The global hydraulic lash adjuster market is experiencing steady growth, driven by increasing demand for efficient engine technologies in the automotive and industrial sectors. According to Mordor Intelligence, the Hydraulic Components Market—which includes critical parts like hydraulic lash adjusters—is projected to grow at a CAGR of over 4.5% from 2023 to 2028. This expansion is fueled by the rising production of commercial vehicles, passenger cars, and off-road machinery that rely on precision valve train systems to enhance engine performance and reduce noise, vibration, and harshness (NVH). Hydraulic lash adjusters play a pivotal role in maintaining optimal valve clearance automatically, contributing to improved fuel efficiency and reduced emissions—key priorities in modern engine design. With original equipment manufacturers (OEMs) increasingly prioritizing reliability and compliance with stringent emission norms, the demand for high-performance hydraulic lash adjusters continues to rise. This report highlights the top nine manufacturers leading innovation, quality, and market share in this specialized niche of engine components.

Top 9 Hydraulic Lash Adjuster Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

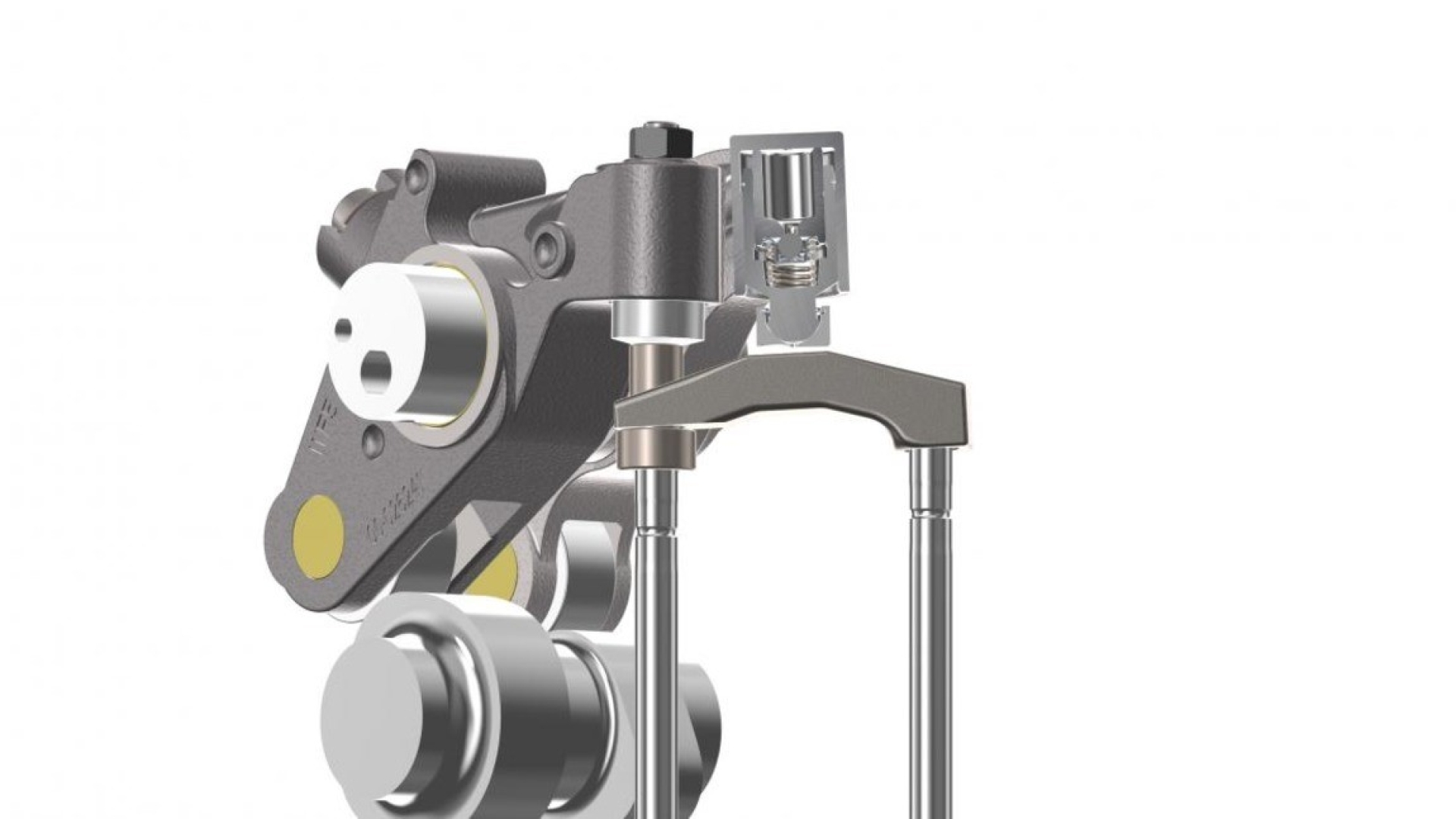

#1 Lashless Valvetrain with Engine Braking

Domain Est. 1990

Website: cummins.com

Key Highlights: Hydraulic Lash Adjuster (HLA) technology is desirable on heavy-duty engines to eliminate the need to set and adjust lash as well as to optimize the cam ……

#2 Eaton Valvetrain Technology

Domain Est. 1996

Website: videos.eaton.com

Key Highlights: In this video, we delve into the cutting-edge world of Eaton Valve Train Technology, featuring the game-changing Miller Hydraulic Lash Adjuster….

#3 Hydraulic Valve Lash Adjuster

Domain Est. 2022

Website: parts.chevypartspros.com

Key Highlights: In stock $11 deliveryHydraulic Valve Lash Adjuster – GM ( 12663277). Manufacturer: GM. Part Number: 12663277. Guaranteed fit and 12-mo./ Unlimited-Mile Warranty….

#4 Hydraulic lash adjusters

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton’s hydraulic lash adjusters are specifically designed to automatically adjust valve lash ensuring precise valve seating, optimized engine air flow, and ……

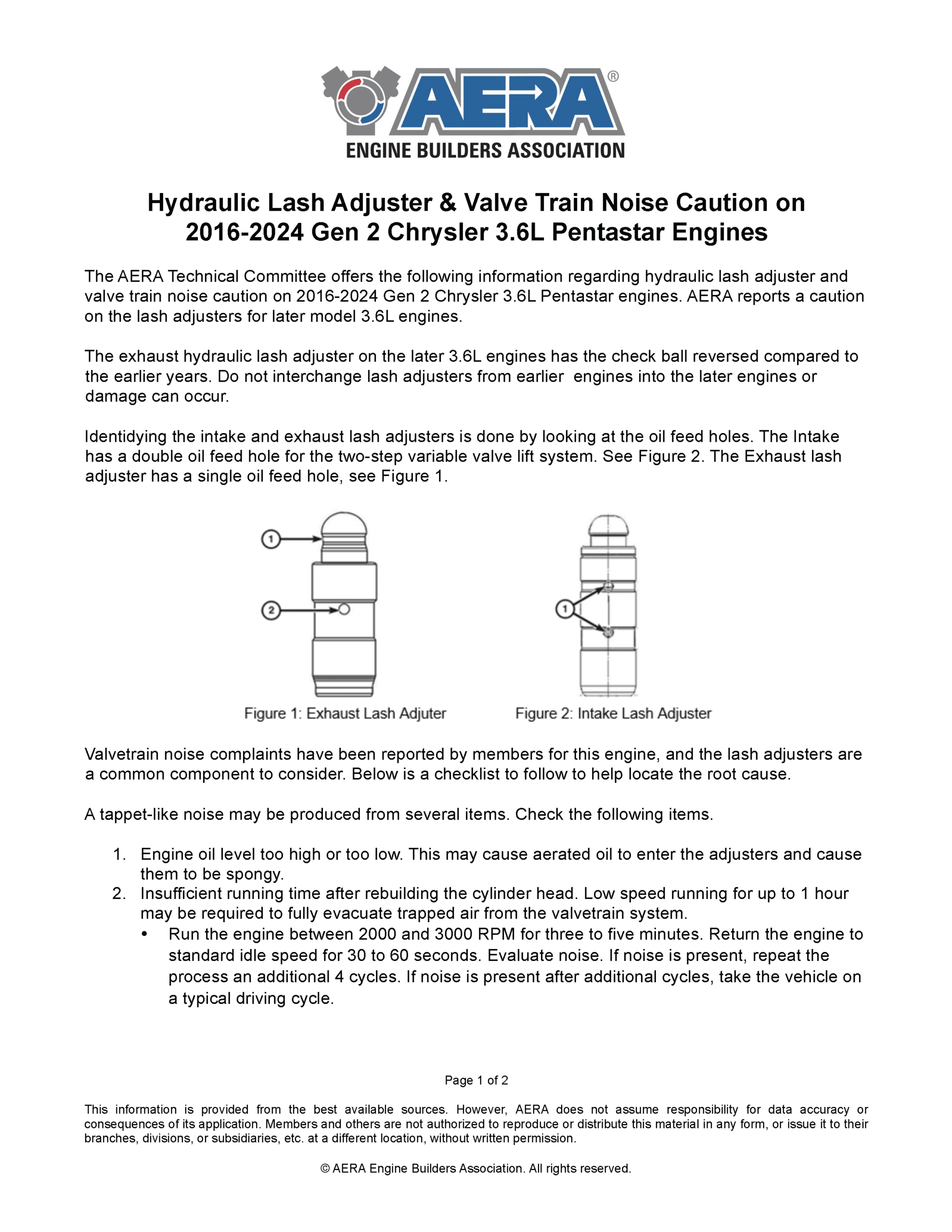

#5 Hydraulic Lash Adjuster & Valve Train Noise Caution 2016

Domain Est. 1996

Website: melling.com

Key Highlights: Hydraulic Lash Adjuster & Valve Train Noise Caution 2016-2024 Gen 2 Chrysler 3.6L ; Customer Service. (517) 787-8172 ; Technical Service. (517) ……

#6 Johnson Lifters

Domain Est. 2003

Website: johnsonlifters.com

Key Highlights: Welcome to the official Johnson Lifters® web page. At Johnson Lifters® we continuously use research and development with tooling and techniques for innovative ……

#7 Kent Moore 529295

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: We carry brand name manufactures from KD Tools, Mityvac, Robinair, and Zinko Jacks just to name a few. Shop By Categories. Categories. Abrasives & Adhesives ……

#8 2884572 Cummins

Domain Est. 2019

Website: s1partscenter.com

Key Highlights: In stock Rating 5.0 (1) The Hydraulic Lash Adjuster (2884572), manufactured by Cummins, is a critical component designed to facilitate the operation of heavy-duty truck engines….

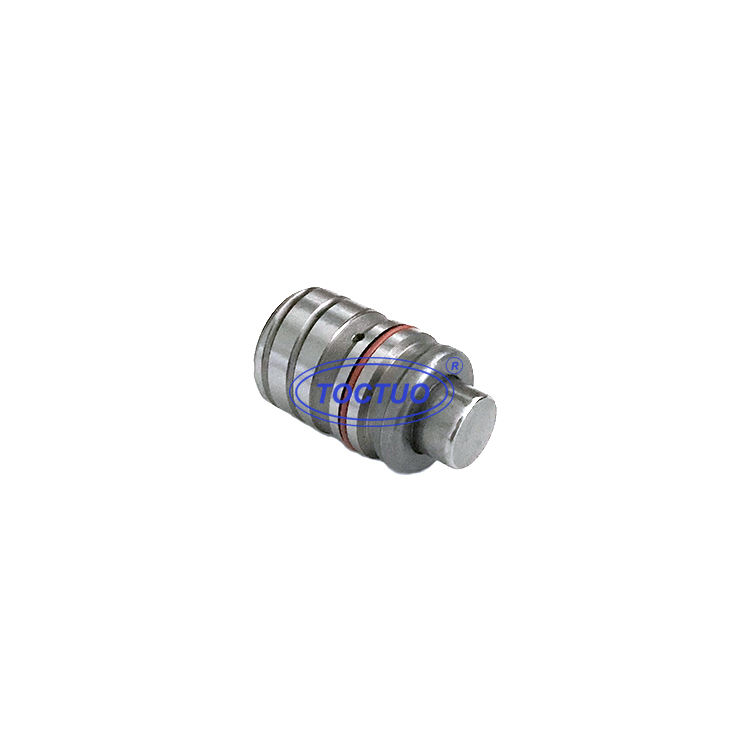

#9 Valve Lifters・Lash Adjusters|NITTAN Corporation

Website: niv.co.jp

Key Highlights: A valve lifter to open and close the engine valve (tappet and roller locker arm) and hydraulic lash adjuster (HLA)….

Expert Sourcing Insights for Hydraulic Lash Adjuster

H2: 2026 Market Trends for Hydraulic Lash Adjusters

The global market for hydraulic lash adjusters (HLAs) is poised for significant evolution by 2026, driven by advancements in internal combustion engine (ICE) technology, emission regulations, and shifts in automotive manufacturing. Despite the growing adoption of electric vehicles (EVs), hydraulic lash adjusters remain critical components in ICE and hybrid powertrains, ensuring quiet, efficient valve train operation. The following key trends are expected to shape the HLA market through 2026:

-

Continued Demand in Hybrid and ICE Vehicles

While the EV market is expanding, hybrid vehicles and traditional ICE platforms will continue to dominate global fleets through 2026, especially in emerging markets. HLAs are essential in maintaining optimal valve clearance in these engines, supporting quieter operation and improved fuel efficiency. As automakers refine hybrid powertrains, demand for high-performance, durable HLAs is expected to remain strong. -

Stringent Emission and Noise Regulations

Global regulations such as Euro 7 (in Europe) and China 6b are pushing automakers to reduce engine noise and emissions. Hydraulic lash adjusters contribute to smoother valve actuation, minimizing mechanical noise and ensuring consistent valve timing—key factors in meeting noise, vibration, and harshness (NVH) standards. This regulatory pressure will drive innovation in HLA design, including low-friction materials and enhanced sealing technologies. -

Material and Design Innovations

By 2026, manufacturers are expected to adopt advanced materials such as high-strength steel alloys and composite coatings to improve HLA durability and performance under high-temperature and high-pressure conditions. Additionally, design optimizations—such as variable bleed rates and improved oil flow dynamics—will enhance responsiveness and reduce wear, extending engine lifespan. -

Consolidation and Vertical Integration Among Suppliers

The HLA supply chain is seeing increased consolidation, with major players like Tenneco, NSK, and ThyssenKrupp expanding their product portfolios and integrating vertically to offer complete valve train systems. This trend allows for better system-level optimization and cost efficiency, giving OEMs a competitive edge. -

Growth in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, will remain key growth regions due to rising vehicle production and urbanization. Local manufacturers are increasingly adopting advanced engine technologies, boosting demand for reliable HLA solutions tailored to regional fuel qualities and operating conditions. -

Focus on Lightweighting and Efficiency

Automakers are prioritizing lightweight components to improve fuel economy. HLA designs are being optimized to reduce mass without compromising strength or performance. Miniaturization and integration with other valve train components are expected trends by 2026. -

Digitalization and Predictive Maintenance

Though still in early stages, some manufacturers are exploring smart HLAs equipped with sensors to monitor wear and performance in real time. While not mainstream by 2026, this digital integration could pave the way for predictive maintenance in high-end and commercial vehicle segments.

In conclusion, the hydraulic lash adjuster market in 2026 will be shaped by persistent demand in ICE and hybrid applications, regulatory pressures, material innovation, and regional growth dynamics. While electrification will impact long-term outlooks, HLAs will remain indispensable in the global mobility ecosystem for the foreseeable future.

Common Pitfalls Sourcing Hydraulic Lash Adjusters (Quality, IP)

Sourcing Hydraulic Lash Adjusters (HLAs) involves critical considerations beyond basic cost and availability. Overlooking quality and intellectual property (IP) risks can lead to significant operational, legal, and reputational damage. Here are key pitfalls to avoid:

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

Suppliers, particularly from low-cost regions, may lack rigorous quality control systems, resulting in inconsistent dimensional accuracy, material composition, or heat treatment. This variability can cause premature failure, noise, or engine performance issues.

Substandard Materials and Components

Using inferior-grade steel or low-quality internal seals compromises durability. Poor materials are prone to wear, corrosion, and cracking under high-pressure and high-temperature engine conditions, leading to increased warranty claims and customer dissatisfaction.

Inadequate Testing and Validation

Some suppliers skip or simulate essential performance tests such as leak testing, pressure cycling, and endurance testing. Without proper validation, HLAs may pass initial inspections but fail in real-world applications, risking engine damage.

Lack of Traceability and Documentation

Poor batch tracking and incomplete quality documentation (e.g., material certifications, process validation reports) make it difficult to investigate failures or comply with automotive industry standards like IATF 16949.

Intellectual Property (IP) Risks

Counterfeit or Reverse-Engineered Products

Sourcing from unauthorized or unverified suppliers increases the risk of receiving counterfeit HLAs that mimic original equipment (OE) designs. These products often infringe on patents and trademarks, exposing the buyer to legal liability.

Patent Infringement Exposure

Many HLAs incorporate patented technologies related to check valve mechanisms, plunger design, or damping characteristics. Sourcing non-licensed copies—even unknowingly—can result in cease-and-desist orders, litigation, and financial penalties.

Limited Legal Recourse

Suppliers in jurisdictions with weak IP enforcement may not offer warranties against IP infringement. Buyers may bear full responsibility if third parties assert patent or design rights, especially in markets with stringent IP laws.

Reputational Damage

Association with counterfeit or IP-infringing parts can harm brand credibility, particularly for OEMs or tier-one suppliers committed to quality and compliance. Regulatory bodies and customers increasingly demand transparency in sourcing practices.

To mitigate these risks, conduct thorough supplier audits, require IP compliance certifications, prioritize partners with OE experience, and implement robust incoming inspection protocols. Engaging legal counsel to review supply agreements for IP indemnification clauses is also strongly advised.

Logistics & Compliance Guide for Hydraulic Lash Adjuster

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, handling, storage, and regulatory adherence of Hydraulic Lash Adjusters (HLAs). These components are critical in internal combustion engines for maintaining proper valve clearance and ensuring optimal engine performance. Adhering to the procedures in this document ensures safety, regulatory compliance, and product integrity throughout the supply chain.

Classification & HS Code

Hydraulic Lash Adjusters are typically classified under the following Harmonized System (HS) code:

8481.80 – Parts suitable for use solely or principally with the articles of heading 8481 (valves, including pressure-reducing valves and thermostatically controlled valves).

Note: Confirm the exact code with local customs authorities, as classification may vary by country and specific product design.

Packaging & Marking Requirements

- Packaging: HLAs must be packed in moisture-resistant, shock-absorbent materials to prevent corrosion and mechanical damage. Use sealed plastic bags with desiccants for individual units, then place in sturdy corrugated cardboard boxes or reusable container systems.

- Marking: Each package must be clearly labeled with:

- Product name and part number

- Quantity per package

- Net and gross weight

- Handling symbols (e.g., “Do Not Stack”, “Fragile”, “This Side Up”)

- Country of origin

- Manufacturer name and address

- Batch/lot number for traceability

Transportation Requirements

- Mode of Transport: HLAs can be shipped via air, sea, or land freight. For high-value or time-sensitive shipments, air freight is recommended.

- Temperature & Humidity: Store and transport in a dry environment with temperatures between 5°C and 35°C. Avoid condensation and exposure to direct sunlight.

- Stacking Limits: Adhere to manufacturer-specified stacking heights to prevent package deformation or part damage.

- Hazardous Materials: HLAs are generally non-hazardous. However, if lubricants or hydraulic fluids are pre-filled, verify MSDS and classify accordingly (e.g., UN3082 for environmentally hazardous substances, if applicable).

Import/Export Compliance

- Documentation: Ensure all shipments include:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (preferably Form A for preferential tariffs under trade agreements)

- Export Declaration (if required by exporting country)

- Regulatory Approvals: Verify compliance with destination country regulations (e.g., REACH, RoHS in the EU; TSCA in the US). Provide material declarations upon request.

- Duty & Tariff Relief: Investigate eligibility for duty reductions under free trade agreements (e.g., USMCA, EU-South Korea FTA) based on rules of origin.

Storage Conditions

- Environment: Store in a clean, dry, temperature-controlled warehouse. Relative humidity should not exceed 65%.

- Shelf Life: Typically, HLAs have a shelf life of 24 months from date of manufacture when stored properly. Monitor batch expiration dates.

- Inventory Management: Implement FIFO (First In, First Out) practices to prevent aging of stock. Conduct regular audits for damage or contamination.

Environmental & Safety Compliance

- RoHS Compliance: Ensure HLAs are free from restricted substances (e.g., lead, cadmium, hexavalent chromium) per Directive 2011/65/EU.

- REACH Regulation: Confirm no Substances of Very High Concern (SVHC) are present above threshold levels. Provide SVHC declarations if requested.

- Waste Disposal: Follow local regulations for disposal of packaging and non-functional units. Metal components may be recyclable; consult certified recycling partners.

Quality & Traceability

- Lot Tracking: Maintain full traceability from raw materials to finished goods using unique batch or serial numbers.

- Inspection: Conduct pre-shipment inspections to verify packaging integrity, marking accuracy, and compliance with purchase order specifications.

- Non-Conformance Handling: Establish procedures for quarantine, return, or rework of non-compliant shipments in coordination with quality assurance teams.

Conclusion

Proper logistics and compliance management for Hydraulic Lash Adjusters ensures product reliability, minimizes supply chain disruptions, and supports global market access. Regular training for logistics personnel and continuous monitoring of regulatory changes are recommended to maintain compliance across all regions of operation.

Conclusion for Sourcing Hydraulic Lash Adjusters

In conclusion, sourcing hydraulic lash adjusters requires a strategic approach that balances quality, cost, reliability, and technical compatibility. These critical engine components play a vital role in maintaining optimal valve train performance, reducing noise, and ensuring long-term engine durability. Therefore, selecting the right supplier is paramount.

Key considerations in the sourcing process include the manufacturer’s technical expertise, adherence to OEM specifications, material quality, production consistency, and compliance with industry standards. Evaluating potential suppliers based on certifications, track record, and after-sales support helps mitigate risks related to performance failures and warranty claims.

Additionally, geographical factors, lead times, and logistical capabilities should be assessed to ensure a reliable and efficient supply chain. Establishing strong partnerships with reputable suppliers—whether original equipment manufacturers or certified aftermarket producers—can lead to improved cost efficiency, innovation sharing, and long-term operational success.

Ultimately, a well-executed sourcing strategy for hydraulic lash adjusters not only enhances engine performance and reliability but also contributes to lower maintenance costs and increased customer satisfaction. Continuous monitoring, supplier performance reviews, and staying informed about technological advancements will further support optimal sourcing decisions in the evolving automotive and industrial sectors.