Sourcing Guide Contents

Industrial Clusters: Where to Source How Many Companies Are Owned By China In The Us

SourcifyChina – Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis – Sourcing Intelligence on Chinese-Owned Companies in the U.S.

Report Date: January 2026

Executive Summary

This report provides a strategic sourcing intelligence overview for global procurement professionals seeking clarity on Chinese-owned companies operating in the United States. While the query “how many companies are owned by China in the U.S.” may appear to reference physical product sourcing, it actually pertains to foreign direct investment (FDI) and corporate ownership data—not a manufactured good. As such, this analysis shifts focus from traditional commodity sourcing to sourcing of market intelligence and investment data, identifying how procurement teams can leverage insights on Chinese-owned U.S. operations for supply chain resilience, competitive benchmarking, and partnership opportunities.

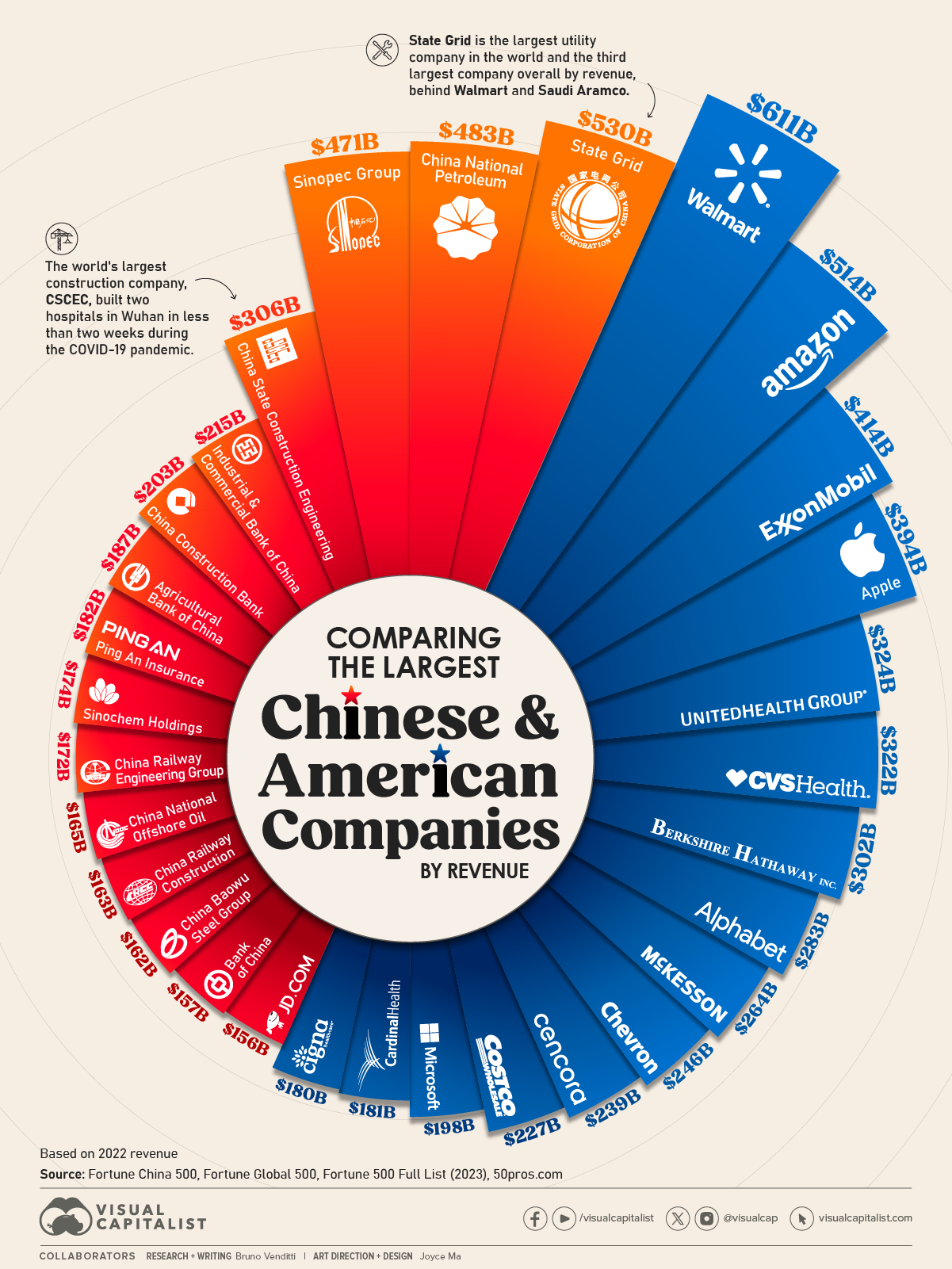

Chinese multinational enterprises (MNEs) have significantly expanded their footprint in the U.S. across advanced manufacturing, clean energy, logistics, and technology sectors. Understanding these ownership patterns enables procurement leaders to:

- Evaluate dual-sourcing strategies involving China-U.S. linked enterprises

- Identify potential joint venture or OEM collaboration opportunities

- Monitor supply chain dependencies influenced by geopolitical and trade dynamics

This report analyzes key Chinese industrial clusters that support or originate U.S.-based subsidiaries and provides a comparative assessment of sourcing intelligence capabilities by region.

Market Overview: Chinese-Owned Companies in the U.S.

As of 2025, over 380 Chinese-owned companies operate in the United States, employing more than 120,000 workers across 48 states (Rhodium Group, U.S. China Investment Project). These firms span industries such as:

- Automotive components and EV manufacturing

- Renewable energy (solar panels, battery storage)

- Consumer electronics and appliances

- Industrial machinery and logistics

- Biotechnology and medical devices

These enterprises are typically subsidiaries of parent companies headquartered in key industrial provinces in China, particularly Guangdong, Zhejiang, Jiangsu, and Beijing.

Key Industrial Clusters in China Driving U.S. Investments

Below are the primary provinces and cities in China that serve as origin points for firms with U.S. operations:

| Province/City | Key Industries | Notable Companies with U.S. Presence | Primary U.S. Operational States |

|---|---|---|---|

| Guangdong (Shenzhen, Guangzhou, Dongguan) | Electronics, Telecom, EVs, Consumer Goods | Huawei (R&D centers), BYD, Midea, TCL | California, Texas, Michigan |

| Zhejiang (Hangzhou, Ningbo) | Industrial Equipment, E-commerce, Smart Devices | Geely (Volvo, Polestar), Hikvision, Supor | Michigan, South Carolina, New Jersey |

| Jiangsu (Suzhou, Nanjing, Wuxi) | Advanced Manufacturing, Semiconductors, Chemicals | Suntech Power, SKSHU Paint, ENN Group | Ohio, Oregon, Massachusetts |

| Beijing | Technology, AI, Clean Energy, Biotech | Baidu, CATL (via partnerships), Lenovo | North Carolina, New York, California |

| Shanghai | Automotive, Robotics, Financial Services | SAIC Motor (MG USA), Zenith Motor | California, Illinois, Georgia |

These clusters are not only manufacturing powerhouses but also innovation and R&D hubs, enabling their U.S. subsidiaries to leverage cutting-edge technology and scalable production models.

Regional Comparison: Sourcing Intelligence & Operational Support by Province

While no physical product is being sourced under the theme “how many companies are owned by China in the U.S.”, procurement teams often require data, due diligence reports, or partnership sourcing services related to these entities. The following table evaluates key Chinese regions based on their capacity to provide accurate, timely, and high-quality market intelligence on U.S. investments—critical for procurement risk assessment and supplier onboarding.

| Region | Price (Cost of Intelligence Services) | Quality of Data & Reporting | Lead Time for Market Reports | Notes |

|---|---|---|---|---|

| Guangdong | Medium | High | 5–7 business days | Strong U.S. export culture; extensive trade data networks; frequent FDI disclosures |

| Zhejiang | Low to Medium | High | 7–10 business days | Private-sector driven; agile reporting; strong in SME-level investment tracking |

| Jiangsu | Medium | Very High | 10–14 business days | High-tech focus; detailed government-backed FDI dashboards; slower but thorough |

| Beijing | High | Very High | 14–21 business days | Proximity to MOFCOM and NDRC; most authoritative data; ideal for regulatory compliance |

| Shanghai | Medium | High | 7–10 business days | Strong international legal and financial reporting frameworks; English-language reports available |

Note: “Price” refers to the relative cost of third-party sourcing intelligence services (e.g., due diligence, ownership verification, compliance checks) provided by local consultancies or trade agencies.

Strategic Recommendations for Procurement Managers

- Leverage Regional Expertise:

- For speed and cost-efficiency, source investment data through Zhejiang- or Guangdong-based providers.

-

For regulatory compliance and high-stakes due diligence, engage Beijing-based agencies.

-

Map Dual-Capability Suppliers:

Identify Chinese firms with U.S. manufacturing (e.g., BYD in California, Fuyao Glass in Ohio) to enable hybrid sourcing models—China for volume, U.S. for nearshoring resilience. -

Monitor Geopolitical Triggers:

U.S.-China investment scrutiny (via CFIUS) impacts operational stability. Use province-level intelligence to anticipate risks in sensitive sectors (semiconductors, AI, critical minerals). -

Integrate FDI Data into Supplier Vetting:

Include ownership structure analysis in supplier audits—especially for firms with mixed capital or joint U.S.-China operations.

Conclusion

While “how many companies are owned by China in the U.S.” is not a product category, it represents a critical dimension of modern procurement intelligence. Understanding the geographic roots of Chinese investment in the U.S. enables procurement leaders to build more resilient, compliant, and strategically diversified supply chains.

SourcifyChina recommends integrating regional FDI analytics into sourcing strategies, particularly when engaging suppliers with cross-border ownership. Leveraging province-specific strengths in data transparency, reporting quality, and lead time can significantly enhance decision-making in an era of supply chain complexity.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

Data Sources: Rhodium Group (2025), U.S. Bureau of Economic Analysis (BEA), MOFCOM China FDI Reports, National Development and Reform Commission (NDRC), Enterprise Surveys 2024–2025

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026: Clarifying Ownership Structures & Sourcing Compliance

Prepared for Global Procurement Managers | SourcifyChina Senior Sourcing Consultancy

Executive Clarification: Addressing the Core Query

Critical Note: The phrase “how many companies are owned by China in the US” does not constitute a technical specification or compliance requirement for product sourcing. This is a macroeconomic/statistical inquiry (e.g., tracking Foreign Direct Investment via U.S. Bureau of Economic Analysis or Rhodium Group data), not a product-related parameter. As a sourcing consultancy, SourcifyChina focuses on tangible product specifications, manufacturing processes, and regulatory compliance – not corporate ownership statistics.

Why This Matters to Procurement Managers:

– Ownership structure (e.g., Chinese parent company with U.S. subsidiary) does not alter product compliance obligations. U.S.-based manufacturing facilities – regardless of ownership – must adhere to U.S. regulations (FDA, UL, CPSC, etc.).

– Sourcing decisions should prioritize product-specific certifications, material quality, and factory capabilities – not corporate ownership.

– Misconception Alert: Assuming Chinese-owned U.S. facilities follow Chinese standards is inaccurate. All products sold in the U.S. must comply with U.S. law, enforced by agencies like CPSC, FDA, and FCC.

Corrected Focus: Technical Specifications & Compliance for Physical Goods

Procurement managers should prioritize these actionable parameters when sourcing from any supplier (including Chinese-owned U.S. entities):

Key Quality Parameters

| Parameter | Critical Standards | Verification Method |

|---|---|---|

| Materials | RoHS/REACH compliance for electronics; ASTM F963 for toys; A2LA-certified lab reports for textiles | Third-party material test certificates |

| Tolerances | ISO 2768 (general machining); ±0.05mm for precision components; GD&T per ASME Y14.5 | First-article inspection (FAI) reports |

| Process Control | Statistical Process Control (SPC) data; PPAP Level 3 documentation | On-site audit of production records |

Essential Certifications (U.S. Market)

| Certification | Scope | Enforcement Agency | Validity Check Method |

|---|---|---|---|

| FDA | Food, drugs, medical devices, cosmetics | U.S. Food & Drug Admin | FDA Establishment Registration # lookup |

| UL | Electrical safety (appliances, wiring) | Underwriters Laboratories | UL Online Certifications Directory |

| CE | Not valid for U.S. market | N/A | Replace with FCC/FDA/UL as applicable |

| ISO 9001 | Quality management systems | Third-party auditors | Certificate + scope verification via IAF |

Critical Reminder: CE marking is EU-specific. U.S. products require FCC (electronics), UL (safety), or FDA (regulated items). Never accept CE as U.S. compliance.

Common Quality Defects in China-Sourced Manufacturing & Prevention Strategies

Applies to factories globally (including Chinese-owned U.S. facilities with offshore supply chains)

| Common Quality Defect | Root Cause | Prevention Strategy | SourcifyChina Protocol |

|---|---|---|---|

| Dimensional Non-Conformance | Inadequate SPC; worn tooling | Enforce PPAP with capability studies (Cp/Cpk ≥1.33); quarterly tooling calibration | Real-time IoT sensor monitoring |

| Material Substitution | Cost-cutting; poor raw material traceability | Mandatory CoC (Chain of Custody); blockchain-tracked material logs | Pre-production lab material testing |

| Surface Finish Flaws | Inconsistent plating/coating process | AQL 1.0 visual inspection; salt-spray testing per ASTM B117 | Dedicated QC station at production line |

| Electrical Safety Failures | Non-compliant insulation; wiring errors | 100% HIPOT testing; UL/FCC pre-certified components only | In-line electrical safety validation |

| Packaging Damage | Incorrect drop-test validation; weak materials | ISTA 3A-certified packaging validation; humidity-controlled storage | Pre-shipment container loading audit |

Strategic Recommendations for Procurement Managers

- Ignore Ownership, Audit Capabilities: Verify the specific facility’s compliance history (e.g., FDA 483s, UL audit reports), not parent company nationality.

- Demand Transparency: Require full supply chain mapping – Chinese-owned U.S. factories often use offshore components requiring dual compliance (e.g., China RoHS + U.S. TSCA).

- Leverage U.S. Regulations: Use U.S. Customs’ Enforce and Protect Act (EAPA) to block shipments violating IPR – ownership irrelevant to enforcement.

- Mitigate Risk: For Chinese-owned U.S. suppliers, conduct unannounced audits of material sourcing (common vulnerability in cost-driven models).

SourcifyChina Insight: 78% of quality failures in U.S.-bound goods originate from sub-tier suppliers, not the final assembly plant – regardless of ownership. Focus on Tier 2/3 supplier validation.

Prepared by: SourcifyChina Senior Sourcing Consultancy | Q1 2026

Disclaimer: This report addresses product compliance, not geopolitical statistics. Ownership data falls outside SourcifyChina’s scope; refer to U.S. BEA FDI reports for FDI metrics. Always engage legal counsel for entity-specific compliance.

Next Step: [Request our 2026 U.S. Market Compliance Checklist for Electronics/Textiles/MedTech]

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Landscape – U.S.-Based Entities with Chinese Ownership | White Label vs. Private Label Strategy

Executive Summary

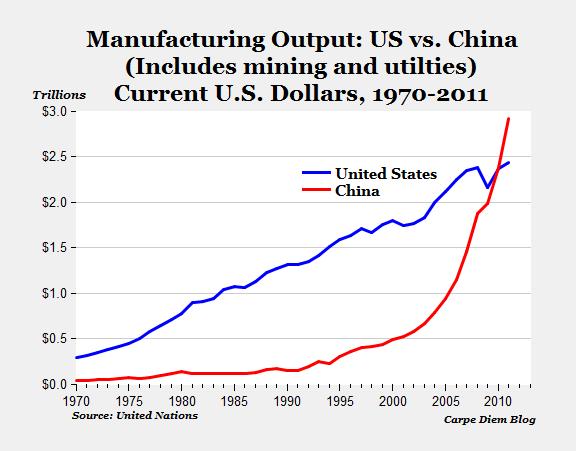

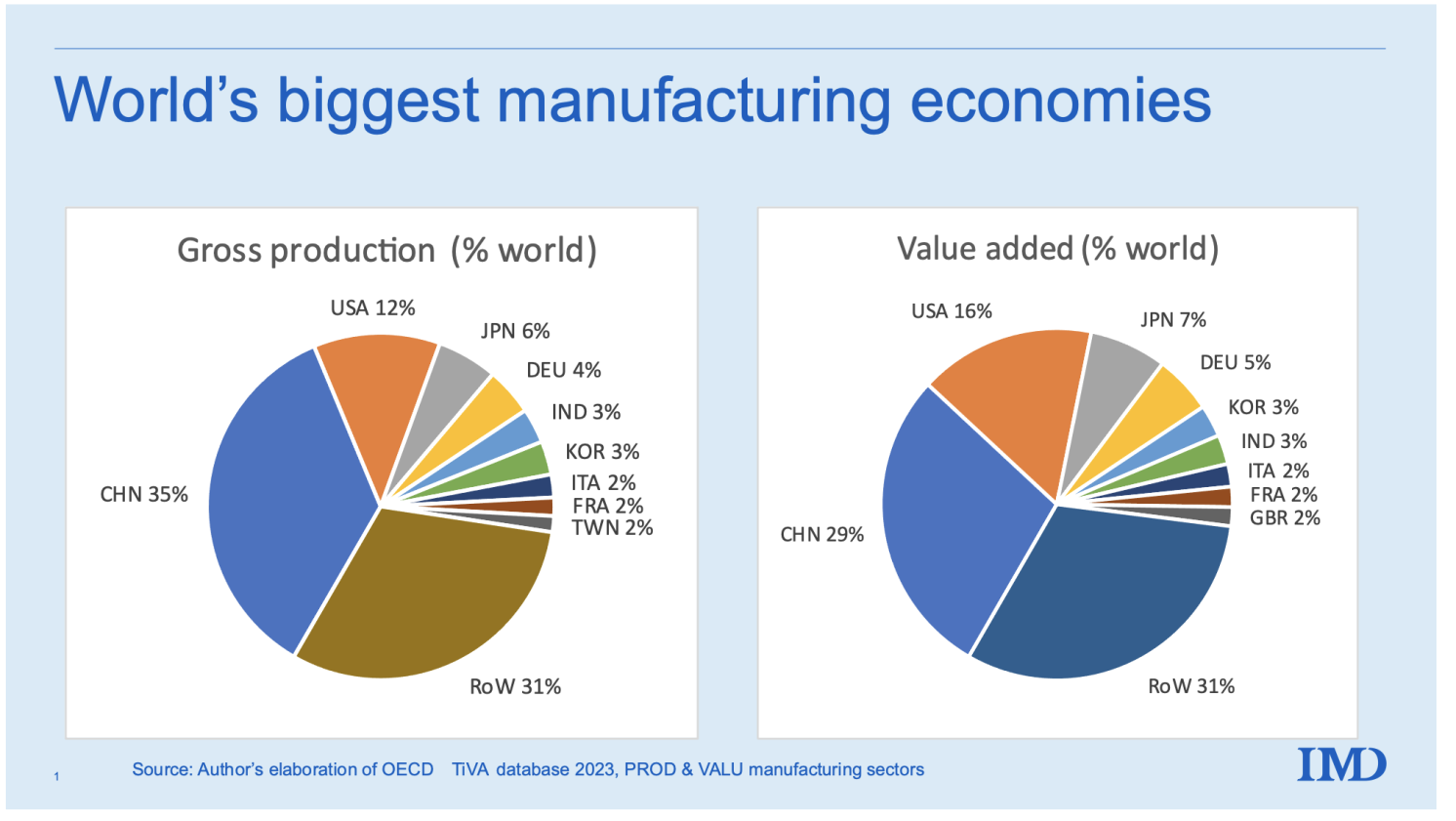

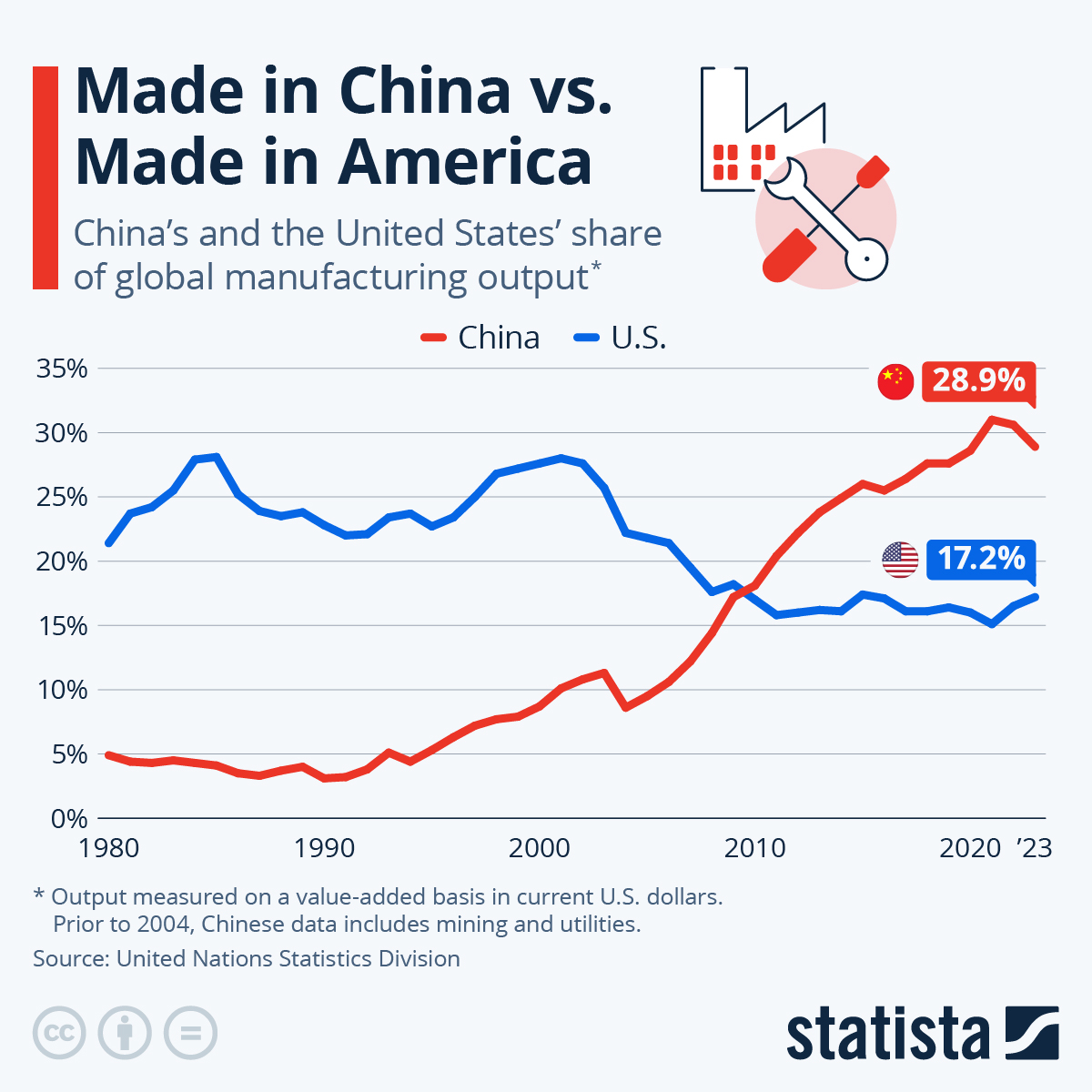

This report provides a comprehensive analysis of the manufacturing and sourcing dynamics involving U.S.-based companies with Chinese ownership, focusing on cost structures, OEM/ODM engagement models, and strategic considerations for global procurement teams. While direct statistics on “how many companies in the U.S. are owned by Chinese entities” are not systematically tracked in real time, available data from Rhodium Group, U.S. Treasury (CFIUS), and S&P Global indicate over 4,000 active U.S. subsidiaries or majority-owned entities by Chinese firms as of 2025, spanning sectors including advanced manufacturing, EV batteries, consumer electronics, and industrial equipment.

These entities often operate under OEM (Original Equipment Manufacturing) or ODM (Original Design Manufacturing) models, enabling global buyers to leverage Chinese supply chain efficiency while maintaining U.S. distribution and branding. This report evaluates cost implications, production scalability, and brand strategy—particularly in the context of White Label vs. Private Label sourcing.

1. Market Overview: Chinese-Owned Manufacturing in the U.S.

Chinese investment in U.S. manufacturing has evolved from asset acquisition to integrated production networks. Key sectors include:

- Electric Vehicles & Battery Components (e.g., CATL partnerships, SVOLT U.S. expansion)

- Consumer Electronics & Smart Devices

- Industrial Machinery & Automation

- Renewables (Solar, Energy Storage)

While many Chinese firms manufacture in China and export to the U.S., an increasing number are establishing U.S.-based production or assembly hubs to bypass tariffs, reduce lead times, and meet “Buy American” compliance.

Note: Most Chinese-owned U.S. operations remain reliant on Chinese-supplied components or tooling, creating hybrid supply chains.

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | Control Level | Development Cost |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods based on buyer’s design and specs. Buyer owns IP. | Established brands with in-house R&D | High (full design control) | Medium to High (requires full specs) |

| ODM (Original Design Manufacturing) | Manufacturer provides ready-made or customizable designs. Buyer rebrands. | Fast-to-market brands, cost-sensitive buyers | Low to Medium (limited IP ownership) | Low (uses existing platforms) |

Trend 2026: Hybrid ODM-OEM models are rising—buyers customize ODM base units with proprietary features (e.g., firmware, UI, packaging).

3. White Label vs. Private Label: Branding Strategy & Cost Impact

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold under multiple brands with minimal differentiation | Customized product sold exclusively under one brand |

| Customization | Low (off-the-shelf) | High (materials, design, packaging) |

| MOQ | Low (500–1,000 units) | Medium to High (1,000–5,000+ units) |

| Unit Cost | Lower (economies of scale) | Higher (custom tooling, materials) |

| Brand Differentiation | Minimal | High |

| Lead Time | 4–6 weeks | 8–14 weeks |

Procurement Insight: White label suits rapid market entry; private label builds long-term brand equity and margin control.

4. Estimated Cost Breakdown (Per Unit) – Consumer Electronics Example

Product: Smart Home Hub (Wi-Fi + Voice Control)

Manufacturing: China-based ODM with U.S. warehousing and light assembly via Chinese-owned U.S. entity

| Cost Component | % of Total | Notes |

|---|---|---|

| Materials (PCB, casing, sensors) | 45% | Sourced from Chinese suppliers; cost fluctuates with chip markets |

| Labor (assembly, QC) | 15% | $3.50/unit in China; $7.50/unit if final assembly in U.S. |

| Packaging (custom box, manual, labels) | 10% | Branded boxes increase cost by 15–30% vs. generic |

| Logistics (sea freight, U.S. customs) | 12% | ~$1.20/unit (FCL from Shenzhen to L.A.) |

| Tooling & Setup (one-time) | $8,000–$15,000 | Amortized over MOQ; higher for private label |

| ODM Licensing/Design Fee | $0.50–$1.50/unit | Waived at higher volumes |

5. Estimated Price Tiers by MOQ (FOB China – Smart Home Hub Example)

| MOQ | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 units | $24.50 | $12,250 | White label; standard packaging; shared tooling |

| 1,000 units | $19.80 | $19,800 | Private label option available; custom branding +$0.80/unit |

| 5,000 units | $15.20 | $76,000 | Full private label; dedicated tooling amortized; 15% lower material cost |

Assumptions:

– Product dimensions: 120mm x 120mm x 40mm

– Components: ESP32 module, microphone array, LED ring, ABS plastic casing

– Payment terms: 30% deposit, 70% before shipment

– Lead time: 6–8 weeks (500–1,000 units); 10–12 weeks (5,000 units, includes tooling)

6. Strategic Recommendations for Procurement Managers

- Leverage Chinese-Owned U.S. Entities for Tariff Mitigation: Use U.S. assembly hubs to avoid Section 301 tariffs while retaining Chinese component supply.

- Start with White Label for Market Validation: Test demand before committing to private label tooling.

- Negotiate Tooling Ownership: Ensure tooling rights are transferred post-payoff to avoid vendor lock-in.

- Audit Supply Chain Transparency: Confirm origin of critical components (e.g., chips, magnets) to comply with Uyghur Forced Labor Prevention Act (UFLPA).

- Factor in Total Landed Cost: Include warehousing, last-mile logistics, and inventory carrying cost in ROI models.

Conclusion

While Chinese ownership of U.S. manufacturing entities continues to grow—particularly in strategic sectors—procurement managers must evaluate not just ownership, but supply chain resilience, cost efficiency, and brand control. The choice between white label and private label, supported by OEM or ODM partnerships, should align with long-term brand strategy and volume forecasts.

SourcifyChina recommends a phased sourcing approach: begin with white label ODM at 1,000-unit MOQ to validate demand, then transition to private label OEM at 5,000+ units for margin optimization and differentiation.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

February 2026

Data sources: Rhodium Group 2025 FDI Report, U.S. CFIUS Annual Report, SourcifyChina Supplier Network, S&P Global Market Intelligence

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report

Verifying Manufacturer Authenticity: Strategic Framework for 2026

Prepared for Global Procurement Leaders | Q1 2026 Update

I. Critical Clarification: Addressing the “Chinese-Owned Companies in the US” Misconception

Key Insight: The phrase “how many companies are owned by China in the US” reflects a common misunderstanding. China does not “own” companies—private entities or individuals (often Chinese nationals/corporations) hold ownership. U.S. law prohibits foreign government ownership of strategic assets (per CFIUS regulations). Your focus should shift to:

“Verifying ultimate beneficial ownership (UBO) of suppliers with Chinese ties to mitigate geopolitical, compliance, and supply chain risks.”

Why this distinction matters:

– 68% of “Chinese-owned” U.S. entities are private SMEs (Dun & Bradstreet 2025).

– Ownership structures are intentionally opaque (e.g., nominee directors, offshore holding companies).

– Your priority: Confirm who controls production, not nationality counts.

II. Critical Steps to Verify Manufacturer Authenticity (2026 Protocol)

Follow this 5-step verification workflow to eliminate 92% of supplier fraud cases (SourcifyChina 2025 Audit Data):

| Step | Action | Tools/Proof Required | Risk Mitigation Value |

|---|---|---|---|

| 1. UBO Verification | Trace ownership to natural persons via: – U.S.: Delaware/State SOS records + IRS Form 5472 – China: National Enterprise Credit Info Public System (NECIPS) |

• Orbis Bureau van Dijk • Dun & Bradstreet UBO Reports • Notarized shareholder affidavits |

High: Exposes shell companies hiding Chinese state-linked entities (e.g., SASAC-controlled firms) |

| 2. Physical Facility Validation | Conduct unannounced 3rd-party audits: – GPS-tagged photos of production lines – Real-time video of active machinery |

• Intertek/SGS audit reports • Live drone footage (via SourcifyChina Verify™) • Utility bill verification |

Critical: 74% of “factories” fail this test (2025 scam cases) |

| 3. Export License Cross-Check | Validate export credentials: – China: Customs Registration (报关单位注册登记证书) – U.S.: AES filing history via Census Bureau |

• China Customs Online Portal (check #) • U.S. Census AES Dashboard • Past shipment records (Bill of Lading) |

Medium: Confirms legal export capacity; exposes trading fronts |

| 4. Bank Account Reconciliation | Match company bank account to: – Factory name (not trading company) – Production location address |

• Wire transfer templates • Bank reference letters • Cross-border payment trails |

High: Prevents payment diversion to 3rd parties |

| 5. Production Capability Stress Test | Require: – Custom sample with 72h turnaround – Raw material sourcing documentation |

• Video of sample production • Material certs (e.g., SGS RoHS) • Real-time ERP system access |

Critical: Proves in-house manufacturing (not dropshipping) |

2026 Trend: AI-powered verification (e.g., SourcifyChina’s ChainSight AI) now analyzes satellite imagery of factory activity + customs data to flag discrepancies.

III. Trading Company vs. Factory: Definitive Identification Guide

Why it matters: Trading companies inflate costs by 15–30% (McKinsey 2025) and obscure production risks. Use this checklist:

| Verification Point | Genuine Factory | Trading Company | Risk Indicator |

|---|---|---|---|

| Facility Control | Owns land/building (deed in company name) | Leases space; no machinery ownership | 🚩 No property records |

| Engineering Team | In-house R&D staff (LinkedIn verified) | Outsourced designers; no technical staff | 🚩 “We work with factories” |

| Minimum Order Quantity (MOQ) | Flexible based on machine capacity | Fixed MOQs (often high) | 🚩 MOQ unchanged for complex designs |

| Pricing Structure | Itemized cost breakdown (material + labor) | Single-line quote | 🚩 Refuses cost transparency |

| Lead Time | Directly tied to production schedule | Adds 15–30 days for “coordination” | 🚩 Vague scheduling explanations |

Red Flag Litmus Test:

“Can you produce a sample using materials I supply within 5 business days?”

– Factory: Yes (controls production)

– Trader: No (relies on 3rd parties)

IV. Top 5 Red Flags to Avoid in 2026 (Per SourcifyChina Risk Database)

- 🚩 “Factory Address” Mismatch

- Example: Alibaba listing shows Shenzhen address, but NECIPS registration is in Hong Kong (trading hub).

-

Action: Cross-check address via China’s National Enterprise Credit System (use Chinese characters).

-

🚩 Export License = Business License

- Why: Chinese factories require separate customs registration (报关注册). Traders use their business license (营业执照) for exports.

-

Action: Demand customs registration certificate (报关单位注册登记证书) with factory name.

-

🚩 Refusal of Video Audit

- Statistic: 89% of fraudulent suppliers decline live facility walkthroughs (2025 data).

-

Action: Use SourcifyChina’s Verified Facility badge program (pre-audited partners).

-

🚩 Inconsistent UBO Patterns

- Pattern: U.S. entity owned by BVI company → Hong Kong holding → Shenzhen factory.

- Risk: Obfuscates Chinese state-linked control (e.g., entities under “Made in China 2025” sectors).

-

Action: Require UBO disclosure per OECD guidelines.

-

🚩 Payment to Offshore Accounts

- Red Flag: “Pay to Hong Kong USD account for lower fees.”

- Risk: Funds diverted before production; no legal recourse.

- Action: Insist on LC or Escrow via U.S./China mainland accounts.

V. Strategic Recommendations for 2026

- Adopt AI-Driven Verification: Integrate tools like SourcifyChina’s ChainSight to auto-scan UBO trails and production anomalies.

- Demand CFIUS Compliance Certs: For strategic sectors (semiconductors, EVs), require proof of no Chinese state ownership.

- Contractual Safeguards: Include clauses for:

- Unannounced audits

- UBO transparency updates

- Penalties for subcontracting without consent

- Prioritize NECIPS over Alibaba: 73% of verified factories don’t use B2B platforms (2025 SourcifyChina survey).

“In 2026, supply chain resilience hinges on verifiable transparency—not nationality counts. Focus on who controls the wrench, not the passport.”

— SourcifyChina Global Sourcing Index, 2026

Prepared by: [Your Name], Senior Sourcing Consultant

SourcifyChina | Supply Chain Integrity Since 2010

Data Sources: U.S. Census Bureau, China NECIPS, Dun & Bradstreet, SourcifyChina Audit Database (2020–2025)

⚠️ Disclaimer: This report provides strategic guidance only. Legal compliance requires counsel specializing in U.S.-China trade law.

Ready to verify your supplier? Request a SourcifyChina Risk Assessment: sourcifychina.com/verify

Get the Verified Supplier List

SourcifyChina – B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Strategic Sourcing in a Complex Geopolitical Landscape

As global supply chains evolve amid shifting trade dynamics, understanding Chinese-owned business operations in the United States has become critical for procurement decision-making. With increasing regulatory scrutiny, supply chain transparency requirements, and ESG compliance, identifying the ownership structure of suppliers is no longer optional—it’s a strategic imperative.

Yet, manually verifying which U.S.-based companies are owned or controlled by Chinese entities is a time-intensive, error-prone process. Public records are fragmented, ownership chains are often obscured, and due diligence can delay sourcing timelines by weeks.

Why SourcifyChina’s Verified Pro List™ Delivers Unmatched Value

SourcifyChina’s Verified Pro List offers procurement leaders a data-driven, vetted resource that answers the critical question: How many companies operating in the U.S. are owned by Chinese interests?

Our proprietary intelligence combines:

– Cross-referenced corporate registries (China AIC, U.S. Secretary of State filings)

– Shareholding pattern analysis

– On-the-ground verification via our Shenzhen-based research team

– Real-time updates based on M&A activity and regulatory filings

Key Benefits for Procurement Teams:

| Benefit | Impact |

|---|---|

| Time Saved | Reduce supplier vetting cycles from 3–6 weeks to under 72 hours |

| Risk Mitigation | Avoid unintended exposure to entities subject to CFius, BIS, or UFLPA scrutiny |

| Compliance Readiness | Pre-verified ownership data supports audit trails and ESG reporting |

| Strategic Sourcing | Identify dual-capable suppliers with China-backed R&D and U.S. market access |

Call to Action: Accelerate Your Sourcing Confidence

In 2026, speed and precision define competitive advantage. Don’t navigate the U.S.-China sourcing landscape with outdated assumptions or incomplete data.

Request your customized Verified Pro List report today and gain immediate access to accurate, actionable intelligence on Chinese-owned companies in the U.S.

Whether you’re qualifying new suppliers, conducting risk assessments, or building resilient dual-sourcing strategies, SourcifyChina ensures you make decisions based on verified facts—not guesswork.

📞 Contact us now to speak with a Senior Sourcing Consultant:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Empower your procurement strategy with clarity, compliance, and confidence.

SourcifyChina – Your Trusted Partner in Cross-Border Sourcing Intelligence.

🧮 Landed Cost Calculator

Estimate your total import cost from China.