The global air compressor market is experiencing steady expansion, driven by rising industrial automation, growing demand in manufacturing, and increased infrastructure development. According to Mordor Intelligence, the market was valued at USD 35.6 billion in 2023 and is projected to grow at a CAGR of over 4.8% from 2024 to 2029. Air compressors, particularly reliable models like the Ingersoll Rand 2475, remain essential across industries such as automotive, construction, and oil & gas due to their durability and consistent performance. As demand for efficient compressed air systems rises, so does the need to identify top-tier manufacturers producing or servicing legacy models like the 2475. While Ingersoll Rand is the original equipment manufacturer, several specialized industrial firms have emerged as leaders in reconditioned, compatible, or aftermarket support for such units. Based on market presence, customer reviews, and service capabilities, the following three manufacturers stand out in delivering high-quality solutions for the Ingersoll Rand 2475 air compressor platform.

Top 3 Ingersoll Rand 2475 Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ingersoll Rand 2475 Two

Domain Est. 1999

Website: compressorworld.com

Key Highlights: In stock Rating 5.0 3 Ingersoll Rand 2475 Two-Stage Piston Air Compressor. 5 or 7.5 HP compressor with up to 24 CFM capacity at 175psi, designed for heavy shop or industrial use….

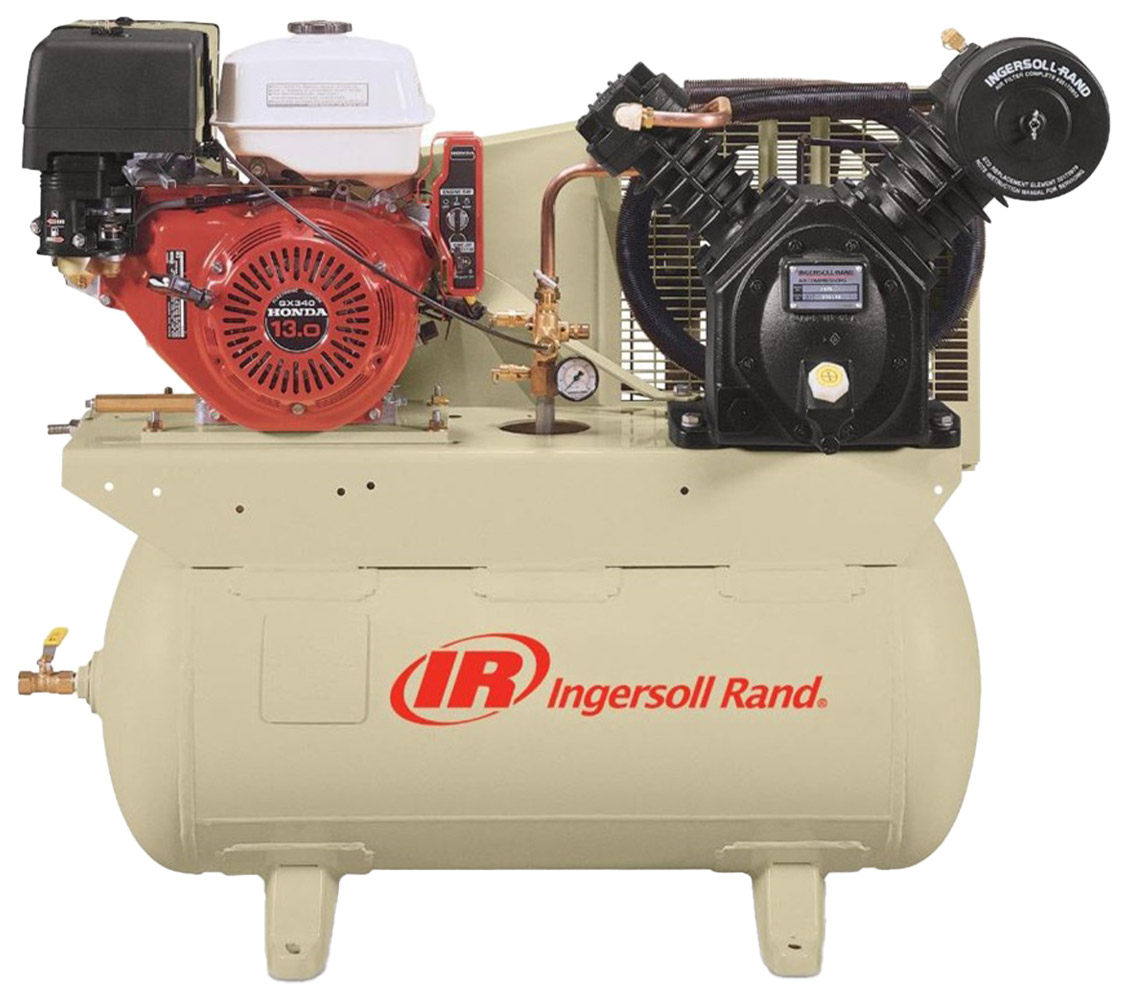

#2 2

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: Ingersoll Rand’s Two-Stage 5-7.5 hp Reciprocating model comprises the latest compressor technology with unmatched reliability. Click here to view….

#3 2475N7.5

Domain Est. 2013

Website: ingersollrandcompressedair.com

Key Highlights: Each unit includes a two-stage, 100% cast iron pump, ODP electric motor, automatic start stop control with a NEMA 1 pressure switch mounted and an ASME coded ……

Expert Sourcing Insights for Ingersoll Rand 2475 Air Compressor

H2: Projected 2026 Market Trends for the Ingersoll Rand 2475 Air Compressor

As the industrial and manufacturing sectors continue to evolve, the market outlook for durable, high-performance air compressors like the Ingersoll Rand 2475 is expected to remain robust through 2026. This analysis explores key market trends shaping demand, competition, technological advancements, and customer preferences that will influence the positioning and performance of the Ingersoll Rand 2475 Air Compressor in the coming years.

-

Rising Industrial Automation and Maintenance Demand

The global push toward automation in manufacturing, automotive, and construction industries is driving sustained demand for reliable compressed air systems. The Ingersoll Rand 2475, known for its durability and consistent performance in heavy-duty applications, is well-positioned to benefit from increased maintenance, repair, and operations (MRO) spending. As aging infrastructure in North America and Europe undergoes upgrades, demand for dependable piston compressors like the 2475 is expected to grow, particularly in small to mid-sized workshops and industrial facilities. -

Energy Efficiency and Sustainability Pressures

While the 2475 is a reciprocating (piston) compressor and generally less energy-efficient than modern rotary screw models, the 2026 market will place greater emphasis on energy consumption and carbon footprint. Regulatory pressures and rising energy costs may lead some customers to consider more efficient alternatives. However, the 2475’s reputation for longevity, ease of maintenance, and lower upfront cost will continue to attract price-sensitive and intermittent-use operations, especially in developing markets and rural industrial settings. -

Shift Toward Hybrid and Smart Compressed Air Systems

Although the 2475 is a traditional mechanical compressor without integrated digital controls, the broader market is moving toward smart compressors with IoT connectivity, remote monitoring, and predictive maintenance features. By 2026, Ingersoll Rand’s newer product lines may dominate in high-tech industrial environments. However, the 2475 will retain relevance in niche and legacy applications where simplicity, ruggedness, and serviceability are prioritized over smart functionality. -

Continued Aftermarket and Service Opportunities

One of the 2475’s enduring strengths is its widespread service network and availability of replacement parts. By 2026, the established aftermarket ecosystem will support ongoing demand for refurbished units, retrofits, and replacement components. Ingersoll Rand’s strong brand reputation and service infrastructure will help sustain customer loyalty, particularly among independent repair shops and contractors who value reliability and long-term support. -

Competitive Landscape and Product Lifecycle

While Ingersoll Rand continues to innovate with advanced rotary and variable-speed drive (VSD) compressors, the 2475 remains a staple in its reciprocating compressor lineup. By 2026, it may face increased competition from cost-effective Asian manufacturers offering similar piston compressors. However, its U.S.-based engineering, build quality, and brand trust will maintain its premium positioning in markets that prioritize durability and safety compliance.

Conclusion

The Ingersoll Rand 2475 Air Compressor is expected to maintain a stable market presence through 2026, particularly in sectors requiring rugged, low-maintenance compressed air solutions. While macro trends favor energy efficiency and digital integration, the 2475 will continue to serve a vital role in applications where reliability, ease of service, and proven performance outweigh the need for advanced technology. Its longevity in the market underscores Ingersoll Rand’s legacy of engineering excellence and customer-focused product design.

H2: Common Pitfalls When Sourcing the Ingersoll Rand 2475 Air Compressor (Quality and Intellectual Property Concerns)

Sourcing the Ingersoll Rand 2475 air compressor—especially older or discontinued models—can present several challenges related to product quality and intellectual property (IP) risks. Buyers must be vigilant to avoid counterfeit products, substandard replicas, and legal complications. Below are key pitfalls to watch for:

1. Counterfeit or Replica Units

The Ingersoll Rand 2475 is a sought-after model due to its durability and performance, making it a target for counterfeiters. Unauthorized manufacturers often produce look-alike compressors bearing fake Ingersoll Rand branding. These replicas may use inferior materials and lack proper engineering, leading to poor performance, safety hazards, and premature failure.

Tip: Always purchase from authorized distributors or verified resellers. Check for authentic branding, part numbers, and certification labels. When in doubt, contact Ingersoll Rand directly to verify authenticity.

2. Lack of Quality Control in Third-Party Suppliers

Used or refurbished 2475 compressors are frequently sold through third-party suppliers, online marketplaces, or auction sites. These units may not have undergone proper inspection, maintenance, or testing, resulting in undetected mechanical issues such as worn pumps, leaking seals, or faulty pressure switches.

Tip: Request service records, inspection reports, or videos of the unit in operation. Prefer suppliers who offer warranties or return policies.

3. Intellectual Property (IP) Infringement Risks

Rebranded or cloned versions of the 2475 may infringe on Ingersoll Rand’s trademarks, design patents, or technical specifications. Using or distributing such products—even unknowingly—can expose buyers or resellers to legal liability, especially in regulated industries or international markets.

Tip: Avoid suppliers offering “compatible” or “equivalent” models that closely mimic the 2475’s design. Ensure all documentation, including manuals and labels, complies with IP laws.

4. Misrepresentation of Specifications

Some sellers exaggerate performance metrics (e.g., CFM, PSI, duty cycle) or claim compliance with safety standards (like CE or ANSI) without certification. This misrepresentation can lead to mismatched equipment and operational inefficiencies.

Tip: Verify technical specifications against the original Ingersoll Rand documentation. Request third-party test reports if available.

5. Out-of-Warranty and Unsupported Units

Since the 2475 is no longer in active production, sourcing genuine replacement parts and technical support can be difficult. Buyers may end up relying on incompatible or low-quality aftermarket parts, affecting long-term reliability.

Tip: Confirm parts availability and service support before purchasing. Consider modern equivalents if long-term maintenance is a concern.

By understanding these common pitfalls, buyers can make informed decisions, protect against IP risks, and ensure they acquire a reliable, high-quality air compressor solution.

Logistics & Compliance Guide for Ingersoll Rand 2475 Air Compressor

1. Product Overview & Specifications

The Ingersoll Rand 2475 is a heavy-duty, industrial-grade rotary screw air compressor designed for continuous operation in demanding environments. It delivers reliable compressed air with high efficiency and durability. This guide outlines key logistics handling, transportation, and regulatory compliance considerations to ensure safe and compliant operations.

2. Packaging & Handling Requirements

- Original Packaging: Transport the compressor in its original manufacturer-approved crate or skid to protect against damage during transit. Ensure all lifting points are clearly marked.

- Lifting Procedures: Use certified forklifts or overhead cranes with appropriate capacity. Lift only from designated lifting lugs—never from hoses, piping, or electrical panels.

- Surface Protection: Place protective material (e.g., plywood or rubber mats) under the unit when moving across sensitive floors.

- Orientation: Keep the unit upright at all times during transport and handling to prevent oil migration and internal damage.

3. Transportation Guidelines

- Mode of Transport: Suitable for truck, rail, and containerized shipping. For international shipping, ensure compliance with IATA/IMDG regulations if shipped by air or sea.

- Securement: Secure the compressor to the transport vehicle using rated straps or chains anchored to the skid. Prevent shifting during transit.

- Environmental Conditions: Avoid exposure to extreme temperatures, moisture, or corrosive environments during transport. Use weatherproof tarps if necessary.

- Documentation: Include packing list, bill of lading, and technical specifications with the shipment.

4. Import/Export Compliance

- HS Code: 8414.80.80 (Air pumps, compressors, and fans – other compressors). Confirm with local customs authority for accuracy based on region.

- Export Controls: The 2475 may be subject to U.S. Department of Commerce Export Administration Regulations (EAR). Verify ECCN (Export Control Classification Number); typically classified under 2B350 or EAR99 depending on configuration.

- Restricted Destinations: Screen end-users and destinations against U.S. government restricted party lists (e.g., OFAC, BIS Denied Parties List).

- Documentation: Prepare commercial invoice, packing list, certificate of origin, and export license if required.

5. Safety & Regulatory Compliance

- OSHA Compliance (U.S.): Ensure safe installation and operation per OSHA 29 CFR 1910.169 (Compressed Air Equipment and Usage). Includes pressure vessel inspection and guarding of moving parts.

- Pressure Vessel Certification: The 2475 air receiver tank must meet ASME Boiler and Pressure Vessel Code (Section VIII) and be stamped with NB-261 or “U” certification.

- Electrical Standards: Comply with NFPA 70 (National Electrical Code) and local regulations for wiring, grounding, and disconnects.

- Noise Emissions: Confirm sound pressure levels meet OSHA 29 CFR 1910.95 and local noise ordinances. Unit typically operates below 80 dBA at 3 ft—verify with spec sheet.

- CE Marking (Europe): For EU shipments, ensure compliance with:

- Machinery Directive 2006/42/EC

- EMC Directive 2014/30/EU

- Pressure Equipment Directive 2014/68/EU

- Provide Declaration of Conformity and technical file upon request.

6. Environmental & Energy Regulations

- Energy Efficiency: The 2475 meets or exceeds U.S. DOE and EU Ecodesign (ErP) standards for air compressors. Refer to CAGI Performance Verification for certified efficiency data.

- Refrigerant Compliance (if applicable): If equipped with an integrated refrigerated dryer, ensure refrigerants (e.g., R-134a, R-513A) comply with EPA SNAP program (U.S.) and F-Gas Regulation (EU).

- Oil Management: Use only ISO-approved synthetic compressor oil. Dispose of used oil in accordance with EPA 40 CFR 260–273 (U.S.) or EU Directive 2008/98/EC for hazardous waste.

7. Installation & Site Requirements

- Foundation: Mount on a level, vibration-absorbing surface capable of supporting total weight (verify model-specific weight in manual).

- Ventilation: Provide minimum 3 ft (1 m) clearance around the unit for cooling. Ambient temperature must not exceed 43°C (110°F).

- Air Intake: Install in a clean, dry environment free from dust, fumes, or explosive vapors (per NEC Class I, Division 2 if applicable).

- Piping & Drains: Use properly sized Schedule 40 piping. Install automatic condensate drains compliant with local plumbing codes.

8. Documentation & Recordkeeping

- Required Manuals: Retain operation, maintenance, safety, and parts manuals as provided by Ingersoll Rand.

- Compliance Records: Maintain logs for:

- ASME pressure vessel inspections

- Oil and filter changes

- Safety valve testing (annually)

- Energy performance audits

- Regulatory Filings: Submit equipment registration where required by local authorities (e.g., pressure systems in Canada under CSA B52).

9. Disposal & End-of-Life

- Waste Electrical Equipment (WEEE): In the EU, dispose of electronic components under WEEE Directive 2012/19/EU.

- Hazardous Materials: Drain and recycle compressor oil, coolant, and batteries per RCRA (U.S.) or national hazardous waste laws.

- Asset Recovery: Contact Ingersoll Rand or authorized dealer for certified decommissioning and recycling services.

10. Support & Contact

For compliance inquiries, technical support, or documentation requests:

– Ingersoll Rand Global Support: +1-800-444-2470 (U.S.) or www.ingersollrandproducts.com

– Regulatory Affairs: [email protected]

Note: Always consult the latest product manual and local regulations prior to installation, operation, or shipment.

Conclusion for Sourcing the Ingersoll Rand 2475 Air Compressor:

Sourcing the Ingersoll Rand 2475 air compressor proves to be a strategic and reliable decision for operations requiring durable, high-performance compressed air solutions. Known for its robust construction, consistent output, and energy efficiency, the 2475 model exemplifies Ingersoll Rand’s reputation for engineering excellence and long-term reliability. Despite being a legacy model, its widespread use and continued support through spare parts and service networks ensure ease of maintenance and reduced downtime.

When sourcing this compressor, considerations such as condition (new, used, or refurbished), availability of documentation, warranty coverage, and supplier reputation are essential to maximize value and operational efficiency. Purchasing from authorized distributors or certified resellers ensures authenticity, compliance with safety standards, and access to technical support.

In summary, the Ingersoll Rand 2475 remains a viable and cost-effective choice for industrial and commercial applications. Proper sourcing not only secures a dependable asset but also contributes to long-term operational stability, making it a sound investment for businesses prioritizing performance and uptime.