The global environmental test chamber market, driven by rising demand for reliability testing across industries such as electronics, pharmaceuticals, and automotive, is projected to grow at a CAGR of 6.8% from 2023 to 2030, according to Grand View Research. With humidity chambers forming a critical component of this segment—essential for simulating real-world environmental conditions—the market expansion reflects increasing regulatory standards and quality assurance requirements. Mordor Intelligence further underscores this trajectory, estimating a CAGR of nearly 7.2% over the forecast period (2024–2029), fueled by technological advancements and intensified R&D activities in emerging economies. As demand surges, leading manufacturers are scaling innovation in precision, energy efficiency, and smart monitoring capabilities. Against this backdrop, identifying the top 10 humidity chamber manufacturers offers key insights into industry leaders shaping the future of environmental testing.

Top 10 Humidity Chamber Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leading Humidity Chamber Manufacturers

Domain Est. 2012

Website: testchambermanufacturers.com

Key Highlights: Review humidity chamber information and learn how manufacturers design, engineer and manufacture different kinds of industrial humidity chambers….

#2 Parameter

Domain Est. 1998

Website: humiditycontrol.com

Key Highlights: Parameter Generation & Control is an internationally respected manufacturer & innovator of precise humidity control chambers & temperature control systems….

#3 ESPEC Humidity Testing Chambers

Domain Est. 1996

Website: espec.com

Key Highlights: ESPEC offers the widest selection of Humidity Testing Chambers in North America. Visit here to browse our high quality products and learn more!…

#4 Temperature & Humidity

Domain Est. 1996

Website: thermotron.com

Key Highlights: Thermotron temperature chambers come in a variety of sizes and performance configurations, including optional humidity capabilities….

#5 Humidity Testing Chambers

Domain Est. 1997

Website: labrepco.com

Key Highlights: 5–9 day delivery 30-day returnsHumidity Testing Chambers are cabinets that offer a controlled humidity environment for use in research and product testing applications….

#6 BINDER

Domain Est. 2001

Website: binder-world.com

Key Highlights: Precise environmental simulation for research and industry. Reliable quality, sustainable products and expert support – best conditions for your success….

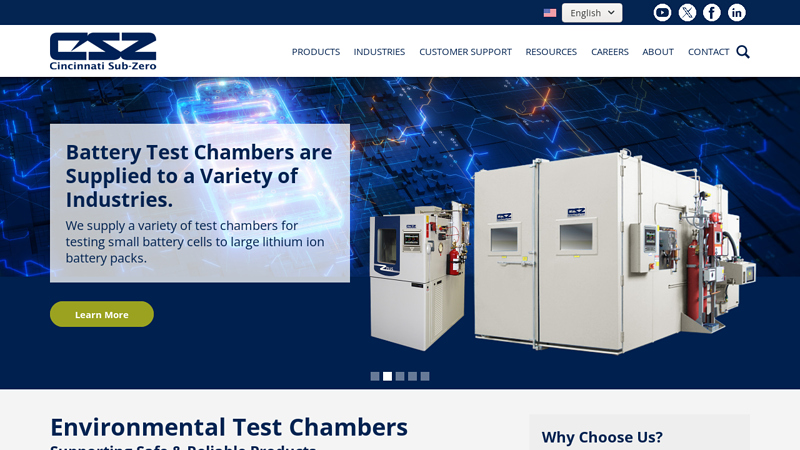

#7 CSZ Environmental Test Chambers

Domain Est. 2002

Website: cszindustrial.com

Key Highlights: We offer a full range of standard and custom-designed environmental chambers providing solutions to meet demanding environmental testing requirements….

#8 Humidity Chamber

Domain Est. 2003

Website: darwinchambers.com

Key Highlights: Darwin Chambers designs high-performance humidity chambers for stability testing, conditioning, and environmental simulation. Precise, reliable, and ready ……

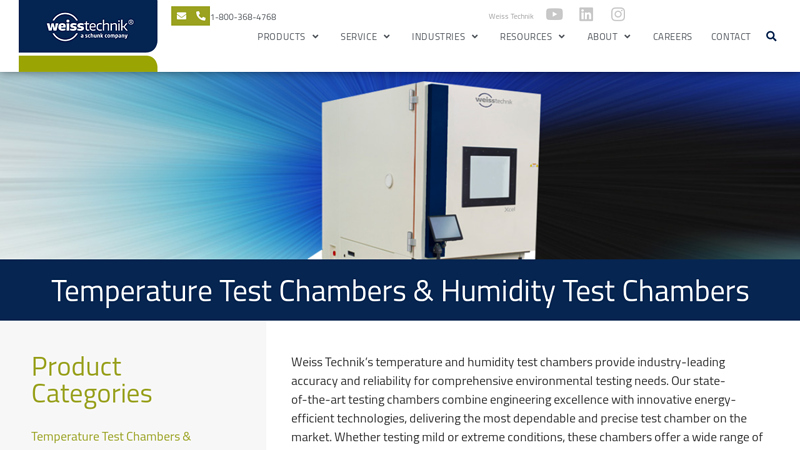

#9 Temperature & Humidity Test Chambers

Domain Est. 2013

Website: weiss-na.com

Key Highlights: Weiss Technik’s temperature and humidity test chambers provide industry-leading accuracy and reliability for comprehensive environmental testing needs….

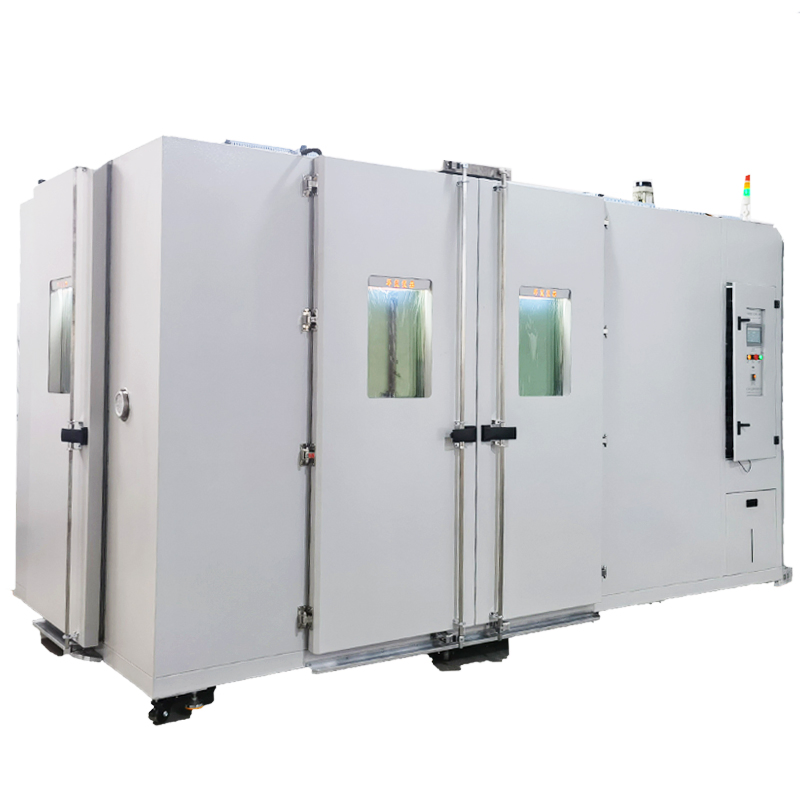

#10 Environmental Chambers

Domain Est. 2018

Website: sanwood.cc

Key Highlights: SANWOOD environmental test chambers are capable of simulating air flow, altitude, temperature fluctuations, vibration and pressure, as well as weathering and ……

Expert Sourcing Insights for Humidity Chamber

H2: Projected Market Trends for Humidity Chambers in 2026

As we approach 2026, the global humidity chamber market is expected to witness significant growth and transformation, driven by expanding industrial applications, technological advancements, and increasing regulatory demands for product reliability testing. Humidity chambers—also known as environmental or climate chambers—are essential tools used across industries such as electronics, pharmaceuticals, automotive, aerospace, and materials science to test the effects of controlled humidity and temperature conditions on products and components.

One of the primary drivers of market growth by 2026 is the rising need for quality assurance and compliance with international standards (e.g., ISO, IEC, ASTM). In sectors like electronics and medical devices, where product failure due to moisture exposure can have serious consequences, manufacturers are investing heavily in environmental testing equipment. This trend is amplified by the growing complexity of electronic components, particularly in consumer electronics and IoT devices, which require rigorous reliability testing under various climatic conditions.

Technological innovations are also shaping the 2026 market landscape. Next-generation humidity chambers are increasingly integrating smart features such as IoT connectivity, remote monitoring, real-time data analytics, and automated control systems. These enhancements improve testing accuracy, reduce operational downtime, and allow for seamless integration into digital quality management systems. Vendors are focusing on energy-efficient designs and improved chamber uniformity to meet sustainability goals and stringent performance requirements.

Regionally, the Asia-Pacific market is expected to lead in terms of growth, fueled by rapid industrialization, booming electronics manufacturing (especially in China, India, and South Korea), and expanding pharmaceutical R&D activities. North America and Europe will maintain strong market positions due to advanced research infrastructure, strict regulatory frameworks, and sustained investments in aerospace and defense testing.

Additionally, the customization of humidity chambers for specific industry needs—such as high-precision chambers for semiconductor testing or large-scale chambers for automotive component validation—is becoming a key competitive differentiator among manufacturers.

In summary, the 2026 humidity chamber market is poised for robust expansion, driven by technological innovation, regulatory compliance, and increasing demand across high-growth industries. Companies that offer intelligent, energy-efficient, and application-specific solutions are likely to gain a strategic advantage in this evolving marketplace.

Common Pitfalls When Sourcing a Humidity Chamber: Quality and Intellectual Property (IP) Concerns

Sourcing a humidity chamber involves more than just selecting the right specifications. Overlooking critical quality and intellectual property aspects can lead to significant operational, financial, and legal risks. Here are key pitfalls to avoid:

Quality-Related Pitfalls

1. Inadequate Calibration and Traceability

Many suppliers offer chambers with factory calibration, but fail to provide NIST-traceable documentation. Without proper traceability, test results may not be valid for regulatory compliance (e.g., ISO 17025, FDA audits), leading to rejected data or product recalls.

2. Poor Construction Materials and Corrosion Resistance

Low-cost chambers often use substandard stainless steel or coatings that degrade under prolonged exposure to high humidity and temperature cycles. This leads to chamber failure, contamination of test samples, and increased maintenance costs.

3. Inaccurate or Unstable Environmental Control

Some chambers exhibit poor humidity and temperature uniformity across the test chamber, or struggle to maintain setpoints under load. This undermines test reliability, especially for sensitive applications like pharmaceutical stability testing or electronic component validation.

4. Lack of Validation Support (IQ/OQ/PQ)

Suppliers may not provide comprehensive installation, operational, and performance qualification (IQ/OQ/PQ) documentation. This increases the burden on the buyer to validate the equipment, delaying project timelines and increasing costs.

5. Insufficient After-Sales Service and Technical Support

Choosing a supplier with limited local service coverage or poor technical expertise can result in prolonged downtime. Spare parts may be unavailable, and firmware/software updates may not be supported, affecting long-term usability.

Intellectual Property (IP)-Related Pitfalls

1. Use of Counterfeit or Reverse-Engineered Components

Some low-cost manufacturers incorporate cloned sensors, controllers, or software that infringe on original equipment manufacturers’ (OEMs) IP. This exposes the buyer to legal liability and risks non-compliance with industry standards.

2. Proprietary Software Lock-In and Data Ownership

Certain suppliers use proprietary software with restrictive licensing that limits data export, analysis, or integration with enterprise systems. This can hinder data traceability and create vendor dependency, compromising data ownership and regulatory audits.

3. Lack of Transparency in Design and Manufacturing

Suppliers may obscure the origin of critical components or use unlicensed firmware. This lack of transparency makes it difficult to assess IP risks and may violate internal procurement or compliance policies, particularly in regulated industries.

4. Inadequate Protection of Custom Configurations

If you request a customized chamber (e.g., unique size, control logic), ensure your design specifications are protected via clear contractual terms. Otherwise, the supplier may reuse or resell your design to competitors.

5. Non-Compliance with International IP Regulations

Sourcing from regions with weak IP enforcement increases the risk of inadvertently acquiring equipment that violates patents or trademarks. This can result in shipment seizures, legal action, or reputational damage.

Best Practices to Mitigate Risks

- Verify certifications: Ensure the supplier complies with ISO 9001, ISO/IEC 17025, and relevant regional standards.

- Request full traceability: Demand NIST-traceable calibration certificates and component datasheets.

- Audit the supplier: Conduct factory audits or request third-party inspection reports.

- Review software and licensing: Confirm open data formats, API access, and clear IP ownership clauses in contracts.

- Use legal agreements: Include IP indemnification clauses and confidentiality agreements for custom designs.

By proactively addressing these quality and IP pitfalls, organizations can ensure reliable, compliant, and legally secure operation of their humidity chambers.

H2: Logistics & Compliance Guide for Humidity Chamber

H3: Pre-Shipment Logistics & Preparation

-

Secure Packaging:

- Use the original manufacturer’s crate or a custom-built wooden crate with internal bracing and shock-absorbing materials (e.g., foam, bubble wrap).

- Ensure the chamber is securely immobilized within the crate to prevent movement during transit.

- Protect sensitive components (e.g., sensors, display, door seals) with additional padding.

- Clearly label the crate with “Fragile,” “This Side Up,” and “Do Not Stack.”

- Seal all openings to prevent dust and moisture ingress during transport.

-

Documentation:

- Commercial Invoice: Accurately detail product description (“Environmental Test Chamber, Humidity Capability”), HS Code (e.g., 8479.89 – Other machines… not elsewhere specified), value, weight, dimensions, and country of origin.

- Packing List: List all items in the shipment (chamber, accessories, manuals, power cords) with quantities, weights, and dimensions per package.

- Certificate of Conformity (CoC): Obtain from the manufacturer, confirming compliance with relevant safety and EMC standards (e.g., CE, UL, CSA).

- User Manual & Technical Specifications: Include copies for customs and recipient.

- Bill of Lading (BOL) / Air Waybill (AWB): Accurately completed by the freight forwarder.

-

Regulatory Compliance (Pre-Shipment):

- Determine Applicable Regulations: Identify target market requirements (e.g., CE marking for EEA, UKCA for UK, FCC/UL for USA, CCC for China, PSE for Japan).

- Verify Markings: Ensure the chamber bears the required certification marks (CE, UL, etc.) before shipment. Do not ship non-compliant units.

- RoHS/REACH/Prop 65: Confirm the chamber complies with substance restrictions (EU RoHS, REACH SVHC, California Prop 65) based on destination.

- WEEE Registration (If Applicable): If shipping to certain EU countries, ensure the manufacturer/supplier is registered under WEEE regulations.

- Power Supply Compliance: Verify voltage, frequency, and plug type match the destination country’s standards or that appropriate adapters/transformers are included/specified.

H3: Transportation & Handling

-

Freight Mode Selection:

- Air Freight: Fastest, suitable for high-value or urgent shipments. Higher cost. Ensure compliance with IATA Dangerous Goods Regulations (generally not applicable for standard humidity chambers, but verify).

- Ocean Freight: Most economical for heavy/large chambers. Requires longer planning. Use standard dry containers; ensure adequate ventilation if possible.

- Ground Freight (Truck/Rail): Suitable for regional/continental shipments. Ensure vehicle suspension is adequate for sensitive equipment.

-

Handling Procedures:

- Lifting: Use the chamber’s designated lifting points (forklift slots, lifting eyes) only. Never lift by handles, doors, or control panels.

- Tilt/Angle: Adhere strictly to the manufacturer’s specified maximum tilt angle (often 45 degrees) during loading/unloading and transport. Exceeding this can damage the refrigeration system or internal components.

- Forklift Use: Ensure forks are long enough to support the entire base. Lift smoothly; avoid sudden movements or drops.

- Environmental Exposure: Minimize exposure to extreme temperatures, direct sunlight, rain, or high humidity during loading/unloading and while in transit yards. Cover if necessary.

H3: Importation & Customs Clearance

- Engage a Customs Broker: Utilize a licensed broker familiar with scientific/industrial equipment and the destination country’s procedures.

- Provide Complete Documentation: Submit the Commercial Invoice, Packing List, BOL/AWB, CoC, and any required import licenses/permits to the broker promptly.

- Duties & Taxes: Be prepared to pay applicable import duties, VAT/GST, and customs processing fees based on the declared value and HS code.

- Customs Inspection: The shipment may be subject to physical or documentary inspection. Ensure the chamber and documentation are readily accessible.

- Regulatory Verification: Customs authorities may verify compliance with safety, EMC, or energy efficiency standards. The CoC and product markings are critical here.

H3: Post-Delivery & Installation Compliance

-

Unpacking & Inspection:

- Unpack carefully in a clean, dry, level area meeting the chamber’s environmental requirements (temp, humidity, ventilation).

- Conduct a thorough visual inspection for transit damage immediately upon unpacking. Document and photograph any damage.

- Verify all components listed on the packing list are present.

-

Installation & Commissioning:

- Site Preparation: Ensure the installation site meets requirements for floor loading, clearances (front, back, sides, top for ventilation), power supply (correct voltage, phase, grounding, dedicated circuit), and ambient conditions (temp, humidity limits).

- Qualified Personnel: Installation, electrical connection, and initial setup should be performed by qualified technicians following the manufacturer’s manual.

- Calibration: Perform initial calibration according to the manufacturer’s procedure or a certified calibration service. Maintain calibration records.

- Safety Checks: Verify emergency stop function, door interlocks (if applicable), and proper grounding.

-

Operational Compliance:

- User Training: Ensure operators are trained on safe operation, procedures, and emergency protocols.

- Maintenance: Adhere strictly to the manufacturer’s preventive maintenance schedule (e.g., filter cleaning/replacement, condensate drain checks, sensor verification).

- Record Keeping: Maintain logs for operation, maintenance, calibration, and any repairs.

- Regulatory Updates: Monitor for changes in regulations (e.g., updated EMC standards, new substance restrictions) that may impact continued compliance.

H3: Key Considerations by Region

- European Union (EU) / European Economic Area (EEA): CE Marking (based on Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU, LVD 2014/35/EU, RoHS 2011/65/EU), WEEE registration obligation.

- United Kingdom (UK): UKCA Marking (replacing CE for GB market, though CE often still accepted), UK RoHS.

- United States (USA): UL/ETL Listing (safety), FCC Part 15 (EMC – unintentional radiator), NRTL approval, Prop 65 compliance.

- Canada: CSA/ULC Certification (safety), ICES-003 (EMC).

- China: CCC Marking (for certain equipment types – verify applicability), China RoHS.

- Other Regions: Research specific national requirements (e.g., PSE in Japan, KC in Korea, BIS in India).

Disclaimer: This guide provides general information. Regulations and requirements are complex and subject to change. Always consult with the equipment manufacturer, freight forwarders, customs brokers, and legal/regulatory experts specific to your shipment’s origin and destination for definitive advice and compliance assurance.

Conclusion for Sourcing a Humidity Chamber

After a thorough evaluation of available options, sourcing a humidity chamber is a strategic decision that supports consistent product testing, quality assurance, and compliance with industry standards. The chosen chamber meets critical requirements including precise control of temperature and humidity, adequate chamber capacity, reliability, energy efficiency, and compliance with relevant regulatory standards (e.g., ISO, ASTM, or IEC).

Key factors influencing the sourcing decision include supplier reputation, after-sales service, calibration and maintenance support, and long-term cost of ownership. By selecting a humidity chamber that balances performance, durability, and value, the organization enhances its ability to conduct accurate environmental testing, thereby improving product reliability and accelerating time-to-market.

Ultimately, investing in the right humidity chamber strengthens testing capabilities and supports continuous improvement in product development and quality control processes.