The global demand for high-quality textile fabrics, particularly luxury and breathable materials like hopsack, has seen steady growth driven by rising consumer preference for premium menswear and tailored garments. According to a 2023 report by Grand View Research, the global woven fabric market size was valued at USD 98.6 billion and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, fueled by increasing demand in the fashion and apparel sector. Hopsack cloth, known for its open, plain-woven structure and lightweight feel, is particularly favored in high-end suiting and summer wear, positioning it as a niche yet growing segment within the broader luxury textile market. As brands and tailors seek reliable, sustainable, and innovative suppliers, the need for top-tier hopsack manufacturers has intensified. The following list highlights eight leading manufacturers renowned for their craftsmanship, material quality, and technological advancement in hopsack cloth production.

Top 8 Hopsack Cloth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

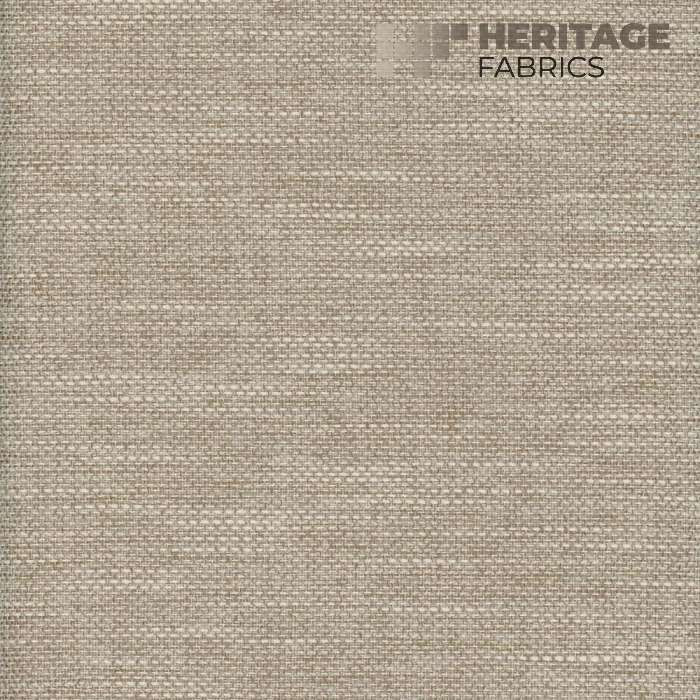

#1 HOPSACK & KNIT EFFECT 50.6638/31

Domain Est. 2014

Website: reda1865.com

Key Highlights: This pure Merino wool fabric is distinguished by a three-dimensional Hopsack mesh texture, is perfect for creation contemporary blazers.Missing: cloth manufacturer…

#2 Shire

Domain Est. 1996

#3 Hopsack fabrics

Domain Est. 1997

Website: vitalebarberiscanonico.com

Key Highlights: Discover the Hopsack fabrics, made by Biellese historical Woollen Mill Vitale Barberis Canonico. Made in Italy….

#4 Hopsack Products

Domain Est. 1997

#5 Shire

Domain Est. 1998

Website: irwinseating.com

Key Highlights: Shire – Hopsack ; Source: Absecon Mills ; Color Family: Brown ; Grade: 1 ; Fabric Type: Woven ; Fabric Content: 100% Polyolefin with acrylic backing….

#6 Hopsack fabrics

Domain Est. 2000

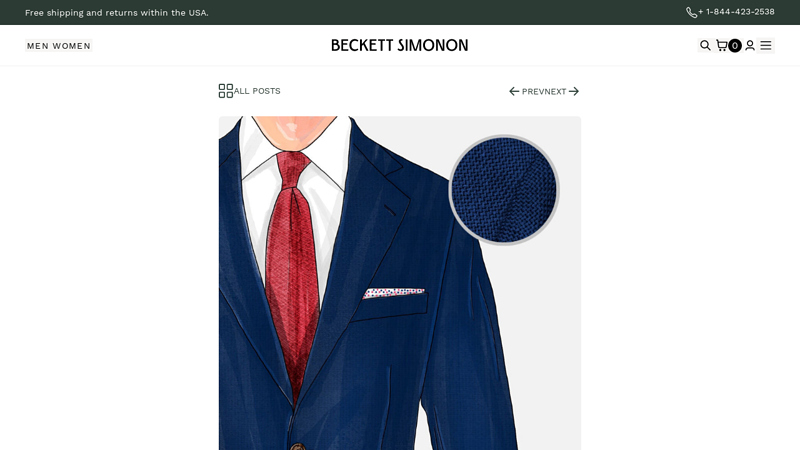

#7 What Is Hopsack? (Should You Be Wearing It?)

Domain Est. 2012

Website: beckettsimonon.com

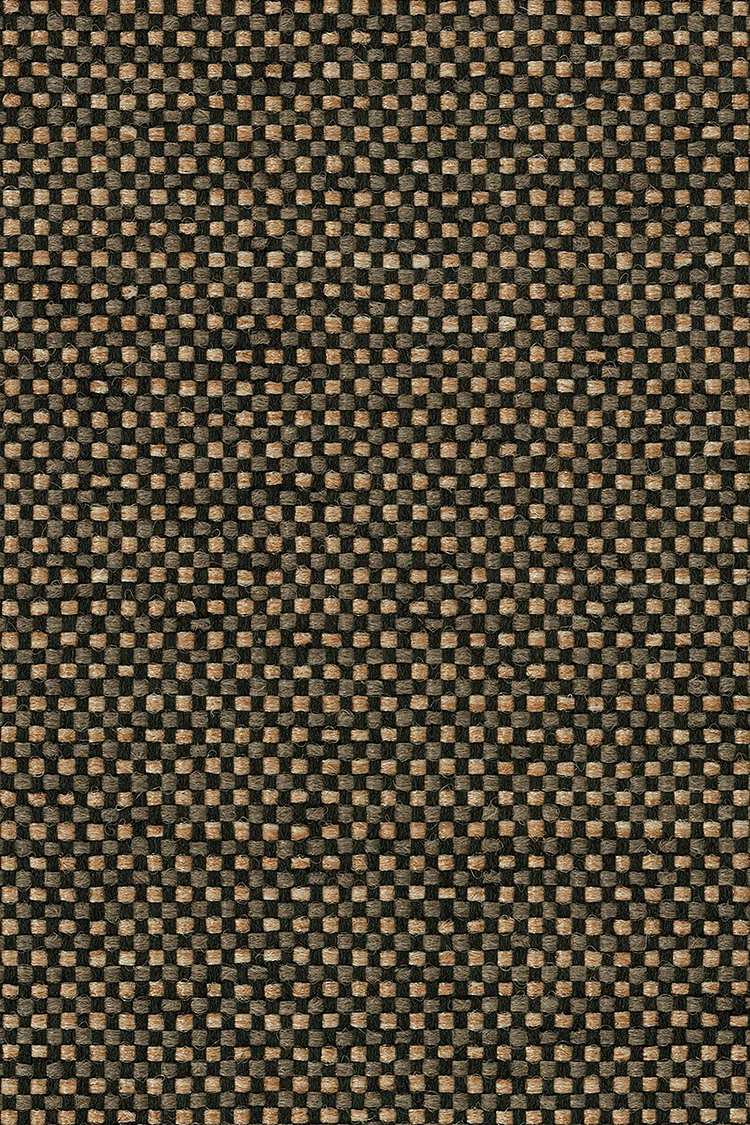

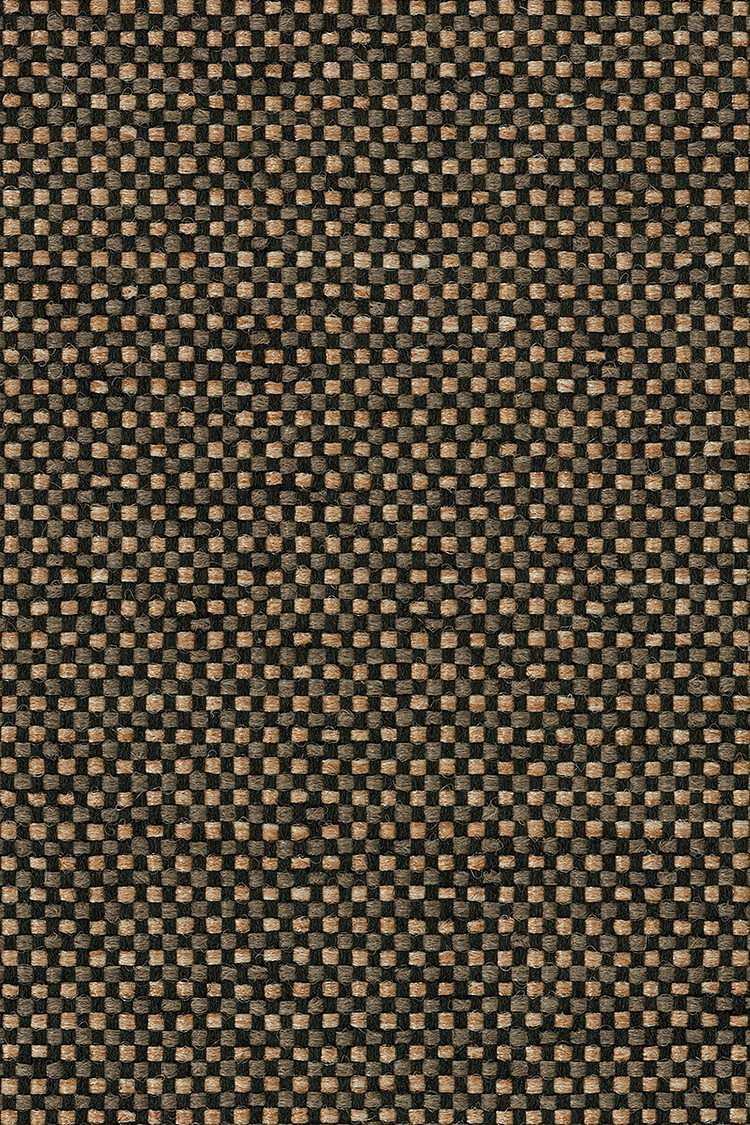

Key Highlights: Hopsack is not really a type of fabric, but a type of weave. It is a basket-like pattern (see the first image) with subtle variations of colors between the ……

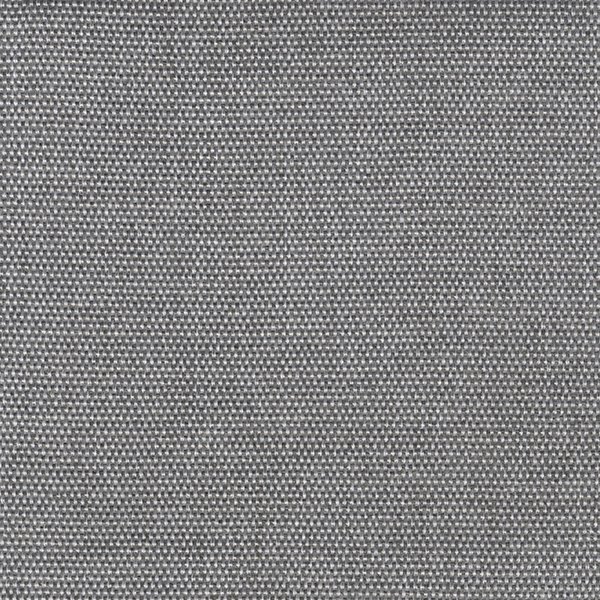

#8 Strada Collection

Domain Est. 2024

Website: cristinamarrone.co.uk

Key Highlights: Available in 18 beautiful shades, our Strada collection consists of heavyweight hopsack fabrics suitable for every upholstery use….

Expert Sourcing Insights for Hopsack Cloth

H2: 2026 Market Trends for Hopsack Cloth

Hopsack cloth, a classic basketweave textile traditionally associated with tailored summer suiting and blazers, is poised for nuanced evolution in 2026. Driven by shifting consumer values, technological advancements, and sustainability imperatives, the market will likely see several key trends:

1. Sustainability as the Core Driver:

By 2026, sustainability will transition from a niche concern to a fundamental market expectation. Demand will surge for hopsack made from:

* Organic & Regenerative Fibers: Organic cotton, linen, and wool sourced from regenerative agriculture practices will gain significant traction, appealing to environmentally conscious consumers and brands with ESG commitments.

* Recycled Content: Hopsack incorporating recycled cotton, wool, or even innovative recycled synthetics (like rPET used in performance blends) will become more common, reducing reliance on virgin resources.

* Low-Impact Processing: Transparency in dyeing and finishing processes (low-water, non-toxic dyes, reduced chemical usage) will be a major differentiator. Certifications like GOTS or OEKO-TEX will carry substantial weight.

2. Performance & Functionality Integration:

The traditional “summer weight” definition will expand. Consumers demand versatility and durability:

* Technical Blends: Hopsack will increasingly incorporate performance yarns (e.g., moisture-wicking, wrinkle-resistant, lightweight stretch) to enhance comfort, ease of care, and suitability for travel or active lifestyles, moving beyond purely formal wear.

* Climate-Adaptive Textiles: Research into hopsack weaves that offer better thermoregulation (keeping cool in heat, potentially some insulation) will gain momentum, extending its wearable season.

3. Diversification of End-Use Applications:

While menswear suiting remains core, hopsack will see growth in adjacent markets:

* Women’s Fashion: Designers will leverage its texture and drape for sophisticated separates, dresses, and lightweight outerwear, moving beyond traditional tailoring.

* Luxury Casual & Sportswear: High-end casual jackets, unstructured blazers, trousers, and even accessories (bags, footwear) will utilize hopsack for its premium, textured aesthetic.

* Interior Design: Demand for hopsack in upholstery (especially for lighter, breathable summer furniture) and decorative applications will grow, driven by its natural aesthetic and texture.

4. Supply Chain Transparency & Regionalization:

Post-pandemic and geopolitical shifts will push for:

* Traceability: Brands will demand full traceability of raw materials (farm to fabric) to verify sustainability and ethical claims. Blockchain technology may play a role.

* Nearshoring/Reshoring: To mitigate risks and reduce carbon footprint, some production may shift closer to end markets (e.g., increased European or US-based weaving for those regions), though cost pressures will keep significant manufacturing in traditional hubs (Italy, UK, Japan, India) with strong sustainability credentials.

5. Innovation in Weave & Aesthetics:

Manufacturers will innovate to maintain relevance:

* Novel Yarns & Blends: Experimentation with silk, Tencel, hemp, or innovative bio-based fibers within the hopsack weave will create unique textures, sheens, and performance characteristics.

* Bolder Textures & Colors: While classic neutrals persist, expect more varied slub yarns, subtle color effects (melanges, heathers), and bolder seasonal color palettes to cater to fashion-forward consumers.

Challenges & Considerations:

* Cost vs. Sustainability: Premium sustainable fibers and processes increase costs, potentially limiting accessibility. Balancing premium positioning with broader market appeal will be key.

* Competition from Synthetics: High-performance synthetic fabrics offer durability and ease of care at lower prices, posing competition for traditional natural fiber hopsack.

* Fast Fashion Pressure: The trend towards rapid trend cycles challenges the inherent “slow fashion” and durability ethos often associated with quality hopsack.

Conclusion for 2026:

The hopsack cloth market in 2026 will be defined by a successful integration of its timeless heritage with modern demands. Success will belong to producers and brands that prioritize sustainability, transparency, and functional innovation while expanding its application beyond traditional suiting. Hopsack will evolve from a seasonal staple to a versatile, performance-oriented, and ethically produced textile valued for its unique combination of aesthetic appeal, comfort, and responsible credentials.

Common Pitfalls When Sourcing Hopsack Cloth: Quality and Intellectual Property Risks

Sourcing high-quality hopsack cloth can be challenging, particularly when balancing cost with performance and authenticity. Buyers often encounter critical pitfalls related to both material quality and intellectual property (IP) concerns. Being aware of these issues is essential for ensuring product integrity and avoiding legal or reputational risks.

Poor Fabric Quality and Inconsistent Weave

One of the most frequent issues when sourcing hopsack cloth is inconsistent or subpar fabric quality. Hopsack is characterized by its distinctive basket weave—typically a two-up, two-down or three-up, one-down structure—which gives it breathability and a slightly textured surface. However, low-cost suppliers may compromise on yarn quality, thread count, or weave precision, resulting in:

- Fabric that lacks the traditional soft drape and structure

- Uneven weave patterns that affect appearance and durability

- Use of short-staple cotton or synthetic blends that diminish breathability and increase pilling

These defects can lead to garments that look unrefined or wear poorly, undermining brand reputation.

Misrepresentation of Fiber Content and Origin

Mislabeling fiber composition is a common pitfall. Authentic hopsack is traditionally made from 100% cotton, linen, or wool, depending on the application. However, some suppliers may blend in polyester or other synthetics to reduce costs, then market the fabric as natural fiber. This not only affects performance but can mislead consumers and breach labeling regulations, especially in regions with strict textile laws (e.g., EU or U.S. FTC guidelines).

Additionally, falsely claiming a fabric’s country of origin—such as labeling mass-produced fabric as “Italian” or “British mill” when it’s not—can deceive buyers about quality and heritage.

Intellectual Property Infringement and Pattern Copying

Hopsack cloth itself is a generic weave and not subject to IP protection. However, specific branded versions, proprietary weaves, or designer patterns may be protected by trademarks, copyrights, or design patents. Sourcing from unverified suppliers increases the risk of:

- Purchasing counterfeit or imitation fabrics that replicate protected designs

- Using trademarks (e.g., mill names or registered fabric lines) without authorization

- Inadvertently violating licensing agreements, particularly when sourcing “inspired by” fabrics

For example, sourcing a fabric labeled as “similar to Holland & Sherry” or “like Loro Piana hopsack” can blur the line between inspiration and infringement, potentially leading to legal disputes.

Lack of Supply Chain Transparency

Many buyers overlook the importance of traceability in the textile supply chain. Without visibility into spinning, weaving, and finishing processes, it’s difficult to verify quality claims or ensure ethical production. Opaque sourcing increases the risk of:

- Unintentional use of unauthorized subcontractors

- Inconsistent batch-to-batch quality

- Exposure to greenwashing or false sustainability claims

Conclusion

To avoid these pitfalls, buyers should conduct due diligence by requesting fabric swatches, lab test reports, and documentation of fiber origin. Partnering with reputable mills or certified suppliers, and consulting legal experts when replicating design elements, can mitigate both quality and IP risks. Proper vetting ensures that the hopsack cloth not only meets aesthetic and functional standards but also aligns with ethical and legal best practices.

Logistics & Compliance Guide for Hopsack Cloth

Overview of Hopsack Cloth

Hopsack cloth is a lightweight, open-weave fabric traditionally made from cotton, linen, or synthetic fibers. It is commonly used in apparel (e.g., summer suits, shirts), bags, and industrial applications. Due to its specific textile characteristics, proper handling, transportation, and compliance with international trade regulations are essential.

Classification & Tariff Codes

Proper classification ensures correct duties and compliance with customs authorities. Hopsack cloth is generally classified under the Harmonized System (HS) code for woven fabrics:

– HS Code Example: 5208.51 (for 100% cotton plain weave fabric, unbleached) or 5516.44 (for woven fabrics of artificial staple fibers).

– Note: Exact code depends on fiber composition (cotton, linen, polyester, blend), weight, finish, and country of import. Always verify with local customs or a licensed customs broker.

Country of Origin Requirements

- Labeling must include the country where the fabric was manufactured or substantially transformed.

- Misdeclaration can result in fines, shipment delays, or seizure.

- Rules of origin vary by trade agreement (e.g., USMCA, EU-UK TCA); ensure compliance when claiming preferential tariffs.

Import & Export Documentation

Essential documents include:

– Commercial Invoice (with detailed product description, HS code, value, and Incoterms)

– Packing List (specifying rolls, weight, dimensions)

– Bill of Lading or Air Waybill

– Certificate of Origin (if claiming preferential treatment)

– Textile Declaration (required in some markets, e.g., EU for fiber content)

Packaging & Handling Guidelines

- Rolls should be wrapped in protective plastic or kraft paper to prevent moisture, dirt, and abrasion.

- Use sturdy cardboard cores and secure ends with caps or tape.

- Palletize rolls to avoid shifting; use stretch wrap or strapping.

- Avoid direct contact with concrete floors during storage to prevent moisture absorption.

Transportation Considerations

- Maritime Shipping: Use moisture-absorbing desiccants in containers; avoid condensation by proper ventilation.

- Air Freight: Faster but more expensive; suitable for high-value or time-sensitive orders.

- Overland Transport: Ensure trailers are enclosed and dry; protect from extreme temperatures.

- Avoid stacking heavy items on top of fabric rolls to prevent deformation.

Regulatory Compliance

- REACH (EU): Ensure no restricted substances (e.g., azo dyes, formaldehyde) exceed allowable limits.

- CPSIA (USA): Applicable if used in children’s apparel; requires lead and phthalate testing.

- Oeko-Tex Standard 100: Voluntary certification demonstrating absence of harmful substances; often requested by retailers.

- Customs-Trade Partnership Against Terrorism (C-TPAT): Recommended for U.S.-bound shipments to expedite clearance.

Environmental & Sustainability Standards

- Increasing demand for eco-friendly production: consider certifications like GOTS (Global Organic Textile Standard) or OEKO-TEX.

- Proper waste management for off-cuts and packaging materials.

- Carbon footprint reporting may be required by certain buyers or jurisdictions.

Incoterms Usage

Select appropriate Incoterms to clarify responsibilities:

– FOB (Free On Board): Seller delivers to port; buyer handles main carriage and import.

– CIF (Cost, Insurance, Freight): Seller arranges and pays for shipping and insurance to destination port.

– DAP (Delivered At Place): Seller delivers to buyer’s named location, unloaded.

– Choose based on risk tolerance, cost control, and buyer-seller agreement.

Risk Mitigation

- Insure shipments against loss, damage, or delay.

- Verify supplier compliance with labor and environmental standards (e.g., via SMETA or BSCI audits).

- Use third-party inspection services for quality control pre-shipment.

Conclusion

Successful logistics and compliance for hopsack cloth require attention to classification, documentation, handling, and regulatory standards. Partner with experienced freight forwarders and compliance consultants to ensure smooth international trade operations and avoid penalties or delays.

Conclusion for Sourcing Hopsack Cloth

In conclusion, sourcing hopsack cloth requires a strategic approach that balances quality, cost, sustainability, and supplier reliability. Hopsack, known for its lightweight, breathable structure and slightly open weave, is ideal for tailored garments such as summer suits and lightweight blazers. When sourcing this fabric, it is essential to partner with reputable mills or suppliers that offer consistent quality, preferably those with certifications in sustainable and ethical production practices.

Key considerations include fiber content—typically wool, cotton, linen, or blends—depending on the intended end use. Evaluating sample swatches for drape, durability, and finish helps ensure the fabric meets design and performance requirements. Additionally, lead times, minimum order quantities (MOQs), and logistical factors should be assessed to align with production schedules and cost targets.

Ultimately, successful sourcing of hopsack cloth hinges on building strong relationships with suppliers, staying informed about fabric innovations and market trends, and prioritizing materials that reflect brand values—especially as demand for eco-friendly and responsibly produced textiles continues to grow. By carefully managing the sourcing process, brands can secure high-quality hopsack fabric that enhances both product appeal and customer satisfaction.