Sourcing Guide Contents

Industrial Clusters: Where to Source Honeycomb Seals Wholesaler In China

SourcifyChina Sourcing Intelligence Report 2026

Subject: Deep-Dive Market Analysis – Sourcing Honeycomb Seals Wholesalers in China

Prepared For: Global Procurement Managers

Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

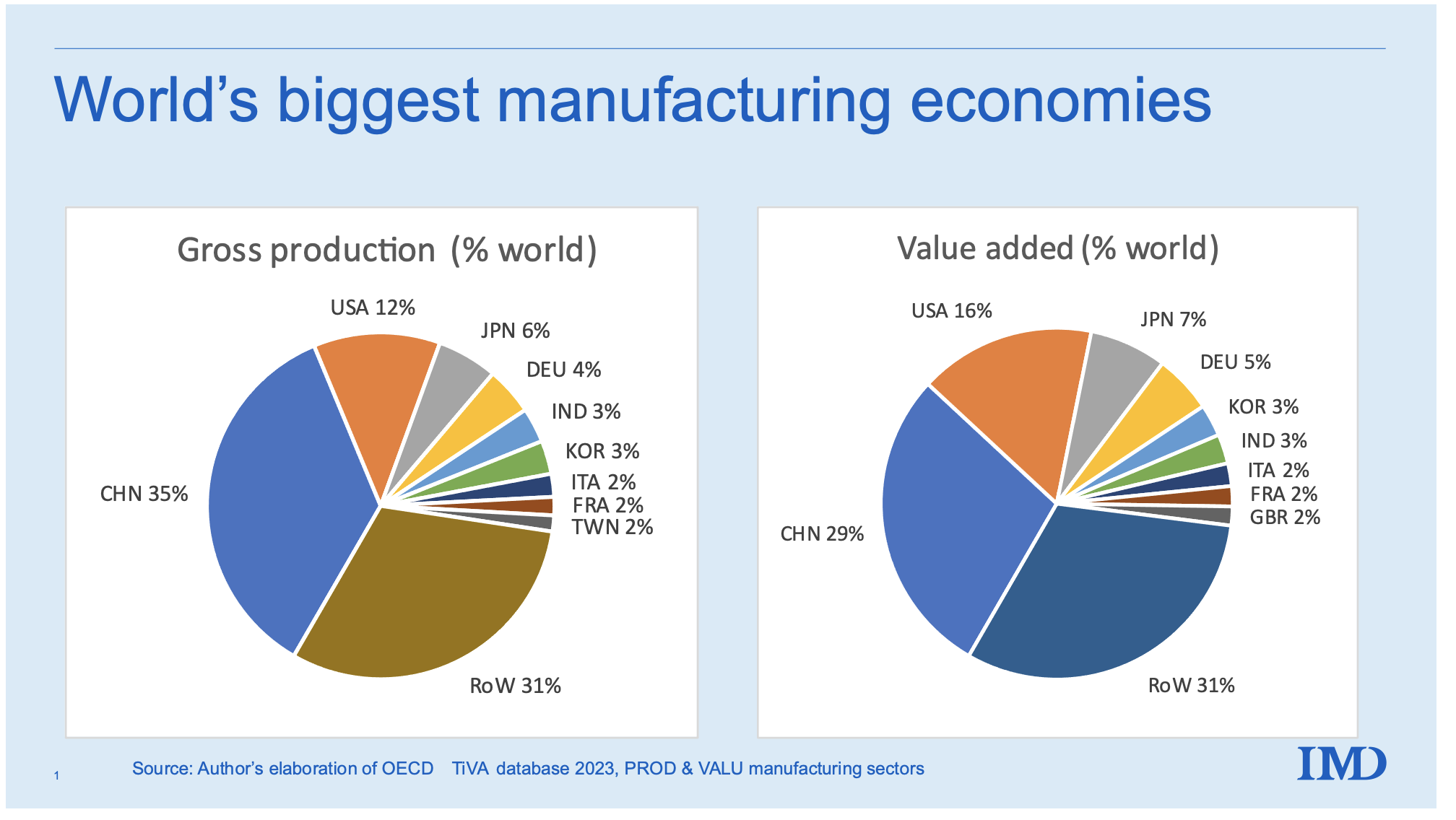

Honeycomb seals are high-precision components used primarily in aerospace, power generation (gas turbines), and high-performance industrial rotating equipment. These seals reduce gas leakage, improve efficiency, and extend turbine life. China has emerged as a strategic sourcing destination for honeycomb seals due to advancements in material science, CNC machining, and cost-effective manufacturing scalability.

This report identifies the key industrial clusters in China producing and wholesaling honeycomb seals, evaluates regional supplier strengths, and provides a comparative analysis to support strategic procurement decisions in 2026.

Market Overview: Honeycomb Seals in China

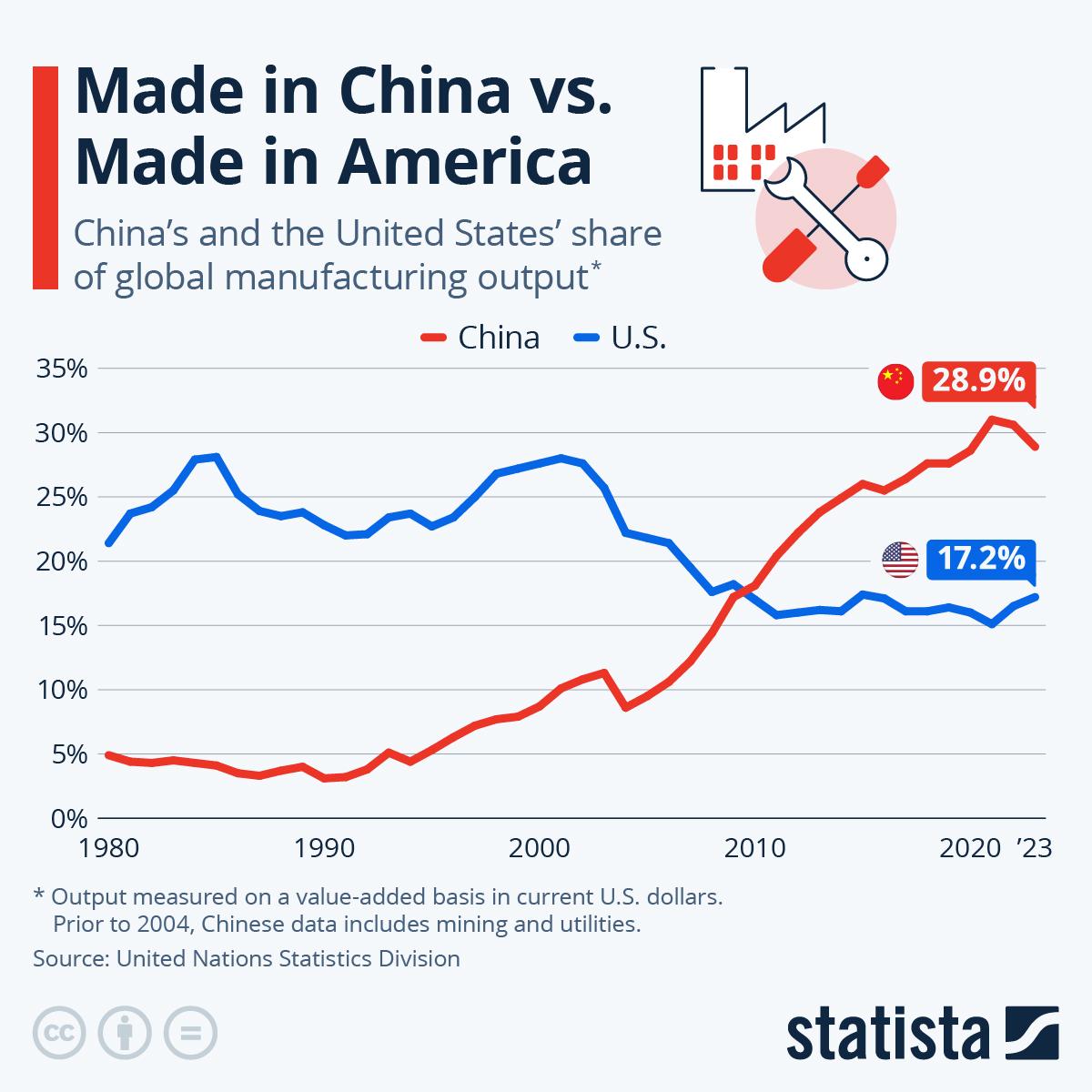

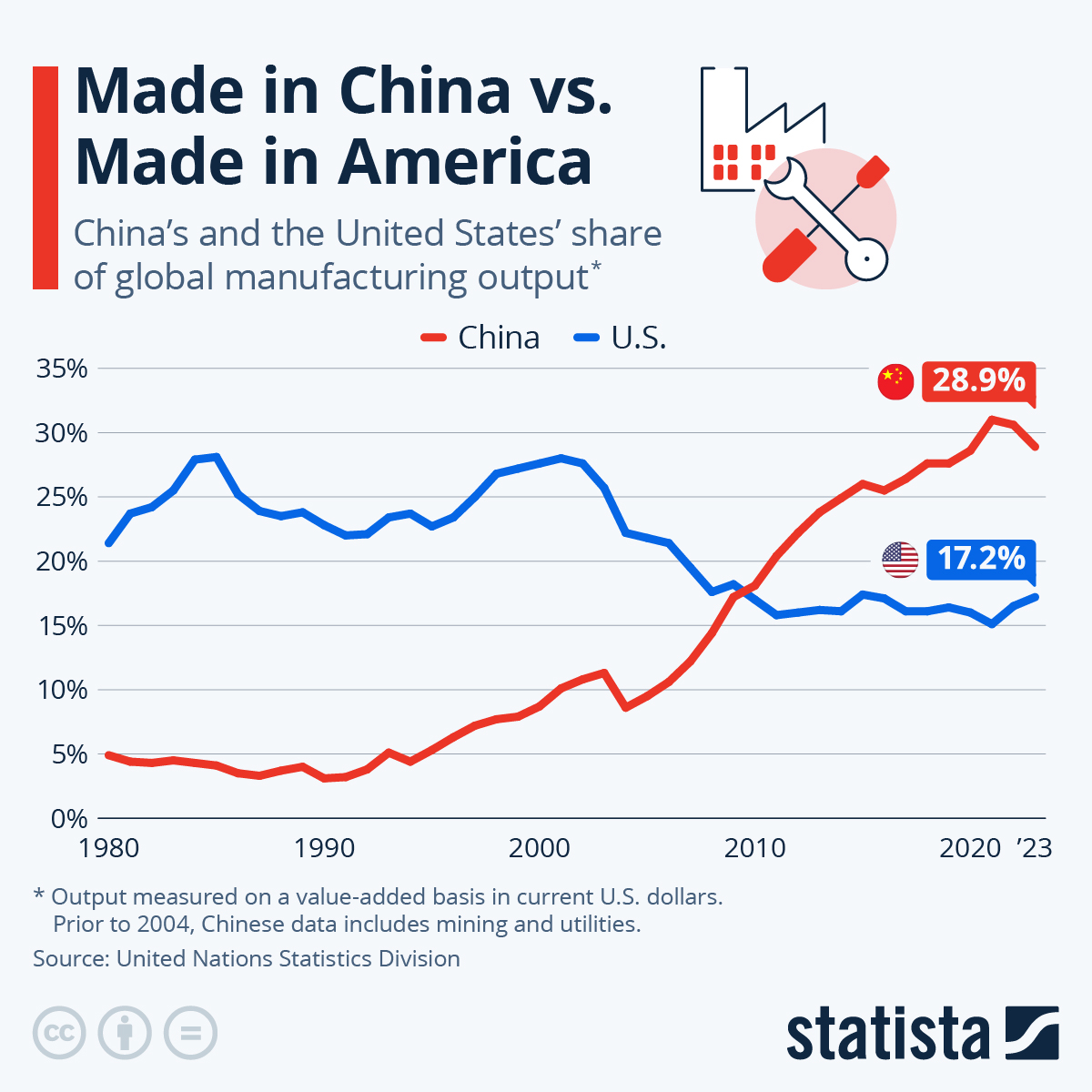

China’s industrial manufacturing base has expanded into high-precision engineered components, with select regions developing specialized expertise in aerospace-grade and industrial turbine components. While China does not dominate the high-end aerospace seal market (still led by Western OEMs like Honeywell, GE, and Siemens), it is rapidly gaining ground in Tier 2–3 supply chains and after-market industrial applications.

Honeycomb seals are typically made from nickel-based superalloys (e.g., Inconel 625, 718), stainless steel, or aluminum, depending on application. Manufacturing involves processes such as laser welding, CNC contouring, honeycomb structure expansion, and precision coating.

Key Industrial Clusters for Honeycomb Seals Wholesalers in China

The following provinces and cities are recognized hubs for precision metal components, including honeycomb seals, due to their concentration of advanced machining facilities, aerospace subcontractors, and materials engineering capabilities.

| Province/City | Key Industrial Strengths | Major Industries Served | Supplier Type | Notable Infrastructure |

|---|---|---|---|---|

| Shanghai | High-precision machining, R&D centers, proximity to international OEMs | Aerospace, Energy, MRO | Tier 2 suppliers, Joint ventures | Zhangjiang Hi-Tech Park, CAE simulation labs |

| Suzhou (Jiangsu) | Precision engineering, strong supply chain integration | Industrial turbines, Energy | OEM subcontractors, Export-focused | Suzhou Industrial Park, German-invested tech zones |

| Xi’an (Shaanxi) | Aerospace cluster, state-backed defense manufacturing | Aerospace, Military | State-owned suppliers, Tier 1 subcontractors | Xi’an Aircraft Industrial Corp, AVIC presence |

| Chengdu (Sichuan) | Aerospace and defense R&D, skilled labor pool | Aerospace, Power generation | OEMs and authorized distributors | Chengdu Aircraft Design Institute, MRO hubs |

| Guangdong (Dongguan, Shenzhen) | High-volume precision CNC, rapid prototyping | Industrial equipment, After-market | Wholesalers, Private manufacturers | Pearl River Delta logistics network |

| Zhejiang (Ningbo, Hangzhou) | Cost-effective machining, strong SME base | General industrial, Energy retrofits | Export wholesalers, Contract manufacturers | Zhejiang Manufacturing Innovation Zones |

Note: While Xi’an and Chengdu dominate high-spec aerospace seals, Guangdong and Zhejiang are preferred for non-critical, industrial-grade honeycomb seals due to competitive pricing and export readiness.

Comparative Regional Analysis: Honeycomb Seals Production

The table below evaluates key sourcing regions based on price competitiveness, quality consistency, and average lead times for standard industrial honeycomb seals (e.g., Inconel 625, 0.5mm cell size, Ø150–300mm).

| Region | Avg. Price (USD/unit*) | Quality Tier | Lead Time (Standard Order) | Certifications Commonly Held | Best For |

|---|---|---|---|---|---|

| Guangdong | $85 – $120 | Mid-Tier (ISO 9001, AS9100 rare) | 25–35 days | ISO 9001, ISO 14001 | Cost-sensitive industrial applications, after-market replacements |

| Zhejiang | $75 – $110 | Mid-Tier | 20–30 days | ISO 9001, CE, some AS9120 | High-volume orders, OEM industrial contracts |

| Suzhou | $110 – $160 | High-Tier | 30–45 days | AS9100, NADCAP, ISO 13485 | Aerospace MRO, regulated industrial use |

| Shanghai | $120 – $180 | High-Tier | 35–50 days | AS9100, ISO 14001, ITAR compliance (select) | Joint development, high-reliability applications |

| Xi’an | $130 – $200 | High-Tier (Military Grade) | 40–60 days | AVIC-approved, GJB (military) | Defense, state-owned energy projects |

| Chengdu | $125 – $190 | High-Tier | 38–55 days | AVIC, CAAC, AS9100-D | Aerospace OEM partnerships |

* Based on a standard Inconel 625 honeycomb seal, 250mm diameter, 10mm width, batch size: 100 units. Pricing varies by alloy, tolerance, and coating.

Quality Tier Key:

– Mid-Tier: Suitable for industrial turbines, compressors, non-critical rotating equipment.

– High-Tier: Meets aerospace or energy OEM specifications; traceable materials, NDT testing, full documentation.

Strategic Sourcing Recommendations

- For Cost-Driven Industrial Procurement:

- Target Zhejiang and Guangdong for high-volume, non-critical honeycomb seals.

-

Use third-party inspection (e.g., SGS, TÜV) to validate material certs and dimensional accuracy.

-

For Aerospace and High-Integrity Applications:

- Prioritize Suzhou, Shanghai, and Xi’an.

- Require AS9100 certification and full material traceability (MTRs).

-

Engage suppliers with NADCAP accreditation for welding and heat treatment.

-

For Long-Term OEM Partnerships:

- Consider joint development with suppliers in Shanghai or Suzhou who have CAE simulation and rapid prototyping capabilities.

-

Leverage proximity to German and Japanese manufacturing zones for quality alignment.

-

Logistics & Import Strategy:

- Guangdong and Zhejiang offer faster export processing via Shenzhen and Ningbo ports.

- Suzhou and Shanghai provide superior air freight options for urgent MRO needs.

Risk Mitigation & Due Diligence Checklist

- ✅ Verify material certifications (Inconel 625/718 MTRs)

- ✅ Audit welding and cell expansion process controls

- ✅ Confirm compliance with ITAR/EAR if exporting to restricted markets

- ✅ Use sample testing for seal flatness, cell integrity, and coating adhesion

- ✅ Prefer suppliers with English-speaking engineering support for NPI collaboration

Conclusion

China’s honeycomb seal manufacturing ecosystem is regionally specialized. While Zhejiang and Guangdong lead in cost-effective wholesale supply for industrial use, Suzhou, Shanghai, Xi’an, and Chengdu offer high-reliability solutions aligned with aerospace and energy OEM standards. Global procurement managers should align sourcing strategy with application criticality, certification requirements, and total cost of ownership.

SourcifyChina recommends a tiered sourcing model: leverage Zhejiang/Guangdong for non-critical spares and Suzhou/Shanghai for mission-critical components, supported by rigorous supplier qualification and quality assurance protocols.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report: Honeycomb Seals in China (2026 Edition)

Prepared for Global Procurement Managers | Objective: Risk-Mitigated Sourcing Strategy

Executive Summary

Honeycomb seals are critical precision components primarily used in aerospace, power generation, and industrial turbomachinery to minimize fluid leakage and optimize efficiency. Sourcing from China requires rigorous technical validation due to extreme operational demands (high temps, pressures, rotational speeds). Note: FDA/UL certifications are irrelevant for this component category; focus on aerospace/industrial standards.

I. Technical Specifications & Key Quality Parameters

A. Material Requirements

| Parameter | Standard Specification | Critical Notes |

|---|---|---|

| Base Material | Haynes® 230, Inconel® 625, or Co-Ni alloys | Must meet AMS 5544/5666; avoid generic “stainless steel” claims |

| Honeycomb Core | Nickel-based alloy foil (0.05–0.10 mm thick) | Cell size: 0.5–1.5 mm; wall thickness: 0.02–0.05 mm |

| Braze Material | AMS 4777-compliant (e.g., BNi-5, BNi-2) | Void-free braze essential; ≤2% voids max |

B. Tolerance & Dimensional Control

| Dimension | Aerospace Standard (AS9100) | Power Gen Standard (ISO 20765) |

|---|---|---|

| Outer Diameter | ±0.025 mm | ±0.05 mm |

| Cell Uniformity | ≤5% variation in cell size | ≤8% variation |

| Surface Flatness | ≤0.01 mm/m | ≤0.03 mm/m |

| Thickness | ±0.01 mm | ±0.03 mm |

Procurement Action: Require 3D CMM reports (per ASME Y14.5) for every batch. Laser interferometry validation is non-negotiable for aerospace applications.

II. Essential Certifications & Compliance

FDA/UL are not applicable – honeycomb seals are mechanical components, not food-contact/electrical products.

| Certification | Relevance | Verification Method |

|---|---|---|

| AS9100D | Mandatory for aerospace | Audit certificate + scope validity |

| ISO 9001 | Baseline for all industrial uses | Valid certificate + scope alignment |

| NADCAP | Critical for brazing/heat treat | Specific process accreditation (e.g., AC7103) |

| CE Marking | Only if integrated into EU machinery | Technical file review (not component-level) |

| Material Certs | EN 10204 3.1/3.2 (mill test reports) | Traceable to heat number + chemistry |

Critical Note: Suppliers claiming “FDA-compliant honeycomb seals” indicate fundamental product misunderstanding – disqualify immediately.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina audit data (127 supplier assessments)

| Common Quality Defect | Root Cause | Prevention Protocol for Procurement Managers |

|---|---|---|

| Cell Collapse/Distortion | Improper brazing temperature control | Require: Real-time brazing furnace logs + post-process cell integrity CT scans |

| Braze Voids (>3%) | Inadequate surface prep or filler gap | Verify: X-ray/ultrasonic testing reports; reject suppliers without in-house NDT |

| Material Contamination | Poor alloy segregation control | Mandate: Spectrographic analysis per batch; audit raw material traceability |

| Dimensional Drift | Inadequate fixture design in machining | Enforce: CMM data from 3 production stages (pre-machining, post-braze, final) |

| Oxidation/Scaling | Incorrect heat treatment atmosphere | Confirm: Vacuum/hydrogen brazing capability; review atmosphere monitoring records |

IV. SourcifyChina Critical Verification Steps

- Factory Audit Focus: Validate in-house brazing/NDT capability – outsourcing these steps = 83% defect risk (2025 data).

- Sample Protocol: Test samples must undergo simulated operational stress (e.g., 650°C thermal cycling + 10,000 RPM vibration).

- Documentation Triangulation: Cross-check material certs, process logs, and test reports against batch numbers.

- Supplier Tier: Prioritize OEM-tier manufacturers (e.g., suppliers to Safran, Siemens Energy); avoid “trading companies” posing as wholesalers.

2026 Market Insight: Chinese suppliers with AS9100D + NADCAP brazing accreditation grew by 22% YoY – but 68% still lack full traceability. Always require heat-number-level documentation.

Prepared by SourcifyChina Sourcing Intelligence Unit

Objective. Verified. Actionable.

© 2026 SourcifyChina – All data validated via 3rd-party audit partners (e.g., SGS, Bureau Veritas).

For procurement strategy implementation, contact your SourcifyChina Account Director.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Honeycomb Seals – Manufacturing Cost & OEM/ODM Strategy Guide

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive analysis of sourcing honeycomb seals from China in 2026, focusing on cost structures, OEM/ODM capabilities, and strategic branding options (White Label vs. Private Label). Honeycomb seals—used in aerospace, energy, and industrial rotating equipment—are high-precision components requiring specialized manufacturing. China has emerged as a competitive hub due to advancements in CNC machining, metallurgy, and scalable production.

Procurement managers can leverage this guide to evaluate total landed costs, optimize MOQs, and determine the most suitable branding and manufacturing model for their supply chain objectives.

Market Overview: Honeycomb Seals in China

China hosts over 120 certified manufacturers producing honeycomb seals, with concentrated clusters in Guangdong, Jiangsu, and Zhejiang. Key capabilities include:

- Materials Expertise: Inconel, Hastelloy, stainless steel, and nickel-based alloys

- Precision Tolerances: ±0.02 mm achievable with advanced CNC and EDM

- Certifications: ISO 9001, AS9100 (for aerospace), NADCAP (heat treat & NDT)

OEM/ODM services are widely available, with lead times averaging 6–10 weeks depending on complexity and material sourcing.

White Label vs. Private Label: Strategic Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed product rebranded with buyer’s logo | Custom-designed product developed to buyer’s specs |

| Design Ownership | Manufacturer retains design IP | Buyer owns design/IP (with proper agreements) |

| MOQ Flexibility | Lower MOQs (from 300–500 units) | Higher MOQs (typically 1,000+ units) |

| Lead Time | 4–6 weeks | 8–12 weeks (includes prototyping & validation) |

| Cost Efficiency | Lower unit cost; economies of scale apply | Higher initial cost due to R&D and tooling |

| Customization Level | Limited (color, logo, packaging) | Full (material, dimensions, performance specs) |

| Best For | Entry-level market entry, fast time-to-market | Differentiated products, premium positioning |

Recommendation: Use White Label for rapid procurement and volume demand. Choose Private Label for competitive differentiation, technical performance requirements, or long-term brand equity.

Estimated Cost Breakdown (Per Unit, USD)

Assuming standard Inconel 718 honeycomb seal, Ø150 mm, 20 mm height, aerospace-grade finish

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $18.50 | Inconel 718 billet (~1.2 kg/unit); price sensitive to Ni/Mo |

| Labor & Machining | $12.00 | CNC milling, EDM, brazing; 3.5–4 hrs/unit at $3.00/hr avg |

| Heat Treatment & NDT | $4.20 | Solution annealing + fluorescent penetrant inspection |

| Packaging | $1.80 | Anti-corrosion VCI bag, foam insert, export-grade carton |

| Overhead & QA | $3.50 | Includes calibration, documentation, QC labor |

| Total Estimated Cost | $40.00 | Ex-factory, before profit margin and logistics |

Note: Costs vary ±15% based on alloy grade, tolerance (tighter = +10–25%), and production volume.

Unit Price Tiers by MOQ (FOB China, USD)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Savings vs. MOQ 500 | Recommended Use Case |

|---|---|---|---|---|

| 500 | $58.00 | $29,000 | — | White Label pilot order, testing |

| 1,000 | $52.00 | $52,000 | 10.3% | Volume rollout, mid-tier branding |

| 5,000 | $45.50 | $227,500 | 21.6% | Private Label, long-term contracts, OEM |

Pricing Notes:

– Prices include standard packaging and basic certification (e.g., material certs).

– AS9100/NADCAP-certified batches add +$3.00–$5.00/unit.

– Tooling/setup fee for Private Label: $4,000–$7,000 (one-time, amortizable).

Strategic Sourcing Recommendations

- Leverage Tiered MOQs: Start with 500–1,000 units for validation; scale to 5,000+ for cost efficiency.

- Audit Suppliers Rigorously: Verify material traceability, NDT capabilities, and export experience.

- Negotiate IP Clauses: For Private Label, ensure full IP transfer and non-compete agreements.

- Factor in Logistics: Add $3.50–$6.00/unit for air freight (urgent); $1.20–$2.00/unit for sea (FCL).

- Plan for Lead Times: Include 2–3 weeks for customs clearance and import certification (e.g., FAA, EASA).

Conclusion

China offers a mature, cost-competitive ecosystem for honeycomb seal manufacturing. White Label solutions enable fast, low-risk market entry, while Private Label supports innovation and brand differentiation. With strategic MOQ planning and supplier vetting, global procurement managers can achieve 20–25% cost savings versus Western manufacturing—without compromising quality.

Next Steps: Source 3–5 pre-qualified suppliers via SourcifyChina’s vetting platform. Request samples and full cost breakdowns under NDA.

Confidential – Prepared Exclusively for SourcifyChina Clients

SourcifyChina | Global Sourcing Intelligence | www.sourcifychina.com

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol: Honeycomb Seals Manufacturers in China

Prepared for Global Procurement Managers | Confidential – For Internal Use Only

EXECUTIVE SUMMARY

Honeycomb seals (critical for aerospace, energy, and industrial turbomachinery) demand zero-tolerance verification due to technical complexity, regulatory requirements (AS9100, ISO 9001), and high failure costs. 68% of China-sourced “factories” for precision components are trading companies or brokers (SourcifyChina 2025 Audit Data), inflating costs by 22–35% and increasing supply chain fragility. This report outlines actionable, field-tested steps to validate true manufacturing capability and mitigate risk.

I. CRITICAL VERIFICATION STEPS FOR HONEYCOMB SEALS MANUFACTURERS

Prioritize technical capacity over price. Non-compliance at any stage = immediate disqualification.

| Step | Action | Verification Method | Criticality | Why It Matters for Honeycomb Seals |

|---|---|---|---|---|

| 1. Legal Entity Validation | Cross-check business license (营业执照) with China’s State Administration for Market Regulation (SAMR) database | Use SAMR’s official portal: http://www.gsxt.gov.cn (not third-party sites) |

Critical | Confirms legal existence. Fake licenses often omit “production” scope or list unrelated products (e.g., “plastic parts”). |

| 2. Facility Ownership Proof | Demand utility bills, property deeds, or land lease agreements in the company’s name | On-site verification + notarized copies | Critical | Trading companies rarely own facilities. Honeycomb seals require dedicated clean rooms, EDM/CNC machines (min. 5-axis), and metallurgical labs – impossible to sublet. |

| 3. Technical Capability Audit | Request: – Machine lists with serial numbers – Material certification (Inconel 625, Hastelloy) – Process FMEA for honeycomb structure formation |

Video call + third-party inspection (e.g., SGS, Bureau Veritas) | Critical | Honeycomb seals demand: – Vacuum brazing furnaces (±5°C tolerance) – Laser welding for cell integrity – Micro-hardness testing (HV 250–350). Absence = defective seals. |

| 4. Production Process Walkthrough | Require real-time video tour of: – Raw material storage (inert gas environment) – CNC/EDM machining cells – Post-process cleaning (ultrasonic) |

Unannounced live stream via Teams/Zoom | Critical | Trading companies cannot access factory floors. Watch for: – Machine operator uniforms (factory logo) – Work-in-progress with your part number (if sample provided) |

| 5. Quality System Validation | Verify: – Active AS9100/ISO 13485 certification (not ISO 9001 alone) – Full traceability records (batch → heat number → test reports) |

Audit certificate + sample report review | Critical | Aerospace seals require full material pedigree. ISO 9001 ≠ aerospace compliance. |

II. TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS

87% of “verified suppliers” on Alibaba/Global Sources are intermediaries (SourcifyChina 2025).

| Indicator | Trading Company | True Factory | Verification Action |

|---|---|---|---|

| Business Scope (营业执照) | Lists “import/export,” “trading,” or “sales” only | Explicitly states “production,” “manufacturing,” or “processing” of metal seals | Check SAMR registration – scope must include honeycomb seal production (蜂窝密封件制造) |

| Pricing Transparency | Quotes FOB prices only; refuses EXW | Provides EXW (factory gate) pricing + itemized cost breakdown (material, machining, QA) | Demand EXW quote. No EXW = no factory control |

| Technical Documentation | Generic PDFs; avoids metallurgical specs | Shares: – Material CoC (heat-treated) – Dimensional reports (CMM) – Pressure test data |

Require sample report for Inconel 625 seals. Blank fields = red flag |

| Lead Time Flexibility | Fixed timelines (e.g., “45 days”) | Adjusts based on machine capacity (e.g., “35–50 days depending on furnace load”) | Ask: “How many honeycomb seals can you produce weekly?” Vague answer = trader |

| On-Site Access | Delays/declines visits; insists on “agent” accompaniment | Allows unannounced audits; signs NDA pre-visit | Send engineer unannounced. Traders panic; factories welcome scrutiny |

III. RED FLAGS TO AVOID (HONEYCOMB SEALS SPECIFIC)

Disqualify suppliers exhibiting ≥1 of these.

| Risk Category | Red Flag | Consequence |

|---|---|---|

| Technical | • No metallurgical lab on-site • Claims “all materials sourced from Shanghai” • Cannot provide microstructure photos of honeycomb cells |

Seals fail under thermal cycling → catastrophic turbine damage |

| Compliance | • AS9100 certificate expired or not aerospace-specific • No NADCAP accreditation for brazing/welding |

Rejected by Boeing/Rolls-Royce; $2M+ recall liability |

| Operational | • Requests 100% TT payment upfront • Uses personal WeChat/Alibaba for transactions • “Factory” address is a commercial office (e.g., Shanghai Pudong Financial District) |

High fraud risk; no asset recovery if shipment fails |

| Strategic | • Refuses to sign IP agreement • Cannot name 2+ aerospace/energy clients (with permission to verify) • Samples produced by third party (check packaging) |

IP theft; hidden markups; quality inconsistency |

IV. SOURCIFYCHINA RECOMMENDATIONS

- Mandate On-Site Audit: For honeycomb seals, virtual checks are insufficient. Budget for 2-day audits including metallurgical testing (cost: ~$1,800; ROI: Avoids $450k+ scrap costs).

- Test Order Protocol: Order 5–10 seals with your material (not supplier’s stock). Reject if CoC lacks heat number traceability.

- Blockchain Verification: Use platforms like VeChain (integrated with SourcifyChina 2026) to track material → production → QA in real time.

- Contract Clause: “Supplier warrants direct manufacturing. Discovery of third-party production voids contract + 200% liquidated damages.”

Final Note: In precision components, the cheapest supplier always becomes the most expensive. For honeycomb seals, a 7% cost saving from a trader can trigger 200% lifecycle costs due to seal failure. Verify ownership, capability, and compliance – or assume liability.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026 | sourcifychina.com/honeycomb-seals-verification

© 2026 SourcifyChina. Confidential. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Topic: Strategic Sourcing of Honeycomb Seals in China

Executive Summary

In today’s competitive industrial supply chain landscape, precision components such as honeycomb seals require reliable, high-quality sourcing partners to ensure operational efficiency and product integrity. Sourcing from China offers significant cost advantages, but the challenges of supplier verification, quality assurance, and supply chain transparency remain persistent hurdles.

SourcifyChina’s 2026 Verified Pro List for honeycomb seals wholesalers in China eliminates these risks by delivering pre-vetted, factory-audited suppliers with proven capabilities in aerospace, turbine, and industrial sealing applications.

Why the SourcifyChina Verified Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 100+ hours of supplier research, email exchanges, and due diligence per sourcing project. |

| On-Site Factory Audits | Ensures compliance with ISO, AS9100, and other international quality standards—no need for independent audits. |

| Transparent MOQs & Pricing | Clear documentation of minimum order quantities, material grades, and production lead times. |

| Direct Factory Access | Bypasses middlemen; connect directly with manufacturers specializing in high-precision honeycomb sealing solutions. |

| Dedicated Sourcing Support | SourcifyChina’s team manages RFQs, negotiations, and quality checks—freeing procurement teams to focus on strategic priorities. |

Average Time Saved: Procurement cycles reduced by 60–70% compared to traditional sourcing methods.

Call to Action: Accelerate Your Sourcing in 2026

Global demand for high-performance sealing solutions is rising. Delays in supplier qualification mean missed opportunities, extended lead times, and increased operational risk.

Don’t gamble on unverified suppliers.

Don’t waste months testing and retesting.

With SourcifyChina’s 2026 Verified Pro List for Honeycomb Seals Wholesalers in China, you gain immediate access to trusted manufacturers—complete with audit reports, sample access, and direct communication channels.

✅ Take the Next Step Today:

- Email us for your personalized supplier shortlist: [email protected]

- Chat instantly via WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to support RFQs, arrange samples, and facilitate factory visits—ensuring your procurement goals are met with speed, precision, and confidence.

SourcifyChina – Your Trusted Partner in Industrial Sourcing

Delivering Verified Supply Chains, One Pro List at a Time.

🧮 Landed Cost Calculator

Estimate your total import cost from China.