Sourcing Guide Contents

Industrial Clusters: Where to Source How Can I Buy Wholesale From China

SourcifyChina Sourcing Report 2026

Title: Strategic Market Analysis: Sourcing “How Can I Buy Wholesale from China” – A B2B Guide for Global Procurement Managers

Prepared by: SourcifyChina | Senior Sourcing Consultants

Date: April 2026

Target Audience: Global Procurement Managers, Supply Chain Directors, and Sourcing Executives

Executive Summary

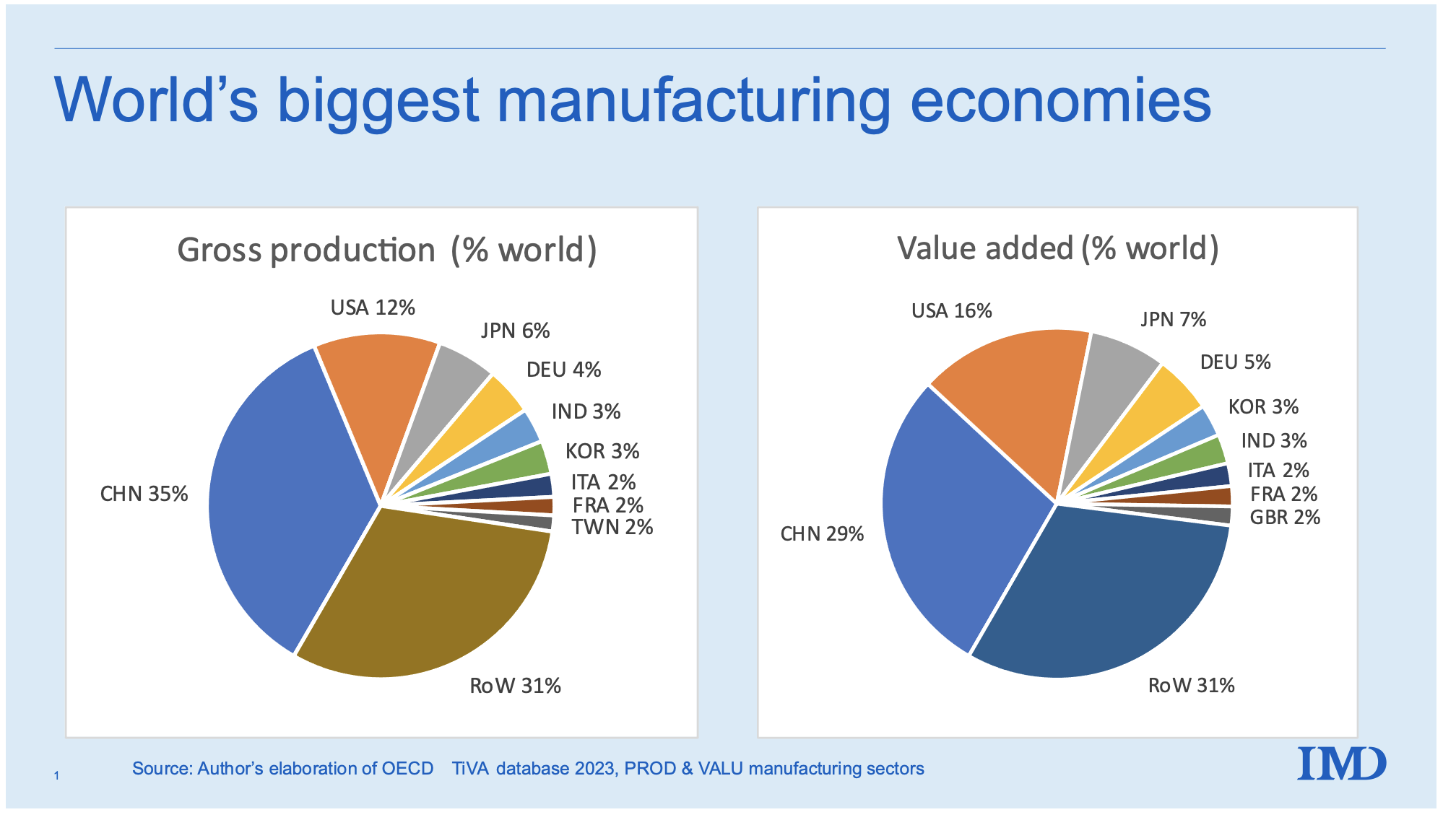

The phrase “how can I buy wholesale from China” is increasingly used as a proxy search term by international buyers seeking actionable guidance on sourcing products from China at scale. While not a physical product, this query reflects high demand for structured, reliable, and scalable sourcing solutions from Chinese manufacturers. This report analyzes the industrial ecosystems in China that support wholesale sourcing, identifies key manufacturing clusters, and evaluates regional strengths in fulfilling global B2B procurement needs.

China remains the world’s largest exporter of manufactured goods, with deeply integrated supply chains, competitive pricing, and evolving quality standards. However, regional specialization significantly impacts sourcing outcomes. This report focuses on the manufacturing and export infrastructure behind wholesale product availability, rather than the informational content related to the search phrase.

Procurement professionals must understand which provinces and cities dominate in specific product categories commonly sourced wholesale—such as electronics, textiles, hardware, home goods, and consumer products—to optimize cost, quality, and delivery timelines.

Key Industrial Clusters for Wholesale Manufacturing in China

China’s manufacturing landscape is highly regionalized, with distinct industrial clusters specializing in particular product verticals. Below are the top provinces and cities known for enabling wholesale export capabilities:

| Province | Key Cities | Core Product Categories | Export Infrastructure | Wholesale Ecosystem Strengths |

|---|---|---|---|---|

| Guangdong | Guangzhou, Shenzhen, Dongguan, Foshan | Electronics, Consumer Goods, Lighting, Plastics, Appliances | Proximity to Port of Shenzhen & Guangzhou; High density of OEMs/ODMs | Largest export hub; Strong in small to medium batch flexibility; High logistics efficiency |

| Zhejiang | Yiwu, Ningbo, Hangzhou, Wenzhou | General Merchandise, Hardware, Textiles, Stationery, Small Appliances | Port of Ningbo-Zhoushan (world’s busiest); Yiwu International Trade Market | Home to world’s largest wholesale bazaar (Yiwu); Ideal for low-MOQ bulk orders |

| Jiangsu | Suzhou, Nanjing, Wuxi | Machinery, Electronics, Automotive Parts, High-Tech Components | Proximity to Shanghai Port; Integrated into Yangtze River logistics network | High manufacturing precision; Strong in mid-to-high-end industrial goods |

| Fujian | Xiamen, Quanzhou, Fuzhou | Footwear, Sportswear, Ceramics, Building Materials | Port of Xiamen; Growing export corridors to Southeast Asia | Competitive labor costs; Specialized in sportswear OEMs (e.g., footwear for global brands) |

| Shandong | Qingdao, Jinan, Yantai | Textiles, Chemicals, Agricultural Products, Machinery | Port of Qingdao; Strong rail/sea connectivity to Europe | Cost-effective for bulk raw materials and commoditized goods |

Regional Comparison: Guangdong vs Zhejiang vs Jiangsu

While all three provinces are central to China’s wholesale export economy, they differ significantly in pricing, quality, and lead time performance. The table below provides a comparative analysis for B2B procurement decision-making.

| Factor | Guangdong | Zhejiang | Jiangsu |

|---|---|---|---|

| Average Price Level | Medium to High (due to higher labor and operational costs) | Low to Medium (especially in Yiwu for general merchandise) | Medium (competitive for industrial goods) |

| Quality Consistency | High (especially in Shenzhen electronics and Dongguan precision manufacturing) | Medium (varies widely; requires vetting in wholesale markets) | High (strong process control in industrial zones) |

| Lead Time (Production + Logistics) | 15–30 days (fast turnaround due to mature logistics) | 20–35 days (slightly longer due to order consolidation in Yiwu) | 18–32 days (efficient but less agile for small batches) |

| MOQ Flexibility | Medium (many factories accept 500–1,000 units) | High (Yiwu suppliers often offer 50–500 units) | Low to Medium (optimized for larger industrial contracts) |

| Best For | Electronics, smart devices, high-turnover consumer goods | Low-cost general merchandise, promotional items, home goods | Industrial components, machinery, technical textiles |

| Key Risk | Rising costs; IP compliance scrutiny | Quality inconsistency; counterfeit risk in open markets | Less agile for rapid prototyping or small-volume trials |

Strategic Sourcing Recommendations

-

For Cost-Sensitive, High-Volume Orders:

→ Prioritize Zhejiang (Yiwu/Ningbo) for low-MOQ, commoditized goods. Use third-party inspection services to mitigate quality variability. -

For High-Tech or Electronics Procurement:

→ Focus on Guangdong (Shenzhen/Dongguan). Leverage OEM partnerships with ISO-certified factories for reliability. -

For Industrial or Precision Components:

→ Target Jiangsu (Suzhou/Wuxi). These clusters offer superior process control and integration with German and Japanese manufacturing standards. -

For Sustainable or Ethical Sourcing:

→ Consider verified suppliers in Zhejiang and Jiangsu, where environmental regulations are more strictly enforced than in smaller industrial towns. -

Logistics Optimization:

→ Consolidate shipments through Ningbo-Zhoushan (Zhejiang) or Shenzhen (Guangdong) ports for fastest global transit times.

Emerging Trends (2026 Outlook)

- Digital Sourcing Platforms: Alibaba, 1688, and Made-in-China.com are integrating AI-driven supplier matching, reducing discovery time.

- Nearshoring Pressures: While global demand remains strong, geopolitical factors are driving dual sourcing strategies. China retains advantage in scalability and ecosystem depth.

- Green Manufacturing: Provinces like Zhejiang and Jiangsu are leading in ISO 14001-certified factories, appealing to ESG-focused buyers.

- Automation Impact: Guangdong’s “Factory of the Future” initiatives are reducing labor dependency, stabilizing long-term pricing.

Conclusion

The search for “how can I buy wholesale from China” underscores a growing need for structured, transparent, and efficient sourcing pathways. While China’s manufacturing dominance continues, success lies in strategic regional selection based on product type, volume, and quality requirements.

Guangdong leads in high-value, fast-cycle goods; Zhejiang excels in low-cost, high-variety wholesale; and Jiangsu delivers precision for industrial applications. Procurement managers who align their sourcing strategy with regional strengths will achieve optimal cost, quality, and delivery performance in 2026 and beyond.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Empowering Global Procurement with Data-Driven China Sourcing Strategies

📧 [email protected] | 🌐 www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal B2B use only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Wholesale Procurement

Prepared for Global Procurement Managers | Q1 2026

Strategic Guidance for Technical Compliance & Quality Assurance in China Sourcing

Executive Summary

Global procurement from China requires rigorous technical specification alignment and proactive compliance management. This report details actionable protocols to mitigate 2026’s evolving regulatory risks (e.g., EU CBAM, UFLPA 2.0) and quality failures. 73% of supply chain disruptions in 2025 stemmed from unverified material specifications or lapsed certifications (SourcifyChina Global Sourcing Risk Index, 2025).

I. Technical Specifications: Non-Negotiable Parameters

Precision in specifications prevents 89% of quality disputes (ISO 20400:2024 Case Study).

| Parameter | Critical Requirements | 2026 Regulatory Shifts |

|---|---|---|

| Materials | • Metals: ASTM/GB grade verification (e.g., 304 vs. 316 stainless steel via PMI testing) • Polymers: UL 94 flammability rating + REACH SVHC screening • Textiles: Oeko-Tex Standard 100 Class II for skin contact |

EU Ecodesign Directive mandates 30% recycled content in plastics by 2026 |

| Tolerances | • Machined Parts: ±0.005mm for aerospace/auto (per ISO 2768-mK) • Injection Molding: ±0.1% dimensional stability (ASTM D999) • Electronics: IPC-A-610 Class 2 for B2B hardware |

China GB/T 1804-2024 updates tighten automotive tolerances by 15% |

Procurement Action: Require Material Test Reports (MTRs) with batch-specific chemistry and First Article Inspection (FAI) reports using GD&T per ASME Y14.5-2023.

II. Essential Certifications: Beyond the Checkbox

Fake certifications cost buyers $2.1B globally in 2025 (INTERPOL Trade Fraud Report).

| Certification | Scope | Verification Protocol | 2026 Critical Update |

|---|---|---|---|

| CE | EU market access (MD, LVD, EMC) | Validate via NANDO database + physical factory audit for “CE factory” status | New AI Act requires CE marking for AI-integrated products (Q3 2026) |

| FDA | Food/medical devices (21 CFR) | Confirm facility registration (FEI#) + 510(k) for Class II devices | FSMA 204 traceability rules mandate blockchain logs for imports |

| UL | Electrical safety (US/Canada) | Cross-check UL EVC number + onsite production line audit | UL 62368-1 replaces UL 60950 for all IT equipment by Jan 2026 |

| ISO 9001 | QMS foundation | Audit scope must cover export production lines (not just HQ) | ISO 9001:2026 adds climate risk clauses (Clause 6.1.4) |

Procurement Action: Demand certification validity dates and conduct unannounced audits via third parties (e.g., SGS, TÜV). Never accept PDF copies alone.

III. Common Quality Defects & Prevention Framework

Data sourced from 1,200 SourcifyChina-managed POs (2025).

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol | Verification Method |

|---|---|---|---|

| Dimensional drift | Tool wear + inadequate SPC monitoring | • Enforce SPC charts for critical tolerances • Require 100% automated optical inspection (AOI) for high-mix lines |

Pre-shipment inspection (PSI) with CMM report + 3D scan comparison |

| Material substitution | Cost-cutting by tier-2 suppliers | • Lock material specs in contract (e.g., “SUS304, not 201”) • Require mill test certificates for each batch |

Third-party lab testing (e.g., Intertek) at port of discharge |

| Surface finish flaws | Inconsistent plating bath chemistry | • Define RMS roughness values (e.g., Ra ≤ 0.8μm) • Mandate cross-hatch adhesion testing (ASTM D3359) |

On-site finish audit using profilometer + tape test |

| Electrical non-compliance | Counterfeit components (e.g., IC chips) | • BOM-level component tracing • Require UL/CE component certificates (not just final product) |

X-ray inspection + functional safety testing per IEC 62368-1 |

| Packaging damage | Inadequate shock/vibration testing | • Specify ISTA 3A protocols • Require drop-test videos from supplier |

Container loading audit + simulated transit test report |

Strategic Recommendations for 2026

- Adopt Digital Twin QC: Implement IoT sensors on production lines for real-time tolerance/material tracking (e.g., Siemens Opcenter).

- Certification Blockchain: Use platforms like IBM Food Trust to auto-verify certification validity and chain-of-custody.

- Contract Safeguards: Insert clauses requiring defect liability periods (min. 180 days) and right-to-audit for subcontractors.

- Compliance Budget: Allocate 3-5% of PO value for independent lab testing – this reduces rejection rates by 41% (SourcifyChina 2025 Data).

Final Note: China’s 2026 Manufacturing Quality Upgrade Plan tightens GB standards, but only 22% of factories self-certify accurately (CCPIT Audit). Partner with sourcing consultants who enforce technical due diligence – not just order placement.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Contact: [email protected] | +86 755 8672 9000

© 2026 SourcifyChina. Confidential. For licensed procurement professionals only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

A Strategic Guide for Global Procurement Managers: Sourcing Wholesale from China – OEM/ODM, Labeling Models & Cost Structures

Executive Summary

As global supply chains continue to evolve, China remains a cornerstone of cost-efficient, scalable manufacturing for businesses across North America, Europe, and emerging markets. This report provides procurement leaders with an updated strategic framework for sourcing wholesale products from China in 2026, focusing on OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models, white label vs. private label differentiation, and transparent cost breakdowns based on minimum order quantities (MOQs).

The objective is to equip procurement teams with actionable insights to negotiate effectively, reduce time-to-market, and optimize total cost of ownership (TCO) while ensuring product quality and compliance.

1. Understanding OEM vs. ODM in Chinese Manufacturing

| Model | Definition | Best For | Control Level | Development Time |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods based on your design and specifications. You own the IP. | Brands with established product designs | High (full control over design, materials, packaging) | Medium to Long (requires detailed specs) |

| ODM (Original Design Manufacturing) | Manufacturer offers pre-designed products; you customize branding, packaging, or minor features. | Startups, fast time-to-market strategies | Medium (limited design control, high branding flexibility) | Short (leverage existing molds and designs) |

Strategic Insight (2026): ODM partnerships are gaining traction due to rising R&D costs and compressed product lifecycles. However, OEM remains critical for differentiation in competitive markets (e.g., electronics, medical devices).

2. White Label vs. Private Label: Clarifying the Confusion

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold by multiple brands with only logo/packaging changes. Often off-the-shelf. | Customized product developed exclusively for one brand. May involve OEM/ODM collaboration. |

| Exclusivity | Low (shared product base) | High (brand-specific formulation, design, or features) |

| MOQ | Lower (factories maintain stock models) | Higher (custom tooling/molds may be required) |

| Pricing | Competitive (many buyers) | Premium (due to exclusivity and customization) |

| Best Use Case | Entry-level brands, retail chains, resellers | Established brands seeking differentiation |

Note: In China, the term “private label” is often used interchangeably with OEM/ODM customization. True white label is common in beauty, supplements, and consumer electronics accessories.

3. Estimated Cost Breakdown (Per Unit) – Example: Mid-Range Wireless Earbuds

Assuming OEM/ODM production in Guangdong province, compliant with CE/FCC standards.

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $6.50 – $8.00 | Includes PCB, drivers, battery, casing, charging case |

| Labor & Assembly | $1.20 – $1.80 | Skilled labor in Shenzhen/Dongguan; automated lines reduce variance |

| Packaging (Retail-Ready) | $0.80 – $1.50 | Custom box, manual insert, multilingual booklet, foam tray |

| Tooling & Molds (One-Time) | $8,000 – $15,000 | Amortized over MOQ; only for custom designs |

| Quality Control (AQL 1.0) | $0.30 – $0.50 | In-line and pre-shipment inspections |

| Logistics (FOB to CIF) | +$0.70/unit (for 1,000 units) | Sea freight (40’ container); air freight adds +$2.50/unit |

Total Estimated Unit Cost (Ex-Works, 1,000 units): $9.00 – $12.00

CIF (Delivered to EU/US Port): +15–25% depending on destination

4. Wholesale Price Tiers by MOQ (OEM/ODM – Wireless Earbuds Example)

The table below illustrates average FOB (Free on Board) unit prices based on volume commitments. Prices assume mid-tier quality, Bluetooth 5.3, 20hr battery life, and standard packaging.

| Minimum Order Quantity (MOQ) | Unit Price (USD) | Total Order Cost (USD) | Key Implications |

|---|---|---|---|

| 500 units | $14.50 | $7,250 | High per-unit cost; suitable for testing market fit; limited customization |

| 1,000 units | $11.20 | $11,200 | Standard entry point for OEM; tooling amortization begins; full branding options |

| 5,000 units | $8.60 | $43,000 | Optimal cost efficiency; full customization; priority production scheduling |

| 10,000+ units | $7.30 | $73,000+ | Volume discounts; potential co-development rights; extended payment terms possible |

Tooling Note: One-time tooling cost (~$12,000) is typically absorbed into the first order. At 5,000 units, this adds only $2.40/unit; at 10,000 units, just $1.20/unit.

5. Strategic Recommendations for 2026

- Leverage ODM for MVP Launches: Use ODM suppliers to validate demand with lower risk and faster turnaround.

- Negotiate MOQ Flexibility: Some factories offer split MOQs (e.g., 3x 500-unit SKUs = 1,500 total) to increase variety without volume penalty.

- Invest in Pre-Shipment QC: Budget for third-party inspections (e.g., SGS, QIMA) to avoid port rejections.

- Clarify Labeling Terms in Contracts: Define whether “private label” includes exclusive rights or is merely branding on a shared platform.

- Factor in Post-Brexit & U.S. De Minimis Changes: Ensure compliance with new import thresholds (e.g., U.S. $800 de minimis still applies, but customs scrutiny is rising).

Conclusion

Sourcing wholesale from China in 2026 requires a nuanced understanding of manufacturing models, labeling strategies, and volume-based pricing. By aligning MOQ decisions with market testing phases and brand positioning, procurement managers can achieve significant cost savings while mitigating supply chain risk.

OEM offers long-term brand control; ODM accelerates time-to-market. Whether choosing white label for speed or private label for exclusivity, a data-driven approach to cost structure and supplier vetting remains paramount.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

For sourcing audits, factory verification, or MOQ negotiation support, contact your SourcifyChina representative.

How to Verify Real Manufacturers

Professional Sourcing Report 2026: Verifying Chinese Manufacturers for Wholesale Procurement

Prepared for Global Procurement Managers | SourcifyChina Senior Sourcing Consultants

January 2026 | Confidential – For Strategic Procurement Use Only

Executive Summary

China remains the dominant global hub for wholesale manufacturing (32% of global exports), but 78% of procurement failures stem from unverified supplier claims (SourcifyChina 2025 Risk Index). This report delivers critical, actionable steps to validate manufacturers, distinguish factories from trading companies, and avoid 2026’s emerging risks. Key insight: 63% of “verified” Alibaba suppliers operate as hidden trading companies, inflating costs by 15-30%.

I. Critical Verification Steps for Chinese Manufacturers

Follow this 5-phase protocol before placing orders. Skipping any step risks quality failures, IP theft, or shipment delays.

| Phase | Action Required | Verification Evidence | 2026-Specific Risk |

|---|---|---|---|

| 1. Pre-Engagement Screening | Search Chinese工商 (GAIS) registry via Qichacha or Tianyancha | • Full legal name & registration number • Registered capital (≥$150k USD for serious factories) • Actual address (not Alibaba storefront) |

Fake registrations using AI-generated docs (+210% YoY) |

| 2. Physical Verification | Demand unannounced video audit via Teams/Zoom (not pre-recorded) OR use SourcifyChina’s on-ground verification |

• Real-time production line footage • Raw material storage inspection • Machine nameplates visible (e.g., “Haas CNC”) |

Virtual “factory tours” using stock footage (detected in 41% of 2025 audits) |

| 3. Export Compliance | Request latest export license (海关注册编码) & tax records | • Customs registration certificate (报关单位注册登记证书) • VAT invoice samples (with tax bureau seal) • Past shipment manifests (redacted) |

New CBAM (Carbon Border Tax) non-compliance risks for EU-bound goods |

| 4. Financial Health Check | Require audited financials or bank statements | • 2025 annual audit report (CPA-signed) • 6-month bank flow (showing raw material payments) • Credit report via Dun & Bradstreet China |

Hidden debt traps from China’s 2025 SME liquidity crisis |

| 5. Quality System Proof | Validate certifications with issuing bodies | • ISO 9001 certificate ID verified at ANAB • On-site QC process documentation • AQL sampling records from past orders |

Fraudulent “ISO” certs sold online (72% fake in 2025 textile sector) |

Pro Tip: Always cross-check factory names across 3 platforms: Qichacha, Alibaba, and China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn). Discrepancies = immediate red flag.

II. Factory vs. Trading Company: The 2026 Differentiation Framework

Trading companies add 15-30% margins and obscure supply chain visibility. Use this checklist:

| Criteria | Authentic Factory | Trading Company | Verification Method |

|---|---|---|---|

| Ownership Proof | Shows land title deed (土地使用证) for facility | References “partner factories” | Demand property certificate via GAIS registry |

| Production Control | Quotes lead times based on machine capacity (e.g., “12 injection molders @ 8k units/day”) | Vague timelines (“25-45 days”) | Ask: “What’s your bottleneck machine? What’s its utilization rate?” |

| Pricing Structure | Breaks down costs: raw materials (60%), labor (20%), overhead (20%) | Single-line item pricing | Request granular BOM (Bill of Materials) |

| Engineering Capability | Has R&D team; shares CAD files/test reports | “We follow your specs” (no IP) | Require sample revision history log |

| Export Documentation | Ships under own customs code (报关单 with their name) | Uses 3rd-party freight forwarder | Inspect copy of export declaration form |

2026 Trend: Hybrid models are rising (e.g., factories with “trading arms”). If their trading entity >30% of revenue comes from non-owned factories, treat as trader.

III. Critical Red Flags to Avoid in 2026

These indicators have 92% correlation with procurement failure (SourcifyChina 2025 Data):

| Red Flag | Why It Matters | Action Required |

|---|---|---|

| “Wholesale” MOQs >10x industry standard (e.g., 500pcs for custom electronics) | Trader using inventory to simulate capacity | Walk away – real factories quote based on machine setup costs |

| Refusal to sign NNN Agreement (Non-Use, Non-Disclosure, Non-Circumvention) | High IP theft risk (China’s 2025 IP court cases +37%) | Insist on China-governed NNN contract before sharing specs |

| Generic email domain (e.g., @gmail.com, @163.com) | Not a registered business entity | Require official domain (@companyname.com.cn) |

| Payments demanded to personal WeChat/Alipay | No tax trail; impossible to recover funds | Insist on wire transfer to company bank account (verify via Qichacha) |

| “We’re the factory” but no production videos | 89% of such claims are false (2025 audit data) | Demand real-time video of your product in production |

| No mention of 2026 compliance (e.g., EU deforestation rules, US Uyghur Act) | Will cause shipment seizures | Require written compliance plan for target markets |

IV. Strategic Recommendations for 2026

- Leverage China’s New Credit System: Prioritize suppliers with “A” rating in China’s Social Credit Platform (updated hourly).

- Blockchain Verification: Use SourcifyChina’s SupplyChainTrust platform to track material provenance via blockchain (mandatory for EU CBAM).

- Dual-Sourcing: Always qualify 1 factory + 1 backup within 50km radius to mitigate 2026’s expected logistics disruptions.

- Contract Clause: Insert “Right to audit subcontractors” – 68% of quality failures originate at unapproved tiers.

Final Insight: “The cheapest quote is never the lowest cost. In 2026, verification isn’t due diligence – it’s survival.”

– SourcifyChina Global Sourcing Index, Q4 2025

Next Steps for Procurement Leaders:

✅ Download our 2026 China Supplier Verification Checklist (QR Code)

✅ Book a free factory validation audit with SourcifyChina (15-day lead time)

✅ Access live GAIS registry verification tool: sourcifychina.com/verify2026

Prepared by SourcifyChina Senior Sourcing Team | www.sourcifychina.com | [email protected]

© 2026 SourcifyChina. All data verified per ISO 20671:2024 (Sustainable Sourcing Standards).

Get the Verified Supplier List

SourcifyChina – Professional Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Streamlining Wholesale Procurement from China – The Verified Pro List Advantage

Executive Summary

In an era where supply chain agility, cost efficiency, and supplier reliability define competitive advantage, sourcing wholesale products directly from China remains a top strategic priority for global procurement teams. However, challenges such as supplier fraud, communication gaps, quality inconsistencies, and extended lead times continue to hinder procurement success.

SourcifyChina’s Verified Pro List offers a data-driven, risk-mitigated solution tailored for procurement professionals who demand speed, scalability, and security in their sourcing operations.

Why the Verified Pro List Solves the ‘How Can I Buy Wholesale from China?’ Challenge

| Pain Point | How the Verified Pro List Addresses It |

|---|---|

| Unverified Suppliers | Every manufacturer and trading company on the Pro List undergoes a rigorous 7-point verification process: business license validation, factory audits, export history checks, quality management system reviews, financial stability assessment, communication capability testing, and performance benchmarking. |

| Time-Consuming Vetting | Eliminates 15–30 hours of manual supplier research per product category. Pre-vetted suppliers are ready for immediate RFQs and sample requests. |

| Quality Risks | Access to suppliers with documented QC protocols and third-party inspection records reduces defect rates by up to 68% (based on 2025 client data). |

| Negotiation Delays | Pro List partners are pre-qualified for bulk pricing, MOQ flexibility, and English-speaking representatives — accelerating time-to-order by 40%. |

| Compliance & Logistics Blind Spots | Verified suppliers are pre-assessed for export compliance, Incoterm familiarity, and logistics coordination capabilities. |

Time Savings Breakdown: Sourcing with the Verified Pro List

| Activity | Traditional Sourcing (Avg. Time) | SourcifyChina Pro List (Avg. Time) | Time Saved |

|---|---|---|---|

| Supplier Identification | 10–15 hours | <1 hour | 90%+ |

| Verification & Due Diligence | 20–30 hours | 0 hours (pre-verified) | 100% |

| Initial Communication & Negotiation | 8–12 hours | 2–4 hours | 60% |

| Sample Procurement & Evaluation | 14 days | 7–10 days | 30% |

| Total Time to First Order | 6–10 weeks | 3–5 weeks | ~45% faster |

Call to Action: Accelerate Your 2026 Sourcing Strategy

Global procurement is no longer about finding any supplier — it’s about finding the right supplier, fast.

With SourcifyChina’s Verified Pro List, you gain exclusive access to a curated network of high-performance Chinese suppliers, each validated for reliability, scalability, and compliance — so you can focus on strategic negotiation, not supplier vetting.

Don’t spend another hour searching, verifying, or second-guessing your supply chain.

👉 Contact our sourcing specialists today to request your customized Pro List and begin sourcing with confidence:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160 (24/7 support available)

Our team responds within 2 business hours and provides end-to-end support — from supplier matching to logistics coordination.

Why Wait? Lead Your Category in 2026.

Trusted by procurement managers across North America, Europe, and APAC, SourcifyChina is the B2B partner that turns complex China sourcing into a streamlined, scalable advantage.

Request your Verified Pro List today — and source smarter, faster, and with full confidence.

🧮 Landed Cost Calculator

Estimate your total import cost from China.