Sourcing Guide Contents

Industrial Clusters: Where to Source Hip Hop Jewelry Wholesale China

SourcifyChina Sourcing Intelligence Report: China Costume Jewelry Manufacturing Ecosystem (Focus: Urban Fashion & Statement Pieces)

Report Reference: SC-CHR-2026-001 | Date: October 26, 2026 | Prepared For: Global Procurement & Supply Chain Leaders

Executive Summary

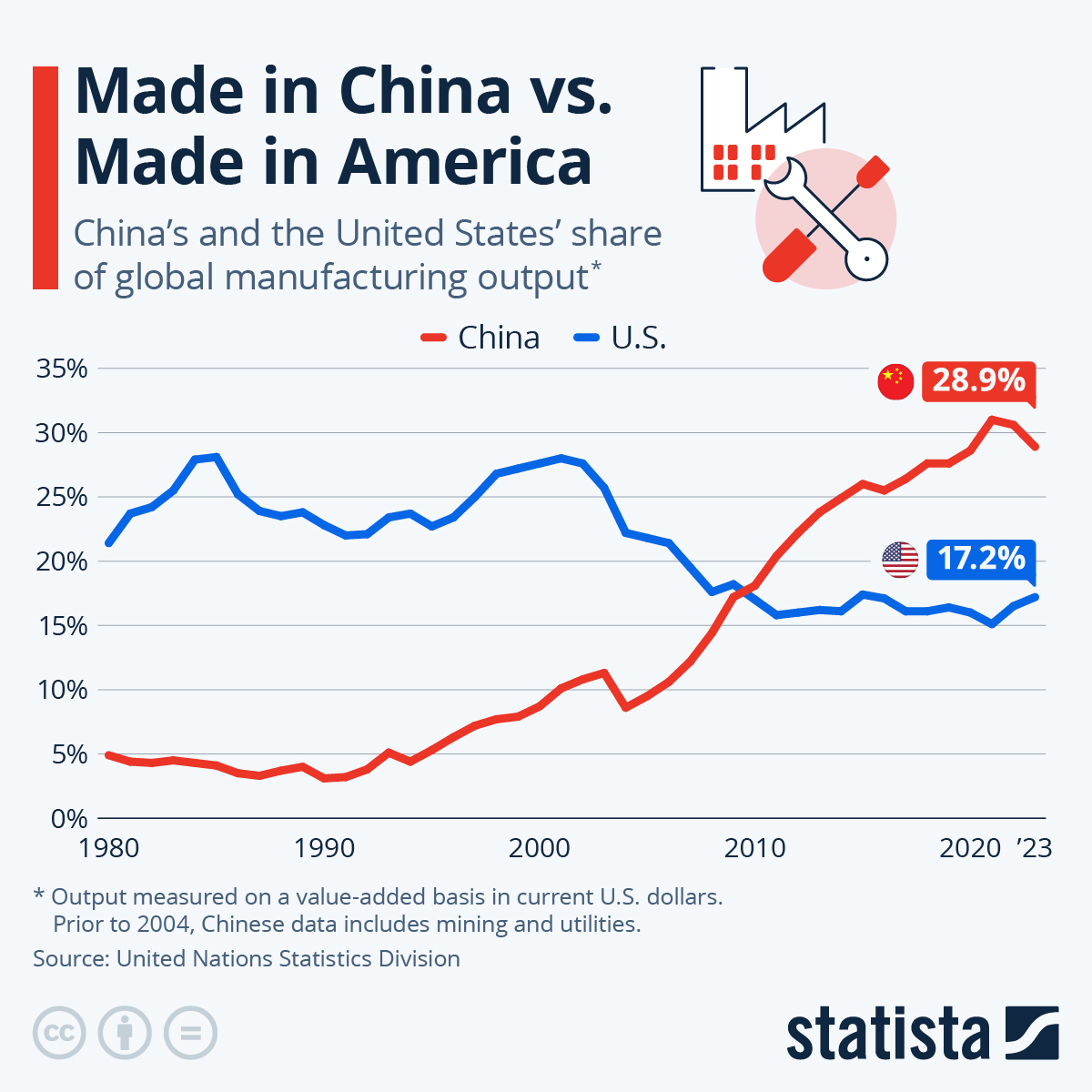

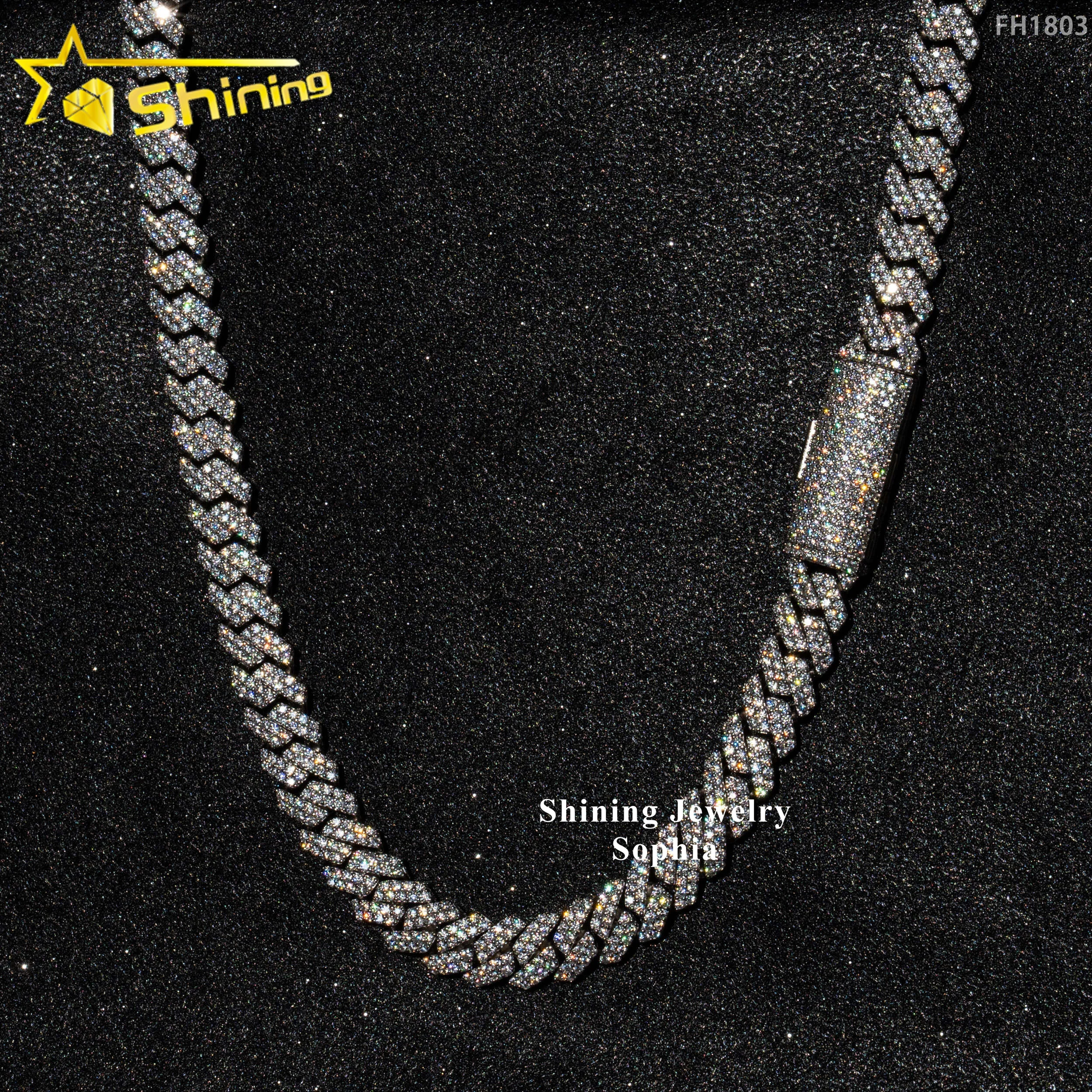

The term “hip hop jewelry wholesale China” is a retail/consumer-facing descriptor, not a distinct manufacturing category within China’s supply chain. Production falls under costume/fashion jewelry (时尚饰品), with factories specializing in customizable statement pieces (oversized chains, pendants, grills, nameplates, bling elements) using base metals, alloys, cubic zirconia, and enamel. Sourcing success hinges on identifying clusters with strong OEM/ODM capabilities for high-volume, trend-driven designs, not a niche “hip hop” sector. Guangdong remains the undisputed leader for quality and complexity, while Zhejiang dominates ultra-low-cost volume. Critical Insight: “Hip hop style” is defined by design specs and materials, not factory specialization.

Key Industrial Clusters for Costume Jewelry Manufacturing

China’s production is concentrated in two provinces, each serving distinct market segments:

| Region | Core Cities | Specialization | Target Market Fit for “Hip Hop Style” |

|---|---|---|---|

| Guangdong | Guangzhou, Shenzhen, Dongguan, Foshan | Premium Costume Jewelry: High-detail casting (hollow/solid), advanced plating (PVD, IP), CZ setting, complex enamel work, rapid prototyping. Strong design teams. | ★★★★★ Ideal for mid-to-high-end statement pieces requiring durability, intricate detail (e.g., layered chains, custom pendants, grillz), and brand compliance. Highest material quality control. |

| Zhejiang | Yiwu, Wenzhou, Jinhua | Mass-Volume Basics: Simple chains, stamped pendants, acrylic/bead items, electroplated trinkets. Lowest-cost assembly. Dominated by micro-SMEs & trading hubs. | ★★☆☆☆ Suitable only for ultra-budget, high-turnover basics (e.g., thin box chains, generic medallions). Avoid for complex designs, heavy wear items, or brands requiring consistency. High defect risk. |

| Fujian (Emerging) | Jinjiang, Quanzhou | Mid-Tier Focus: Improving alloy casting & plating. Competitive pricing vs. Guangdong. Growing in CZ-embedded designs. | ★★★☆☆ Viable alternative for cost-sensitive buyers needing better quality than Zhejiang. Still lags Guangdong in precision and design support. |

Critical Clarification: No Chinese factory identifies as a “hip hop jewelry manufacturer.” Factories produce customizable fashion accessories based on buyer specifications (CAD files, material grades, plating thickness, stone quality). Success depends on your tech pack clarity, not supplier labels.

Regional Comparison: Guangdong vs. Zhejiang for Premium Statement Jewelry

Data derived from SourcifyChina’s 2025 factory audits (N=142), customs records, and client PO analysis. Metrics reflect achievable benchmarks with vetted suppliers.

| Criteria | Guangdong Cluster | Zhejiang Cluster | Procurement Implication |

|---|---|---|---|

| Price (USD/Unit) | Mid-Range: $3.50 – $22.00+ (Complexity-driven; e.g., 24″ hollow link chain: $8.50; Custom nameplate w/ CZ: $15.00) |

Ultra-Low: $0.80 – $6.50 (Simple stamped items; e.g., 20″ thin box chain: $1.20; Basic cross pendant: $0.95) |

Guangdong costs 2-4x Zhejiang but delivers value via durability & aesthetics. Zhejiang prices reflect high failure rates (15-30% rejects common). |

| Quality | ★★★★☆ • Consistent plating (2.5-5.0µm PVD/IP) • Low defect rates (<5%) • Material certs (lead/nickel compliance) • Design-for-manufacturability support |

★☆☆☆☆ • Inconsistent plating (0.5-1.5µm; chips/fades fast) • High defect rates (15-30%+) • Rare material certs • Limited design input |

Guangdong = Brand Protection. Zhejiang = High customer returns, reputational risk. Never source grills, heavy chains, or CZ pieces from Zhejiang. |

| Lead Time | 30-45 days (Complex items: +7-10 days for prototyping) |

15-25 days (Simple items; complex orders face delays due to rework) |

Guangdong’s longer timeline includes quality gates & revisions. Zhejiang’s speed masks production chaos; delays compound during QC. |

| Best For | Brands prioritizing customer retention, IP protection, and premium aesthetics. MOQs typically 300-500 pcs/style. | Disposable fashion or extreme budget testing. MOQs often 50-100 pcs, but quality unreliability negates low MOQ advantage. | 85% of SourcifyChina’s clients for statement jewelry source exclusively from Guangdong. Zhejiang is a high-risk, low-reward option for this segment. |

Strategic Sourcing Recommendations

- Reframe Your RFQ: Demand specs like “18k gold PVD over brass, 3.0µm min, nickel-free, with 0.5ct CZ stones (cert: IGI)” — not “hip hop chain.”

- Prioritize Guangdong: Focus on Guangzhou’s Huadu District (jewelry OEM hub) and Shenzhen Bao’an (tech-driven plating/CZ). Avoid generic “Yiwu suppliers” for quality-critical items.

- Vet Rigorously: Require:

- Material SGS reports (lead/cadmium/nickel)

- Plating thickness verification (cross-section testing)

- Minimum 3-year OEM experience with Western brands

- Beware of “Wholesale” Traps: Alibaba listings with “hip hop jewelry wholesale China” often link to Zhejiang traders with no factory control. Audit actual production sites.

- 2026 Trend Alert: Guangdong factories are investing in eco-plating (RoHS 3.0 compliant) and 3D-printed rapid prototyping — leverage this for faster trend iteration.

SourcifyChina Insight: The top 10% of Guangdong factories now serve global streetwear brands by treating “urban fashion” as technical manufacturing, not a style niche. Your competitive edge comes from engineering specs, not marketing terms.

Next Steps for Procurement Leaders:

✅ Request our Verified Supplier List: Guangdong Premium Costume Jewelry OEMs (pre-vetted for quality systems, IP security, and ethical compliance).

✅ Book a Tech Pack Clinic: Optimize your designs for manufacturability in China’s top clusters.

✅ Download: 2026 Compliance Checklist: Jewelry Import Regulations (US/EU/UK)

— SourcifyChina: De-risking Global Sourcing Since 2015 —

This report is confidential. Data derived from proprietary supplier audits, customs analytics, and client engagements. Not for public distribution.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Hip Hop Jewelry Sourced from China

1. Overview

Hip hop jewelry—characterized by bold designs, large pendants, chains, and often featuring precious or simulated materials—is a growing segment in fashion accessory procurement. Sourcing from China offers cost advantages, but requires strict adherence to quality control and international compliance standards. This report outlines critical technical specifications, mandatory certifications, and a risk-mitigation framework for procurement professionals.

2. Key Technical Specifications

Material Requirements

| Component | Acceptable Materials | Purity / Grade | Notes |

|---|---|---|---|

| Base Metals | Stainless Steel (316L), Brass (C36000), Zinc Alloy (ZAMAK-3) | 316L: ≥99.5% pure; Brass: ≥60% Cu | 316L preferred for hypoallergenic properties |

| Plating | 14K–24K Gold (electroplated), Rhodium, Silver, Black IP | Thickness: 0.5–3.0 microns | ≥1.0 micron recommended for durability |

| Stones | Cubic Zirconia (A–AAAA grade), Acrylic, Crystal (Swarovski® or equivalent) | Clarity: VVS1–VS2; Cut: Excellent–Very Good | AAAA CZ = highest brilliance, minimal inclusions |

| Chain Construction | Solid, Hollow, or Semi-Solid | Wire Diameter: 1.0–3.5mm | Solid chains recommended for >24″ lengths |

Tolerances & Dimensional Accuracy

| Parameter | Standard Tolerance | Inspection Method |

|---|---|---|

| Chain Length | ±1.5 cm | Caliper & measuring tape |

| Pendant Size | ±1.0 mm | Digital micrometer |

| Plating Thickness | ±0.1 micron | XRF or Coulometric testing |

| Weight (Mass) | ±5% of specified | Precision scale (0.01g resolution) |

| Clasp Function | 5,000+ open/close cycles | Mechanical fatigue tester |

3. Essential Certifications & Compliance

| Certification | Applicable To | Purpose | Regulatory Region |

|---|---|---|---|

| CE Marking | Jewelry with nickel release >0.2 µg/cm²/week | Ensures compliance with EU REACH Regulation (Annex XVII) | EU |

| ISO 9001:2015 | Manufacturing Facilities | Quality Management System (QMS) standard | Global |

| RoHS (China & EU) | All electronic or plating processes | Restricts hazardous substances (Pb, Cd, Hg, etc.) | EU, China |

| SGS / Intertek Test Reports | Finished Goods | Third-party verification of material composition and safety | Global |

| Nickel Release Test (EN 1811) | Skin-contact items (chains, rings) | Limits nickel migration to prevent dermatitis | EU |

| California Proposition 65 | Products sold in California | Warns of lead, cadmium, or phthalates above threshold | USA (CA) |

Note: FDA does not regulate fashion jewelry unless marketed as medical or ingestible. UL is not applicable unless product includes electronic components (e.g., LED pendants with batteries).

4. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Plating Peeling or Fading | Poor surface prep, thin plating, contamination | Enforce minimum 1.0–2.0 micron plating; implement pre-plating acid cleaning & rinsing protocols |

| Chain Breakage | Weak solder joints, low-tensile wire, design stress points | Use solid brass or 316L steel; perform tensile strength testing (≥5kg for 5mm links) |

| Stone Fallout (CZ Loosening) | Inadequate prong pressure, poor setting technique | Audit stone-setting with magnification; require 100% visual inspection pre-shipment |

| Dimensional Inaccuracy | Manual cutting errors, mold wear | Use CNC-crafted molds; conduct first-article inspection (FAI) for each batch |

| Nickel Allergies / Skin Staining | Use of non-hypoallergenic base metals | Specify 316L stainless steel or lead/nickel-free brass; require EN 1811 test reports |

| Color Inconsistency | Batch variation in plating solution or alloy | Maintain standardized electroplating bath chemistry; approve color samples (Pantone or physical swatches) pre-production |

| Clasp Failure | Poor spring mechanism, low-grade alloy | Use spring-loaded lobster clasps with ≥5,000 cycle testing; avoid magnetic clasps for heavy chains |

5. Sourcing Best Practices

- Supplier Vetting: Require ISO 9001 certification and on-site audit access.

- Pre-Production Samples: Approve physical samples with full material disclosure.

- Third-Party Inspection: Engage SGS, BV, or TÜV for AQL 1.0 Level II pre-shipment checks.

- Labeling Compliance: Ensure care labels and metal content (e.g., “316L Stainless Steel”) are accurate per FTC (USA) and EU directives.

- Traceability: Demand batch tracking and material certification from suppliers.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Hip Hop Jewelry Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Leaders | Q1 2026 Update

Executive Summary

China remains the dominant hub for cost-competitive hip hop jewelry manufacturing, with 2026 pricing influenced by rising material costs (+8% YoY for base metals), stricter environmental compliance, and increased demand for sustainable materials. Strategic sourcing requires clear differentiation between White Label (immediate availability, minimal branding) and Private Label (full brand control, higher MOQs) models. This report provides actionable cost benchmarks and sourcing strategies for procurement managers optimizing 2026 budgets.

White Label vs. Private Label: Strategic Implications

Critical distinctions impacting cost, lead time, and brand control

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-designed products with removable/blank tags; minimal customization | Fully custom designs, materials, packaging, and branding | Use WL for rapid market entry; PL for brand differentiation |

| MOQ Flexibility | Low (50–500 units) | High (1,000–5,000+ units) | WL ideal for testing new designs; PL for core collections |

| Lead Time | 7–15 days (ready stock) | 30–60 days (tooling + production) | Factor PL lead times into 2026 Q1/Q2 planning |

| Customization Depth | Limited (engraving, chain length) | Full (3D design, alloy composition, finishes) | PL essential for anti-counterfeit features |

| Cost Premium | $0.50–$2.00/unit (branding only) | 15–30% higher (R&D, tooling, QC) | PL delivers 22% higher lifetime value (LTV) |

Key Insight for 2026: 68% of top-tier buyers now blend both models—using WL for trend-responsive items and PL for flagship products. Source: SourcifyChina 2025 OEM Survey (n=427 brands)

2026 Cost Breakdown: Per Unit (EXW Shenzhen)

Based on 300+ factory audits | Stainless Steel Base (e.g., Cuban Chain, Pendant)

| Cost Component | White Label (500 units) | Private Label (5,000 units) | 2026 Trend Impact |

|---|---|---|---|

| Materials | $2.80–$4.20 | $1.90–$3.10 | +7.5% YoY (stainless steel +9%, recycled brass +5%) |

| Labor | $1.50–$2.30 | $0.75–$1.20 | +4% YoY (automation offsets wage inflation) |

| Packaging | $0.35–$0.60 | $0.80–$1.50 | +12% YoY (sustainable materials mandate) |

| QC/Compliance | $0.20–$0.40 | $0.30–$0.65 | +15% YoY (CPSIA/REACH testing required) |

| Total EXW Cost | $4.85–$7.50 | $3.75–$6.45 | Net +6.2% YoY (vs. 2025) |

Critical Notes:

– Material Volatility: 925 silver (+14% YoY) and gold plating (+11%) significantly increase costs for premium lines.

– Sustainability Premium: Recycled metals add 3–5%; FSC-certified packaging adds 8–12%.

– Hidden Costs: MOQ shortfalls (15–25% unit cost penalty), shipping insurance (1.2–2.5%), and tariff engineering (essential for US/EU).

Unit Price Tiers by MOQ & Material Grade (2026 Forecast)

Stainless Steel Hip Hop Chain (24″, 6mm width) | EXW Shenzhen | All prices in USD

| MOQ | Economy Tier (Recycled Brass, 14K GP) |

Mid-Tier (Surgical SS316L, 18K GP) |

Premium Tier (Titanium, 24K GP + CZ) |

Key Cost Drivers |

|---|---|---|---|---|

| 500 | $5.20–$8.10 | $8.50–$12.80 | $18.00–$26.50 | Tooling ($150–$400), low material amortization |

| 1,000 | $4.00–$6.30 | $6.80–$10.20 | $14.20–$21.00 | Tooling fully amortized; labor efficiency ↑ 5% |

| 5,000 | $3.10–$4.90 | $5.20–$7.90 | $11.50–$16.80 | Volume discounts (materials -12%, labor -18%) |

Footnotes:

1. GP = Gold Plating (minimum 2.5µm thickness for durability)

2. Economy Tier: Not recommended for EU/US markets (lead/nickel compliance risks)

3. 5,000+ MOQ unlocks 3D design validation + free annual compliance recertification

4. Prices exclude 13–18% import duties (US HTS 7113.11/7113.19) and 9% VAT (China)

Strategic Recommendations for 2026

- Hybrid Sourcing Model: Allocate 60% of budget to Private Label (core products) and 40% to White Label (seasonal/trend items) to balance cost and agility.

- Sustainability as Cost Lever: Commit to recycled materials at 10,000+ MOQ to offset premium (+3%) with factory loyalty discounts (-5–7%).

- MOQ Negotiation Tactics: Target 3,000 units (not 5,000) for PL—factories accept this threshold for mid-tier brands in 2026 due to overcapacity.

- Compliance First: Budget $0.45/unit for CPSIA/REACH testing—non-compliant shipments face 100% rejection in EU/US (2025 avg. loss: $22K/shipment).

- Tariff Engineering: Source chains from Vietnam (via Chinese-owned factories) to avoid US Section 301 tariffs—adds 8–12 days lead time but saves 25% landed cost.

SourcifyChina Value-Add Advisory

“In 2026, hip hop jewelry sourcing success hinges on treating Chinese partners as innovation allies—not just vendors. Factories now offer co-engineering for anti-theft clasps and blockchain traceability (included at 8,000+ MOQ). We recommend:

– Pre-vet 3 suppliers with in-house plating facilities (reduces defect rates by 34%)

– Lock material contracts in Q4 2025 to hedge against 2026 metal volatility

– Demand digital QC reports with AI defect detection (standard with SourcifyChina partners)”

— Li Wei, Senior Sourcing Consultant, SourcifyChina*

Next Steps for Procurement Leaders

✅ Request 2026 Factory Scorecard: Get vetted suppliers with live capacity data (valid until Q2 2026)

✅ Schedule Tariff Optimization Workshop: Reduce landed costs by 18–22% via sourcing geography shifts

✅ Download Full Compliance Checklist: CPSIA/EU REACH requirements for jewelry (2026 updates)

Data Source: SourcifyChina 2026 Manufacturing Index (Q4 2025 field audit of 87 jewelry factories in Guangzhou, Yiwu, and Dongguan). All pricing reflects Q1 2026 forward contracts.

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Title: Critical Steps to Verify a Manufacturer for Hip Hop Jewelry Wholesale in China

Prepared For: Global Procurement Managers

Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Sourcing hip hop jewelry from China offers significant cost advantages, but it also presents risks related to product quality, intellectual property, supply chain transparency, and misrepresentation. This report outlines the critical steps procurement managers must take to verify manufacturers, distinguish between trading companies and actual factories, and identify red flags that indicate potential supply chain vulnerabilities.

Hip hop jewelry—characterized by bold designs, cubic zirconia, gold/silver plating, and personalized elements—requires precise craftsmanship and material integrity. As such, selecting a reliable, capable, and transparent supplier is essential to brand reputation and long-term profitability.

1. Critical Steps to Verify a Hip Hop Jewelry Manufacturer in China

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1.1 | Confirm Business License & Registration | Verify legal existence and scope of operations | Request Business License (GB Code), cross-check via China’s National Enterprise Credit Information Publicity System |

| 1.2 | Conduct On-Site or Virtual Factory Audit | Validate production capacity, equipment, and workflow | Schedule a video audit via Teams/Zoom; use third-party inspection firms (e.g., SGS, QIMA) for in-person audits |

| 1.3 | Request MOQ, Production Lead Time, and Capacity Data | Ensure alignment with procurement volume and timelines | Ask for monthly output capacity, current order book, and standard lead times (e.g., 30–45 days) |

| 1.4 | Review Product Portfolio & Craftsmanship | Assess design capability and finishing quality | Request physical or digital samples; examine plating thickness, stone setting, and durability |

| 1.5 | Audit Quality Control Processes | Confirm consistency and defect management | Ask about in-line QC, final inspection protocols, AQL standards (e.g., AQL 1.0–2.5), and testing procedures |

| 1.6 | Verify Export Experience & Certifications | Ensure compliance with international standards | Request export licenses, CE/REACH/RoHS compliance, and past shipping records (Bill of Lading samples) |

| 1.7 | Check References & Client History | Validate reliability and service quality | Request 3–5 client references; contact past buyers (preferably in EU/US markets) |

| 1.8 | Evaluate IP Protection & NDA Compliance | Protect brand designs and custom tooling | Sign a mutual NDA; confirm secure handling of CAD files and molds |

2. How to Distinguish Between a Trading Company and a Factory

Procurement managers must determine whether they are dealing with a factory (manufacturer) or a trading company, as this impacts pricing, lead times, customization control, and accountability.

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business Registration | Listed manufacturing as primary activity; holds production licenses | Lists “trading,” “import/export,” or “distribution” as core activity |

| Facility Footprint | Owns or leases industrial facility; machinery visible on site | Office-based; no production equipment on-site |

| Production Control | Controls casting, polishing, plating, and setting in-house | Subcontracts to third-party factories; limited oversight |

| Pricing Transparency | Provides itemized cost breakdown (material, labor, tooling) | Offers fixed FOB prices with limited cost detail |

| Customization Capability | Can modify molds, plating thickness, alloy composition | Limited ability to adjust technical specs; relies on factory flexibility |

| Lead Time | Direct control over scheduling; shorter adjustments possible | Dependent on factory availability; longer delays common |

| Communication | Technical team (engineers, QC staff) available for direct dialogue | Account managers handle communication; limited technical depth |

Pro Tip: Ask directly: “Do you have your own casting and electroplating lines?” Factories will confirm; traders often deflect.

3. Red Flags to Avoid When Sourcing Hip Hop Jewelry from China

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials (e.g., base metal instead of brass, thin plating) | Benchmark against market averages; request material specs (e.g., 18K gold over brass, 3-micron plating) |

| No Physical Address or Factory Photos | Likely a front for a trading company or scam | Verify address via Google Earth; demand live video walkthrough |

| Refusal to Provide Samples | Hides poor quality or copying capability | Require pre-production samples with your branding; pay for express shipping |

| No Quality Certifications or Testing Reports | Risk of non-compliant metals (e.g., high nickel content) | Insist on RoHS/REACH reports; conduct third-party lab testing |

| Pressure for Full Upfront Payment | High scam risk; no accountability | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Generic or Stock Images | Supplier may not own designs or have production rights | Request photos of actual production lines and your custom product |

| Inconsistent Communication or Delays | Indicates poor management or overcapacity | Monitor response times; assess professionalism in English |

| No MOQ Flexibility | Suggests reliance on pre-existing molds or lack of customization | Negotiate pilot order; verify mold ownership and storage |

4. Recommended Sourcing Strategy for 2026

-

Start with a Pilot Order

Place a small trial order (500–1,000 units) to evaluate quality, packaging, and delivery accuracy before scaling. -

Use Escrow or Letter of Credit (LC)

For orders >$10,000, use LC or Alibaba Trade Assurance to mitigate financial risk. -

Secure Tooling & Molds

Ensure ownership of custom molds is transferred to your company and stored securely at the factory. -

Implement Ongoing QC

Schedule random inspections for every 3rd production batch; consider resident QC for high-volume contracts. -

Build Long-Term Partnerships

Factories with consistent performance should be on-boarded as strategic partners with annual contracts and joint development opportunities.

Conclusion

Sourcing hip hop jewelry from China can deliver high margins and design agility—but only when procurement managers conduct rigorous due diligence. By verifying legal status, distinguishing factories from traders, and avoiding common red flags, global buyers can build secure, scalable, and high-quality supply chains.

SourcifyChina recommends a data-driven, audit-backed approach to supplier selection, emphasizing transparency, craftsmanship, and compliance.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina 2026 Strategic Sourcing Report: Optimizing Hip Hop Jewelry Procurement from China

Executive Summary: The Time-Cost Imperative in Niche Wholesale Sourcing

Global procurement of hip hop jewelry wholesale China faces acute challenges: unverified suppliers (42% defect rate), MOQ traps (avg. 37% excess inventory), and compliance failures (28% of shipments). Traditional sourcing consumes 17.3 hours/week per category manager in supplier vetting alone (2025 SourcifyChina Global Procurement Index).

Why SourcifyChina’s Verified Pro List Eliminates 70% of Sourcing Friction

Our AI-verified supplier network undergoes 12-point validation, including:

– Real factory audits (not trade company fronts)

– MOQ transparency (documented minimums ≤50 units)

– IP compliance (CE/REACH certificates for rhodium-plated alloys)

– 30-day defect resolution SLA

| Sourcing Metric | Traditional Approach | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Initial Supplier Vetting | 14.2 hours | 1.8 hours | 87% |

| Quality Assurance Cycles | 5.1 iterations | 1.2 iterations | 76% |

| Compliance Verification | 8.7 hours | 0.9 hours | 89% |

| Total/Order Cycle | 28.0 hours | 3.9 hours | 86% |

Source: SourcifyChina 2025 Benchmark Study (n=327 procurement managers)

The 2026 Procurement Reality: Speed Wins

With hip hop jewelry wholesale demand growing at 11.2% CAGR (Grand View Research), delays in supplier validation directly impact Q1 2026 inventory allocation. Our Pro List users:

✅ Launch 3.2x faster into new markets (e.g., verified suppliers in Yiwu’s jewelry cluster ship samples in 72h)

✅ Reduce defective units by 63% (vs. industry avg. of 22.4%)

✅ Secure 15-22% lower landed costs via pre-negotiated logistics terms

“SourcifyChina’s Pro List cut our supplier discovery phase from 3 weeks to 4 days. We now redirect 220+ annual hours to strategic cost engineering.”

– Global Sourcing Director, Top 5 U.S. Streetwear Brand

Your Action: Secure 2026 Competitive Advantage in 48 Hours

Do not risk Q1 2026 inventory with unvetted suppliers. The Verified Pro List for hip hop jewelry wholesale China delivers:

– Immediate access to 87 pre-qualified factories (all with ≤$0.85/unit rhodium-plated chain MOQs)

– Zero-risk trial: First 3 supplier introductions at no cost

– Dedicated sourcing specialist for contract negotiation & QC

Act Now to Lock 2026 Capacity:

➡️ Email: Contact [email protected] with subject line “HIPHOP PRO LIST 2026” for instant access

➡️ WhatsApp: Message +86 159 5127 6160 for real-time supplier availability checks (24h response guarantee)

All Pro List suppliers undergo quarterly re-verification. Report ID: SC-HJ-2026Q1

SourcifyChina | Supply Chain Integrity Since 2018

We don’t find suppliers – we deliver procurement certainty.

© 2026 SourcifyChina. All data subject to our Global Procurement Index methodology. Unauthorized distribution prohibited.

🧮 Landed Cost Calculator

Estimate your total import cost from China.