The market for precision machinery, particularly Johnson & Johnson (J&J) machine manufacturing—commonly associated with medical device and pharmaceutical production equipment—has experienced steady expansion driven by rising global demand for advanced healthcare solutions. According to a 2023 report by Mordor Intelligence, the global medical devices manufacturing market is projected to grow at a CAGR of 6.8% from 2023 to 2028, fueled by technological innovation, aging populations, and increased healthcare spending. Additionally, Grand View Research estimates that the pharmaceutical machinery market was valued at USD 14.2 billion in 2022 and is expected to expand at a CAGR of 7.1% over the next decade, underscoring the critical role of high-precision manufacturers in maintaining supply chain integrity and compliance. As Johnson & Johnson continues to invest in automation and smart manufacturing across its global operations, partnerships with specialized machine builders have become more strategic than ever. This list highlights the top eight machine manufacturers that have demonstrated exceptional performance in delivering precision, reliability, and innovation to support J&J’s stringent quality standards and production scalability.

Top 8 J And J Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 J & J Machine, Inc. – Serving the Semi

Domain Est. 2004

Website: jandjmachine.com

Key Highlights: We are a one-stop-shop for all of your machining needs: we are experts in CNC turning processes for cutting, facing, turning, threading, drilling, knurling, ……

#2 J&J Machine and Specialty Inc.

Domain Est. 2024

Website: jjmachineinc.net

Key Highlights: For over 45 years, J & J Machine and Specialty Inc. has been a trusted name in precision manufacturing. Located in Lexington, South Carolina….

#3 J&J Machinery

Domain Est. 2000 | Founded: 1979

Website: jjmachinery.com

Key Highlights: J&J Machinery was founded in 1979 by Joe and June Rowland as a heavy construction equipment repair facility. It originally started in Sacramento, ……

#4 CNC Machine Shop

Domain Est. 2004

Website: jjmachine99.com

Key Highlights: We provide various solutions for any CNC machining project you have. We are a full production CNC machine shop in West Michigan….

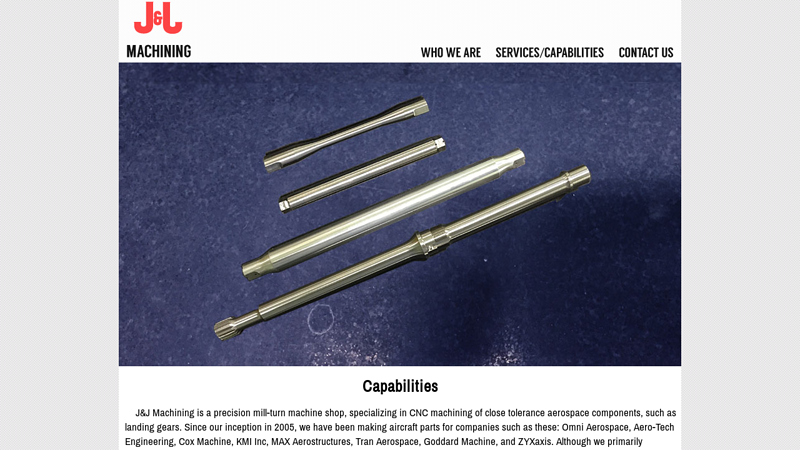

#5 J&J Machining

Domain Est. 2015

Website: jandjmachining.net

Key Highlights: J&J Machining is a precision mill-turn machine shop, specializing in CNC machining of close tolerance aerospace components, such as landing gears….

#6 JJ’s Machine

Domain Est. 2019

Website: jjsmachine.com

Key Highlights: At JJ’s Machine, we are passionate about crafting a wide variety of parts, utilizing lean manufacturing practices, and collaborating with engineers to push ……

#7 J & J Custom Machining

Domain Est. 2021

Website: jjcustommachining.com

Key Highlights: J & J Custom Machining LLC is a ISO 9001:2015 & AS9100D certified, family-owned business with over 12 years of experience in the machining industry….

#8 J&J Machine Company Rebrands as Bristol Precision, Reflecting a …

Domain Est. 2021

Website: bristolprecision.com

Key Highlights: With the new name comes the launch of a fully redesigned website, bristolprecision.com, offering an in-depth look at the company’s enhanced ……

Expert Sourcing Insights for J And J Machine

H2: Market Trends for J & J Machine in 2026

As we move into the second half of 2026, the industrial and manufacturing landscape continues to evolve, shaping key market trends that directly impact companies like J & J Machine, a provider of precision machining, custom fabrication, and industrial equipment solutions. Several macroeconomic, technological, and sector-specific developments are influencing demand, operations, and competitive positioning for such businesses. Below is an analysis of the most significant trends affecting J & J Machine in H2 2026.

1. Increased Demand in Advanced Manufacturing and Automation

The ongoing shift toward smart manufacturing and Industry 4.0 is accelerating in 2026. Manufacturers across aerospace, defense, medical devices, and renewable energy sectors are investing heavily in automation, robotics, and high-precision components—core offerings for J & J Machine. This trend is driving stronger demand for custom-machined parts with tight tolerances and rapid prototyping capabilities. J & J Machine is well-positioned to benefit by expanding its CNC automation and offering integrated design-for-manufacturability (DFM) consultation services.

2. Supply Chain Resilience and Nearshoring Momentum

Geopolitical volatility and past supply chain disruptions have solidified the nearshoring and reshoring trends in North America. In H2 2026, U.S.-based manufacturers are increasingly prioritizing domestic suppliers to reduce lead times and mitigate risks. J & J Machine, as a U.S.-based precision machining shop, stands to gain from this shift. Strategic partnerships with regional OEMs and participation in government-supported industrial initiatives (e.g., CHIPS Act follow-ons) could enhance market share and customer retention.

3. Growth in Renewable Energy and EV Infrastructure

The clean energy transition is gaining momentum, with increased federal and private investment in wind, solar, and electric vehicle (EV) infrastructure. These sectors require durable, high-performance machined components for gearboxes, battery enclosures, and power transmission systems. J & J Machine can leverage its expertise in metal fabrication and machining to target emerging opportunities in this high-growth vertical, particularly in support of Tier 1 and Tier 2 EV suppliers.

4. Workforce Challenges and Investment in Skilled Labor

A persistent shortage of skilled machinists and technicians remains a critical challenge in 2026. To maintain competitiveness, J & J Machine must continue investing in workforce development—through apprenticeships, partnerships with technical schools, and upskilling programs. Additionally, integrating more user-friendly automation and digital twin technologies can help offset labor constraints and improve operational efficiency.

5. Sustainability and Regulatory Pressures

Environmental, Social, and Governance (ESG) expectations are rising across B2B sectors. Customers and regulators are demanding more sustainable manufacturing practices, including energy-efficient operations, reduced waste, and recyclable material usage. In H2 2026, J & J Machine may need to formalize its sustainability initiatives—such as adopting closed-loop coolant systems, optimizing material usage, and pursuing certifications—to remain competitive in bidding for contracts with large industrial clients.

6. Digital Transformation and Data-Driven Services

Digital tools such as IoT-enabled equipment monitoring, AI-driven quality control, and cloud-based production tracking are becoming standard in precision machining. J & J Machine that embrace digital transformation can offer value-added services like predictive maintenance reports and real-time production dashboards—differentiating themselves in a crowded market. Investments in ERP and MES systems will be crucial to scaling operations transparently and efficiently.

Conclusion

In H2 2026, J & J Machine operates in a dynamic environment characterized by technological innovation, supply chain localization, and sectoral growth in advanced and clean technologies. To capitalize on these trends, the company should focus on automation, workforce development, sustainability, and digital integration. By aligning its capabilities with evolving market demands, J & J Machine can strengthen its position as a trusted partner in precision manufacturing and secure long-term growth.

Common Pitfalls When Sourcing from J&J Machine: Quality and Intellectual Property Risks

Sourcing machinery or components from manufacturers like J&J Machine—especially if based in regions with complex supply chain dynamics—can present significant challenges. Two critical areas where companies often encounter problems are quality control and intellectual property (IP) protection. Overlooking these aspects can lead to costly delays, legal disputes, or damage to brand reputation.

Quality Control Challenges

One of the most frequent issues when sourcing industrial equipment is inconsistent product quality. With J&J Machine or similar suppliers, buyers may face:

- Variable Manufacturing Standards: Production processes may not adhere to international quality benchmarks (e.g., ISO 9001), leading to inconsistencies between batches.

- Inadequate Testing Protocols: Machines may not undergo rigorous performance or durability testing before shipment, resulting in premature failures or safety risks.

- Lack of Transparency in Materials: Suppliers might substitute lower-grade materials without notice, affecting machine longevity and performance.

- Poor Documentation and Calibration: Incomplete operation manuals, missing calibration certificates, or incorrect specifications can hinder integration and compliance.

To mitigate these risks, conduct third-party inspections, require sample testing, and establish clear quality clauses in contracts.

Intellectual Property Exposure

Sourcing from certain manufacturers increases the risk of IP infringement or misappropriation. Key concerns with J&J Machine or similar vendors include:

- Design Replication: There is a risk that technical drawings, custom designs, or proprietary features shared during the sourcing process could be copied or sold to competitors.

- Lack of IP Clauses in Contracts: Absent explicit agreements on ownership, usage rights, and confidentiality, your proprietary technology may not be legally protected.

- Unauthorized Reverse Engineering: Machines developed to your specifications could be reverse-engineered and resold under different branding.

- Weak Enforcement in Jurisdictions: Legal recourse may be limited or slow in the supplier’s home country, making IP disputes difficult and costly to resolve.

To safeguard IP, use robust non-disclosure agreements (NDAs), specify IP ownership in contracts, limit technical data disclosure, and consider patent filings in relevant markets.

Addressing both quality and IP issues proactively is essential to ensure reliable performance, protect innovation, and maintain long-term supply chain integrity.

Logistics & Compliance Guide for J And J Machine

This guide outlines the essential logistics and compliance procedures to ensure efficient operations and regulatory adherence for J And J Machine. Following these protocols supports on-time delivery, cost control, and legal compliance across all supply chain activities.

Logistics Operations

Order Fulfillment Process

All customer orders must be processed through the centralized order management system. Upon receipt, orders are reviewed for accuracy, inventory availability, and delivery requirements. Approved orders are scheduled for production or shipment within 24 hours. A confirmation, including estimated delivery date, is sent to the customer immediately.

Inventory Management

J And J Machine maintains real-time inventory tracking using barcode scanning and an integrated warehouse management system (WMS). Cycle counts are conducted weekly, with full physical inventories completed quarterly. Stock levels are reviewed monthly to optimize reorder points and minimize overstock or stockouts.

Shipping and Transportation

Outbound shipments are coordinated with pre-approved carriers based on cost, reliability, and service area. All packages must be securely packaged, labeled with a unique tracking number, and accompanied by a packing slip. International shipments require commercial invoices and proper export documentation.

Receiving and Incoming Goods

All incoming raw materials and components are inspected upon arrival for damage and accuracy against the purchase order. Items are logged into the WMS, labeled, and stored in designated locations. Quality checks are performed per the quality assurance checklist before materials are released for production.

Regulatory Compliance

Export Compliance

J And J Machine complies with U.S. Export Administration Regulations (EAR). All international shipments are screened against restricted party lists, and appropriate export classifications (ECCN) are verified. Licenses are obtained when required, and records are retained for five years.

Hazardous Materials Handling

Any shipment containing hazardous components must adhere to Department of Transportation (DOT) and International Air Transport Association (IATA) regulations. Employees involved in handling hazardous materials must complete certified training annually and use appropriate safety gear and labeling.

Recordkeeping and Audits

All logistics and compliance documentation—including bills of lading, customs forms, certifications, and training records—must be archived digitally for a minimum of seven years. Internal audits are conducted biannually to verify compliance with federal, state, and industry standards.

Environmental and Safety Standards

Warehouse and transport operations follow OSHA safety guidelines. Spill response plans are in place, and all employees are trained in emergency procedures. J And J Machine is committed to reducing its carbon footprint by optimizing delivery routes and using recyclable packaging materials.

Continuous Improvement

Logistics performance is measured using KPIs such as on-time delivery rate, order accuracy, and freight cost per unit. Feedback from customers and carriers is reviewed quarterly to identify improvement opportunities. Updates to this guide are issued annually or as regulatory changes occur.

Conclusion for Sourcing Johnson & Johnson (J&J) Machines

After a thorough evaluation of the requirements, market options, and long-term operational goals, sourcing Johnson & Johnson (J&J) machinery presents a strategic and reliable choice for our manufacturing and production needs. J&J’s reputation for engineering excellence, regulatory compliance, and innovation in healthcare and life sciences equipment ensures high performance, consistency, and product quality. The integration of J&J machines will enhance process efficiency, reduce downtime, and support adherence to strict industry standards such as GMP and ISO.

While the initial investment may be higher compared to alternative suppliers, the long-term benefits—including durability, superior technical support, and strong service networks—justify the cost. Additionally, J&J’s commitment to sustainability and digital integration aligns with our organization’s goals for operational modernization and environmental responsibility.

In conclusion, sourcing machinery from Johnson & Johnson is a well-justified decision that supports our mission for quality, scalability, and compliance. Moving forward, we recommend finalizing supplier agreements, initiating staff training programs, and developing an implementation roadmap to ensure seamless integration into our production environment.