The global demand for durable liquid storage and dispensing solutions has driven steady growth in the jerry can and spout manufacturing sector. According to Grand View Research, the global plastic containers market—encompassing jerry cans and related accessories—was valued at USD 120.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030, fueled by rising needs in automotive, agriculture, and industrial applications. Additionally, Mordor Intelligence projects continued market expansion due to increased focus on portable fuel and water storage in both emerging economies and emergency preparedness sectors. With durability, leak-proof design, and material safety becoming critical selection criteria, manufacturers are innovating to meet stringent international standards. In this evolving landscape, we highlight the top 9 jerry can and spout manufacturers leading the market through quality, scalability, and technological advancement.

Top 9 Jerry Can And Spout Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Overland Fuel

Website: overlandfuel.eu

Key Highlights: We are the OEM manufacturer of overland fuel and water Jerry cans for the adventure and specialist market. We proudly produce the Elephant Brand the toughest ……

#2 Metal Safety Cans for Flammable Liquids & Gas

Website: eagle.justrite.com

Key Highlights: 30-day returnsEagle can provide your job site, shop, or factory with OSHA approved safety cans for the dispensing or disposal of flammable liquids….

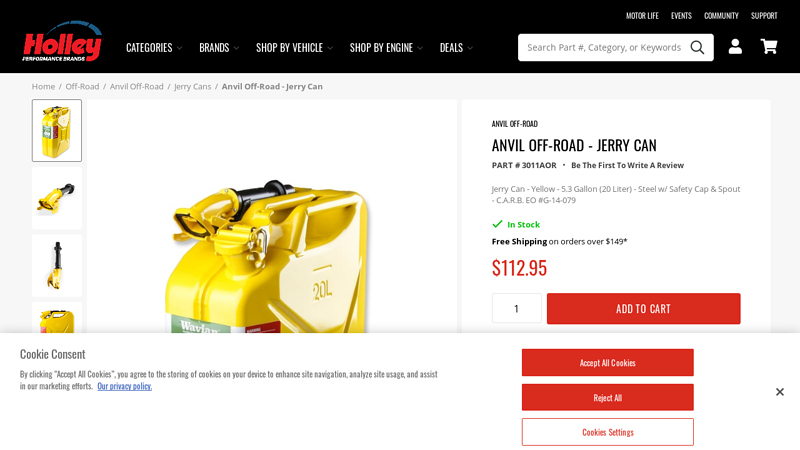

#3 Anvil Off

Domain Est. 1995

Website: holley.com

Key Highlights: In stock Rating 5.0 2 Highest Quality Jerry Can on the Market; Ideal for Use w/ Gasoline, Diesel Fuel, or Kerosene; Steel Thickness 0.035″. About Anvil Off-Road. Shop the officia…

#4 Jerry Can

Domain Est. 1998

Website: jerrycan.com

Key Highlights: Free delivery 14-day returnsJerry Can (In Stock & Free Shipping) carry certificates recognized throughout the European Union. Suitable for NATO missions….

#5 MIDWEST CAN

Domain Est. 1999

Website: midwestcan.com

Key Highlights: Midwest Can is an industry-leading expert in the safe handling, transportation, & storing of flammable liquids. Your safety is our priority….

#6 Jerry Can Spout

Domain Est. 2000

Website: ruggedridge.com

Key Highlights: In stock Free deliveryEach spout features all steel construction, flexible design, a locking base plate for secure attachment and is designed to work with our Metal Jerry Cans….

#7 The Jerry Can

Domain Est. 2008

Website: priorityplastics.com

Key Highlights: These more modern variations are lighter, cheaper and more durable than jerry cans. They’re just as easy to open, close and carry and even easier to love….

#8 Nato Jerry Cans that are built to last …

Domain Est. 2009

Website: lexingtoncontainercompany.com

Key Highlights: Nato jerry can by Valpro/Wavian are the world’s best jerry can that money can buy, own one of the most durable nato fuel cans on the global market!…

#9 Wavian NATO Steel Jerry Can YELLOW

Domain Est. 2018

Expert Sourcing Insights for Jerry Can And Spout

2026 Market Trends for Jerry Cans and Spouts

The global market for jerry cans and spouts is poised for significant evolution by 2026, driven by regulatory shifts, sustainability imperatives, technological advancements, and changing end-user demands across industrial, automotive, agricultural, and consumer sectors. Key trends shaping this market include:

Increasing Demand for Sustainable and Recyclable Materials

Environmental regulations, particularly in Europe and North America, are accelerating the shift away from single-use plastics. By 2026, manufacturers are expected to prioritize HDPE (High-Density Polyethylene) and other recyclable polymers that comply with circular economy standards. Biodegradable or bio-based plastic alternatives may begin entering niche markets, especially in agricultural and consumer-grade products. The integration of post-consumer recycled (PCR) content in jerry cans is anticipated to become a competitive differentiator, driven by corporate sustainability goals and consumer preference for eco-friendly packaging.

Technological Innovations in Spout Design and Safety Features

Spout technology is advancing to enhance user safety, reduce spillage, and improve fluid control. By 2026, smart spouts with integrated flow regulators, automatic shut-off valves, and child-resistant mechanisms will gain traction, particularly in fuel and chemical handling. Anti-siphon and vapor recovery spouts are expected to see wider adoption in response to environmental and safety regulations. Additionally, ergonomic designs that reduce user fatigue and improve pouring accuracy will be increasingly demanded in both industrial and retail applications.

Growth in Emerging Markets and Industrial Applications

Developing economies in Asia-Pacific, Africa, and Latin America will drive volume growth due to expanding infrastructure, agriculture, and off-grid energy use. Jerry cans remain vital for fuel and water transport in regions with limited distribution networks. By 2026, demand in these regions will be fueled by urbanization and the need for portable liquid storage, particularly in backup power systems using diesel or biofuels. Industrial users, including construction and mining sectors, will demand high-capacity, durable jerry cans with UN-certified ratings for transporting hazardous materials.

Regulatory Pressures and Standardization

Stringent global regulations on fuel storage and transport—such as the EU’s Directive on Fuel Storage and OSHA/UN standards—will continue to influence product design. By 2026, compliance with UN 1H2 testing standards for hazardous goods will be a baseline requirement in many markets. Governments may introduce labeling mandates, tamper-evident features, and restrictions on non-vented or non-approved spouts to reduce fire hazards and environmental contamination. These regulations will favor established manufacturers with certification capabilities, potentially consolidating market share.

E-Commerce and Direct-to-Consumer Sales Expansion

The rise of online B2B and B2C platforms will reshape distribution channels. By 2026, brands offering customizable, drop-shipped jerry cans with branded spouts will gain competitive advantage. Enhanced product visualization, compatibility filters (e.g., fuel type, capacity), and subscription models for replacement spouts could emerge as value-added services. This trend will increase demand for lightweight, stackable, and durable designs suitable for shipping and home use.

Integration with Smart Monitoring Systems (Niche but Emerging)

While still in early stages, a nascent trend involves smart jerry cans equipped with IoT-enabled spouts that monitor fluid levels, detect leaks, or log usage data. By 2026, these solutions may find applications in fleet management, emergency response, and precision agriculture, offering data-driven insights for efficiency and safety. Though limited to premium segments, this innovation signals a long-term shift toward connected liquid storage.

In conclusion, the 2026 jerry can and spout market will be defined by sustainability, safety, and smart functionality. Companies that invest in eco-design, regulatory compliance, and user-centric innovation will be best positioned to capture growing demand across diverse global markets.

Common Pitfalls When Sourcing Jerry Cans and Spouts (Quality and Intellectual Property)

Sourcing jerry cans and spouts—especially for fuel, water, or industrial use—requires careful attention to both quality standards and intellectual property (IP) risks. Overlooking these aspects can lead to safety hazards, compliance failures, and legal disputes. Below are key pitfalls to avoid.

Poor Material Quality and Durability

One of the most frequent issues is receiving jerry cans made from substandard materials. Low-quality HDPE (High-Density Polyethylene) or inferior metal alloys can lead to cracking, leakage, or degradation when exposed to UV light, extreme temperatures, or certain chemicals. This compromises user safety and product lifespan, especially in rugged environments.

Inadequate Sealing and Leak-Prone Spouts

Spouts that do not form airtight or watertight seals can result in spills, evaporation, or contamination. Poorly designed or manufactured spouts may lack proper threading, gaskets, or locking mechanisms. This not only affects functionality but may also violate transportation regulations for flammable liquids.

Non-Compliance with Safety and Regulatory Standards

Many sourced jerry cans fail to meet international safety standards such as UN certification (e.g., UN 1H1/Y), ISO 10564 for fuel cans, or EPA and CARB emissions requirements in the U.S. Using non-compliant products can lead to rejected shipments, customs delays, or liability in case of accidents.

Counterfeit or IP-Infringing Designs

Popular jerry can designs—such as the iconic German WWII-era shape or branded versions like those from Gerald or Reliance—are often protected by trademarks, design patents, or utility patents. Sourcing look-alike products from suppliers who replicate these designs without authorization exposes buyers to intellectual property infringement claims, product seizures, or lawsuits.

Lack of Traceability and Manufacturer Credibility

Suppliers may provide limited information about manufacturing processes, material sourcing, or quality control procedures. Without traceability, it’s difficult to verify compliance or address issues during audits, recalls, or warranty claims. Relying on unvetted manufacturers increases the risk of receiving inconsistent or unsafe products.

Inconsistent Production Quality

Especially with low-cost overseas suppliers, batch-to-batch inconsistencies in wall thickness, spout alignment, or closure tightness are common. Without rigorous incoming inspections or third-party quality audits, these variations may go unnoticed until they cause field failures.

Overlooking Environmental and Recycling Considerations

Some jerry cans are not designed for recyclability or may contain restricted substances (e.g., phthalates, heavy metals). Sourcing non-compliant products can conflict with environmental regulations like RoHS or REACH, particularly in European markets.

Failure to Secure IP Rights for Custom Designs

If you develop a proprietary jerry can or spout design, failing to file for patents or design protection leaves your innovation vulnerable. Suppliers in some regions may reverse-engineer and resell your design without permission, undercutting your market position.

Conclusion

To mitigate these risks, conduct thorough due diligence on suppliers, demand compliance certifications, perform product testing, and consult legal experts on IP matters. Investing in quality and IP protection upfront prevents costly disruptions and protects your brand reputation.

Logistics & Compliance Guide for Jerry Can and Spout

Product Overview

Jerry cans and spouts are widely used for the safe storage and transportation of liquids, including fuels, water, chemicals, and food-grade substances. Ensuring proper logistics handling and compliance with regulatory standards is essential to maintain safety, prevent contamination, and meet international and local requirements.

Regulatory Compliance

Compliance with regional and international regulations is mandatory for manufacturing, transporting, and selling jerry cans and spouts. Key regulations include:

– UN Certification (e.g., UN 1A1/Y): Required for the transport of hazardous liquids. Jerry cans must pass drop tests, stacking tests, and pressure tests.

– REACH and RoHS (EU): Ensure materials used in production (especially plastics and metal components) are free from restricted substances.

– FDA Compliance (USA): Necessary for jerry cans and spouts intended for food or beverage storage. Materials must be food-grade and non-toxic.

– EPA and DOT Regulations (USA): Govern the transport of flammable or hazardous materials; include labeling, spill containment, and vapor emission standards.

– ISO Standards: ISO 10565 (spout performance), ISO 9001 (quality management), and ISO 14001 (environmental management) may apply depending on use case.

Material and Construction Standards

- Plastic Jerry Cans: Typically made from HDPE (High-Density Polyethylene). Must be resistant to UV exposure, impact, and chemical degradation.

- Metal Cans: Often constructed from steel or aluminum; require corrosion-resistant coatings.

- Spouts: Must ensure leak-proof sealing, controlled dispensing, and compatibility with container necks (e.g., 58mm or 60mm screw threads). Materials should be chemically inert and durable.

Labeling and Marking Requirements

- UN Markings: Include UN model number, manufacturer ID, year and country of manufacture, and liquid density rating (e.g., “Y” for up to 1.8 specific gravity).

- Hazard Labels: Required for dangerous goods (e.g., flammable, corrosive) per GHS (Globally Harmonized System).

- Content Identification: Clear indication of contents, capacity, material type, and safety warnings (e.g., “Flammable – Keep Away from Heat”).

- Recycling Symbols: Resin identification code (e.g., “2” for HDPE) must be displayed on plastic components.

Packaging and Storage

- Unit Load Configuration: Jerry cans should be packed in sturdy corrugated boxes or on pallets with edge protectors to prevent damage during transit.

- Stacking Limits: Adhere to manufacturer’s maximum stacking height under load to avoid can deformation or collapse.

- Storage Conditions: Store in dry, cool, shaded areas away from direct sunlight and extreme temperatures. Avoid contact with corrosive substances.

Transportation Guidelines

- Domestic and International Shipping:

- For hazardous materials, follow IATA (air), IMDG (sea), or ADR (road) regulations based on transport mode.

- Use certified packaging and provide Safety Data Sheets (SDS) when required.

- Non-Hazardous Liquids: Use secure load restraint methods to prevent shifting or tipping during transport.

- Temperature Sensitivity: Monitor conditions if transporting temperature-sensitive contents (e.g., food-grade liquids).

Leak Prevention and Spill Management

- Spout Design: Incorporate child-resistant, drip-free, and vented spouts where appropriate.

- Sealing Integrity: Ensure gaskets or O-rings are properly installed and tested for pressure and vacuum resistance.

- Spill Kits: For bulk shipments of hazardous liquids, include absorbent materials and containment tools at the delivery site.

Environmental and Sustainability Compliance

- Recyclability: Design for disassembly; use mono-materials where possible.

- End-of-Life Management: Comply with extended producer responsibility (EPR) laws in applicable regions.

- Carbon Footprint: Optimize logistics routes and packaging size to reduce emissions.

Quality Assurance and Testing

- Routine Testing: Conduct periodic drop tests, pressure tests, and seal integrity checks.

- Batch Traceability: Maintain records of material batches, production dates, and test results.

- Third-Party Certification: Obtain independent verification for compliance with UN, FDA, or ISO standards.

Import/Export Documentation

- Commercial Invoice and Packing List: Accurately list product description, quantity, weight, and value.

- Certificate of Compliance: Required for entry into many countries; may include test reports or conformity declarations.

- Customs Classification: Use correct HS codes (e.g., 3923.29 for plastic jerry cans, 7310.29 for metal cans).

Conclusion

Adhering to logistics and compliance standards ensures the safe, legal, and efficient distribution of jerry cans and spouts. Regular audits, staff training, and staying updated with regulatory changes are critical for maintaining compliance across global supply chains.

Conclusion on Sourcing Jerry Cans and Spouts

In conclusion, sourcing jerry cans and spouts requires a strategic approach that balances quality, cost, compliance, and reliability. These essential containers and dispensing components are widely used across industries such as agriculture, automotive, chemical, and humanitarian aid, making it crucial to select suppliers that meet technical specifications, safety standards, and environmental regulations.

Key considerations in the sourcing process include material durability (typically HDPE for cans and food-grade or chemical-resistant materials for spouts), leak-proof design, ease of use, and compliance with international standards such as ISO, UN certification for hazardous materials, or FDA approval where applicable. Additionally, evaluating supplier credibility, production capacity, and logistical capabilities ensures consistent supply and minimizes disruption.

Sustainable sourcing practices—such as opting for recyclable materials and suppliers with environmentally responsible manufacturing processes—are increasingly important in today’s market. Building long-term partnerships with vetted suppliers, conducting regular quality audits, and staying informed on market trends and regulatory changes will further enhance sourcing effectiveness.

Ultimately, a well-executed sourcing strategy for jerry cans and spouts supports operational efficiency, product safety, and sustainability goals, delivering value across the supply chain.