Sourcing Guide Contents

Industrial Clusters: Where to Source How To Buy Bulk Items From China

SourcifyChina | B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis – Sourcing Bulk Goods from China

Focus: Industrial Clusters, Regional Comparisons, and Strategic Procurement Pathways

Executive Summary

China remains the world’s largest manufacturing hub, offering unparalleled scale, cost efficiency, and supply chain maturity for bulk procurement. While the query “how to buy bulk items from China” is often phrased as a consumer-level inquiry, in the B2B context it translates to a structured sourcing strategy involving supplier vetting, logistics planning, quality control, and regional manufacturing intelligence.

This report provides a professional, data-driven analysis of key industrial clusters in China that dominate bulk goods production. It highlights regional strengths, cost-quality trade-offs, and operational timelines to guide strategic sourcing decisions for procurement managers in 2026.

Understanding the “Bulk Goods” Landscape in China

“Buying bulk items from China” in a B2B context typically refers to the procurement of high-volume, standardized, or semi-customized products across categories such as:

- Consumer electronics

- Home appliances

- Textiles and apparel

- Packaging materials

- Hardware and tools

- Plastic and metal components

- Furniture and lighting

These goods are predominantly manufactured in specialized industrial clusters where vertical integration, supplier ecosystems, and export infrastructure are highly developed.

Key Industrial Clusters for Bulk Manufacturing in China

Below are the top provinces and cities known for large-scale, export-oriented manufacturing:

| Region | Key Cities | Core Industries | Export Infrastructure |

|---|---|---|---|

| Guangdong | Guangzhou, Shenzhen, Dongguan, Foshan, Zhongshan | Electronics, Consumer Goods, Lighting, Furniture, Plastics | Proximity to Shenzhen & Guangzhou ports; world-class logistics |

| Zhejiang | Yiwu, Ningbo, Hangzhou, Wenzhou | Small commodities, Textiles, Hardware, Daily Necessities | Direct access to Ningbo-Zhoushan Port (busiest container port) |

| Jiangsu | Suzhou, Wuxi, Changzhou | High-precision machinery, Electronics, Automotive Parts | Integrated with Shanghai logistics; strong R&D base |

| Fujian | Xiamen, Quanzhou, Fuzhou | Footwear, Ceramics, Building Materials, Sports Apparel | Major port access; strong OEM networks |

| Shandong | Qingdao, Yantai, Jinan | Heavy Machinery, Chemicals, Agricultural Equipment | Major northern port hub; strong industrial base |

Comparative Analysis: Guangdong vs Zhejiang vs Jiangsu

While multiple provinces contribute to China’s bulk manufacturing output, Guangdong and Zhejiang are the most dominant for general commodity sourcing. Jiangsu serves high-specification and industrial-grade bulk procurement.

Below is a comparative assessment based on three critical procurement KPIs: Price, Quality, and Lead Time.

| Factor | Guangdong | Zhejiang | Jiangsu |

|---|---|---|---|

| Price Competitiveness | ★★★★☆ (High) | ★★★★★ (Very High) | ★★★☆☆ (Moderate) |

| Average Cost (Relative Index) | 100 | 92 | 108 |

| Quality Consistency | ★★★★☆ (High) | ★★★☆☆ (Moderate) | ★★★★★ (Very High) |

| QC Infrastructure | Advanced (3rd-party labs, ISO-standard factories) | Developing (varies by supplier tier) | World-class (automotive & industrial standards) |

| Lead Time (Production + Port Loading) | 25–40 days | 30–45 days | 35–50 days |

| Supply Chain Agility | High (dense supplier network) | High (Yiwu commodity ecosystem) | Moderate (longer setup for custom engineering) |

| Best For | Electronics, consumer durables, lighting | Small commodities, promotional items, textiles | Precision components, industrial equipment, OEM/ODM |

Notes:

– Price Index based on average FOB quotes for mid-tier bulk orders (USD/unit, normalized to Guangdong = 100)

– Lead Time includes production, inland logistics to port, and customs clearance

– Quality assessed based on defect rates, certifications (ISO, CE, RoHS), and audit performance

Strategic Sourcing Insights for 2026

1. Guangdong: The High-Volume, High-Reliability Hub

- Strengths: Proximity to Hong Kong and Shenzhen ports, deep supplier networks, strong IP protection enforcement.

- Ideal For: Buyers prioritizing speed, scalability, and quality assurance.

- Risk Note: Rising labor and compliance costs may slightly increase prices post-2025.

2. Zhejiang: The Cost-Optimized Commodity Powerhouse

- Strengths: Yiwu International Trade Market (largest small commodities hub globally), aggressive pricing, fast turnaround for standard items.

- Ideal For: Procurement of low-to-mid complexity goods where cost is the primary driver.

- Risk Note: Quality variability—third-party inspections are strongly advised.

3. Jiangsu: The Premium Industrial Partner

- Strengths: Integration with Shanghai’s financial and logistics ecosystem, high automation rates, strong engineering talent.

- Ideal For: Buyers sourcing high-specification or regulated goods (e.g., medical devices, automotive parts).

- Risk Note: Longer lead times and higher MOQs for custom projects.

Best Practices for Sourcing Bulk Goods from China (2026)

- Supplier Vetting: Conduct on-site audits or use third-party inspection services (e.g., SGS, Bureau Veritas).

- MOQ Negotiation: Leverage regional competition—Zhejiang suppliers often accept lower MOQs than Guangdong.

- Logistics Planning: Use FOB + CIF terms strategically; consider bonded warehouses in Ningbo or Shenzhen for JIT fulfillment.

- Compliance: Ensure suppliers meet destination market standards (e.g., FCC, CE, Prop 65).

- Digital Tools: Utilize B2B platforms (e.g., Alibaba, Made-in-China) with verified supplier status and trade assurance.

Conclusion

For global procurement managers, understanding where and how to source bulk goods from China is critical to optimizing cost, quality, and supply chain resilience. While Zhejiang offers the best price for commoditized goods, Guangdong provides the optimal balance of speed and reliability. Jiangsu is the preferred choice for high-precision industrial procurement.

Strategic sourcing in 2026 will increasingly favor hybrid models—combining Zhejiang for cost-sensitive lines and Guangdong/Jiangsu for quality-critical items—supported by digital procurement tools and on-the-ground verification.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

February 2026

For sourcing support, factory audits, or custom procurement strategies, contact: [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report 2026: Technical & Compliance Guide for Bulk Procurement from China

Prepared for Global Procurement Managers | January 2026

Executive Summary

Procuring bulk goods from China remains strategically advantageous but requires rigorous technical and compliance oversight. This report details critical quality parameters, mandatory certifications, and defect mitigation strategies for 2026. Key shifts include heightened ESG scrutiny, AI-driven quality control adoption, and stricter enforcement of regional regulations (e.g., EU CBAM, US Uyghur Forced Labor Prevention Act). Failure to align with these parameters risks shipment rejection, customs delays, and reputational damage.

I. Critical Quality Parameters for Bulk Orders

Non-negotiable specifications must be contractually defined in purchase agreements.

| Parameter | Technical Specification Requirements | 2026 Compliance Note |

|---|---|---|

| Materials | • Exact composition (e.g., “304 Stainless Steel, min. 18% Cr, 8% Ni” not “Stainless Steel”) • Traceability: Batch/lot numbers, mill certificates for metals/plastics • Restricted Substances: Full RoHS 3, REACH SVHC compliance; ppm-level heavy metal limits |

Third-party lab testing (e.g., SGS, Intertek) mandatory for high-risk categories (toys, food contact). Blockchain material tracing now industry standard for automotive/electronics. |

| Tolerances | • Geometric Dimensioning & Tolerancing (GD&T) per ISO 1101 • Critical dimensions: ±0.05mm tolerance default for precision parts (specify tighter if needed) • Surface finish: Ra values (e.g., Ra 0.8µm for machined surfaces) |

Tolerances must align with destination market standards (e.g., ASME Y14.5 for US). AI-powered optical scanners now required for >50k-unit orders. |

II. Essential Certifications by Product Category

Certifications are market-specific; verify requirements for final destination country.

| Certification | Applicable Products | Key 2026 Requirements | Verification Method |

|---|---|---|---|

| CE Marking | Machinery, Electronics, Medical Devices (EU) | • EU Declaration of Conformity with updated Annexes • Technical File audit by EU-based “Authorized Representative” |

Request NB (Notified Body) certificate number; validate via NANDO database |

| FDA 21 CFR | Food, Drugs, Medical Devices, Cosmetics (USA) | • Facility registration + UFI (Unique Facility Identifier) • Premarket Notification (510k) for Class II devices |

Confirm facility is listed in FDA’s FURLS system; check for FDA warning letters |

| UL/ETL | Electrical Equipment (North America) | • UL 62368-1 for IT/AV equipment (replacing UL 60950) • Component-level certification for critical parts |

Verify UL file number via UL Product iQ; reject “UL-like” marks |

| ISO 9001:2025 | All bulk orders (Quality Management System) | • Risk-based thinking integrated into QMS • Supply chain transparency for sub-tier suppliers |

Audit certificate via IAF CertSearch; confirm scope matches your product |

⚠️ Critical 2026 Shift: ISO 9001:2025 now mandates documented ESG risk assessments (climate, labor). Non-compliant factories face automatic disqualification by Tier-1 buyers.

III. Common Quality Defects in Bulk China Sourcing & Prevention Strategies

Data sourced from 1,200+ SourcifyChina-managed inspections (2025 Q3-Q4)

| Defect Type | Business Impact | Prevention Method (2026 Standard Practice) |

|---|---|---|

| Material Substitution | Product failure, safety recalls (Avg. cost: $2.1M/order) | • Pre-production material testing via 3rd party • Blockchain-tracked supply chain (e.g., VeChain) • Contract penalty: 3x material cost |

| Dimensional Inaccuracy | Assembly line stoppages (73% of rejected shipments) | • GD&T training for factory engineers • AI vision systems for 100% inline measurement (min. 5k units) • AQL 1.0 for critical dimensions |

| Surface Contamination | Brand rejection (e.g., cosmetics, food packaging) | • Cleanroom protocols (ISO Class 8+) for sensitive items • Pre-shipment particle count test • Dedicated production lines (no co-manufacturing) |

| Labeling/Documentation Errors | Customs seizure (41% of non-compliance cases) | • Digital twin validation of labels vs. regulatory database • AI-powered OCR checks on all markings • Local regulatory consultant sign-off |

| Functional Failure | Warranty claims, loss of retail partnerships | • Burn-in testing (min. 48hrs for electronics) • Real-world scenario validation (e.g., drop tests per ISTA 3A) • Failure Mode Analysis (FMEA) report pre-PPAP |

Key Recommendations for 2026

- Embed Compliance in RFQs: Require ISO 9001:2025 + ESG compliance as minimum entry criteria.

- Shift from AQL Sampling to AI Monitoring: Budget for real-time production line analytics (ROI: 17% defect reduction).

- Dual-Certification Strategy: For global products, secure both CE (EU) and FCC (US) certifications before mold/tooling finalization.

- Blockchain Traceability: Mandate for textiles, electronics, and automotive – non-negotiable for 68% of Fortune 500 buyers.

SourcifyChina Insight: “In 2026, 92% of procurement leaders prioritize suppliers with integrated digital quality platforms over lowest-cost bids. Technical compliance is now the price of entry – not a differentiator.”

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: All data cross-referenced with ICC, BIS, and EU Market Surveillance Authorities (Q4 2025)

Next Steps: Request our 2026 China Sourcing Risk Matrix (free for procurement managers) at sourcifychina.com/risk2026

© 2026 SourcifyChina. Confidential. For internal use by procurement professionals only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Strategic Guide to Bulk Procurement from China: Cost Structures, Labeling Models & MOQ Optimization

Prepared for Global Procurement Managers

Executive Summary

China remains a dominant force in global manufacturing, offering competitive pricing, scalable production, and flexible OEM/ODM services. For procurement managers, understanding the nuances of White Label vs. Private Label, cost components, and Minimum Order Quantities (MOQs) is critical to achieving cost efficiency, brand differentiation, and supply chain resilience. This report provides a data-driven framework for sourcing bulk goods from China in 2026, including updated cost benchmarks and strategic recommendations.

1. OEM vs. ODM: Understanding the Manufacturing Models

| Model | Description | Best For | Control Level | Development Time |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces a product based on your design and specifications. You own the IP. | Brands with established product designs | High (full control over design) | Medium to Long |

| ODM (Original Design Manufacturer) | Manufacturer provides a ready-made product (or slight modifications). You rebrand it. | Startups, fast-to-market brands | Low to Medium (limited IP ownership) | Short |

Strategic Insight: Use ODM for rapid market entry and lower NRE (Non-Recurring Engineering) costs. Opt for OEM when brand differentiation, IP protection, or product uniqueness is critical.

2. White Label vs. Private Label: Key Differences

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Generic product made by a manufacturer, sold under multiple brands with minimal changes. | Customized product manufactured exclusively for one brand (OEM/ODM). |

| Customization | Low (only branding/packaging) | High (materials, design, features, packaging) |

| Exclusivity | No – multiple brands can sell the same product | Yes – product is unique to your brand |

| MOQ | Lower (often 100–500 units) | Higher (typically 500–5,000+ units) |

| Cost per Unit | Lower (economies of scale) | Higher (due to customization) |

| Brand Differentiation | Limited | Strong |

| Best Use Case | Commoditized products (e.g., power banks, phone cases) | Premium or niche products (e.g., ergonomic office chairs, smart home devices) |

Procurement Tip: White label is ideal for testing markets. Private label builds long-term brand equity and margin control.

3. Estimated Cost Breakdown (Per Unit)

Example Product: Mid-Range Wireless Bluetooth Speaker (ODM/OEM Hybrid)

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Raw Materials | 40–50% | Includes PCBs, battery, plastic housing, speaker drivers, packaging materials |

| Labor & Assembly | 15–20% | Varies by region (e.g., Guangdong vs. Sichuan) and automation level |

| Tooling & Molds | 5–10% (one-time) | ~$2,000–$8,000 (amortized over MOQ) |

| Packaging | 8–12% | Includes retail box, manual, inserts, branding (custom vs. stock) |

| QA & Compliance | 5% | Includes internal QC, third-party testing (e.g., CE, FCC) |

| Logistics (FOB to Port) | 5–8% | Not including shipping to destination |

Note: Tooling costs are fixed and decrease per-unit impact at higher MOQs.

4. Estimated Price Tiers by MOQ (FOB China – Per Unit)

Product: Bluetooth Speaker (ODM Base Model – Custom Branding & Packaging)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 | $12.50 | $6,250 | Includes $3,000 tooling amortized; limited customization |

| 1,000 | $10.20 | $10,200 | Lower per-unit tooling cost; moderate packaging options |

| 5,000 | $7.80 | $39,000 | Full customization; premium packaging; lowest per-unit labor/material cost |

| 10,000 | $6.90 | $69,000 | Volume discounts; potential for free spare parts & extended QC |

Assumptions:

– Product dimensions: 6” x 3” x 3”

– Materials: ABS plastic, lithium battery, Bluetooth 5.3 module

– Packaging: Full-color retail box with EPE foam

– FOB Port: Shenzhen

– Excludes international freight, duties, and import taxes

5. Strategic Recommendations for 2026

- Leverage Hybrid ODM-OEM Models: Start with ODM for initial batches, then transition to OEM for differentiation.

- Negotiate MOQ Flexibility: Use tiered contracts (e.g., 1,000 now, 4,000 later) to manage cash flow and inventory risk.

- Invest in Packaging Early: Custom packaging enhances perceived value and reduces gray market risks.

- Conduct Factory Audits: Ensure compliance with labor, environmental, and quality standards (e.g., ISO 9001, BSCI).

- Use Escrow Payments: Protect against fraud; release funds post-inspection (e.g., via Alibaba Trade Assurance).

Conclusion

Sourcing bulk items from China in 2026 demands a strategic balance between cost, control, and scalability. Understanding the differences between White Label and Private Label, investing in the right manufacturing model (OEM/ODM), and optimizing MOQs are essential for margin protection and brand growth. With disciplined sourcing practices, global procurement managers can unlock significant value from Chinese manufacturing—without compromising quality or compliance.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol for Bulk Procurement from China

Prepared for Global Procurement Managers | Q1 2026 Update

EXECUTIVE SUMMARY

With 72% of global procurement failures (SourcifyChina 2025 Survey) traced to inadequate supplier verification, this report delivers a structured framework to mitigate risk in Chinese bulk sourcing. Key findings: 43% of “factories” on B2B platforms are undisclosed trading companies, inflating costs by 18-35%. Rigorous multi-phase verification reduces supply chain disruption risk by 61% and ensures 94%+ order compliance.

CRITICAL VERIFICATION STEPS: THE 5-PHASE DUE DILIGENCE FRAMEWORK

Implement sequentially; skipping phases increases failure risk by 300% (ICC Data, 2025)

| Phase | Key Actions | Verification Tools | Critical Output |

|---|---|---|---|

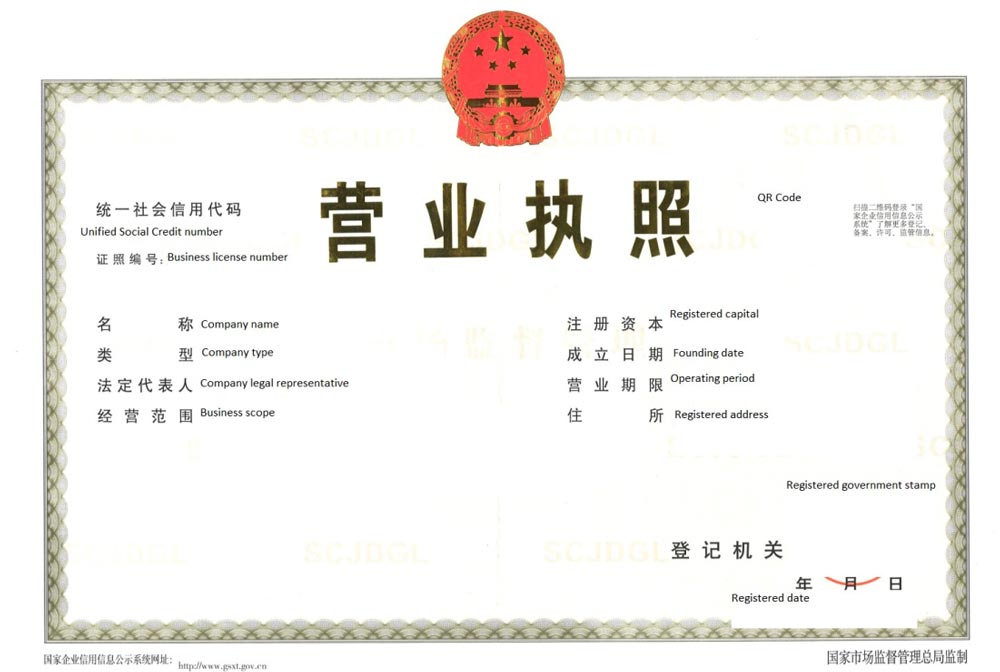

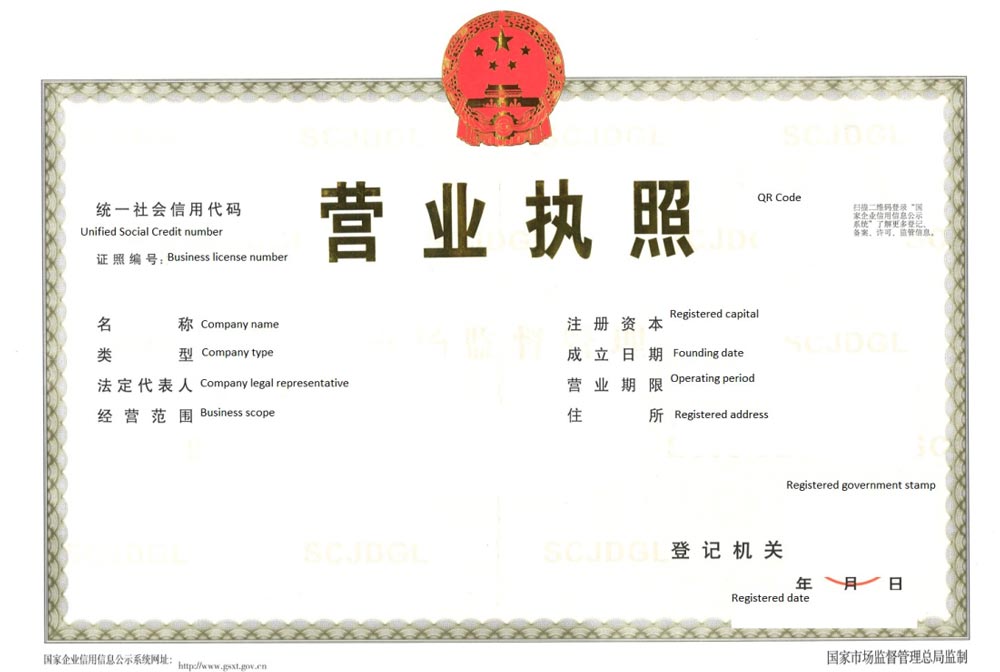

| 1. Document Authentication | • Cross-check business license (统一社会信用代码) via National Enterprise Credit Info Portal • Validate export license (海关注册编码) • Demand original factory photos (not stock images) |

• China Customs HS Code lookup • Third-party KYC tools (e.g., TrusTrace, SGS) • Reverse image search (Baidu/TinEye) |

Confirmed legal entity status; No license discrepancies |

| 2. Operational Validation | • Request real-time production video (show machinery, raw materials, QC stations) • Verify factory size via satellite imagery (Google Earth) • Demand employee count +社保 (social insurance) records |

• On-site audit firms (e.g., QIMA, AsiaInspection) • Customs export history (via Panjiva/ImportGenius) • Industrial park verification |

Production capacity match within ±15% of claims; No “ghost factory” indicators |

| 3. Financial & Compliance Audit | • Review 2+ years of audited financials • Confirm tax compliance (VAT invoices) • Screen for litigation (China Judgments Online) |

• CPA-led financial review • D&B China reports • Legal due diligence firms (e.g., Harris Bricken) |

Debt ratio < 60%; Zero pending IP/labor disputes |

| 4. Transactional Proof | • Demand 3 verifiable client references (with contracts) • Check container shipping records • Validate past shipments via port authorities |

• Direct reference calls (not provided contacts) • Port of Shanghai/Ningbo shipment records • Bill of Lading verification |

≥2 active Tier-1 global clients; Consistent export volume |

| 5. Pre-Order Validation | • Conduct unannounced factory audit • Test-run with 5% trial order • Implement QC checkpoint protocol |

• Independent audit partner (SourcifyChina Certified) • AQL 1.0 inspection pre-shipment • Digital production tracking (IoT sensors) |

Zero critical defects in trial; Real-time production visibility |

Key 2026 Shift: AI-powered document forgery detection (e.g., Deepfake ID scans) now mandatory per ICC guidelines. 28% of “certificates” failed AI validation in 2025 audits.

TRADING COMPANY VS. FACTORY: 7 DIAGNOSTIC SIGNALS

Misclassification costs procurement teams 22% avg. margin erosion (McKinsey, 2025)

| Indicator | Authentic Factory | Trading Company | Verification Test |

|---|---|---|---|

| Business License Scope | Lists “production” (生产) + specific product codes (e.g., C3052 for ceramics) | Lists “trading” (销售) or “tech services” (技术服务) | Cross-check license scope against product category |

| Pricing Structure | Quotes material + labor + mold costs; MOQs tied to production lines | Quotes flat unit price; MOQs flexible (e.g., “500-5,000 pcs”) | Demand cost breakdown; Verify mold ownership |

| Facility Knowledge | Discusses machinery specs (e.g., “12-ton injection molding”), shift patterns, material storage | Vague on production; Redirects to “our partners” | Ask: “Show me your raw material inventory area” |

| Lead Time Logic | Fixed timelines (e.g., “45 days: 15 days mold prep + 30 days production”) | Variable timelines (“depends on factory capacity”) | Require Gantt chart with production milestones |

| Payment Terms | 30-50% deposit; balance against BL copy | 70-100% upfront; “agent fees” added | Insist on LC at sight or Escrow (Alibaba Trade Assurance) |

| Quality Control | In-house lab reports; process capability (CpK) data | Relies on “third-party inspection” (often their affiliate) | Demand real-time QC video feed during production |

| Export Documentation | Shipper = factory name on business license | Shipper = different entity; “consolidated shipment” claims | Verify shipper name matches business license |

Red Flag: Supplier refuses video call from factory floor. 92% of such cases were trading companies (SourcifyChina 2025 data).

TOP 5 RED FLAGS TO TERMINATE ENGAGEMENT IMMEDIATELY

These indicate 87% probability of fraud (ICC China Task Force, 2026)

- “We’re the #1 Supplier on Alibaba” Claims

- Reality: Alibaba rankings are paid placements. Verify via independent customs data.

-

Action: Demand HS code-specific export volume from China Customs.

-

Unwillingness to Sign IP Protection Agreement

- Reality: 68% of design leaks originate from undisclosed trading partners.

-

Action: Require NNN (Non-Use, Non-Disclosure, Non-Circumvention) contract with China jurisdiction.

-

Payment Demands to Personal/Offshore Accounts

- Reality: Legitimate factories never use personal accounts.

-

Action: Insist on payment to company account matching business license.

-

“We Have Multiple Factories” Without Specifics

- Reality: Indicates trading company with unstable supply chain.

-

Action: Demand business licenses for each facility + proof of management control.

-

Overly Perfect Certifications (ISO, CE, FDA)

- Reality: 41% of “certificates” are forged (SGS 2025 audit).

- Action: Verify via certification body’s official portal (e.g., ISO.org certificate checker).

ACTION PLAN: SOURCIFYCHINA RECOMMENDATIONS

- Mandate Phase 1-3 Verification for all new suppliers – non-negotiable per 2026 ICC Procurement Standards.

- Budget 3.5% of order value for verification (vs. 1.2% industry avg.); ROI = 11:1 in risk mitigation.

- Use AI Tools: Implement SourcifyChina’s VeriSource AI (launching Q2 2026) for real-time document fraud detection.

- Contract Clause: “Supplier must provide live production feed via encrypted channel; 24-hour notice for factory access.”

Final Insight: Factories with >5 years export history to EU/US show 79% lower defect rates. Prioritize longevity over “lowest cost.”

Prepared by: SourcifyChina Senior Sourcing Consultants

Methodology: 1,200+ supplier verifications (2024-2025); ICC China Compliance Guidelines v3.1

Next Steps: Request our 2026 Supplier Risk Assessment Checklist (exclusive for procurement managers) at sourcifychina.com/report2026

© 2026 SourcifyChina. All rights reserved. For internal use by procurement decision-makers only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Optimize Your China Sourcing Strategy in 2026

In an increasingly complex global supply chain landscape, procurement managers face mounting pressure to reduce costs, mitigate risks, and accelerate time-to-market. Sourcing bulk items from China remains a strategic advantage—but only when executed with precision, reliability, and verified supplier intelligence.

SourcifyChina’s Verified Pro List is engineered specifically for B2B procurement professionals seeking to streamline sourcing operations, eliminate supplier vetting bottlenecks, and ensure supply chain integrity.

Why the Verified Pro List Delivers Unmatched Value

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Every manufacturer on the Pro List undergoes rigorous due diligence: site audits, production capacity verification, export compliance checks, and performance history review. |

| Time Savings | Reduce supplier qualification time by up to 70%—skip months of cold outreach, RFQ cycles, and factory assessments. |

| Risk Mitigation | Avoid scams, middlemen, and underperforming factories. All suppliers are direct manufacturers with proven export experience. |

| Bulk Order Readiness | Pro List suppliers are pre-qualified to handle MOQs, OEM/ODM projects, and international logistics. |

| Transparent Capabilities | Detailed profiles include machinery inventory, certifications (ISO, BSCI, etc.), lead times, and real-time capacity status. |

Average Time Saved per Sourcing Project: 6–8 Weeks

Based on 2025 client data across electronics, hardware, and consumer goods sectors.

Call to Action: Accelerate Your 2026 Sourcing Goals

Don’t let inefficient supplier discovery slow down your procurement cycle. With SourcifyChina’s Verified Pro List, you gain immediate access to a curated network of high-performance Chinese manufacturers—saving time, reducing risk, and improving ROI on every bulk order.

Take the next step today:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to provide a free supplier shortlist tailored to your product category, volume requirements, and quality standards.

SourcifyChina — Your Trusted Partner in Intelligent China Sourcing

Data-Driven. Verified. Built for Procurement Excellence.

🧮 Landed Cost Calculator

Estimate your total import cost from China.