The global irrigation tubing market is experiencing steady growth, driven by rising agricultural automation, increasing water scarcity, and the expansion of precision farming techniques. According to Grand View Research, the global agricultural irrigation market was valued at USD 14.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 8.5% from 2023 to 2030. A key component within this ecosystem, irrigation tubing plays a critical role in micro-irrigation systems such as drip and sprinkler setups, where efficiency and durability are paramount. As demand surges—particularly in emerging agricultural economies and arid regions—the need for reliable tubing in standardized sizes has intensified. This growth trajectory, supported by technological advancements and government support for water-efficient farming, has elevated the prominence of manufacturers specializing in consistent, high-performance irrigation tubing. The following list highlights the top 10 manufacturers leading innovation and market share in irrigation tubing sizes, from standard 1/4″ to 1″ diameters, serving large-scale farms to smallholder operations worldwide.

Top 10 Irrigation Tubing Sizes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle is the innovative leader that combines advanced technology with superior customer service to create the industry’s most sophisticated and diverse ……

#2 Cresline Plastic Pipe Co.

Domain Est. 1998

Website: cresline.com

Key Highlights: As one of the largest full-line pipe manufacturers, Cresline’s family of companies offers industry leading coast-to-coast service….

#3 Polyethylene Tubing for Drip Irrigation & Water Systems

Domain Est. 1996

Website: ndspro.com

Key Highlights: Provide efficient drip irrigation supply and water distribution with poly tubing from NDS, featuring an outer layer treated with UV inhibitors for durability….

#4 Premium Drip Irrigation Tubing – DIG Corp

Domain Est. 1996

Website: digcorp.com

Key Highlights: Premium Drip Irrigation Tubing · 1/4″ MICRO-POLYFLEX Tubing · 1/4″ Poly Micro Tubing · 1/2″ Polyethylene Drip Tubing · 1/2″ (.710 OD) Poly Drip Tubing….

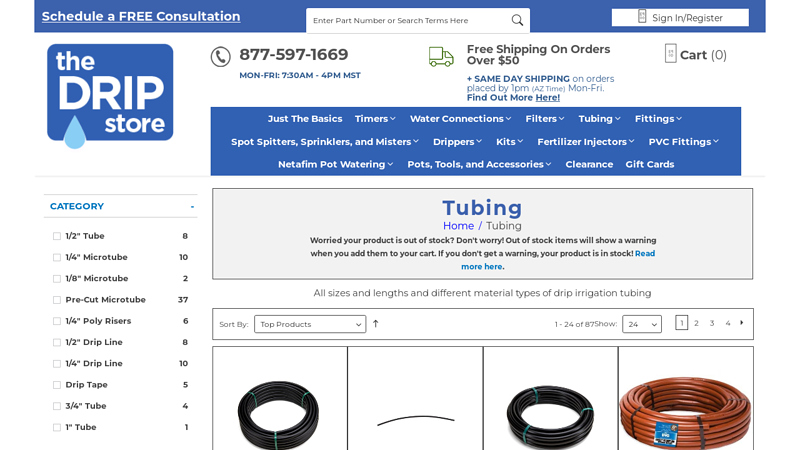

#5 Drip Irrigation Tubing

Domain Est. 1997

Website: dripirrigation.com

Key Highlights: Free delivery 30-day returnsTubing ; 100′ 3/4″ Black Poly Tubing (.820 ID x .940 OD) · $32.00 · 44 Available ; 42″ x 1/4″ Poly Tube / .170 X .250 · $0.29 · 1,000+ Available ; 50 Ft…

#6 Diamond Plastics Corporation

Domain Est. 1998

Website: dpcpipe.com

Key Highlights: Diamond Plastics manufactures a variety of PVC plastic irrigation pipe for the agricultural industry….

#7 Watering Pipe, Hose & irrigation Tubing

Domain Est. 2000

Website: netafimusa.com

Key Highlights: Netafim’s pipe, irrigation hose and tubing line includes: Micro, Oval, and PolyNet tubing. All manufactured with the highest quality resin for durability and ……

#8 Supply Tubing

Domain Est. 2001

Website: hunterirrigation.com

Key Highlights: Hunter now offers a thick-walled, UV-resistant ½” polyethylene supply tubing and ¼” distribution line in both vinyl and polyethylene….

#9 Rain

Domain Est. 2008

Website: rainfloirrigation.com

Key Highlights: An agricultural leader in vegetable planting equipment, vegetable growing products, T-Tape drip tape for drip irrigation, plastic mulch, portable water pumps….

#10 Poly Tubing Buying Guide

Domain Est. 2005

Website: help.dripdepot.com

Key Highlights: How to choose the right irrigation tubing. Polyethylene dripline and blank tubing specifications and sizes….

Expert Sourcing Insights for Irrigation Tubing Sizes

2026 Market Trends for Irrigation Tubing Sizes

The global irrigation tubing market is poised for significant evolution by 2026, driven by advancements in agricultural technology, increasing water scarcity, and the growing adoption of precision farming. A critical component of this transformation is the demand for specific tubing sizes, which are being optimized for efficiency, durability, and compatibility with modern irrigation systems. This analysis explores key trends shaping the demand and innovation in irrigation tubing sizes through 2026.

Shift Toward Smaller Diameter Tubing in Drip Irrigation

One of the most prominent trends is the rising preference for smaller diameter tubing—particularly sizes ranging from 1/4 inch to 3/8 inch—in drip irrigation systems. These sizes are increasingly favored due to their precision in water delivery, reduced material costs, and flexibility in installation across diverse crop types and terrains. By 2026, the demand for micro-diameter tubing is expected to grow at a compound annual growth rate (CAGR) of 7.3%, primarily driven by smallholder farms and high-value crop cultivation in regions such as Southeast Asia, the Middle East, and sub-Saharan Africa.

Manufacturers are responding by innovating lightweight, UV-resistant polyethylene (LDPE) and polyvinyl chloride (PVC) formulations tailored for narrow tubing, ensuring longevity even under intense sunlight and fluctuating temperatures.

Standardization of 1/2-Inch and 5/8-Inch Tubing for Mainlines and Sub-Mains

While smaller tubing dominates emitter lines, 1/2-inch and 5/8-inch diameters remain standard for mainline and sub-main distribution networks due to their optimal balance of flow rate and pressure regulation. By 2026, these mid-range sizes are projected to maintain approximately 45% of the global irrigation tubing market share. The trend is supported by the expansion of large-scale agricultural projects, especially in North America, Australia, and South America, where uniformity and system reliability are paramount.

Smart irrigation integrations—such as pressure-compensating emitters and flow sensors—are being designed specifically for compatibility with 1/2-inch tubing, further reinforcing its market position.

Growth in Large-Diameter Tubing for Center Pivot and Linear Move Systems

Larger tubing sizes, including 2-inch, 3-inch, and even 4-inch diameters, are experiencing renewed demand in mechanized irrigation systems such as center pivot and linear move systems. These systems are expanding in arid and semi-arid regions like the U.S. Great Plains, Central Asia, and parts of Australia. The push for water-efficient large-scale operations is driving innovations in collapsible and high-pressure-resistant tubing materials, enabling longer reach and reduced energy consumption.

By 2026, the large-diameter tubing segment (>2 inches) is expected to grow by 5.8% CAGR, fueled by government subsidies for water-saving infrastructure and private investment in agri-tech.

Regional Variations in Tubing Size Preferences

Regional agricultural practices and water policies significantly influence tubing size demand. In Europe, stringent environmental regulations are promoting the use of 3/8-inch and 1/2-inch tubing with integrated filtration to minimize runoff and leaching. In contrast, India and China are witnessing a boom in 1/2-inch lay-flat hoses due to government-supported micro-irrigation programs targeting water-stressed farming zones.

Meanwhile, in North America, the trend leans toward modular systems utilizing multiple tubing sizes in hybrid configurations, allowing farmers to customize irrigation layouts based on crop rotation and soil variability.

Sustainability and Recyclability Influencing Size and Material Choices

Sustainability is becoming a decisive factor in tubing size selection. By 2026, there is a growing shift toward thinner-walled tubing in standard sizes (e.g., 1/2 inch) made from recyclable or biodegradable materials. This reduces plastic waste and transportation emissions without compromising performance. Industry leaders are investing in closed-loop recycling programs and developing tubing with longer service lives—up to 10–15 years—to reduce replacement frequency.

Conclusion

The 2026 irrigation tubing size landscape reflects a market balancing precision, scalability, and sustainability. While smaller diameters gain traction in targeted delivery systems, mid- and large-sized tubing continue to serve critical roles in extensive and mechanized agriculture. As digital agriculture and climate-smart practices accelerate, tubing size innovation will remain closely aligned with efficiency, adaptability, and environmental responsibility.

Common Pitfalls When Sourcing Irrigation Tubing Sizes (Quality, IP)

Sourcing the right irrigation tubing involves more than just selecting a diameter or length—overlooking key quality and Ingress Protection (IP) factors can lead to system inefficiencies, frequent maintenance, and premature failure. Below are common pitfalls to avoid:

Choosing Tubing Based Solely on Diameter

Many buyers focus exclusively on tubing size (e.g., 13mm, 16mm, or 20mm) without considering wall thickness, material quality, or pressure ratings. This can result in leaks, bursts, or inconsistent water flow. Always match tubing dimensions to system pressure and environmental conditions.

Ignoring Material Quality and UV Resistance

Low-quality polyethylene (PE) or polyvinyl chloride (PVC) tubing degrades quickly under sunlight and temperature fluctuations. Poor UV resistance leads to brittleness and cracking. Ensure tubing is made from high-density polyethylene (HDPE) with UV stabilizers, especially for outdoor applications.

Overlooking Pressure Ratings and Flow Requirements

Using tubing with insufficient pressure ratings (e.g., low-pressure drip line in a high-pressure system) causes blowouts or uneven distribution. Confirm the tubing’s pressure rating (measured in bar or psi) aligns with your pump and system design. Mismatched flow rates can also starve crops of water.

Neglecting Ingress Protection (IP) Ratings for Fittings and Connectors

While tubing itself may not carry an IP rating, associated control valves, sensors, and connectors often do. Using components with inadequate IP ratings (e.g., IP65 vs. IP68) in wet or buried environments risks water ingress, corrosion, and electrical failure. Always verify IP ratings for electronic and mechanical parts in the irrigation system.

Failing to Consider Long-Term Durability and Chemical Resistance

Some tubing degrades when exposed to fertilizers, chlorine, or acidic soil conditions. Without proper chemical resistance, tubing can weaken and fail prematurely. Opt for tubing rated for agricultural chemicals if your system uses fertigation.

Purchasing Non-Standard or Inconsistent Sizing

Inconsistent inner/outer diameters across batches lead to poor fitting connections and leaks. Sourcing from unverified suppliers increases the risk of non-standard tubing. Always request dimensional specifications and test samples before bulk ordering.

Not Verifying Compliance with Industry Standards

Reputable irrigation tubing should meet international standards such as ISO 8779 (for drip irrigation tubing) or ASTM F2128 (for PE piping). Lack of certification may indicate subpar quality. Always request compliance documentation.

By avoiding these common pitfalls—focusing on both physical quality and appropriate IP protection for system components—you can ensure a reliable, efficient, and long-lasting irrigation setup.

Logistics & Compliance Guide for Irrigation Tubing Sizes

Understanding the logistics and compliance requirements for irrigation tubing is essential for efficient distribution, installation, and adherence to industry and regulatory standards. Proper selection of tubing size impacts not only system performance but also transportation, storage, and regulatory compliance.

Tubing Size Standards and Specifications

Irrigation tubing is manufactured according to industry standards that ensure consistency, compatibility, and performance. Common standards include:

- ASTM D2241 – Standard specification for polyethylene (PE) pressure pipe based on controlled outside diameter (OD).

- ISO 4427 – International standard for polyethylene pipes and fittings for water supply, including irrigation.

- ASAE S376.2 – American Society of Agricultural and Biological Engineers standard for plastic pipeline used in irrigation.

Tubing sizes are typically designated by:

– Outside Diameter (OD) – Measured in millimeters (mm) or inches (in).

– Inside Diameter (ID) – Varies based on wall thickness.

– Wall Thickness / Pressure Rating – Expressed as Schedule (e.g., Schedule 40) or Pressure Class (e.g., 60 psi, 80 psi, 100 psi).

Common irrigation tubing sizes include:

– 1/2 inch (12.7 mm)

– 3/4 inch (19.05 mm)

– 1 inch (25.4 mm)

– 1.5 inch (38.1 mm)

– 2 inch (50.8 mm)

– Larger diameters up to 12 inches (304.8 mm) for mainlines

Transportation and Handling Logistics

Proper logistics planning ensures tubing arrives undamaged and ready for installation:

- Coiled vs. Straight Lengths:

- Small to medium tubing (up to 2 inches) is often shipped in coils (e.g., 100 ft, 500 ft).

- Larger diameters are typically shipped in straight 20-foot sections.

- Weight and Volume:

- Coiled tubing is lightweight and space-efficient; ideal for truck or palletized shipping.

- Larger diameter tubing requires flatbed trucks and careful stacking to prevent deformation.

- Packaging:

- Coils are usually wrapped in UV-protective plastic and banded.

- Straight pipes are bundled and crated to prevent end damage.

- Storage Requirements:

- Store indoors or under shade to prevent UV degradation.

- Keep off the ground on pallets to avoid moisture and dirt.

- Avoid sharp bends or kinking during handling.

Regulatory and Environmental Compliance

Compliance ensures safety, sustainability, and legal operation:

- Drinking Water Safety:

- If used in potable water systems (e.g., drip irrigation for edible crops), tubing must be NSF/ANSI 61 certified for health effects.

- Agricultural Chemical Resistance:

- Tubing must resist degradation from fertilizers and agrochemicals; check manufacturer’s chemical compatibility charts.

- Environmental Regulations:

- In sensitive ecosystems, local regulations may dictate material types or burial depth.

- Recyclability: PE tubing is recyclable (resin identification code #2 or #4); proper disposal or recycling is encouraged.

- Local Codes and Permits:

- Some regions require permits for irrigation system installation, especially for large-scale or groundwater-fed systems.

- Compliance with local water conservation ordinances may influence tubing size and flow rate choices.

Pressure and Flow Rate Considerations

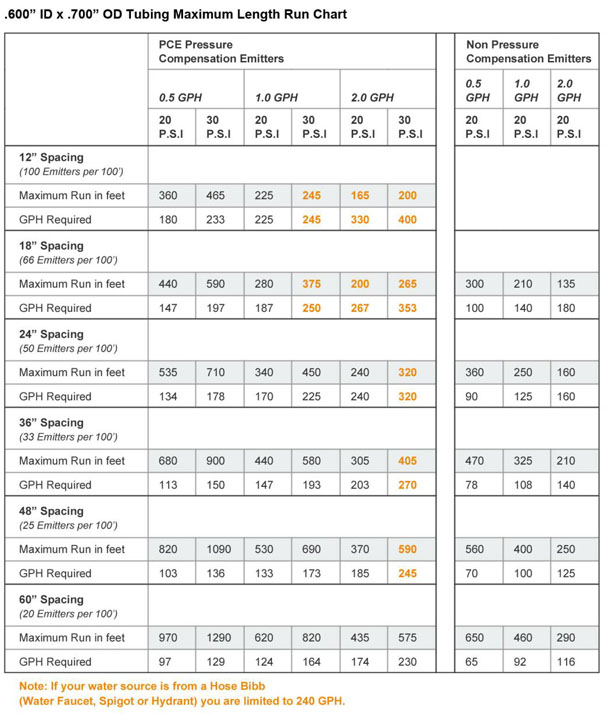

Correct sizing ensures compliance with hydraulic performance standards:

- Friction Loss: Larger diameters reduce friction loss over long runs.

- Flow Velocity: Maintain velocity below 5 ft/sec to prevent water hammer and pipe wear.

- System Design Standards:

- Follow standards like ASAE EP405.1 for microirrigation system design.

- Use software or tables to match tubing size with required flow (GPM) and pressure (PSI).

Labeling and Documentation

Ensure compliance through proper labeling and records:

- Product Labels:

- Must include size (OD), material (e.g., HDPE), pressure rating, standard (e.g., ASTM D2241), and manufacturer info.

- Certificates of Compliance:

- Retain documentation proving NSF, ASTM, or ISO compliance for audits or inspections.

- Batch Traceability:

- Maintain records of lot numbers for quality control and recall management.

Conclusion

Selecting the correct irrigation tubing size involves more than hydraulic performance—it affects logistics, handling, regulatory compliance, and long-term system reliability. Adhering to recognized standards, proper shipping and storage protocols, and local regulations ensures efficient delivery and legal, sustainable operation of irrigation systems. Always consult manufacturer specifications and local authorities when planning large-scale installations.

In conclusion, selecting the appropriate irrigation tubing size is a critical decision that directly impacts the efficiency, performance, and sustainability of an irrigation system. The optimal tubing diameter—whether 1/4″, 1/2″, 5/8″, or larger—depends on several key factors including system water pressure, flow rate requirements, total system length, number of emitters or sprinklers, and the type of irrigation method (drip, sprinkler, or micro-spray).

Smaller diameter tubing is cost-effective and suitable for short, low-flow applications, while larger diameters are necessary to minimize pressure loss over longer distances or in high-demand zones. Proper sizing ensures uniform water distribution, reduces energy and water waste, and extends the lifespan of the system. Consulting technical guidelines, conducting a hydraulic analysis, and considering future expansion can further refine the selection process.

Ultimately, careful evaluation of site-specific conditions and irrigation goals leads to informed sourcing decisions, maximizing both crop productivity and resource efficiency.