 Spike

Domain Est. 2002

Website: ispikeit.com

Key Highlights: 2–5 day delivery 15-day returnsOur extensive variety of products includes tournament strength aerosol attractants, scented dye markers, soft plastic lures, paints and powder coats …

#7 Make Lure

Domain Est. 2009

Website: makelure.com

Key Highlights: Make your own custom lures. Design. Create. Mold. Cast. Shop here. Starter kits $99.95. Everything you need for making your first fishing lure….

#8 BOSS Outdoors

Domain Est. 2007

Website: fishboss.com

Key Highlights: Make your own custom skirted bass jigs. Working with top pros and pioneers of jig-fishing, BOSS Outdoors has created an unmatched offering of Jig Heads….

Expert Sourcing Insights for Jig Making Materials

2026 Market Trends for Jig Making Materials

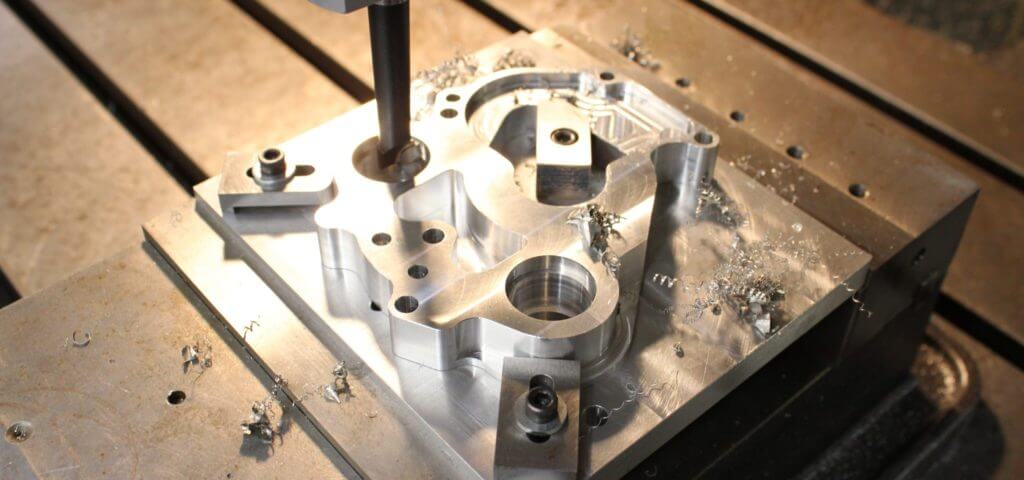

The global market for jig making materials is poised for steady evolution by 2026, driven by advancements in manufacturing technologies, shifting industrial demands, and a growing emphasis on efficiency and precision. Key trends shaping this specialized segment include:

1. Rising Demand for High-Performance Materials:

Traditional materials like mild steel and aluminum will remain foundational, but demand for advanced composites, high-strength alloys, and specialized polymers is accelerating. Manufacturers increasingly seek materials offering superior strength-to-weight ratios, enhanced wear resistance, and dimensional stability under thermal cycling. Carbon fiber-reinforced polymers (CFRPs) and high-performance thermoplastics like PEEK are gaining traction, particularly in aerospace and automotive sectors where weight reduction and precision are critical.

2. Integration with Automation and Industry 4.0:

The proliferation of automated assembly lines, robotics, and smart manufacturing is reshaping jig design and material requirements. Jigs must now accommodate sensors, be compatible with robotic handling, and maintain micron-level accuracy over extended cycles. This drives demand for materials that are not only durable but also non-conductive, non-magnetic, and capable of integrating seamlessly with digital monitoring systems. Materials enabling rapid prototyping—such as engineering-grade 3D printing resins—are also becoming essential for agile jig development.

3. Sustainability and Material Efficiency Gains Prominence:

Environmental regulations and corporate sustainability goals are pushing manufacturers toward recyclable, low-impact materials. Aluminum, already valued for its machinability and lightweight properties, benefits further from its high recyclability. Biodegradable or bio-based polymers may begin to appear in low-stress jig applications. Additionally, material-efficient design practices—such as topology-optimized structures made possible by additive manufacturing—are reducing waste and lifecycle costs.

4. Regional Manufacturing Shifts Influence Supply Chains:

Geopolitical dynamics and supply chain resilience efforts are leading to nearshoring and regionalization of manufacturing. This impacts the sourcing and availability of jig making materials, increasing demand for localized material suppliers and driving innovation in regional material production. Asia-Pacific, particularly India and Vietnam, is expected to see heightened activity in jig material consumption due to expanding industrial bases.

5. Customization and Rapid Prototyping Drive Material Innovation:

The need for faster time-to-market is fueling adoption of rapid tooling techniques. Additive manufacturing (3D printing) using metal powders and high-temperature resins allows for complex, lightweight jig geometries that were previously unfeasible. This trend supports the growth of specialized materials tailored for additive processes, such as aluminum-silicon alloys and reinforced photopolymers, enabling on-demand, low-volume jig production.

In conclusion, the 2026 jig making materials market will be characterized by a blend of traditional reliability and cutting-edge innovation. Success will depend on material suppliers’ ability to deliver solutions that meet escalating demands for precision, durability, sustainability, and compatibility with smart manufacturing ecosystems.

Common Pitfalls in Sourcing Jig Making Materials: Quality and Intellectual Property Concerns

When sourcing materials for jig making—critical tools used to guide cutting, machining, or assembly processes—two major areas of risk are material quality inconsistencies and intellectual property (IP) vulnerabilities. Overlooking these can lead to production delays, compromised product accuracy, legal disputes, and damage to brand reputation.

Inconsistent Material Quality

One of the most frequent challenges is receiving materials that do not meet the required specifications for precision, durability, or performance. Poor-quality metals, plastics, or composites can deform under stress, wear quickly, or fail to maintain dimensional accuracy, ultimately affecting the consistency and quality of the final manufactured parts.

Common quality-related issues include:

– Non-compliance with material standards (e.g., using sub-grade aluminum or steel not meeting ASTM or ISO specifications).

– Variability in hardness, grain structure, or thermal stability, especially with recycled or uncertified materials.

– Poor surface finish or internal defects (such as voids or inclusions) that compromise jig integrity.

– Inadequate documentation or traceability, making it difficult to verify material origin or performance history.

To mitigate these risks, establish strict supplier qualification processes, request material test reports (MTRs), and conduct incoming inspections or third-party testing when necessary.

Intellectual Property Exposure

Jig designs often contain proprietary information and represent significant engineering investment. When sourcing materials—especially when working with external suppliers or contract manufacturers—there is a risk of unintentional IP leakage or unauthorized use of design data.

Key IP pitfalls include:

– Sharing detailed design files without proper non-disclosure agreements (NDAs), potentially exposing sensitive geometries or manufacturing methods.

– Using suppliers who lack robust data security protocols, increasing the risk of design theft or unauthorized replication.

– Ambiguity in ownership rights when suppliers contribute to jig design or suggest material substitutions that incorporate their own IP.

– Cross-border sourcing risks, where differing IP laws in foreign jurisdictions may offer weaker protection.

To safeguard IP, ensure all partners sign comprehensive NDAs, limit design data access to only what is necessary, clearly define IP ownership in contracts, and consider working with suppliers certified in data protection standards.

By addressing both material quality and IP concerns proactively, organizations can ensure reliable, secure, and cost-effective jig production.

Logistics & Compliance Guide for Jig Making Materials

This guide outlines key considerations for the safe, efficient, and compliant transportation, handling, and use of materials commonly used in jig and fixture manufacturing.

Material Classification and Handling Requirements

Identify and categorize all materials based on their physical and chemical properties. Common jig-making materials such as steel, aluminum, plastics (e.g., Delrin, acrylic), adhesives, and coatings may have unique handling needs. Ensure proper labeling, segregation, and storage conditions (e.g., dry, temperature-controlled) to prevent degradation or contamination. Use appropriate lifting equipment for heavy metal stock and protective coverings to avoid scratches or warping.

Transportation and Packaging Standards

Package materials to prevent damage during transit. Use wooden crates, edge protectors, and void fill for metal components; anti-static bags for sensitive polymers. Secure loads to prevent shifting. Follow carrier-specific regulations for weight, dimensions, and hazardous classifications. For international shipments, ensure compliance with ISPM 15 for wooden packaging materials.

Regulatory Compliance (OSHA, EPA, REACH, RoHS)

Verify that all materials comply with relevant regional and international regulations:

– OSHA (U.S.): Ensure Safety Data Sheets (SDS) are available for all chemicals and composite materials; implement hazard communication (HazCom) programs.

– EPA (U.S.): Comply with rules on volatile organic compounds (VOCs) in adhesives or coatings.

– REACH (EU): Confirm registration and safe use of chemical substances in imported raw materials.

– RoHS (EU): Ensure materials do not contain restricted hazardous substances, especially if jigs are used in electronics manufacturing.

Import/Export Documentation and Duties

Prepare accurate documentation for cross-border shipments, including commercial invoices, packing lists, and certificates of origin. Classify materials using correct HS (Harmonized System) codes to determine duty rates. Be aware of export controls on dual-use materials or technologies that may require licenses.

Storage and Inventory Management

Store materials according to manufacturer recommendations and regulatory requirements. Flammable adhesives or solvents must be kept in approved safety cabinets, away from ignition sources. Implement a first-in, first-out (FIFO) system to prevent material obsolescence. Conduct regular audits to maintain inventory accuracy and identify expired or compromised supplies.

Waste Disposal and Environmental Responsibility

Develop procedures for responsible disposal of scrap metal, plastic offcuts, and chemical waste. Recycle metal turnings and polymer remnants where possible. Dispose of hazardous waste (e.g., used solvents, contaminated rags) through licensed facilities in accordance with local environmental regulations. Maintain disposal records for compliance audits.

Supplier Conformity and Traceability

Require suppliers to provide material test reports (MTRs), compliance certificates, and traceable batch/lot numbers. Establish vendor qualification processes to ensure consistent quality and regulatory adherence. Maintain a documented supply chain for audit readiness and quality control.

Workplace Safety and Training

Train personnel on safe handling, storage, and emergency response procedures for all jig-making materials. Provide appropriate personal protective equipment (PPE), such as gloves, goggles, and respirators when working with fine particulates or chemicals. Conduct regular safety drills and maintain up-to-date SDS accessible to all employees.

Conclusion for Sourcing Jig Making Materials:

Sourcing materials for jig making requires a careful balance between quality, cost, availability, and suitability for the intended application. Selecting the right materials—such as aluminum, steel, plastics like Delrin, or composite materials—depends on factors including durability, dimensional stability, ease of machining, and resistance to wear. Reliable suppliers and consistent material specifications are essential to ensure precision and repeatability in jig performance. Establishing strong relationships with trusted vendors, evaluating lead times, and considering long-term supply chain stability further contribute to efficient production. Ultimately, a well-planned sourcing strategy not only enhances the functionality and longevity of jigs but also supports overall manufacturing efficiency, reduces downtime, and improves product quality.