The global hydraulic clamp market is experiencing steady expansion, driven by increasing demand for heavy-duty clamping solutions across manufacturing, construction, and oil & gas sectors. According to Mordor Intelligence, the hydraulic tools market—including hydraulic clamps—is projected to grow at a CAGR of approximately 6.2% from 2023 to 2028. This growth is fueled by the need for precision, safety, and efficiency in industrial applications, particularly in emerging economies investing in infrastructure and advanced manufacturing. As automation and high-pressure systems become more prevalent, the demand for reliable hydraulic clamps has elevated, placing a spotlight on manufacturers known for innovation, durability, and performance. Amid this trend, eight key manufacturers have emerged as leaders, combining engineering excellence with scalable production to meet rising global demand.

Top 8 Hydraulic C Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

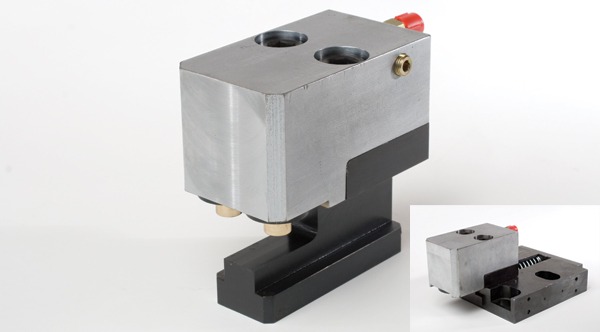

#1 TAIWAN AMAC CLAMP INDUSTRIAL CO., LTD.

Domain Est. 2000

Website: clamp.com.tw

Key Highlights: Taiwan AMAC Clamp Ind. Co., Ltd. We design and manufacture a wide variety of cylinders for jig applications on various special purpose machine and machining ……

#2 World Leader in Hydraulic and Pneumatic Workholding

Domain Est. 1996

Website: vektek.com

Key Highlights: Vektek manufactures hydraulic and pneumatic clamps, work supports, and fixture solutions, delivering reliable, precision-engineered workholding products ……

#3 Clamps, DIN 3015

Domain Est. 1996

Website: catalog.hydac.com

Key Highlights: Whether customized one-off productions or cost-effective and versatile series products, at HYDAC you will find an economical solution for almost all industries….

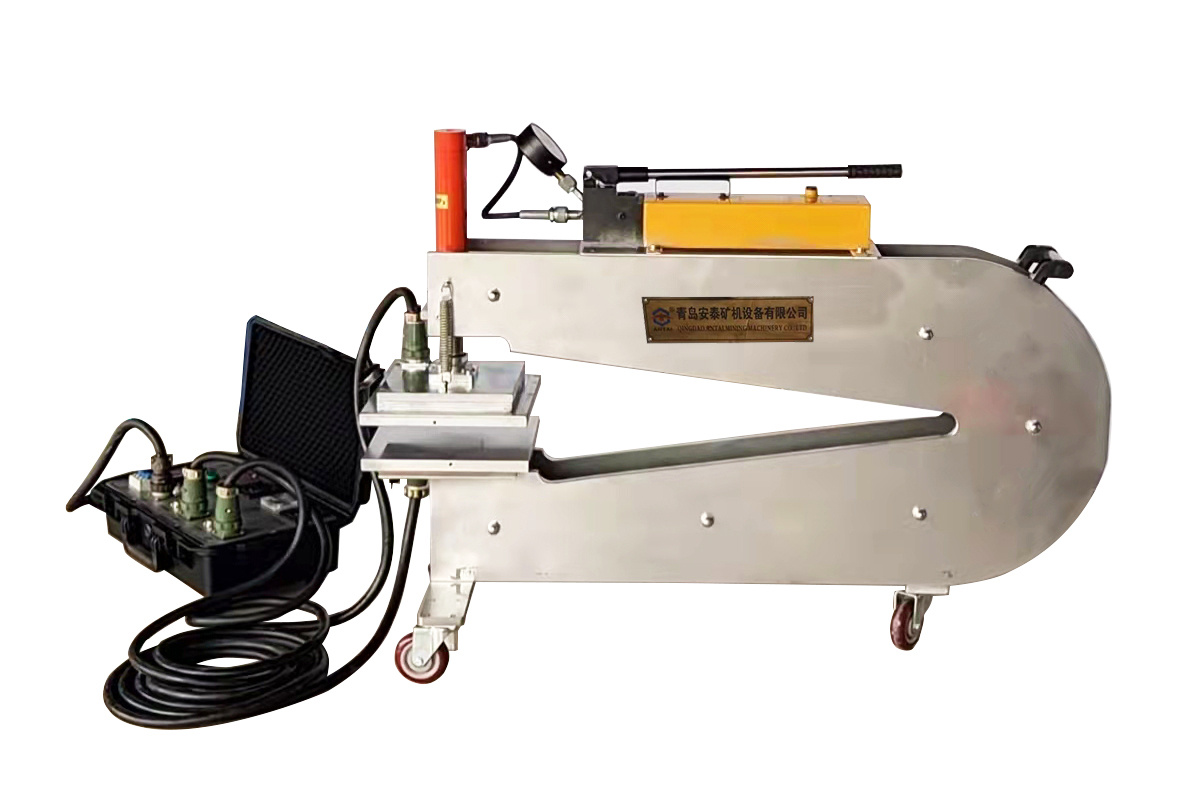

#4 Quick Die Change Systems

Domain Est. 1997

Website: pfa-inc.com

Key Highlights: Available in the single piston style Model 283 and double piston style Model 283D, “C” clamps require only 1.25″ to 1″ of die plate engagement, respectively, ……

#5 C-Clamp

Domain Est. 2002

Website: gustininc.com

Key Highlights: Free deliveryWe sell virtually C-Clamp. Gustin Hydraulics is here to help, call now!…

#6 Wilton C

Domain Est. 2006

Website: wiltontools.com

Key Highlights: Browse our selection of high-quality c-clamp kits featuring multiple clamps for all your clamping needs. Get the best deals on c-clamp sets at Wilton Tools….

#7 Clamptek Encyclopedia

Domain Est. 2019

Website: clamptekglobal.com

Key Highlights: A hydraulic clamp is a hydraulic clamping device that converts the hydraulic pressure into a clamping force to secure the workpiece….

#8 KOSMEK LTD. [Workholding, Mold/Die Change, Automation]

Website: kosmek.co.jp

Key Highlights: Kosmek offers productivity solutions with Work Clamping Systems, Quick Mold Change Systems, Quick Die Change Systems, Diecast Clamping Systems and Robotic ……

Expert Sourcing Insights for Hydraulic C Clamp

H2: 2026 Market Trends for Hydraulic C Clamp

The global Hydraulic C Clamp market is poised for steady growth and transformation by 2026, driven by advancements in industrial automation, rising demand from manufacturing and construction sectors, and the increasing emphasis on precision and efficiency in metalworking and assembly operations.

One of the key trends shaping the market is the integration of smart technologies into hydraulic tools. By 2026, manufacturers are increasingly incorporating digital monitoring systems, pressure sensors, and IoT-enabled features into Hydraulic C Clamps. These enhancements allow for real-time performance tracking, predictive maintenance, and improved safety—making them especially attractive in high-precision industries such as automotive and aerospace.

Additionally, the shift toward lightweight yet durable materials—such as high-grade aluminum alloys and reinforced composites—is expected to influence product design. This evolution supports portability and reduces operator fatigue, particularly in field applications and on construction sites. The demand for ergonomic and modular clamping solutions is also on the rise, as industries prioritize worker safety and operational flexibility.

Geographically, Asia-Pacific is projected to dominate the market by 2026, fueled by rapid industrialization in countries like China, India, and Vietnam. Expanding infrastructure projects and government support for manufacturing growth are boosting demand for reliable clamping tools. Meanwhile, North America and Europe continue to lead in innovation, with a focus on energy-efficient hydraulic systems and compliance with stringent safety standards.

Sustainability is another emerging trend. By 2026, manufacturers are expected to emphasize recyclable materials and energy-efficient production processes to align with global environmental regulations and corporate sustainability goals.

In summary, the Hydraulic C Clamp market in 2026 will be characterized by technological innovation, regional growth imbalances, and a strong push toward smarter, lighter, and more sustainable tools—positioning the industry for long-term expansion across diverse industrial applications.

Common Pitfalls When Sourcing Hydraulic C Clamps (Quality, IP)

Sourcing Hydraulic C Clamps involves navigating several critical challenges, particularly concerning product quality and intellectual property (IP) protection. Overlooking these aspects can lead to operational failures, safety risks, and legal complications.

Poor Material and Build Quality

Many suppliers, especially low-cost manufacturers, use substandard materials such as inferior-grade steel or weak hydraulic seals. This compromises the clamp’s load capacity, durability, and resistance to wear. Poor welding, inconsistent machining, or lack of proper heat treatment can result in structural failure under pressure, leading to safety hazards and costly downtime.

Inaccurate or Exaggerated Performance Specifications

Some suppliers may overstate key performance metrics like maximum clamping force, stroke length, or pressure ratings. Without third-party certification or verifiable test data, buyers risk acquiring underperforming equipment that fails to meet application requirements. This is particularly dangerous in high-pressure industrial environments where precision and reliability are critical.

Lack of IP Compliance and Risk of Counterfeiting

Sourcing from regions with weak IP enforcement exposes buyers to counterfeit or cloned products that mimic patented designs. These copies often lack engineering validation, use reverse-engineered components, and may infringe on original manufacturers’ intellectual property. Using such products can expose the buyer to legal liability, warranty voidance, and reputational damage.

Inadequate IP Protection in Supplier Agreements

Failure to include clear IP clauses in procurement contracts—such as ownership of custom designs, confidentiality, and restrictions on reverse engineering—leaves companies vulnerable. Suppliers may reuse design specifications for other clients or sell them to competitors, eroding competitive advantage and innovation investment.

Insufficient Certifications and Compliance Documentation

Reputable Hydraulic C Clamps should meet international standards (e.g., ISO, CE, or ANSI). Suppliers may provide forged or incomplete documentation, making it difficult to verify compliance with safety and environmental regulations. This is especially critical in regulated industries such as aerospace, automotive, or oil and gas.

Supply Chain Transparency Issues

Opaque supply chains make it difficult to trace component origins or verify manufacturing processes. This lack of traceability increases the risk of receiving non-compliant or contaminated materials and complicates quality audits or root-cause analysis in case of failure.

Avoiding these pitfalls requires due diligence, including supplier audits, independent quality testing, legal review of IP terms, and procurement from reputable, certified manufacturers.

Logistics & Compliance Guide for Hydraulic C Clamp

Product Overview

The Hydraulic C Clamp is a high-strength clamping tool designed for industrial applications requiring controlled pressure and secure holding. It utilizes hydraulic mechanisms to generate substantial clamping force within a C-shaped frame, making it suitable for welding, assembly, machining, and repair tasks. Proper logistics handling and compliance adherence are critical due to the tool’s weight, pressurized components, and potential safety hazards.

Packaging Requirements

Hydraulic C Clamps must be packaged securely to prevent damage during transit. Use robust wooden crates or heavy-duty corrugated cardboard with internal foam or molded inserts to immobilize the clamp. Ensure all hydraulic ports are capped or sealed to prevent contamination and fluid leakage. Include desiccant packs in sealed packaging when shipping to humid or marine environments to prevent internal corrosion. Clearly label packages with orientation markers (e.g., “This Side Up”) and “Fragile” warnings.

Transportation Guidelines

Transport Hydraulic C Clamps via ground or air freight based on urgency and destination. For international shipments, comply with IATA (air) or IMDG (sea) regulations if hydraulic fluid is present. Empty the hydraulic system or secure fluid reservoirs to meet transport restrictions on pressurized or liquid components. Ensure clamps are fastened within containers or vehicles to prevent shifting. Avoid exposure to extreme temperatures during transit, which may compromise seals or internal components.

Import/Export Compliance

Verify classification under the Harmonized System (HS) Code—typically 8467.89 for mechanical hand tools with hydraulic components. Confirm country-specific import regulations, including CE marking (EU), UKCA (UK), or ANSI/ASME standards (USA). Some regions may require certification from recognized bodies (e.g., TÜV, UL) for industrial tools. Complete accurate commercial invoices, packing lists, and certificates of origin. Declare any hydraulic fluid composition if exceeding regulatory thresholds.

Safety & Regulatory Standards

Hydraulic C Clamps must comply with relevant safety standards such as:

– ISO 13849: Safety of machinery – Safety-related parts of control systems

– ANSI B107.200: American National Standard for Hand Tools

– EN 12198: Safety of machinery – Assessment and reduction of risks from radiation emitted by machinery

Ensure product labeling includes maximum pressure rating, safe working load (SWL), manufacturer details, and CE or equivalent conformity marking. User manuals must be provided in the local language of the destination country.

Handling and Storage Instructions

Handle Hydraulic C Clamps with appropriate lifting equipment due to their weight. Store in a dry, temperature-controlled environment away from direct sunlight and corrosive chemicals. Keep clamps in upright position with jaws closed and pressure fully released. Conduct periodic inspections for leaks, seal degradation, or structural damage before use. Follow manufacturer-recommended maintenance schedules to ensure compliance with operational safety standards.

Environmental and Disposal Compliance

Dispose of end-of-life Hydraulic C Clamps in accordance with local environmental regulations. Recycle metal components through certified scrap processors. Hydraulic fluid must be drained and disposed of as hazardous waste where applicable, following EPA (USA), WEEE (EU), or equivalent directives. Document disposal procedures to maintain regulatory compliance and support corporate sustainability reporting.

Documentation and Recordkeeping

Maintain comprehensive records including:

– Product conformity certificates

– Test reports for pressure and load capacity

– Shipping and customs documentation

– Maintenance and inspection logs

Retention periods should align with regional legal requirements—typically 5–10 years for industrial equipment compliance. Digital records should be securely backed up and accessible for audits.

Conclusion for Sourcing Hydraulic C-Clamp

Sourcing hydraulic C-clamps requires a strategic approach that balances performance, reliability, cost-efficiency, and supplier credibility. These specialized clamping tools are essential in industrial applications where high pressure, precision, and durability are critical, such as in fabrication, assembly, and repair operations. After evaluating key factors—including clamping force, stroke length, build material (typically high-strength steel or alloy), safety features, and compatibility with existing systems—it is evident that selecting the right hydraulic C-clamp directly impacts operational efficiency and workplace safety.

To ensure optimal results, it is recommended to source from reputable manufacturers or suppliers with proven track records in hydraulic equipment, relevant certifications (e.g., ISO, CE), and strong after-sales support. Conducting thorough market research, obtaining product samples, and comparing technical specifications across multiple vendors can help identify the most suitable option. Additionally, considering total cost of ownership—factoring in maintenance, longevity, and downtime reduction—will provide long-term value.

In conclusion, a well-informed sourcing decision for hydraulic C-clamps enhances productivity, ensures safety compliance, and supports seamless integration into industrial workflows. Prioritizing quality over upfront cost and fostering reliable supplier relationships are key to achieving sustainable operational success.

![KOSMEK LTD. [Workholding, Mold/Die Change, Automation]](https://www.fobsourcify.com/wp-content/uploads/2026/01/kosmek-ltd-workholding-molddie-change-automation-592.jpg)