The global hand tools market, driven by growing demand in construction, woodworking, and DIY sectors, is projected to expand at a CAGR of 4.8% from 2023 to 2030, according to Grand View Research. Within this landscape, Japan has maintained a revered position in the production of high-precision woodworking chisels, where craftsmanship converges with advanced metallurgy. Known for their razor-sharp edges, exceptional durability, and hand-forged quality, Japanese chisels are preferred by artisans and professional woodworkers worldwide. With the Asia Pacific region expected to dominate market growth—fueled by manufacturing excellence and rising demand for premium tools (Mordor Intelligence, 2023)—Japanese chisel manufacturers continue to set industry benchmarks. This list highlights the top eight Japanese companies leading innovation, quality, and global reputation in woodworking chisel manufacturing.

Top 8 Japanese Woodworking Chisels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Michihamono

Domain Est. 2022

Website: michihamono.com

Key Highlights: Michihamono is a carving-knife manufacturer with a long history, located in Miki City, Hyogo Prefecture, known as the home of blade-making in Japan….

#2 Takagi – Quality Japanese saws

Domain Est. 1998

Website: forezienne.com

Key Highlights: Takagi is a Japanese company specializing in the manufacture of hand tools for woodworking, combining traditional craftsmanship with modern technologies….

#3 Kazu Japanese Chisels

Domain Est. 1998

Website: woodpeck.com

Key Highlights: 1-day delivery 30-day returnsKazu (meaning harmony) are made by the famous Fujikawa makers in Miki City, Japan. The chisels are forged using white paper steel laminated to a wrough…

#4 Mikisyo

Domain Est. 2011

Website: goodsjapan.com

Key Highlights: 15-day returnsMikisyo Power Grip Japanese Wood Carving Tool 7.5mm Woodcarving Round U Gouge Chisel, with Wooden Handle, to Carve Grooves in Woodworking…

#5 Wood Chisels

Domain Est. 2017

Website: suizan.net

Key Highlights: SUIZAN Japanese Wood Chisel 11/16 Inch (18mm) Professional Wood Chisels for Woodworking Oire Nomi Model: WC-005…

#6 Covington & Sons Tools

Domain Est. 2019

Website: covingtonandsons.com

Key Highlights: Covington & Sons Tools – Information about using and maintaining woodworking tools, especially Japanese chisels, planes and handsaws….

#7 Japanese Wood Chisel Sets (1, 3 or 6 pieces)

Domain Est. 2021

Website: kakuritools.com

Key Highlights: At Kakuri, our Japanese chisels are manufactured by joining soft and hard steel, making it easy to sharpen and providing a durable cutting edge. We also make ……

#8 Osaka tools Best japanese tools directly from Japan at best prices …

Domain Est. 2018

Website: osakatools.com

Key Highlights: High quality tools for woodworking directly from Japan at best prices. Saws, Kataba, Dozuki chisels, hand plane, knives, whetstones, waterstones, ……

Expert Sourcing Insights for Japanese Woodworking Chisels

2026 Market Trends for Japanese Woodworking Chisels

Growing Global Demand for Precision and Craftsmanship

By 2026, the international market for Japanese woodworking chisels is expected to expand significantly, driven by a rising appreciation for hand tool craftsmanship and precision in fine woodworking. Woodworkers in North America, Europe, and Australia are increasingly seeking high-quality, hand-forged tools that offer superior edge retention and accuracy—hallmarks of traditional Japanese chisels. This demand is fueled by the global maker movement, the resurgence of artisanal furniture, and the popularity of content creators showcasing hand-tool woodworking on digital platforms.

Increased Adoption of Hybrid Manufacturing Techniques

While traditional forging methods remain central to premium brands like Marples, Kanna, and Masamoto, more manufacturers are integrating modern CNC finishing and heat-treatment processes to improve consistency and scalability. By 2026, expect a rise in hybrid production models that preserve the integrity of Japanese blade geometry while enhancing durability and reducing production costs—making high-performance chisels more accessible to intermediate and hobbyist woodworkers.

Expansion of E-Commerce and Direct-to-Consumer Channels

Online sales of Japanese chisels will continue to grow, with specialized retailers and brand-owned websites offering global shipping, detailed product education, and bundled tool kits. By 2026, augmented reality (AR) product previews and AI-driven tool recommendations may become common, helping buyers choose the right chisel type (e.g., atsuo, sho, or naka) based on their project needs and skill level.

Sustainability and Ethical Sourcing as Key Purchase Drivers

Environmental consciousness is shaping purchasing decisions. Leading Japanese chisel makers are emphasizing sustainable steel sourcing, reduced carbon footprints in forging, and long product lifecycles—aligning with circular economy principles. By 2026, certifications related to ethical manufacturing and material traceability are likely to influence brand loyalty, particularly among younger, eco-conscious woodworkers.

Rising Competition from Premium Domestic Brands

As demand grows, Western manufacturers are developing chisels inspired by Japanese design, often at lower price points. However, authentic Japanese brands maintain a competitive edge through heritage, superior laminated steel construction (e.g., honyaki and san mai), and brand authenticity. In 2026, the market will likely see niche differentiation, with traditional artisans targeting purists and newer entrants focusing on ergonomics and beginner accessibility.

Integration with Digital Woodworking Communities

Social media, YouTube tutorials, and online forums will continue to drive awareness and education about Japanese chisels. By 2026, brands may partner with influencers to launch limited-edition tools or host virtual sharpening workshops, strengthening community engagement and fostering brand advocacy among both novice and expert users.

Common Pitfalls When Sourcing Japanese Woodworking Chisels (Quality and Intellectual Property)

Sourcing authentic, high-quality Japanese woodworking chisels can be challenging, especially for buyers unfamiliar with traditional Japanese toolmaking. Avoiding common pitfalls related to quality and intellectual property (IP) is crucial to ensure you receive durable, functional tools and support ethical craftsmanship.

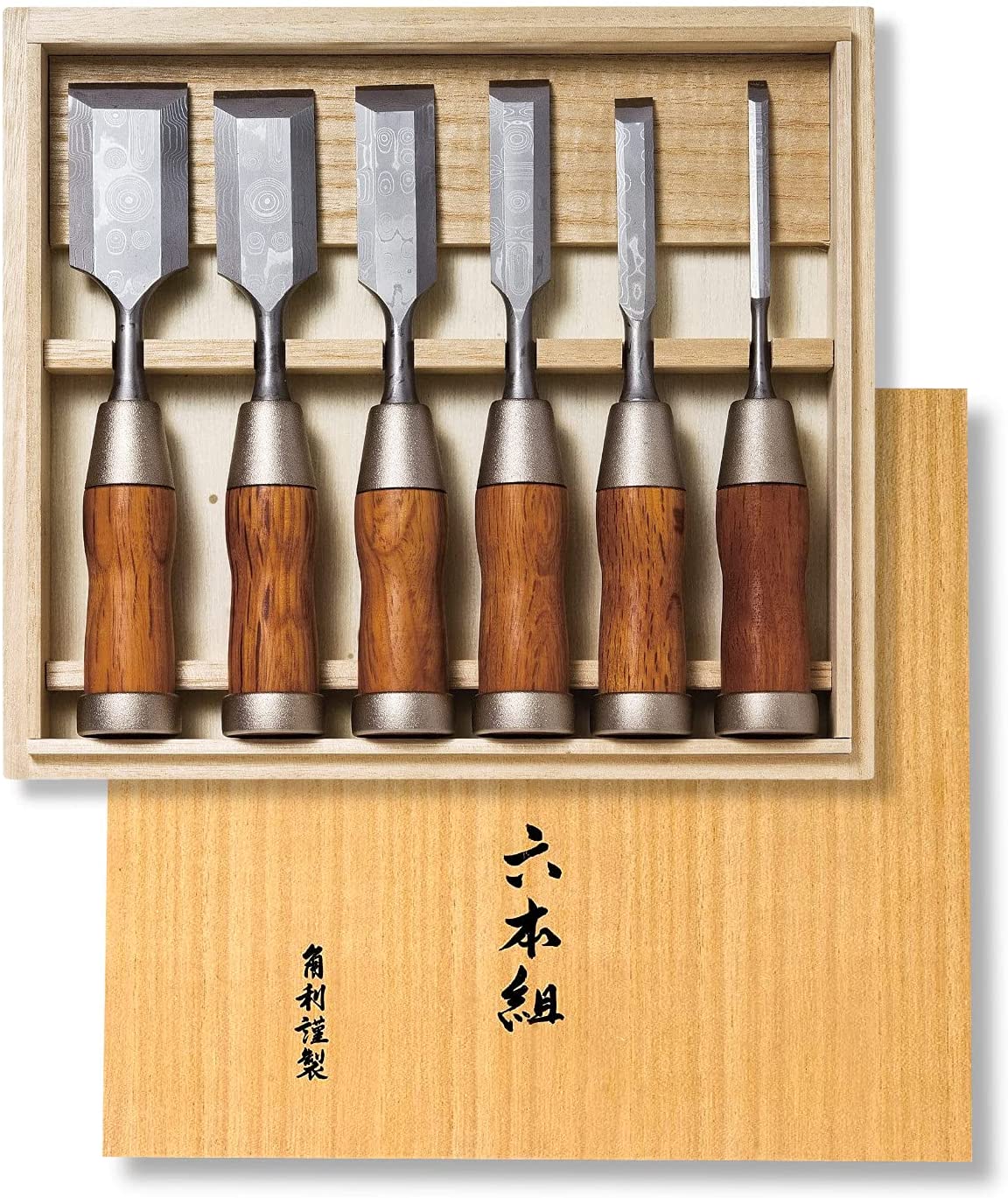

Misidentifying Quality Based on Aesthetics Alone

Many buyers are drawn to the elegant appearance of Japanese chisels—polished blades, beautiful laminated steel patterns, and ornate handles. However, appearance does not guarantee performance. Low-cost imitations often mimic the look of premium chisels using inferior materials and construction methods. For example, some mass-produced chisels use soft or improperly heat-treated steel that dulls quickly or chips under stress. Always prioritize information about steel type (e.g., white paper steel, blue paper steel), heat treatment process, and maker reputation over visual appeal.

Overlooking the Importance of Forged vs. Stamped Blades

Authentic Japanese chisels are traditionally forged, involving skilled blacksmithing techniques that enhance grain structure and durability. A major quality pitfall is purchasing stamped or machine-cut blades marketed as “hand-forged.” These tools lack the integrity and longevity of true forged chisels. Verify the manufacturing process—reputable makers clearly state whether blades are forged and often provide insight into their craftsmanship. Tools made in industrial settings without artisan oversight typically compromise on performance and lifespan.

Confusing Brand Names and Counterfeit Products

The market is flooded with chisels bearing names similar to renowned Japanese makers such as Kanna, Masayoshi, or Tsuji. Some vendors sell counterfeit or counterfeit-style tools that infringe on established brand identities. These fakes often misrepresent country of origin (e.g., labeled as “Made in Japan” when produced in China) and mimic logos or packaging. This not only undermines quality but also raises intellectual property concerns. Always purchase from authorized dealers or directly from the maker’s official channels to avoid IP violations and ensure authenticity.

Ignoring Regional and Maker-Specific Trademarks

Japan has strict geographical indications and artisan certifications for traditional crafts. Genuine chisels from regions like Sakai or Seki may carry official marks indicating authenticity and adherence to traditional methods. Overlooking these IP-protected identifiers increases the risk of purchasing non-compliant or mass-produced copies. For example, the Sakai Uchihamono (Sakai forged blades) designation is a registered collective trademark—tools bearing this mark must meet specific quality and origin criteria. Buyers should research and recognize these marks when sourcing tools.

Relying on Third-Party Sellers Without Verification

E-commerce platforms often host resellers with inconsistent quality control and unclear supply chains. A significant pitfall is purchasing from sellers who cannot verify the chisel’s origin or provide documentation on the maker. This lack of transparency can lead to unintentional support of IP infringement or substandard production. To mitigate risk, engage directly with Japanese specialty tool suppliers or importers with established reputations and verifiable relationships with artisans.

Underestimating the Value of Artisan Documentation and Provenance

High-quality Japanese chisels often come with documentation—such as a certificate of authenticity, maker’s stamp (mei), or details about the forging process. These elements are not just marketing; they serve as proof of IP legitimacy and craftsmanship. Tools lacking such provenance are more likely to be replicas or unauthorized copies. Always request and verify documentation, especially when investing in higher-end chisels.

By understanding these pitfalls, buyers can make informed decisions, support authentic Japanese craftsmanship, and acquire chisels that deliver both performance and heritage value.

Logistics & Compliance Guide for Japanese Woodworking Chisels

Overview

Japanese woodworking chisels are precision hand tools crafted primarily from high-carbon steel and laminated with softer iron, often with hardwood handles. Due to their composition and country of origin, shipping these tools internationally—especially to regions with strict biosecurity and customs regulations—requires careful attention to logistics and compliance protocols. This guide outlines key considerations for importing, exporting, and transporting Japanese chisels across borders.

Import/Export Regulations

- Harmonized System (HS) Code: Japanese chisels typically fall under HS Code 8203.20 (Hand tools, of base metal, without motor, n.e.s.), though specific subcategories may apply depending on blade material and handle type. Accurate classification is essential for customs clearance and duty assessment.

- Country-Specific Restrictions: Some countries impose restrictions on tools with sharp blades. For example, Australia and New Zealand require declarations for tools that could be used as weapons. Verify local customs policies before shipping.

- Export Controls from Japan: Generally, there are no export restrictions on chisels from Japan unless they are classified as cultural artifacts or antiques. Standard commercial chisels are freely exportable.

Phytosanitary and Wood Packaging Requirements

- Wooden Handles and Components: Chisels with wooden handles (e.g., Japanese white oak, magnolia) may be subject to phytosanitary regulations.

- Ensure any wooden components are from certified, pest-free sources.

- Treatments such as kiln drying or heat treatment may be required to meet ISPM 15 standards if shipped with wooden packaging (e.g., pallets, crates).

- Packaging Materials: Avoid using raw or untreated wood in packaging. Use ISPM 15-compliant wood packaging or non-wood alternatives (corrugated cardboard, plastic).

Blade Transport and Air Safety Regulations

- Air Freight and Passenger Transport:

- Sharp tools, including chisels, are prohibited in carry-on baggage under most civil aviation authorities (e.g., TSA, EASA).

- Must be securely packed in checked luggage or shipped as freight.

- Commercial Shipping:

- Clearly label packages as containing sharp tools.

- Secure blades with blade guards or edge protectors to prevent damage and ensure safety during handling.

Customs Documentation

Ensure all shipments include:

– Commercial invoice (detailing item description, value, quantity, HS code, country of origin)

– Packing list

– Certificate of Origin (often required to confirm “Made in Japan”)

– Any import permits, if required by destination country

Duties and Taxes

- Import duties vary by country and are based on the product’s HS code and declared value.

- Some countries (e.g., USA, EU) may apply preferential tariffs under trade agreements, but Japanese tools are generally assessed at standard rates.

- VAT, GST, or other consumption taxes may apply upon importation.

Intellectual Property and Brand Compliance

- Be aware of trademarks and brand names (e.g., Marples, Kanna, Aritsugu). Unauthorized use of brand names in marketing or labeling may violate intellectual property laws.

- Counterfeit or mislabeled chisels may be seized by customs.

Best Practices for Shippers

- Use durable, secure packaging with blade protection.

- Declare contents accurately to avoid delays or penalties.

- Partner with freight forwarders experienced in handling hand tools and metal goods.

- Verify destination country’s import rules prior to shipment.

- Maintain records of compliance documentation for at least 5 years.

Conclusion

Shipping Japanese woodworking chisels requires adherence to international trade regulations, especially concerning wood components, blade safety, and accurate customs declarations. By following this guide, importers and exporters can ensure smooth logistics operations and compliance with global standards. Always consult local customs authorities or a trade compliance expert when in doubt.

In conclusion, sourcing Japanese woodworking chisels requires careful consideration of craftsmanship, steel quality, intended use, and authenticity. Renowned for their precision, sharpness, and durability, Japanese chisels—such as those from trusted makers like Masamoto, Maruki, or Kanna—are a worthwhile investment for both traditional and modern woodworkers. When sourcing, prioritize reputable suppliers or direct channels from Japan to ensure genuine products and avoid counterfeits. Pay attention to blade composition (e.g., white steel, blue steel, or laminated layers) and handle/frog construction, as these impact performance and longevity. Ultimately, investing in high-quality Japanese chisels not only enhances your woodworking capabilities but also connects you to a centuries-old tradition of artisan excellence. With proper care and maintenance, these tools can last a lifetime and become cherished instruments in your workshop.