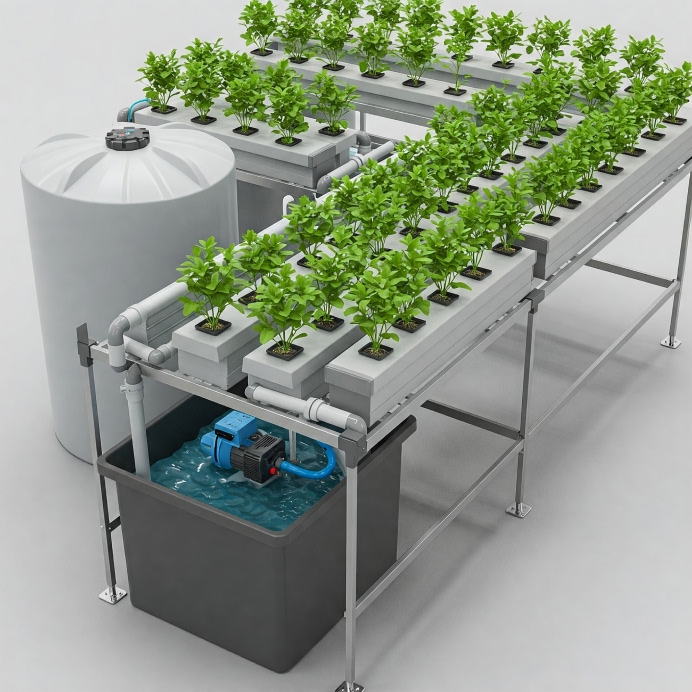

The global hydroponics market is experiencing robust growth, driven by increasing demand for sustainable agriculture and soilless cultivation methods. According to a report by Mordor Intelligence, the hydroponics market was valued at USD 32.5 billion in 2023 and is projected to grow at a CAGR of 12.1% from 2024 to 2029. A key enabler of this expansion is the rising adoption of inert growing media—particularly hydroponic stones such as rockwool, clay pebbles, perlite, and expanded shale—which provide superior aeration, water retention, and root support. As commercial and urban farming scale up worldwide, manufacturers of high-performance hydroponic substrates are playing an increasingly critical role in modern agriculture. With innovation and reliability becoming key differentiators, the following list highlights the top 10 hydroponic stones manufacturers shaping the future of soilless farming.

Top 10 Hydroponic Stones Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HydroGarden is the UK’s leading manufacturer and distributor of …

Domain Est. 1998

Website: hydrogarden.com

Key Highlights: HydroGarden is the UK’s leading manufacturer and distributor of hydroponic equipment and services. We are a wholesaler and distribute the biggest names in ……

#2 DL Wholesale

Domain Est. 2000

Website: dlwholesale.com

Key Highlights: DL Wholesale Inc is a leading wholesale distributor and manufacturer of general hydroponics, indoor gardening, horticulture equipment, grow systems, ……

#3 Begrow

Website: begrow.pro

Key Highlights: We are a manufacturer of hydroponics stone wool substrate. Our substrate is inert, hydrophilic and prevents plant diseases….

#4 to Grodan

Domain Est. 1996

Website: grodan.com

Key Highlights: Grodan offers a crop-specific range of substrate slabs for vegetable growing, specifically for tomato, cucumber, sweet pepper and aubergine crops….

#5 CropKing Inc

Domain Est. 1998

Website: cropking.com

Key Highlights: We’ve manufactured and sold greenhouse structures, hydroponic growing systems, growing supplies, and education materials. Shop now….

#6 Atlantis Hydroponics

Domain Est. 1998

#7 Hort Americas

Domain Est. 2008

Website: hortamericas.com

Key Highlights: Free delivery 90-day returnsHort Americas Hydroponic Fertilizer (9-7-37). $35 – $90….

#8 Agri

Domain Est. 2009

Website: laterlite.com

Key Highlights: Discover Laterlite Agri growing media with neutral pH and ideal chemical and physical characteristics for use in contact with plants….

#9 Hydroponic Growing Systems

Domain Est. 2016

Website: growrillahydroponics.com

Key Highlights: 14-day returnsGrowrilla Hydroponics is a 100% Italian brand of hydroponic growing systems, designed and manufactured in Italy by growers for growers….

#10 GEOLITE Clay Pebbles

Domain Est. 2016

Website: cfhydroponics.com

Key Highlights: Rating 4.9 (10) · 5-day deliveryGEOLITE horticultural clay pebbles are made from 100% natural clay. They are clean, pH stable, and offer great aeration and drainage in hydropon…

Expert Sourcing Insights for Hydroponic Stones

H2: Projected Market Trends for Hydroponic Stones in 2026

The hydroponic stones market is poised for significant evolution by 2026, driven by advancements in sustainable agriculture, rising urban farming initiatives, and growing demand for soilless cultivation systems. As a critical component in hydroponic systems—providing root support, moisture retention, and optimal oxygenation—hydroponic stones such as expanded clay pellets, rockwool, perlite, and coco coir are expected to experience robust growth and innovation.

-

Increased Demand from Urban Agriculture

Urbanization and limited arable land are accelerating the adoption of vertical and indoor farming, particularly in densely populated regions. By 2026, the expansion of urban agriculture, especially in North America, Europe, and parts of Asia-Pacific, will drive higher demand for efficient and reusable growing media like hydroponic stones. Expanded clay pellets (LECA) are anticipated to lead in popularity due to their reusability and neutral pH properties. -

Sustainability and Eco-Friendly Materials

Environmental concerns are shaping material preferences. There will be a noticeable shift toward renewable and biodegradable hydroponic stones, such as coconut coir and rice hull-based substrates. Regulatory pressures and consumer demand for sustainable practices will push manufacturers to innovate eco-friendly alternatives to traditional mineral-based stones like rockwool, which faces scrutiny over disposal and environmental impact. -

Technological Integration and Smart Farming

The integration of IoT and smart farming technologies into hydroponic systems will influence the design and functionality of hydroponic stones. By 2026, expect the emergence of “smart substrates” embedded with sensors to monitor moisture, nutrient levels, and root health. This trend will enhance precision agriculture, reducing waste and improving crop yields. -

Regional Market Growth and Supply Chain Optimization

Asia-Pacific is projected to be the fastest-growing market, fueled by government support for food security and investments in controlled environment agriculture (CEA). Local production of hydroponic stones will rise to reduce import dependency and logistics costs. Meanwhile, North America and Europe will focus on premium, high-performance substrates tailored for commercial greenhouse operations. -

Price Volatility and Raw Material Constraints

Fluctuations in energy prices and raw material availability (e.g., perlite and pumice) may impact production costs. This could lead to price instability in the short term. However, increased recycling programs and alternative material development are expected to mitigate these challenges by 2026. -

R&D and Product Innovation

Ongoing research into hybrid substrates—blends of organic and inorganic materials—will enhance water retention, aeration, and nutrient delivery. Startups and agri-tech firms are likely to introduce proprietary stone formulations optimized for specific crops like leafy greens, herbs, and strawberries.

In conclusion, the hydroponic stones market in 2026 will be characterized by innovation, sustainability, and integration with advanced agricultural technologies. With the global push toward food security and climate-resilient farming, hydroponic stones will play a pivotal role in shaping the future of modern agriculture.

H2: Common Pitfalls When Sourcing Hydroponic Stones (Quality and Intellectual Property)

Sourcing hydroponic stones—such as expanded clay aggregate (LECA), grow rocks, or other inert media—requires careful evaluation to ensure both product quality and compliance with intellectual property (IP) regulations. Below are key pitfalls to avoid:

1. Inconsistent Material Quality

- Porous Structure & Durability: Low-quality stones may break down easily, clogging systems or altering pH stability. Ensure uniform porosity and mechanical strength.

- pH Neutrality: Some stones leach minerals or affect pH. Always verify pH stability through lab testing.

- Contaminants: Poorly processed stones may contain dust, salts, or organic residues that harm plant health and clog irrigation systems.

2. Lack of Standardization

- Suppliers may use inconsistent sizing (e.g., 8–16 mm vs. 4–8 mm), affecting root aeration and water retention. Define precise size requirements in procurement contracts.

3. Misrepresentation of Product Origin or Type

- Be cautious of suppliers falsely labeling materials as “expanded clay” when they are crushed lava rock or other substitutes with different performance characteristics.

4. Intellectual Property (IP) Infringement

- Some hydroponic media brands (e.g., Hydroton, Grow Rocks) are trademarked. Sourcing generic versions is acceptable, but:

- Avoid using branded names or logos without authorization.

- Do not replicate patented product formulations or packaging designs.

- Verify that suppliers do not infringe on existing patents—especially for engineered media with unique coatings or additives.

5. Unreliable Supply Chain and Certification

- Lack of ISO or agricultural-grade certifications increases risk. Source from suppliers with verifiable quality control and traceability.

- Seasonal production or geographic limitations (e.g., clay sourcing regions) can disrupt supply.

6. Hidden Costs and Logistics

- Hydroponic stones are bulky and heavy. Poor logistics planning can inflate shipping costs and carbon footprint.

- Confirm packaging standards (e.g., moisture-resistant bags) to prevent degradation during transit.

Best Practices:

- Request samples and third-party test reports (pH, conductivity, particle size).

- Audit suppliers for manufacturing processes and IP compliance.

- Use clear contracts specifying technical specs, exclusivity clauses, and IP disclaimers.

By addressing these pitfalls, businesses can ensure reliable, high-performance hydroponic media while minimizing legal and operational risks.

Logistics & Compliance Guide for Hydroponic Stones

Overview

Hydroponic stones, commonly known as expanded clay aggregate (LECA), grow rocks, or clay pebbles, are inert, porous media used in hydroponic and aquaponic systems to support plant roots and retain moisture and nutrients. Proper logistics and compliance practices are essential to ensure product quality, regulatory adherence, and customer satisfaction.

Product Classification & HS Code

Hydroponic stones are typically classified under inert growing media and are not considered live plants or soil. The appropriate Harmonized System (HS) code may vary by country but commonly falls under:

- HS Code: 2530.90 – “Other mineral products, not elsewhere specified or included”

(Note: Confirm with local customs authorities; some jurisdictions may use 6802.91 for expanded clay aggregates used in horticulture.)

Always verify the correct HS code with national customs agencies to ensure accurate tariff classification and avoid import delays.

Packaging & Handling

- Packaging:

- Use durable, moisture-resistant polypropylene (PP) or woven polyethylene (PE) bags (e.g., 10L, 20L, 50L volumes).

- Seal bags securely to prevent contamination and moisture ingress.

-

Include UV-resistant packaging if stored outdoors or exposed to sunlight.

-

Labeling:

- Clearly mark product name (e.g., “Hydroponic Clay Pebbles”), net weight, batch number, manufacturer details, and usage instructions.

- Include compliance symbols (e.g., CE mark in Europe if applicable, recyclable packaging symbol).

-

Add handling instructions: “Protect from Moisture,” “Store in Dry Conditions.”

-

Handling:

- Avoid dropping or compressing bags to prevent breakage and dust generation.

- Use pallets for bulk shipments; stack no more than 10 layers high depending on bag strength.

Storage Requirements

- Environment:

- Store in a dry, well-ventilated warehouse.

- Avoid direct contact with soil or standing water.

- Ideal temperature range: 5°C to 35°C (41°F to 95°F).

-

Relative humidity: Below 70% to prevent clumping and mold.

-

Shelf Life:

- Indefinite if stored properly. No expiration date required, but batch traceability should be maintained for 3–5 years.

Transportation & Shipping

- Domestic & International Freight:

- Non-hazardous material; compliant with IATA, IMDG, and ADR regulations as non-dangerous goods.

- Can be shipped via road, rail, sea, or air without special permits.

-

Use covered containers or trucks to prevent rain exposure.

-

Shipping Documentation:

- Commercial invoice

- Packing list

- Certificate of Origin (if required for tariff preferences)

-

Bill of Lading or Air Waybill

-

Cold Chain: Not required.

Regulatory Compliance

- Environmental & Safety Standards:

- Comply with REACH (EU) and RoHS directives if applicable. Ensure no harmful heavy metals (e.g., lead, cadmium) exceed permissible limits.

- In the U.S., adhere to EPA and state environmental regulations regarding inert media.

-

Confirm compliance with local agricultural or horticultural product standards (e.g., OMRI listing if marketed for organic use).

-

Organic Certification (Optional):

- To be used in organic hydroponics, stones must be OMRI (Organic Materials Review Institute) listed or approved by equivalent bodies (e.g., Canada Organic Regime, EU Organic).

-

Ensure no synthetic additives or binders are used in manufacturing.

-

Label Claims:

- Avoid unsubstantiated claims (e.g., “100% Natural,” “Organic Approved”) unless certified.

- Clearly state “Inert Growing Medium – Not a Fertilizer.”

Import & Export Considerations

- Phytosanitary Certificates: Generally not required as hydroponic stones are inorganic and non-propagative.

- Customs Declarations: Declare accurately as “Inert Horticultural Substrate” or similar.

- Country-Specific Regulations:

- USA: USDA does not regulate inert media; CBP handles customs clearance.

- EU: May require conformity with EN 12580 for growing media (if applicable).

- Australia/NZ: Check AQIS/Biosecurity requirements—usually exempt but verify.

- Canada: CFIA does not restrict inert media; ensure packaging complies with Canadian labeling laws.

Returns & Waste Management

- Returns: Accept unopened, undamaged packaging only. Quarantine returned stock to prevent cross-contamination.

- Recycling: Clay pebbles are reusable and recyclable. Encourage end-users to rinse and sterilize before reuse.

- Disposal: Non-toxic; can be disposed of in general waste or repurposed in construction (e.g., lightweight aggregate).

Quality Assurance & Traceability

- Implement batch tracking using unique lot numbers.

- Conduct periodic testing for pH neutrality (ideal: 5.5–7.0), particle size consistency, and absence of fines/dust.

- Maintain records of supplier certifications, test reports, and shipping documentation for at least 5 years.

Summary Checklist

- ✅ Verify HS code with destination country

- ✅ Use moisture-resistant, labeled packaging

- ✅ Store in dry, ventilated conditions

- ✅ Ship as non-hazardous cargo

- ✅ Ensure compliance with REACH, OMRI (if applicable), and local standards

- ✅ Maintain batch traceability and documentation

- ✅ Confirm import requirements (phytosanitary not required in most cases)

Adhering to this guide ensures efficient logistics and full compliance when distributing hydroponic stones globally.

In conclusion, sourcing high-quality hydroponic stones is a critical step in establishing an efficient and sustainable hydroponic system. Materials such as expanded clay pellets, perlite, vermiculite, coconut coir, and rockwool each offer unique benefits in terms of aeration, water retention, pH neutrality, and reusability. When selecting a supplier, factors such as cost, consistency, availability, environmental impact, and certification standards should be carefully evaluated. Local sourcing can reduce transportation costs and support sustainability, while imported options may offer specific qualities not available domestically. Ultimately, choosing the right hydroponic growing medium from a reliable source contributes significantly to plant health, system performance, and long-term agricultural success. A well-informed sourcing strategy ensures optimal growing conditions, maximizes yield, and supports the overall viability of hydroponic farming ventures.