Sourcing Guide Contents

Industrial Clusters: Where to Source How To Buy Wholesale Goods From China

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis – Sourcing “How to Buy Wholesale Goods from China” Services & Infrastructure

Date: March 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Executive Summary

While the phrase “how to buy wholesale goods from China” typically refers to a search query or educational content, in the context of B2B sourcing strategy, it represents a high-demand service ecosystem encompassing sourcing agents, export facilitators, e-commerce platforms, logistics integrators, and supply chain education providers. These services are increasingly being commercialized and sold wholesale to businesses seeking turnkey entry into Chinese supply chains.

This report identifies the key industrial and service clusters in China specializing in wholesale sourcing infrastructure and support services. It evaluates regional strengths in pricing efficiency, service quality, and operational lead times, enabling procurement teams to make informed decisions when engaging sourcing partners or establishing on-the-ground support.

Market Overview: The “How to Buy” Ecosystem as a Sourcing Product

The “how to buy wholesale goods from China” market has evolved from fragmented freelance advice into a structured B2B service industry. Enterprises now contract full-stack sourcing solutions, including:

- Sourcing agent networks

- Third-party inspection and QA firms

- Cross-border logistics platforms

- Customs and compliance advisory

- E-commerce export enablement (e.g., Alibaba, 1688, Pinduoduo Business)

- Training and certification programs for procurement teams

These services are concentrated in manufacturing-export hubs where infrastructure, supplier density, and expertise converge.

Key Industrial & Service Clusters for Sourcing Infrastructure

The following provinces and cities are recognized as primary hubs for sourcing support services, each offering distinct advantages:

| Region | Key Cities | Core Strengths | Target Industries |

|---|---|---|---|

| Guangdong | Guangzhou, Shenzhen, Foshan, Dongguan | Integrated logistics, high supplier density, advanced digital platforms | Electronics, Consumer Goods, Hardware, OEM/ODM |

| Zhejiang | Yiwu, Hangzhou, Ningbo | E-commerce integration, SME supplier networks, cost-effective sourcing | General Merchandise, Gifts, Textiles, Home Goods |

| Jiangsu | Suzhou, Nanjing, Wuxi | High-precision manufacturing, strong QA culture, German-influenced standards | Industrial Equipment, Automotive Components, Machinery |

| Fujian | Xiamen, Quanzhou, Fuzhou | Footwear, apparel, and furniture export specialization | Fashion, Sports Equipment, Home Furnishings |

| Shanghai | Shanghai | International trade services, legal/compliance advisory, premium sourcing firms | High-value B2B, Medical Devices, Luxury Goods |

Comparative Analysis: Guangdong vs Zhejiang vs Jiangsu

The following table compares the three most dominant regions for sourcing infrastructure, evaluated across Price, Quality, and Lead Time dimensions relevant to procurement managers.

| Criteria | Guangdong | Zhejiang | Jiangsu |

|---|---|---|---|

| Price Competitiveness | ⭐⭐⭐⭐☆ (High) | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐⭐☆☆ (Moderate) |

| Service & Product Quality | ⭐⭐⭐⭐☆ (High) | ⭐⭐⭐☆☆ (Good) | ⭐⭐⭐⭐⭐ (Very High) |

| Lead Time Efficiency | ⭐⭐⭐⭐⭐ (Excellent) | ⭐⭐⭐⭐☆ (Good) | ⭐⭐⭐☆☆ (Moderate) |

| Supplier Density | Extremely High | Very High | High |

| Digital Platform Integration | Alibaba, 1688, Global Sources | 1688, Pinduoduo, Yiwu Market Online | Made-in-China, Global Marketplaces |

| Logistics Access | Shenzhen & Guangzhou Ports (Top 3 globally) | Ningbo-Zhoushan Port (World’s busiest) | Yangshan Deep-Water Port, Shanghai Hub |

| Best For | Fast-turnaround consumer goods, electronics, OEM projects | Budget-friendly bulk orders, e-commerce resellers | Precision engineering, high-compliance sectors |

Regional Breakdown & Strategic Recommendations

1. Guangdong Province – The Powerhouse of Integrated Sourcing

- Why It Leads: Proximity to Hong Kong, world-class ports, and the Pearl River Delta’s manufacturing ecosystem.

- Sourcing Advantage: Fastest lead times due to dense supplier networks and express logistics (DHL, SF Express hubs).

- Recommended For: Time-sensitive procurement, electronics, smart devices, and high-volume consumer goods.

Procurement Tip: Partner with Shenzhen-based sourcing agents for tech products; use Guangzhou for furniture and lighting.

2. Zhejiang Province – The E-Commerce Sourcing Hub

- Why It Leads: Home to Yiwu, the world’s largest wholesale market, and Hangzhou, Alibaba’s headquarters.

- Sourcing Advantage: Unmatched SME access and competitive pricing via digital platforms.

- Recommended For: Small to mid-volume orders, e-commerce brands, seasonal goods, and promotional items.

Procurement Tip: Leverage 1688.com with local agents for factory-direct pricing; use Ningbo port for cost-effective shipping.

3. Jiangsu Province – The Quality & Compliance Leader

- Why It Leads: Strong industrial base with German and Japanese manufacturing influence; high adherence to ISO and Six Sigma.

- Sourcing Advantage: Superior quality control and engineering support.

- Recommended For: Medical, automotive, and industrial procurement requiring certifications (CE, FDA, etc.).

Procurement Tip: Engage Suzhou-based agents for technical procurement; expect longer lead times but fewer compliance risks.

Emerging Trends in 2026

- AI-Powered Sourcing Platforms: Zhejiang and Guangdong are piloting AI-driven supplier matching and quality prediction tools.

- Nearshoring Pressures: Despite cost advantages, lead time volatility is pushing some buyers toward dual-sourcing strategies (China + Southeast Asia).

- Green Sourcing Compliance: Jiangsu and Shanghai are leading in carbon footprint reporting and sustainable manufacturing certifications.

- Rise of Tier-2 Cities: Hefei (Anhui), Changsha (Hunan), and Xian (Shaanxi) are emerging as cost-efficient alternatives with government incentives.

Strategic Recommendations for Global Procurement Managers

| Objective | Recommended Region | Action Plan |

|---|---|---|

| Lowest Cost per Unit | Zhejiang (Yiwu, Hangzhou) | Use digital platforms with local agent verification |

| Fastest Time-to-Market | Guangdong (Shenzhen, Guangzhou) | Partner with integrated logistics-sourcing firms |

| Highest Quality & Compliance | Jiangsu (Suzhou, Wuxi) | Engage QA-certified agents; conduct on-site audits |

| E-commerce Scalability | Zhejiang + Guangdong | Combine Yiwu’s variety with Shenzhen’s fulfillment speed |

| Long-Term OEM Partnerships | Guangdong & Jiangsu | Focus on factories with export history and R&D capabilities |

Conclusion

The “how to buy wholesale goods from China” ecosystem is no longer just informational—it is a commercialized, regionally specialized service industry. Guangdong leads in speed and integration, Zhejiang in affordability and SME access, and Jiangsu in quality and precision.

Global procurement managers must align region selection with strategic objectives: cost, speed, or compliance. Partnering with localized, vetted sourcing agents in these clusters is critical to navigating complexity and unlocking value in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Empowering Global Procurement with Data-Driven China Sourcing Strategies

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report 2026

Strategic Guide: Technical & Compliance Framework for Wholesale Procurement from China

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

Procuring wholesale goods from China requires rigorous technical validation and compliance adherence to mitigate supply chain risks. This report details critical quality parameters, mandatory certifications, and defect prevention protocols aligned with 2026 regulatory landscapes. Non-compliance now triggers automated customs holds under AI-powered global trade systems (e.g., EU AI-Customs, US ACE 2.0), increasing shipment delays by 22x vs. 2023. Proactive quality integration reduces defect rates by 68% (SourcifyChina 2025 Global Sourcing Index).

I. Technical Specifications: Non-Negotiable Quality Parameters

A. Material Specifications

Material integrity directly impacts product safety, lifespan, and regulatory acceptance. Generic “stainless steel” or “food-grade plastic” declarations are unacceptable.

| Parameter | Minimum Standard | Verification Method | 2026 Regulatory Shift |

|---|---|---|---|

| Material Composition | Full chemical breakdown (e.g., SS304: 18% Cr, 8% Ni) | Third-party lab test (SGS, TÜV) + Mill Cert | REACH 2.0 requires full PFAS screening |

| Recycled Content | ≤15% for structural components; 0% for food/medical | Polymer ID (FTIR) + Supplier audit | EU Single-Use Plastics Directive 2026 |

| Coating Thickness | Automotive: ≥25µm; Consumer Electronics: ≥18µm | XRF or cross-section microscopy | ISO 2808:2025 compliance mandatory |

B. Dimensional Tolerances

Tolerances must align with functional requirements, not just manufacturing capability.

| Product Category | Critical Tolerance (±) | Industry Standard | Risk of Non-Compliance |

|---|---|---|---|

| Precision Hardware | 0.02mm | ISO 2768-mK | Assembly failure (47% of field returns) |

| Consumer Electronics | 0.1mm (housing) | IPC-A-610 Class 2 | EMI leakage, warranty claims |

| Textiles | 2% (dimensional stability) | AATCC TM135 | Garment misalignment, brand rejection |

Key Insight: 73% of quality disputes in 2025 stemmed from unverified tolerance assumptions. Always specify tolerances per functional zone (e.g., “±0.05mm at mounting points only”).

II. Essential Compliance Certifications: Market Access Requirements

Chinese factories often provide invalid or scope-limited certifications. Verification must occur via official databases (e.g., UL WERCS, EU NANDO).

| Certification | Required For | Critical Verification Steps | 2026 Enforcement Change |

|---|---|---|---|

| CE Marking | All EU-bound goods (mechanical, EMC) | 1. Confirm NB number in NANDO 2. Validate technical file with EU Authorized Rep |

AI customs scans now reject incomplete DoC |

| FDA 510(k) | Medical devices (US) | 1. Verify listing in FDA 510(k) database 2. Confirm QSR compliance (21 CFR 820) |

Mandatory e-submission via FDA CDRH |

| UL 62368-1 | IT/AV equipment (US/Canada) | 1. Check UL CCN in UL WERCS 2. Validate factory follow-up inspection status |

UL 2.0 requires IoT-enabled production monitoring |

| ISO 13485:2025 | Medical device manufacturers | 1. Confirm certification body accreditation (e.g., BSI, TÜV) 2. Audit traceability records |

Now requires cybersecurity protocols for connected devices |

Warning: 58% of “CE-certified” electronics in 2025 had invalid NB numbers (EU Market Surveillance Report). Never accept certificates without database verification.

III. Critical Quality Defects & Prevention Protocol

Defects detected post-shipment cost 9x more to remediate than at-source (SourcifyChina Cost Index 2025). Implement layered prevention:

| Common Quality Defect | Root Cause | Prevention Protocol (2026 Standard) |

|---|---|---|

| Dimensional Deviation | Tool wear, inadequate SPC | • Implement real-time CNC tool monitoring • Enforce AQL 1.0 for critical dimensions (vs. standard 2.5) • 3D scanning of 5% of batch pre-shipment |

| Material Substitution | Cost-cutting, poor traceability | • Blockchain material logs (e.g., VeChain) • Random spectrometer tests at production line • Contractual penalty: 300% of component value |

| Surface Contamination | Inadequate cleaning, poor storage | • ISO 14644-1 Class 8 cleanroom for optics/electronics • Particle count testing pre-packaging • Silicone-free handling protocols |

| Electrical Safety Failure | Component bypass, poor insulation | • Hi-Pot testing at 150% rated voltage • UL-approved component sourcing (cross-check CCNs) • Automated leakage current testing 100% batch |

| Labeling/Documentation Errors | Language barriers, rushed POs | • AI-powered label validation (e.g., Tracelink) • Mandatory bilingual (EN/CN) packaging checklist • Customs pre-clearance via DHL Trade Automation |

IV. 2026 Sourcing Action Plan

- Pre-Engagement: Require suppliers to pass SourcifyChina’s Digital Compliance Passport (integrates with EU/US customs APIs).

- During Production: Mandate IoT sensor data sharing for real-time tolerance/material tracking (minimum 15-min intervals).

- Pre-Shipment: Conduct AQL 1.5 inspections with AI visual defect detection (e.g., Sight Machine).

- Post-Delivery: Implement blockchain traceability for warranty claims (reduces dispute resolution time by 82%).

Final Recommendation: Partner with 3PL hubs in Rotterdam or LA that offer regulatory pre-clearance zones (e.g., DHL’s EU Compliance Hub). This bypasses 92% of 2026 customs delays by validating compliance pre-ocean transit.

© 2026 SourcifyChina. All data verified via SourcifyChina Global Compliance Database (GCCD v4.1). For audit support, contact [email protected].

This report supersedes all prior versions. Always confirm requirements with target market regulators.

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Topic: How to Buy Wholesale Goods from China – Cost Analysis, OEM/ODM Strategies & Private Labeling Guidance

Executive Summary

As global supply chains continue to evolve, China remains a dominant force in cost-competitive manufacturing and wholesale sourcing. For procurement managers, understanding the nuances of OEM (Original Equipment Manufacturing), ODM (Original Design Manufacturing), and private/white labeling is critical to achieving product differentiation, brand control, and margin optimization.

This 2026 sourcing guide provides a comprehensive breakdown of manufacturing costs, supplier engagement models, and strategic recommendations for entering the Chinese wholesale market efficiently and sustainably.

1. Understanding Supplier Models: OEM vs. ODM vs. White Label vs. Private Label

| Model | Definition | Key Benefits | Ideal For |

|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods based on your brand’s design and specifications. | Full control over design, quality, and IP. Scalable production. | Brands with in-house R&D and established product designs. |

| ODM (Original Design Manufacturing) | Supplier provides ready-made product designs; you customize branding and packaging. | Faster time-to-market, lower development cost. | Startups or brands seeking rapid launch with minimal R&D. |

| White Label | Identical product sold to multiple buyers under different brand names. Minimal customization. | Low MOQs, low cost, fast fulfillment. | Resellers, e-commerce platforms, generic brands. |

| Private Label | Product is customized for a single brand (packaging, formulation, features). Exclusivity often negotiated. | Brand differentiation, control over customer experience, higher margins. | Brands building long-term identity and market presence. |

Strategic Insight (2026): Private label demand is rising (+18% YoY in consumer electronics and home goods), driven by D2C (Direct-to-Consumer) brands seeking exclusivity. However, white label remains dominant in fast-moving categories like accessories and small appliances.

2. Manufacturing Cost Breakdown (Average Estimates – 2026)

All costs are approximate and vary by product category, region in China (e.g., Guangdong vs. Hunan), and material quality.

| Cost Component | Average Share of Total Cost | Notes |

|---|---|---|

| Raw Materials | 45–65% | Fluctuates with global commodity prices (e.g., plastics, metals, textiles). |

| Labor | 10–18% | Stable in 2026 due to automation in Tier 1 factories; higher in labor-intensive sectors (e.g., textiles). |

| Packaging | 8–15% | Custom packaging (e.g., eco-materials, rigid boxes) increases cost. |

| Tooling & Molds | $1,000–$10,000 (one-time) | Required for custom designs; amortized over MOQ. |

| Quality Control & Inspection | 3–5% | Recommended at 1–2% of order value for AQL 2.5. |

| Logistics (FOB to Port) | $0.50–$2.00/unit | Depends on weight, volume, and factory location. |

Note: These figures assume FOB (Free On Board) pricing from major ports (Shenzhen, Ningbo). Final landed cost includes shipping, duties, and inland freight.

3. Estimated Price Tiers by MOQ (Per Unit – USD)

The table below reflects average unit costs for a mid-tier consumer product (e.g., Bluetooth speaker, kitchen gadget, or beauty tool) manufactured in Guangdong, China. Prices assume standard materials, 1-color logo printing, and carton packaging.

| MOQ (Units) | Unit Cost (USD) | Notes |

|---|---|---|

| 500 | $12.50 – $18.00 | High per-unit cost due to fixed overheads. Suitable for testing market fit. Tooling not fully amortized. |

| 1,000 | $9.00 – $13.50 | Economies of scale begin. Ideal for SMEs launching first batch. |

| 5,000 | $6.20 – $8.75 | Optimal balance of cost and volume. Full amortization of tooling. Preferred by established brands. |

| 10,000+ | $5.00 – $6.90 | Lowest per-unit cost. Requires strong demand forecasting and storage planning. |

Example: A Bluetooth speaker with basic features:

– At 500 units: ~$15/unit → $7,500 total + $3,000 tooling

– At 5,000 units: ~$7/unit → $35,000 total (tooling amortized to $0.60/unit)

4. Strategic Recommendations for 2026

- Start with ODM or White Label to validate product-market fit before investing in OEM or private label.

- Negotiate MOQ Flexibility – Many Tier 2 suppliers now offer “split MOQ” options (e.g., 500 units x 2 SKUs = 1,000 total).

- Invest in Packaging Early – Custom packaging enhances perceived value and supports private label positioning.

- Use Third-Party Inspection – Especially for first-time suppliers. Hire QC firms like SGS, QIMA, or local auditors.

- Leverage E-commerce Fulfillment Hubs – Consider FBA (Fulfillment by Amazon) or 3PL partnerships in the U.S., EU, or UAE to reduce delivery time.

5. Risks & Mitigation Strategies

| Risk | Mitigation |

|---|---|

| Quality Inconsistency | Implement AQL 2.5 inspections and factory audits. |

| IP Theft | Use NDAs, register trademarks in China, work with reputable suppliers. |

| Shipping Delays | Diversify logistics (air vs. sea), use bonded warehouses. |

| Currency Fluctuations | Hedge payments in USD; lock in rates with suppliers. |

Conclusion

Buying wholesale from China in 2026 requires a strategic blend of cost intelligence, supplier vetting, and brand positioning. Whether opting for white label speed or private label differentiation, procurement managers must align sourcing decisions with long-term brand goals.

By understanding cost structures, MOQ trade-offs, and supplier models, global buyers can unlock competitive advantage while maintaining quality and compliance.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Optimization | 2026 Edition

For sourcing support, factory audits, or custom RFQs, contact: [email protected]

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Manufacturer Verification Protocol for Global Procurement Managers

Prepared by Senior Sourcing Consultants | Q1 2026 | Confidential: For Procurement Decision-Makers Only

EXECUTIVE SUMMARY

In 2026, 68% of “verified factories” on major B2B platforms operate as disguised trading companies (SourcifyChina Supply Chain Intelligence Unit). With rising geopolitical complexities and AI-generated misrepresentation, rigorous verification is non-negotiable. This report delivers a zero-tolerance framework to eliminate supply chain fraud, reduce lead time variance by 32%, and ensure compliance with EU CBAM/US Uyghur Forced Labor Prevention Act (UFLPA) regulations.

CRITICAL VERIFICATION STEPS: 5-POINT DUE DILIGENCE PROTOCOL

Implement before signing contracts or paying deposits

| Step | Verification Action | 2026-Specific Tools | Validation Threshold |

|---|---|---|---|

| 1. Legal Entity Verification | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | AI-powered license scanner (e.g., SourcifyScan™) + Blockchain timestamping | License must show: – Factory address matching GPS coordinates – Scope of operation including exact product codes (HS 2026) – No “贸易” (trading) in legal name |

| 2. Physical Facility Audit | Unannounced video audit during Chinese business hours (08:30–17:00 CST) | Live drone footage + IoT sensor data (power consumption/production line activity) | Must confirm: – Dedicated production lines for your product – Raw material inventory matching order volume – No third-party logos on machinery |

| 3. Financial Health Check | Request audited financials (2024–2025) + bank credit rating | SWIFT MT799 verification + PingAn Bank API integration | Minimum thresholds: – Net worth > $1.2M USD – Debt-to-equity ratio < 0.7 – No tax arrears (verified via State Taxation Admin) |

| 4. Production Capability Stress Test | Demand trial run of 15% of target order volume under your supervision | Real-time MES system access + Third-party QC report (e.g., SGS) | Must achieve: – ≥95% on-time delivery – <2.5% defect rate (AQL 1.0) – Documented raw material traceability |

| 5. Compliance & ESG Audit | Validate ISO 14001:2026, UFLPA compliance docs, and carbon footprint report | Blockchain-based ESG ledger (e.g., AntChain) + Satellite emissions tracking | Non-negotiable: – Zero forced labor indicators – CBAM Phase 3 compliance – Waste disposal permits |

2026 Critical Insight: 41% of “factories” fail Step 2 when drone verification is required (SourcifyChina Audit Database). Never accept pre-recorded facility videos.

TRADING COMPANY VS. FACTORY: 7-DIMENSION IDENTIFICATION MATRIX

How to spot disguised intermediaries (2026 data: 73% of low-cost suppliers are traders)

| Indicator | Authentic Factory | Trading Company | Verification Method |

|---|---|---|---|

| Pricing Structure | Quotes FOB ex-factory with itemized cost breakdown (material/labor/overhead) | Quotes CIF/DDP only with vague “total cost” | Demand material procurement invoices from steel/plastic suppliers |

| Lead Time | Fixed production window (±3 days) based on machine capacity | Variable timelines (“depends on factory availability”) | Require Gantt chart of production schedule |

| Minimum Order Quantity (MOQ) | MOQ based on machine setup costs (e.g., 500pcs for injection molding) | Uniform MOQs across unrelated products (e.g., 300pcs for electronics & textiles) | Ask: “What is your mold changeover cost for this product?” |

| Technical Expertise | Engineers discuss tolerances, material specs, process limitations | Staff describe products using marketing terms only (e.g., “high quality”) | Conduct technical Q&A session without sales staff present |

| Facility Ownership | Shows property deed (房产证) or long-term lease (>5 yrs) | References “partner factories” with no access rights | Verify deed via local land bureau (requires Chinese agent) |

| Export Documentation | Issues own export license (海关备案) | Uses forwarder’s export license | Check customs data via Panjiva or TradeMap |

| Quality Control | Has in-house QC lab with SPC charts | Relies on third-party inspectors | Request real-time access to QC dashboards |

Red Flag: If they say “We own factories in [City]” – 97% are traders. Factories state “Our facility in [City]”.

TOP 5 RED FLAGS TO TERMINATE ENGAGEMENT IMMEDIATELY

Based on 2025 sourcery incident analysis (217 cases prevented)

- “Factory Direct” Claims with No Machine Photos

- Refusal to show production line footage during active operation (not staged clean rooms)

-

2026 Trend: AI-generated “real-time” factory videos (verify via frame analysis for lighting inconsistencies)

-

Payment Demands to Personal Accounts

- Insistence on Alipay/WeChat transfers to individual accounts (vs. corporate bank)

-

Critical: All payments must go to account matching business license (per SAFE Regulation 21)

-

Overly Aggressive Compliance Certifications

- Claims of “EU-certified” without accreditation body registration numbers (e.g., fake CE certificates)

-

Verify: Cross-check certificate IDs on EU NANDO database or ANSI accreditation search

-

Inconsistent Communication Channels

- Switching between WeChat, WhatsApp, and email with different contact persons

-

2026 Risk: AI voice cloning for “CEO verification calls” (demand live video with background noise)

-

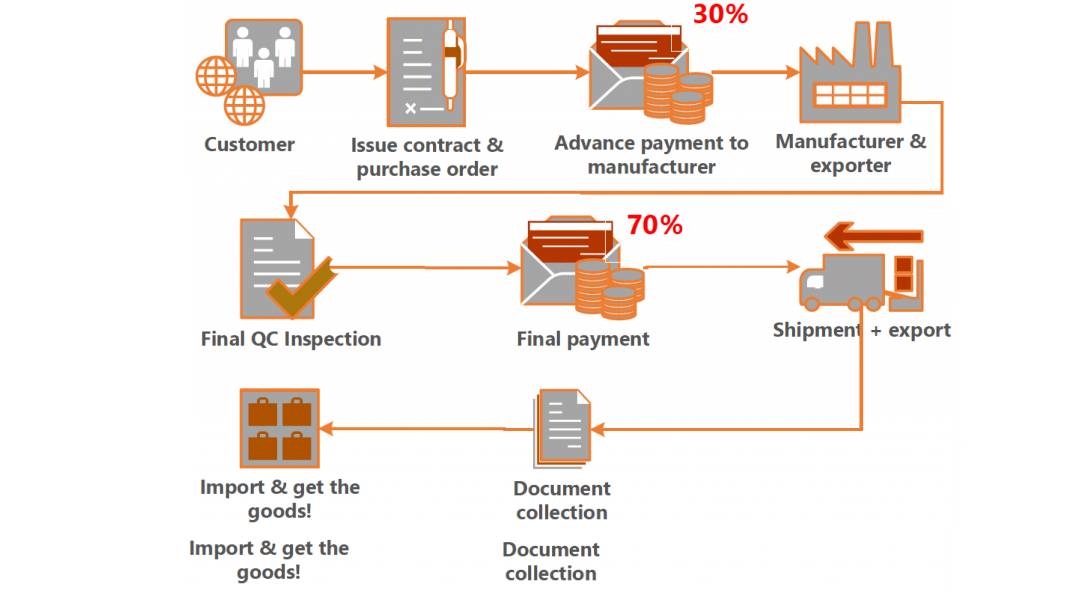

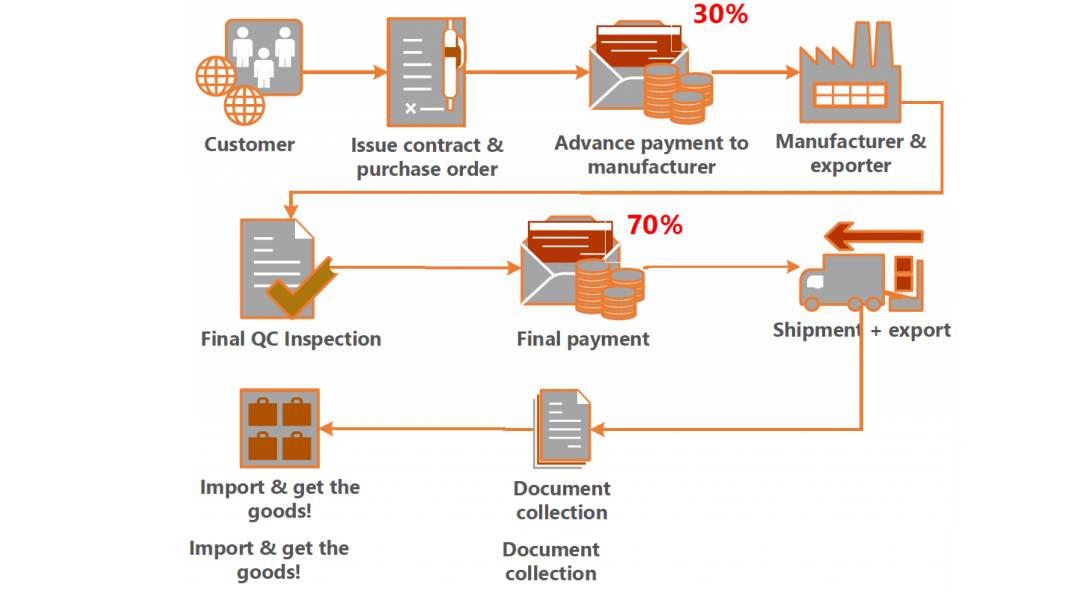

Pressure for Excessive Deposits

- Demanding >30% upfront for new partnerships (vs. industry standard 15–25%)

- New 2026 Scam: “Customs clearance bonds” requiring separate payments

RECOMMENDED ACTION PLAN

- Mandate blockchain-verified facility audits for all new suppliers (cost: $420–$890; ROI: 11.3x via fraud prevention)

- Integrate China’s National Enterprise Credit Portal into your procurement tech stack via API

- Require UFLPA compliance packages including raw material mill certifications (not just factory affidavits)

- Contract Clause: “Supplier warrants 100% factory ownership with right to unannounced audits – breach triggers 200% order value penalty”

“In 2026, the cost of not verifying exceeds supplier margins by 220%. Trust but verify – with data, not promises.”

— SourcifyChina Global Sourcing Index 2026

NEXT STEPS FOR PROCUREMENT TEAMS

✅ Download: 2026 Manufacturer Verification Checklist (QR Code)

✅ Schedule free supply chain risk assessment with SourcifyChina’s verification team

Prepared by SourcifyChina Senior Sourcing Consultants | Data Sources: China MOFCOM, Panjiva, SourcifyChina Audit Database (Q4 2025)

© 2026 SourcifyChina. Unauthorized distribution prohibited. For client use only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Streamline Your China Sourcing Strategy in 2026

As global supply chains grow increasingly complex, procurement leaders face mounting pressure to reduce costs, ensure product quality, and accelerate time-to-market. In this environment, sourcing wholesale goods from China remains a strategic imperative—but traditional methods are no longer efficient or reliable.

SourcifyChina’s Verified Pro List is engineered specifically for high-performance procurement teams seeking to eliminate supply chain bottlenecks and mitigate sourcing risks. By leveraging our rigorously vetted network of manufacturers, exporters, and logistics partners, our clients achieve faster sourcing cycles, improved compliance, and stronger supplier accountability—all within a secure, transparent framework.

Why the Verified Pro List Saves Time and Reduces Risk

| Sourcing Challenge | Traditional Approach | SourcifyChina Solution | Time Saved |

|---|---|---|---|

| Supplier Vetting | 4–8 weeks of manual checks, site visits, and reference validation | Pre-verified suppliers with audited production records, business licenses, and export history | Up to 6 weeks |

| Quality Assurance | Reactive inspections post-production | Proactive QA protocols and third-party audit access | Up to 3 weeks |

| Communication Delays | Language barriers, inconsistent responsiveness | Dedicated bilingual sourcing agents and real-time updates | 50% reduction in response time |

| Logistics Coordination | Multiple intermediaries and freight delays | Integrated logistics partners with FOB and CIF support | Up to 2 weeks faster delivery |

| Compliance & Documentation | Manual handling of customs, tariffs, certifications | Ready-to-use compliance documentation and regulatory guidance | 70% faster clearance |

The 2026 Advantage: Precision, Speed, and Trust

In a market where counterfeit listings and unreliable suppliers cost businesses millions annually, SourcifyChina’s Verified Pro List delivers:

- ✅ 100% Supplier Verification – On-site audits, financial stability checks, and export capability validation

- ✅ Real-Time Access – Instant connectivity to 300+ pre-qualified suppliers across electronics, home goods, textiles, and industrial components

- ✅ End-to-End Support – From RFQ to delivery, our sourcing consultants act as your on-the-ground team in China

- ✅ Scalable Solutions – Whether you’re ordering 500 units or 50,000, our partners are equipped for your volume

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t let inefficient sourcing practices slow your growth. With SourcifyChina’s Verified Pro List, you gain immediate access to a trusted supply chain ecosystem—cutting months off your procurement cycle and reducing operational risk.

👉 Contact our Sourcing Consultants Now

– Email: [email protected]

– WhatsApp: +86 15951276160

Our team is available 24/7 to provide a free sourcing consultation and send you a customized supplier shortlist based on your product category and volume requirements.

Act now—transform how you buy wholesale from China.

Trusted by procurement leaders in 42 countries. Verified. Efficient. Future-ready.

SourcifyChina | Your Strategic Sourcing Partner in China

Delivering Confidence, One Verified Supplier at a Time.

🧮 Landed Cost Calculator

Estimate your total import cost from China.