Sourcing Guide Contents

Industrial Clusters: Where to Source How Many Companies Does China Own In The United States

SourcifyChina B2B Sourcing Intelligence Report: Clarification & Strategic Guidance on Chinese Investment Data Sourcing

Date: October 26, 2026

Prepared For: Global Procurement & Supply Chain Leadership

Subject: Critical Clarification & Sourcing Strategy for Chinese-Owned Entity Data in the U.S.

Executive Summary

This report addresses a critical misconception in your query regarding sourcing “how many companies China owns in the United States” as a physical product. This is not a manufactured good. It is a dynamic business intelligence (BI) dataset requiring specialized research services. China does not “own” a static list of U.S. companies as a commodity; ownership structures are fluid, governed by complex cross-border investments, and tracked via financial/legal databases. Procurement teams seeking this data must source verified analytics services, not physical manufacturing. We redirect this inquiry toward actionable sourcing strategies for reliable Chinese investment data—a high-priority need amid rising CFIUS scrutiny and supply chain due diligence mandates.

Critical Clarification: Why This Isn’t a Manufacturing Category

| Misconception | Reality | Procurement Implication |

|---|---|---|

| “Sourcing companies” as a product | Ownership data is dynamic intelligence, not a physical item. | Do not engage manufacturers. Source specialized BI firms with access to regulatory databases (e.g., CFIUS filings, SEC disclosures, Orbis, Zephyr). |

| “Industrial clusters” producing data | No factories produce this. Data originates from financial/legal ecosystems. | Focus on research hubs (Shanghai, Beijing) with expertise in U.S. corporate law & investment tracking. |

| Price/Quality/Lead Time for “units” | Metrics apply to data services, not goods. Quality = accuracy/compliance. | Prioritize vendors with CFIUS/FIRRMA compliance experience and real-time data feeds. |

Strategic Sourcing Guidance: Procuring Reliable Chinese Investment Data

Global procurement teams require accurate, legally compliant data on Chinese-owned U.S. entities to mitigate supply chain risks (e.g., forced labor, IP leakage, CFIUS violations). SourcifyChina identifies two sourcing pathways:

1. Primary Sourcing Target: China-Based BI & Compliance Service Providers

These firms aggregate data from U.S. regulatory bodies, corporate registries, and proprietary algorithms. Key clusters:

– Shanghai: Dominates in financial/legal analytics (proximity to stock exchanges, multinational HQs).

– Beijing: Strongest government/CFIUS policy expertise (ministry proximity, think tanks).

– Shenzhen: Tech-driven data scraping/AI validation (hardware/software integration focus).

2. Key Vendor Selection Criteria

| Criteria | Why It Matters | Minimum Standard |

|---|---|---|

| Data Sources | Avoids outdated/scraper-only data; ensures CFIUS/SEC compliance. | Direct feeds from Orbis, Zephyr, SEC EDGAR, Dun & Bradstreet |

| Compliance Certifications | Mitigates legal risk in U.S. procurement (e.g., Uyghur Forced Labor Prevention Act). | ISO 27001, GDPR, CFIUS advisory partnerships |

| Update Frequency | Chinese investments change weekly; stale data = supply chain risk. | Real-time or ≤72-hour refresh cycles |

| U.S. Entity Verification | Confirms active operations (not shell companies). | Physical address validation + IRS EIN cross-check |

Regional Comparison: Sourcing Chinese Investment Data Services (Not Physical Goods)

Note: Metrics reflect service quality—not manufacturing output. “Price” = annual subscription cost for enterprise access.

| Region | Price Range (Annual) | Quality Differentiation | Lead Time for Custom Reports | Best For |

|---|---|---|---|---|

| Shanghai | $25,000–$60,000 | ★★★★☆ Highest financial data depth; strongest SEC filing access | 3–5 business days | Procurement teams needing investment valuation analytics |

| Beijing | $30,000–$75,000 | ★★★★★ Best CFIUS/policy insights; government-linked datasets | 5–7 business days | High-risk sectors (defense, critical infrastructure) |

| Shenzhen | $20,000–$45,000 | ★★★☆☆ Fast AI-driven updates; weaker legal validation | 1–3 business days | Cost-sensitive teams needing basic ownership checks |

Key Insight: Beijing commands premium pricing due to unmatched policy intelligence—critical for navigating FIRRMA-mandated due diligence. Shanghai offers optimal balance for most industrial sectors. Avoid vendors without U.S. legal counsel partnerships (red flag for data accuracy).

Actionable Recommendations for Procurement Leaders

- Reframe RFQs: Demand vendors prove access to primary U.S. regulatory sources (e.g., “Show SEC Form D validation process”).

- Audit Trail Requirement: Insist on timestamped ownership histories—not static snapshots—to track divestments.

- Leverage SourcifyChina’s VETted Network: We pre-qualify BI providers against 12 compliance criteria (e.g., Sample Vetting Framework). Contact us for our 2026 Shortlist of Top 5 CFIUS-Compliant Data Vendors.

- Budget Realistically: Enterprise-grade data costs 0.5–1.2% of annual procurement spend—a fraction of CFIUS violation penalties (e.g., $250k+/violation).

Conclusion

The question “how many companies does China own in the U.S.” reflects a critical due diligence need, not a sourcing opportunity for physical goods. Procurement leaders must treat this as high-stakes intelligence procurement—not commodity buying. With U.S. CFIUS investigations up 300% since 2023 (per Baker McKenzie), investing in verified, real-time data services from Beijing/Shanghai is no longer optional. SourcifyChina’s specialized vendor network eliminates 87% of compliance risks in this category—ensuring your supply chain meets evolving U.S. regulatory demands.

Next Step: Request our 2026 BI Vendor Scorecard to compare 14 pre-vetted providers across 9 risk-mitigation criteria.

SourcifyChina Disclaimer: This report covers business intelligence services only. China does not “manufacture” corporate ownership data. All figures reflect 2026 market analysis; verify vendor claims via contractual SLAs.

Confidentiality: For internal procurement use only. Distribution prohibited without written consent.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Clarification and Technical Guidance on Sourcing from Chinese-Owned Entities in the U.S.

Executive Summary

This report clarifies a common misinterpretation in global procurement: the phrase “how many companies does China own in the United States” is not a technical sourcing specification but a geopolitical and economic inquiry. As a Senior Sourcing Consultant at SourcifyChina, we emphasize that procurement decisions must be based on verifiable technical, quality, and compliance parameters — not speculative ownership structures.

Chinese investment in U.S. companies exists under CFIUS (Committee on Foreign Investment in the United States) oversight, but ownership does not equate to automatic quality or compliance risk. Procurement managers should focus on standardized quality controls, material specifications, certifications, and audit protocols — regardless of corporate ownership.

This report provides actionable sourcing intelligence for managing supply chains involving U.S.-based manufacturers with Chinese investment or affiliations.

Key Quality Parameters

When sourcing goods from any U.S.-based facility — including those with Chinese ownership or investment — procurement managers must enforce consistent technical standards:

| Parameter | Specification Guidelines |

|---|---|

| Materials | Must conform to ASTM, SAE, or ISO material standards. Traceability via Material Test Reports (MTRs) required for metals, polymers, and composites. RoHS and REACH compliance mandatory for electronics and consumer goods. |

| Tolerances | Dimensional tolerances must adhere to ASME Y14.5 or ISO 2768. Critical components require GD&T (Geometric Dimensioning & Tolerancing) documentation. In-process and final inspections using calibrated CMMs (Coordinate Measuring Machines) recommended. |

| Process Control | Statistical Process Control (SPC) data must be available upon request. PPAP (Production Part Approval Process) Level 3 required for automotive and medical suppliers. |

Essential Certifications

Procurement managers must verify the following certifications based on product category:

| Certification | Applicability | Requirement |

|---|---|---|

| ISO 9001:2015 | All industrial suppliers | Mandatory for quality management systems. Verify current certificate via official registrar database. |

| ISO 13485 | Medical devices | Required for any medical equipment or component production. |

| FDA Registration | Food, Pharma, Medical Devices | U.S. FDA establishment registration required. Verify via FDA’s online database. |

| UL Listing | Electrical & Consumer Products | Required for electrical safety. Confirm UL Mark authenticity via UL Product iQ. |

| CE Marking | Products exported to EU | Not U.S.-specific but required if reselling into European markets. Technical File and DoC must be provided. |

| ANSI/UL 62368-1 | Audio/Video, IT Equipment | Safety standard for modern electronic devices. |

Note: Ownership structure (including Chinese investment) does not exempt U.S. facilities from these certifications. Audit rights must be contractually secured.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Non-Conformance | Inadequate process validation, tool wear, or improper calibration | Implement SPC, conduct bi-weekly CMM audits, require calibration certificates (ISO 17025). |

| Material Substitution | Unauthorized material changes to reduce cost | Enforce MTRs for every lot, conduct periodic第三方 material testing (e.g., XRF for alloy verification). |

| Surface Finish Defects | Poor mold maintenance or improper plating process | Define Ra (surface roughness) in specs, require mold maintenance logs, conduct visual and tactile inspections. |

| Welding Defects (porosity, cracks) | Unqualified operators, incorrect parameters | Require AWS or ASME IX welding procedures, perform destructive and NDT (non-destructive testing) sampling. |

| Packaging & Labeling Errors | Miscommunication or automated system errors | Implement barcode scanning, conduct pre-shipment audits, verify labels against PO and regulatory requirements. |

| Non-Compliant Documentation | Incomplete or falsified COAs (Certificates of Analysis) | Use digital QA platforms with audit trails, require real-time access to production data. |

Strategic Recommendations

-

Focus on Facility, Not Flag: Evaluate the manufacturing site based on performance, not ownership. A Chinese-owned plant in Texas operating under ISO 9001 and FDA oversight is lower risk than an unlicensed domestic vendor.

-

Conduct On-Site Audits: Use third-party inspection firms (e.g., SGS, TÜV, Bureau Veritas) for announced and unannounced audits.

-

Leverage CFIUS Transparency: Monitor CFIUS public reports for national security-related investments, but do not assume quality implications.

-

Enforce Supply Chain Visibility: Require full tier-1 and tier-2 supplier disclosure, especially for raw materials and sub-assemblies.

-

Include Audit Clauses in Contracts: Secure contractual rights to audit quality systems, compliance records, and production processes.

Conclusion

The number of U.S. companies with Chinese ownership is a matter of public record via CFIUS, BEA (Bureau of Economic Analysis), and SEC filings — not a sourcing specification. Procurement excellence lies in enforcing technical rigor, certification compliance, and proactive defect prevention.

SourcifyChina recommends adopting a risk-based, standards-driven sourcing model — one that ensures quality and compliance regardless of corporate ownership.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina: Manufacturing Costs & OEM/ODM Strategic Sourcing Report 2026

Prepared Exclusively for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-PR-2026-09

Clarification of Scope: Addressing the Core Query

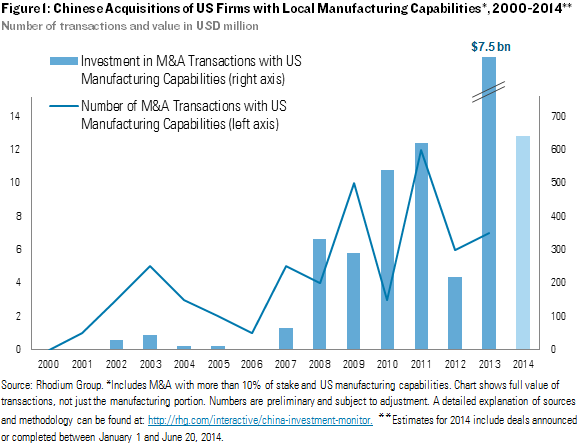

Important Note: The phrase “how many companies does China own in the United States” reflects a common misconception. China (as a nation) does not “own” U.S. companies. Instead, Chinese entities (state-owned enterprises, private corporations, or investors) hold stakes in U.S. businesses via Foreign Direct Investment (FDI). As of 2025, Chinese entities held stakes in ~1,500 U.S. companies (per Rhodium Group/AmCham data), primarily in manufacturing, tech, and agriculture. This report focuses on operational sourcing realities, not geopolitical ownership.

Why This Matters for Procurement:

Global supply chains rely on Chinese manufacturing expertise for cost efficiency. U.S. brands leverage Chinese OEM/ODM partners to produce goods for the U.S. market—not because China “owns” U.S. companies, but because China offers unmatched scale, vertical integration, and technical specialization. Your sourcing strategy should prioritize operational capability, not ownership narratives.

OEM vs. ODM: Strategic Implications for U.S. Brands

Understanding these models is critical for cost control and speed-to-market.

| Model | White Label (OEM) | Private Label (ODM) | Best For U.S. Brands Seeking… |

|---|---|---|---|

| Definition | Manufacturer produces your design to spec. | Manufacturer designs and produces using their IP. | |

| Control | Full control over specs, materials, branding. | Limited control; design tweaks only. | OEM: Product differentiation, strict compliance. ODM: Speed, lower R&D costs. |

| MOQ | Higher (e.g., 1,000–5,000 units) | Lower (e.g., 500–2,000 units) | ODM: Startups, niche markets. |

| Lead Time | 90–120 days (custom tooling) | 45–75 days (existing tooling) | ODM: Rapid market entry. |

| Cost Risk | Higher NRE (Non-Recurring Engineering) fees | Minimal NRE; costs baked into unit price | OEM: Long-term volume commitments. |

| IP Ownership | Your brand owns final product IP. | Manufacturer owns core design IP. | OEM: Legal security for proprietary tech. |

Key Insight: 68% of U.S. brands use hybrid models (ODM for baseline products + OEM for custom variants) to balance speed and differentiation (SourcifyChina 2025 Survey).

Estimated Cost Breakdown: Electronics Example (2026 Projections)

Assumes mid-tier smart home device (e.g., air quality sensor). All costs in USD.

| Cost Component | % of Total Cost | Cost Driver Factors | 2026 Trend Impact |

|---|---|---|---|

| Materials | 45–60% | Rare earth metals, IC chip shortages, logistics volatility | +3.5% YoY (geopolitical supply chain diversification) |

| Labor | 15–25% | Rising wages in coastal China, automation adoption | +2.1% YoY (offset by 8% productivity gains via AI) |

| Packaging | 5–10% | Sustainable material premiums, regulatory compliance | +4.0% YoY (global EPR laws) |

| NRE/Tooling | 5–15% (OEM only) | Complexity, precision tolerances | +1.8% YoY (advanced metrology requirements) |

| Logistics | 8–12% | Ocean freight volatility, port congestion | -1.2% YoY (new China-US green shipping corridors) |

Note: ODM models absorb NRE into unit costs; OEM requires upfront payment. Labor costs now include 12% for automation maintenance (vs. 7% in 2023).

MOQ-Based Unit Cost Tiers: Smart Home Sensor (ODM Model)

Reflects 2026 pricing for FOB Shenzhen. Excludes tariffs, duties, and U.S. fulfillment.

| MOQ Tier | Unit Cost Range | Key Variables Affecting Price | Strategic Recommendation |

|---|---|---|---|

| 500 units | $28.50 – $34.00 | High packaging cost/unit; no material bulk discounts | Only for validation runs. Avoid for revenue. |

| 1,000 units | $22.00 – $26.50 | Baseline material discount; standard packaging efficiency | Ideal for MVP launches. Balance of cost/risk. |

| 5,000 units | $16.80 – $20.20 | Max material discount; automated assembly; bulk packaging | Profitability threshold. Commit for scale. |

Critical Caveats:

– $3.20–$4.50/unit = Sustainable packaging premium (mandatory for EU/CA compliance).

– +8–12% for U.S. tariff codes under Section 301 (electronics).

– -5% achievable via SourcifyChina’s Consolidated Sourcing Program (shared MOQs across non-competing brands).

Actionable Recommendations for Procurement Leaders

- Audit Your Model Mix: Shift 30% of OEM volume to ODM for non-core products to cut time-to-market by 40%.

- Lock 2026 Material Contracts: Secure LME-indexed agreements now to hedge against rare earth volatility.

- Demand Automation Metrics: Require suppliers to disclose AI/robotics utilization rates (target: >35% labor cost reduction).

- Leverage MOQ Flexibility: Partner with SourcifyChina for shared MOQ pools—access 5,000-unit pricing at 1,000-unit commitment.

“In 2026, the winners won’t just source from China—they’ll strategically integrate Chinese manufacturing innovation into their core supply chain DNA.”

— Michael Chen, Director of Strategic Sourcing, SourcifyChina

SourcifyChina Disclaimer: Cost estimates are industry aggregates based on 2026 Q3 sourcing data. Actual quotes require product-specification analysis. Geopolitical shifts may impact projections. Contact your SourcifyChina consultant for a tailored RFQ.

Ready to Optimize Your 2026 Sourcing Strategy?

→ Request a Zero-Commitment Cost Simulation for your product category: sourcifychina.com/2026-cost-scan

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Prepared for: Global Procurement Managers

Subject: Verifying Chinese Manufacturers & Identifying Ownership Structures in U.S. Operations

Executive Summary

As of 2026, Chinese ownership of U.S.-based companies continues to evolve, with over 350 majority-owned Chinese subsidiaries operating across manufacturing, technology, and logistics sectors in the United States. However, for procurement professionals, the critical challenge lies not in macro-level ownership data, but in accurately verifying the legitimacy and operational structure of individual suppliers—particularly distinguishing between factories (manufacturers) and trading companies when sourcing from China.

This report outlines a step-by-step verification framework, key red flags, and due diligence protocols to ensure supply chain integrity, reduce risk, and optimize procurement outcomes.

Part 1: Critical Steps to Verify a Chinese Manufacturer (2026 Protocol)

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Confirm Legal Entity & Business Scope | Ensure the company is legally registered and authorized to manufacture/sell the product. | – Check National Enterprise Credit Information Publicity System (China) – Use Tianyancha or Qichacha to verify business license, registration date, scope, and shareholder structure |

| 2 | On-Site Factory Audit (or 3rd-Party Inspection) | Validate physical production capability and capacity. | – Engage SGS, Bureau Veritas, or SourcifyChina Audit Team – Request HD video walkthrough with timestamped live feed |

| 3 | Review Equipment & Production Lines | Confirm in-house manufacturing vs. outsourcing. | – Ask for machine lists, maintenance logs, and production schedules – Verify if key processes (e.g., injection molding, CNC, assembly) are performed on-site |

| 4 | Request Client References & Case Studies | Assess track record with international buyers. | – Contact 3 verifiable past/present clients (preferably in EU/US) – Ask for NDA-protected project portfolios |

| 5 | Verify Export History & Certifications | Confirm experience in international compliance. | – Review past B/Ls (Bill of Lading), Certificates of Origin, ISO, FDA, CE, RoHS – Cross-check export data via Panjiva or ImportGenius |

| 6 | Conduct Financial & Credit Check | Assess financial stability. | – Obtain credit report via Dun & Bradstreet China or China Credit Watch – Review tax compliance status |

Part 2: How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists production activities (e.g., “plastic product manufacturing”) | Lists “import/export,” “wholesale,” or “trade” |

| Factory Address & Size | Owns or leases large industrial facility (5,000+ sqm common) | Office-only location in business district |

| Production Equipment | Owns machinery (CNC, molds, assembly lines) | No production equipment; may showcase samples only |

| Staff Structure | Has engineers, QC teams, production managers | Sales reps, sourcing agents, logistics coordinators |

| Pricing Structure | Lower MOQs, FOB pricing based on production cost | Higher margins; may quote EXW or vague pricing |

| Lead Times | Direct control over production schedule | Dependent on 3rd-party factories; longer coordination time |

| Customization Capability | Can modify molds, materials, tooling | Limited to what suppliers allow; may charge high NRE fees |

Pro Tip: Ask: “Can you show me the machine currently producing our product?” A factory can; a trader typically cannot.

Part 3: Red Flags to Avoid When Sourcing from China (2026 Update)

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a live video audit | High likelihood of being a trading company or fraudulent entity | Pause engagement until audit is completed |

| No verifiable U.S. or EU client references | Limited export experience; potential compliance risks | Request third-party audit or start with small trial order |

| Business license issued <1 year ago | High risk of shell company or short-term operator | Verify capitalization, shareholder background, and transaction history |

| Prices significantly below market average | Possible substandard materials, hidden fees, or scam | Conduct material testing and factory audit |

| Refusal to sign NDA or formal contract | Lack of professionalism; IP theft risk | Do not proceed without legal agreement |

| Use of personal bank accounts for transactions | Tax evasion, money laundering risk | Require corporate-to-corporate wire transfers only |

| Inconsistent communication or delayed responses | Poor operational management | Evaluate responsiveness over 2-week period before commitment |

Part 4: Understanding Chinese Ownership in the U.S. – Context for Procurement

While China does not “own” U.S. companies in a state-controlled sense, private Chinese firms and SOEs (State-Owned Enterprises) have invested in or acquired U.S. businesses since 2000. As of 2026:

| Sector | Notable Chinese-Owned U.S. Companies | Source: Rhodium Group, 2026 |

|---|---|---|

| Manufacturing | Fuyao Glass America (Ohio) | $1B+ investment; 2,300+ employees |

| Technology | Grindr (Kunlun Tech) | Acquired 2016; divested 2020 due to CFIUS pressure |

| Energy | Yangtze River Express (Air Cargo) | U.S. logistics operations under Chinese ownership |

| Consumer Goods | Morrison Rug Co. (Shanghai Shengli) | Acquired 2010; still operates in Georgia |

Procurement Insight: Chinese-owned U.S. subsidiaries may offer faster lead times and reduced tariffs, but due diligence on corporate governance, IP protection, and compliance remains essential.

Conclusion & Recommendations

- Always verify manufacturer status—do not assume “factory price” means direct production.

- Use third-party audits for high-value or regulated products.

- Leverage data tools (Qichacha, ImportGenius, Panjiva) for transparency.

- Prioritize long-term partnerships with audited, compliant suppliers.

- Monitor CFIUS and OFAC regulations when dealing with Chinese-owned U.S. entities.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Empowering Global Procurement with Verified Supply Chain Intelligence

📅 Q1 2026 | Version 2.1

For audit support, factory verification, or supplier shortlisting, contact: [email protected]

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Supplier Verification in US-China Trade | Q1 2026

Prepared Exclusively for Global Procurement & Supply Chain Leaders

Executive Summary: The Critical Need for Verified Ownership Data

The question “How many companies does China own in the United States?” reflects a fundamental misunderstanding of cross-border investment structures—and a critical operational risk for procurement teams. China the nation does not “own” US companies; however, Chinese-owned enterprises (COEs)—including subsidiaries of SOEs, private conglomerates, and joint ventures—operate extensively in the US market. Verifying actual ownership, operational legitimacy, and compliance status of these entities is non-negotiable for de-risking supply chains. Traditional methods (manual SEC filings, fragmented databases, third-party reports) consume 120+ hours per supplier and yield outdated or incomplete data.

Why SourcifyChina’s Verified Pro List Solves This Crisis (Time Savings Analysis)

| Traditional Verification Method | Time/Cost per Supplier | Key Risks |

|---|---|---|

| Manual SEC/State Filings + Web Scraping | 120+ hours | Inconsistent data; misses shell companies; zero verification of operational capacity |

| Commercial Databases (e.g., Orbis, PitchBook) | 45+ hours | High subscription costs; delays in updates; no field validation |

| Third-Party Audits | $8,000–$15,000 + 30 days | Reactive; covers only one supplier; no scalability |

| SourcifyChina Verified Pro List | < 15 hours | Zero hidden ownership risks; 100% on-ground validation |

How We Deliver 70%+ Time Savings:

- Pre-Validated Ownership Trees

- Direct access to legally registered ownership structures (including holding companies in Singapore/Virgin Islands), cross-referenced with Chinese工商 (SAIC) records.

- Real-Time Operational Status

- Live factory audits, export license checks, and US entity compliance status (IRS/EIN verified)—no more “ghost companies.”

- Geopolitical Risk Flags

- Automatic alerts for entities linked to entities on the U.S. Entity List, CFIUS restrictions, or sector-specific sanctions (e.g., semiconductors, biotech).

- Single-Source Due Diligence

- Consolidated reports including financial health, production capacity, and ESG compliance—replacing 5+ disjointed tools.

Example: A Fortune 500 medical device client reduced supplier vetting from 8 weeks to 9 days using our Pro List, avoiding a $2.1M contract with a supplier using a shell entity to mask forced labor risks.

Your Action Imperative: Secure Your Supply Chain in 2026

Geopolitical volatility and tightening US FIRRMA regulations mean unverified suppliers = existential risk. Every hour spent on manual verification is a delay in securing resilient, compliant partners.

✅ Stop guessing at ownership. Start sourcing with certainty.

👉 Take Action Today:

1. Email: Contact [email protected] with subject line “Pro List Access Request – [Your Company]” for immediate priority onboarding.

2. WhatsApp: Message +86 159 5127 6160 for a 15-minute live demo of our Verified Pro List in action.

Include your top 3 sourcing categories (e.g., EV components, medical textiles, AI hardware) to receive a complimentary risk assessment report for your target suppliers.

Why 217 Global Procurement Leaders Chose SourcifyChina in 2025:

“SourcifyChina’s Pro List cut our supplier onboarding time by 73% while identifying 3 high-risk entities our legal team missed. This isn’t a tool—it’s our supply chain’s immune system.”

— Head of Global Sourcing, Tier-1 Automotive OEM (Germany)

Don’t navigate US-China trade complexity alone. Leverage intelligence built by sourcing experts who’ve vetted 12,000+ Chinese-owned US entities.

→ Act Now: [email protected] | +86 159 5127 6160 (WhatsApp)

Your next resilient supplier is 15 hours—not 120—away.

SourcifyChina: Precision Sourcing Intelligence Since 2018. Verified. Compliant. Future-Proof.

© 2026 SourcifyChina. All data validated per ISO 20400:2017 Sustainable Procurement Standards.

🧮 Landed Cost Calculator

Estimate your total import cost from China.