The global hot melt adhesive market is experiencing robust growth, driven by increasing demand across packaging, automotive, construction, and consumer goods industries. According to Grand View Research, the market was valued at USD 9.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by the shift toward solvent-free, environmentally friendly adhesives and the rising need for high-performance bonding solutions suited to automated manufacturing processes. A critical factor in adhesive performance is melting temperature—determining application speed, bond strength, and material compatibility. As industries optimize for efficiency and sustainability, selecting a hot melt glue manufacturer with precise thermal control and specialized formulations becomes essential. In this context, the following eight manufacturers have emerged as leaders, offering innovative products with well-documented melting temperature profiles that meet the evolving demands of modern production environments.

Top 8 Hot Melt Glue Melting Temperature Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 xmelt

Domain Est. 2006

Website: baumerhhs.com

Key Highlights: Baumer hhs offers everything for the application and processing of hot melt adhesives. The systems and components are used in many industrial applications….

#2 Hot Melt Glue Sticks Manufacturer in Taiwan

Domain Est. 2012

Website: hot-melt-glue.com

Key Highlights: Tex Year is the globally leading hot melt glue stick company in terms of sales. Our self- produced hot melt glue sticks are characterized with the best quality….

#3 Quality Hot Melt Film & TPU Hot Melt Adhesive Film factory from China

Domain Est. 2021

Website: hotmelt-films.com

Key Highlights: High Speed Hot Melt Adhesive Web With Melting Point Of 135-150°C. Application:Apparel, Shoe Materials, Daily Necessities, Home Textiles,etc….

#4 Hot Melt Adhesives

Domain Est. 1988

Website: 3m.com

Key Highlights: Text, Rapid warm up time allows for applicator to be ready for use in 6 minutes. A timer rapidly counts up to 6 minutes as the applicator warms to temperature….

#5 Hot Melt & Reactive Hot Melt Adhesives

Domain Est. 1994

Website: hbfuller.com

Key Highlights: Our reactive hot melt adhesives are high-performance, hot melt materials that crosslink within the polymer matrix and yield a temperature resistant bond line….

#6 Hot Melt Glue Sticks & Adhesives at Hotmelt.com

Domain Est. 1999

#7 Hot Melt Adhesives

Domain Est. 2000

Website: henkel-adhesives.com

Key Highlights: Hot melt adhesives are ideal for situations where simplified processing, streamlined manufacturing, and end-product protection are required….

#8 UV curable hot melts pressure sensitive adhesives

Domain Est. 2022

Website: artiencegroup.com

Key Highlights: It is a UV-curable hot melts pressure sensitive adhesives that has a heat resistance of 100°C or more that can be used for joining and laminating steel ……

Expert Sourcing Insights for Hot Melt Glue Melting Temperature

H2: Projected 2026 Market Trends for Hot Melt Glue Melting Temperature

As the hot melt adhesive (HMA) industry evolves in response to technological advancements, sustainability demands, and shifting industrial applications, the melting temperature of hot melt glues is emerging as a critical performance parameter. By 2026, several key market trends are expected to shape the development and demand for hot melt adhesives with specific melting temperature profiles.

- Shift Toward Lower Melting Temperature Formulations

A prominent trend by 2026 is the increasing demand for low-melting-temperature hot melt adhesives (typically 80–120°C), driven by energy efficiency and substrate sensitivity. Industries such as packaging, hygiene products (e.g., diapers and feminine care), and electronics are prioritizing lower application temperatures to reduce energy consumption, minimize thermal degradation of substrates (e.g., thin plastics and recycled materials), and enhance worker safety. This shift supports sustainability goals and aligns with global energy reduction initiatives.

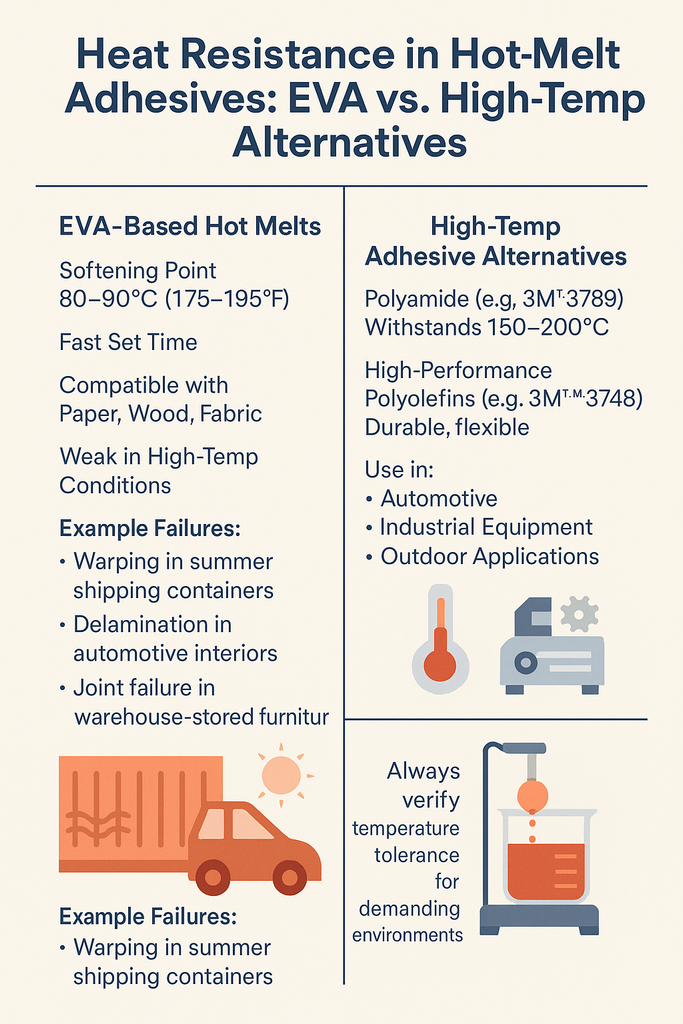

- Growth in High-Performance High-Temperature HMAs

Conversely, there is rising demand for high-temperature hot melt adhesives (150–200°C) in automotive, construction, and industrial assembly applications. These sectors require adhesives with superior heat resistance and bond strength under extreme conditions. With the expansion of electric vehicles (EVs) and lightweight composite materials, high-melting-point polyamide and polyolefin-based HMAs are expected to see increased adoption due to their thermal stability and durability.

- Development of Broad-Range and Tunable Melting Profiles

Innovation in polymer chemistry is enabling the creation of hot melt adhesives with tunable or broad softening/melting ranges. By 2026, formulators are increasingly offering “smart” HMAs that can adjust viscosity and bonding characteristics across temperature gradients. This adaptability meets the needs of automated manufacturing lines where precise control over open time and set speed is essential, particularly in high-speed packaging and product assembly.

- Sustainability and Bio-Based Adhesives Influencing Melting Characteristics

The push for environmentally friendly materials is leading to the development of bio-based hot melt adhesives derived from renewable resources (e.g., vegetable oils, starches, and bio-polyesters). While these materials often exhibit different crystallization and melting behaviors compared to petroleum-based counterparts, advancements in polymer modification are narrowing performance gaps. By 2026, expect to see more bio-based HMAs with optimized melting temperatures tailored for mainstream applications, balancing eco-friendliness with functional performance.

- Regional Market Dynamics and Application-Specific Needs

Regional variations will influence melting temperature preferences. In Asia-Pacific, rapid growth in e-commerce and flexible packaging is driving demand for low-to-mid-range melting adhesives (100–140°C) suitable for high-speed automated lines. In contrast, North America and Europe are seeing stronger demand for high-temperature HMAs in automotive and construction, where regulatory standards emphasize durability and safety.

- Technological Integration and Real-Time Monitoring

By 2026, smart manufacturing technologies will increasingly integrate real-time monitoring of adhesive melt temperature and viscosity. IoT-enabled glue applicators and predictive maintenance systems will optimize melting conditions, reduce waste, and ensure consistent bonding—particularly important for temperature-sensitive formulations.

In summary, the 2026 market for hot melt glue melting temperature is characterized by diversification: lower temperatures for sustainability and efficiency, higher temperatures for performance-critical applications, and innovations enabling precise thermal control. Manufacturers who can offer tailored melting profiles across this spectrum—supported by green chemistry and digital integration—will be best positioned to capture growth in evolving end-use markets.

Common Pitfalls When Sourcing Hot Melt Glue Based on Melting Temperature (Quality & IP Considerations)

When sourcing hot melt adhesives, focusing solely on melting temperature can lead to significant quality issues and intellectual property (IP) risks. Below are key pitfalls to avoid:

Overlooking Performance Beyond Melting Point

Selecting a hot melt adhesive based only on melting temperature ignores critical performance factors such as open time, bond strength, heat resistance, flexibility, and substrate compatibility. A glue that melts at the desired temperature may still fail in application due to poor adhesion or thermal degradation, leading to product defects and increased rework costs.

Assuming Melting Temperature Equals Application Temperature

The melting temperature is not the same as the recommended application temperature. Many hot melt adhesives require heating 20–40°C above their melt point for proper flow and wetting. Sourcing decisions based on incorrect assumptions about processing temperatures can result in charring, poor dispensing, or inconsistent bonding—compromising both product quality and production efficiency.

Ignoring Thermal Stability and Degradation

Hot melt adhesives vary in thermal stability. Some formulations degrade rapidly when held at elevated temperatures, leading to carbon buildup, nozzle clogging, and reduced bond performance. Overlooking this aspect during sourcing can shorten equipment lifespan and increase maintenance costs, especially in high-speed manufacturing environments.

Copying Competitor Formulations Without IP Clearance

Attempting to replicate a competitor’s adhesive by matching melting temperature and other physical properties can infringe on patented formulations or trade secrets. Even if the melting point is similar, the chemical composition might be protected. Sourcing generic alternatives without proper IP due diligence risks litigation, supply chain disruption, and reputational damage.

Relying on Supplier Data Without Verification

Suppliers may provide inaccurate or idealized melting temperature data based on controlled lab conditions. Failing to independently verify performance under actual production conditions can result in adhesive failure. Always request batch-specific test reports and conduct in-house trials before full-scale sourcing.

Neglecting Supply Chain Consistency

Melting temperature can vary between production batches due to raw material fluctuations. Sourcing from suppliers without robust quality control systems may lead to inconsistent adhesive performance. Ensure suppliers adhere to ISO standards and provide certificates of analysis (CoA) to maintain consistent product quality.

Underestimating Environmental and Regulatory Compliance

Some hot melt adhesives contain restricted substances (e.g., phthalates, heavy metals) or emit volatile organic compounds (VOCs) when heated. Sourcing based purely on melting temperature without evaluating compliance with REACH, RoHS, or FDA regulations can result in non-compliant products and market access issues.

By addressing these pitfalls—balancing technical specifications with quality assurance and IP integrity—companies can make more informed sourcing decisions that support reliable performance and legal compliance.

Hot Melt Glue Melting Temperature: Logistics & Compliance Guide

Understanding Melting Temperature Specifications

The melting temperature of hot melt glue—more accurately described as the “softening” or “melting range”—is a critical parameter affecting logistics, handling, and regulatory compliance. Unlike crystalline solids, hot melt adhesives (HMAs) typically soften over a range rather than melt at a single point. This range is commonly measured using the Ring and Ball Softening Point test (ASTM E28 or ISO 4625). Accurate knowledge of this value ensures proper processing and storage throughout the supply chain.

Storage and Handling Requirements

Hot melt glue must be stored in a cool, dry environment, away from direct sunlight and sources of heat. High ambient temperatures can cause premature softening or blockage in bulk forms (e.g., pellets, slugs, or blocks), leading to bridging in hoppers or degradation of adhesive properties. Recommended storage temperatures are typically between 10°C and 35°C (50°F–95°F), depending on the adhesive formulation. Products with a low softening point (<80°C) require extra caution in warm climates or during summer transport.

Transportation Considerations

During shipping, hot melt adhesives must be protected from extreme temperatures. Carriers should avoid leaving shipments in unventilated trucks or containers exposed to direct sun, especially in regions where temperatures exceed 40°C (104°F). Use of temperature-controlled or shaded transport is advised for sensitive formulations. Packaging (e.g., cardboard boxes, bulk totes, or drums) should remain intact and clearly labeled with handling instructions, including warnings about heat exposure.

Regulatory Compliance and Safety

Hot melt adhesives are generally classified as non-hazardous materials for transport under major regulations (e.g., DOT 49 CFR, ADR/RID, IMDG), provided they are not classified as flammable or reactive. However, compliance depends on the specific formulation. Always consult the Safety Data Sheet (SDS) for:

- Flash point: Most HMAs have high flash points (>200°C), making them non-flammable.

- GHS Classification: Verify absence of hazard pictograms related to flammability, skin irritation, or respiratory sensitization.

- Transport Documentation: Include proper shipping names, UN numbers (if applicable), and packaging group as per SDS and regional regulations.

Ensure SDS and product labels reflect the correct melting/softening range and include precautionary statements for high-temperature application equipment.

Application Equipment and Process Control

Melting temperatures directly influence equipment settings. Adhesives are typically applied between 140°C and 200°C (284°F–392°F), depending on formulation. Operators must adhere to manufacturer-recommended melt and application temperatures to prevent degradation (e.g., charring, smoking) or insufficient bonding. Regular calibration of melt tanks, hoses, and nozzles ensures consistent temperature control and compliance with workplace safety standards (e.g., OSHA, EU Machinery Directive).

Environmental and Disposal Compliance

Used or expired hot melt adhesive is generally non-hazardous and can be disposed of as solid waste in accordance with local regulations. However, contaminated adhesive (e.g., mixed with solvents or other chemicals) may require special handling. Confirm disposal procedures via the SDS and local environmental agencies (e.g., EPA, ECHA). Recycling of clean adhesive scrap is encouraged where feasible.

Training and Documentation

Personnel involved in handling, transporting, or applying hot melt glue must be trained on:

- Safe handling practices near high-temperature equipment

- Recognition of adhesive degradation signs (e.g., discoloration, odor)

- Emergency procedures for spills or exposure

- Interpretation of SDS and product specifications

Maintain records of training, temperature monitoring logs, and compliance documentation to support audits and regulatory inspections.

Conclusion

Proper management of hot melt glue melting temperature is essential for maintaining product integrity, ensuring supply chain efficiency, and meeting compliance standards. By adhering to storage, transport, and handling guidelines—and referencing authoritative test methods and safety documentation—organizations can mitigate risks and optimize adhesive performance across operations.

In conclusion, sourcing hot melt glue with the appropriate melting temperature is crucial for ensuring optimal performance, efficiency, and bond strength in various applications. The ideal melting temperature depends on the specific use case, substrate materials, production speed, and environmental conditions. Generally, hot melt adhesives melt within a range of 160°C to 205°C (320°F to 400°F), with lower melt temperatures suitable for heat-sensitive materials and higher temperatures providing faster setting times for industrial processes. When sourcing, it is essential to consult manufacturer specifications, consider application equipment requirements, and conduct testing to verify compatibility and effectiveness. Selecting the right hot melt glue with a suitable melting profile will enhance bonding quality, reduce downtime, and improve overall operational productivity.