The global market for industrial hardware components, including hinge latches, is experiencing steady growth driven by rising demand in automotive, construction, and electronics sectors. According to Grand View Research, the global hinges market size was valued at USD 25.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects increased activity in the hardware market, citing infrastructure development and smart building innovations as key growth accelerators. This expanding demand has intensified competition among manufacturers, with innovation in durability, corrosion resistance, and precision engineering becoming critical differentiators. As industries prioritize reliability and compliance with international standards, a select group of hinge latch manufacturers has emerged as leaders in quality, scalability, and technological advancement—positioning them at the forefront of this growing market.

Top 9 Hinge Latch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Architectural Builders Hardware Mfg. Inc.

Domain Est. 1997

Website: abhmfg.com

Key Highlights: (ABH) is a high quality manufacturer of Overhead Holders & Stops, Hospital Latches, Electromagnetic Holders, Pivots, Strikes and Rescue Stops, Aluminum Hinges, ……

#2 Precision Hinge, Latch, and Fastener Manufacturer

Domain Est. 1998

Website: paneloc.com

Key Highlights: Discover precision-engineered hinges, latches, and fasteners from Paneloc Corporation. Trusted by aerospace, military, and industrial leaders, ……

#3 Hinges and Hardware Inc.

Domain Est. 2015

Website: latchmanufacturers.com

Key Highlights: Hinges and Hardware Inc. is a leading company specializing in the design, manufacturing, and distribution of high-quality latches and related hardware ……

#4 DIRAK

Domain Est. 1996

Website: us.dirak.com

Key Highlights: We develop tailor-made solutions for a wide range of applications! Over 5000 products – find the perfect solution here! Find out more now!…

#5 American Made Custom Hinge Manufacturer,American Made …

Domain Est. 2000

Website: knuthhinge.com

Key Highlights: For over 50 years, Knuth Hinge’s engineering-focused team have been designing and manufacturing precision hinges and latches for customers….

#6 Hinge Outlet

Domain Est. 2004

Website: hingeoutlet.com

Key Highlights: Hinge Outlet, Inc. offers a wide range of spring hinges, residential door hinges, ball bearing hinges, and more. Find out more about our products today….

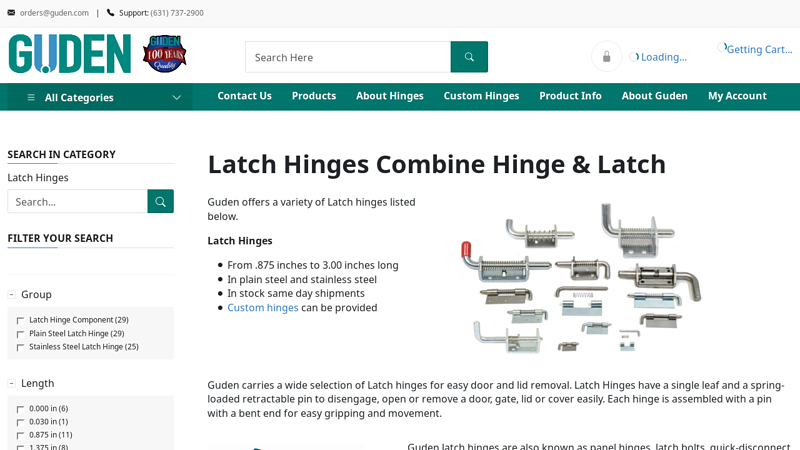

#7 Combination Latch Hinges

Domain Est. 1995

Website: guden.com

Key Highlights: Guden carries a wide selection of Latch hinges for easy door and lid removal. Latch Hinges have a single leaf and a spring-loaded retractable pin….

#8 EMKA

Domain Est. 1996

Website: emka.com

Key Highlights: World market leader for locks and latches, hinges and sealings used in switch and control cabinets for electronics and electrical engineering….

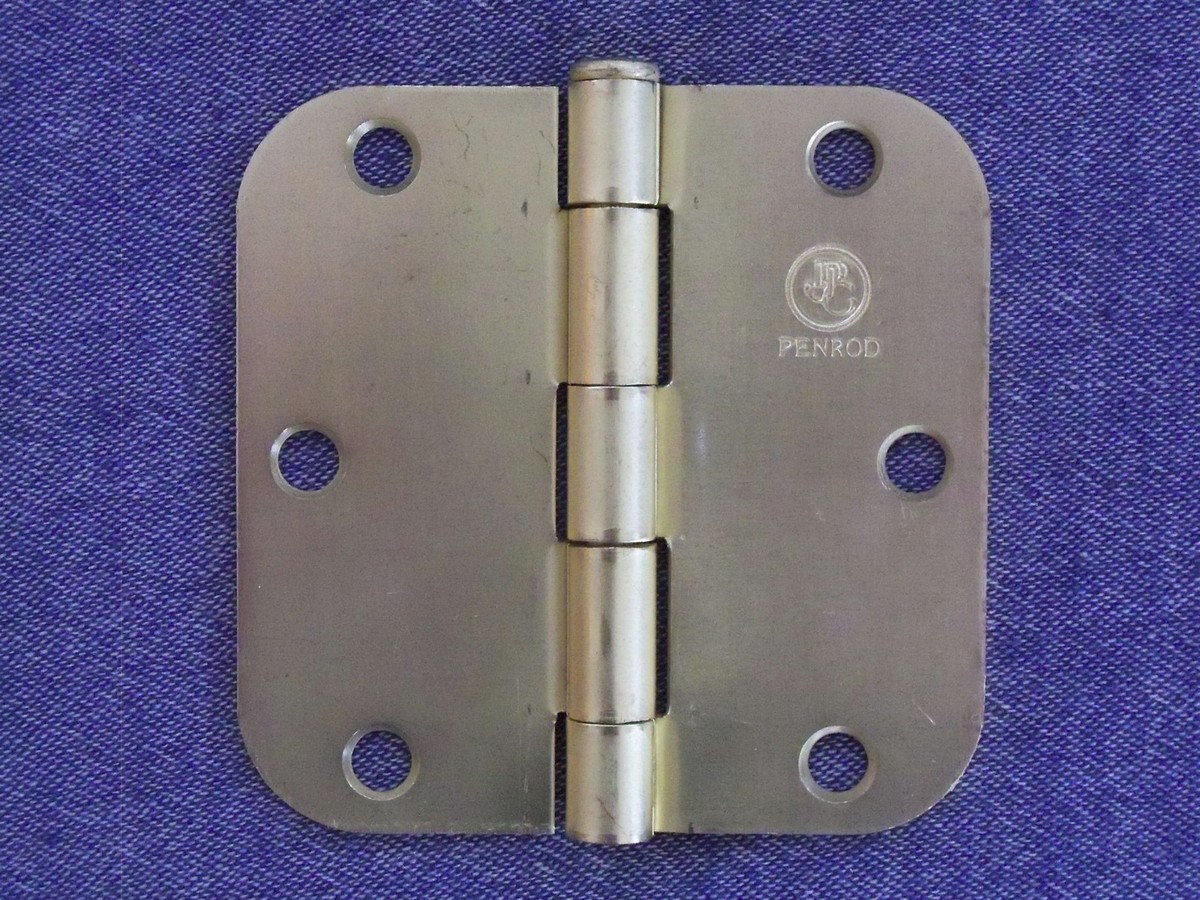

#9 Penrod

Domain Est. 2017

Website: hardwarebypenrod.com

Key Highlights: Penrod supplies high-quality door hardware—hinges, weather stripping, sweeps, barn door hardware, and PVC mouldings—with 35+ years of trusted expertise….

Expert Sourcing Insights for Hinge Latch

H2: Projected 2026 Market Trends for Hinge Latch

The global hinge latch market is anticipated to experience steady growth by 2026, driven by rising demand across residential, commercial, and industrial sectors. Key trends shaping the market include advancements in smart building technologies, increased focus on security and automation, and the expansion of construction activities in emerging economies.

One of the dominant trends is the integration of hinge latches with smart locking systems. As smart homes and automated buildings gain popularity, manufacturers are developing hinge latches compatible with electronic access control, IoT connectivity, and remote monitoring. This shift is particularly evident in North America and Europe, where consumers prioritize convenience and enhanced security.

Sustainability is also becoming a critical factor. By 2026, there is an expected rise in demand for eco-friendly materials and energy-efficient designs in hardware components. Manufacturers are responding by using recycled metals and low-impact production processes to meet green building certifications like LEED and BREEAM.

Regionally, the Asia-Pacific market is projected to witness the highest growth due to rapid urbanization, infrastructure development, and increasing investments in smart cities—particularly in China, India, and Southeast Asia. Meanwhile, mature markets in North America and Western Europe will focus on product innovation and retrofitting existing structures with modern hinge latch solutions.

Additionally, supply chain optimization and digitalization in manufacturing (Industry 4.0) are enabling faster customization and shorter lead times, allowing hinge latch producers to better meet specific customer requirements.

In summary, the 2026 hinge latch market will be defined by technological integration, sustainability, regional expansion, and digital manufacturing—positioning the industry for transformation beyond traditional mechanical applications.

Common Pitfalls Sourcing Hinge Latch (Quality, IP)

Sourcing hinge latches—especially for industrial, automotive, or consumer applications—can be deceptively complex. Overlooking quality and intellectual property (IP) considerations can lead to product failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Poor Material and Build Quality

Many low-cost suppliers use substandard materials such as brittle plastics or low-grade zinc alloys, which compromise durability and load-bearing capacity. Poor manufacturing processes can result in inconsistent tolerances, leading to alignment issues, premature wear, or latch failure under stress.

Lack of Compliance and Certification

Sourcing hinge latches without verifying certifications (e.g., RoHS, REACH, UL, or IP ratings for ingress protection) can result in non-compliance with regional safety and environmental regulations. This is especially critical in electronics, medical devices, and outdoor equipment.

Insufficient Environmental Resistance

Failing to assess resistance to corrosion, UV exposure, temperature extremes, or moisture can lead to premature degradation. For example, using a hinge latch not rated for outdoor use in a marine environment can result in rust and mechanical failure.

Inadequate Load and Cycle Testing Data

Suppliers may provide optimistic performance claims without verifiable testing data. Without documented cycle life (e.g., 10,000+ open/close cycles) or load capacity testing, long-term reliability remains uncertain.

Intellectual Property (IP) Infringement Risks

Sourcing from manufacturers producing look-alike versions of patented hinge latch designs can expose your company to legal liability. Many original designs are protected by utility or design patents, and using counterfeit or cloned products—even unknowingly—can lead to injunctions or fines.

Lack of Traceability and Documentation

Suppliers may not provide detailed material certifications, design specifications, or test reports. This lack of traceability makes it difficult to ensure quality consistency across batches or perform root cause analysis during field failures.

Overlooking Customization and Long-Term Support

Some suppliers offer attractive upfront pricing but lack the capability for customization or ongoing technical support. This becomes problematic when design iterations are needed or when scaling production.

Dependency on Single or Unverified Suppliers

Relying on a single source—especially one without a proven track record—increases supply chain risk. Unexpected production halts, quality deviations, or IP disputes can disrupt operations if no qualified alternatives exist.

To mitigate these risks, conduct thorough due diligence on suppliers, request samples for independent testing, verify IP status through patent databases, and establish clear quality agreements upfront.

Logistics & Compliance Guide for Hinge Latch

This guide provides essential information on the logistics handling and regulatory compliance requirements for the Hinge Latch product to ensure safe, efficient distribution and adherence to international and regional standards.

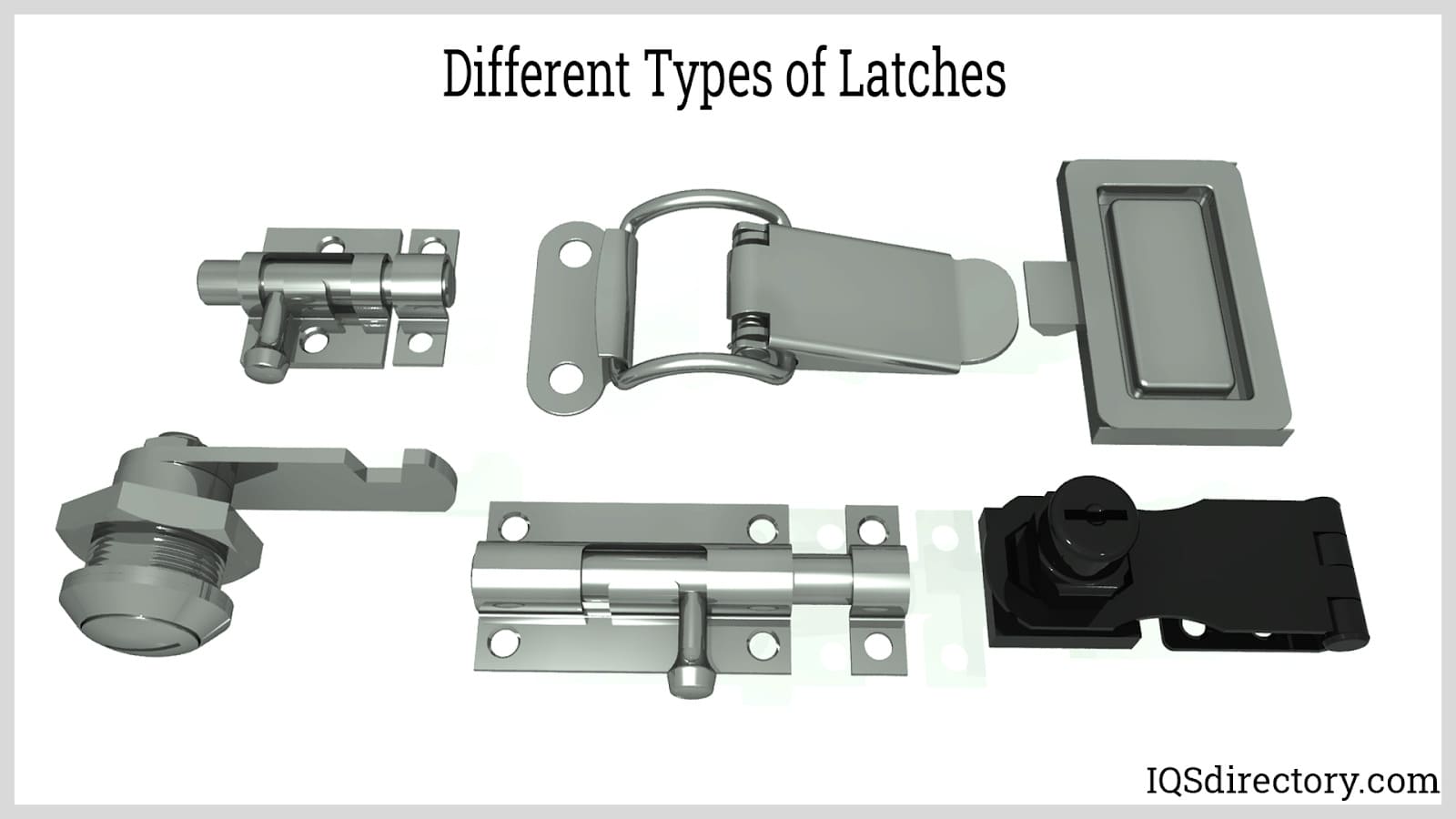

Product Classification & Specifications

The Hinge Latch is classified as a mechanical hardware component used in doors, enclosures, and access panels. Key specifications include material composition (typically zinc alloy or stainless steel), dimensions, weight (approx. 50–150g per unit), and packaging type (blister pack or bulk polybag). Accurate classification under HS Code 8302.41 (other base metal mountings, fittings, and similar articles) is required for customs clearance.

Packaging & Labeling Requirements

All Hinge Latches must be packaged to prevent damage during transit. Retail units require tamper-evident blister packaging with UPC/EAN barcodes, product ID, and safety warnings. Bulk shipments should use sturdy corrugated cartons with internal dividers. Outer packaging must display: product name, quantity, net weight, manufacturer details, country of origin (e.g., “Made in China”), and handling symbols (e.g., “Fragile”, “This Way Up”).

Shipping & Transportation

Standard shipping methods include air freight (for urgent orders) and ocean freight (for bulk shipments). Palletized loads must comply with ISPM 15 regulations for wooden pallets (heat-treated and stamped). Maximum stack height is 8 layers per pallet. Ensure temperature and humidity controls during transit to prevent corrosion, especially for stainless steel variants. Use carriers compliant with IATA (air) or IMDG (sea) regulations as applicable.

Import/Export Compliance

Export documentation must include a Commercial Invoice, Packing List, and Bill of Lading/Air Waybill. Depending on destination, additional certifications may be required, such as a Certificate of Origin or FCC/CE declarations if used in electrical enclosures. Verify import tariffs and restrictions in the destination country—e.g., EU REACH and RoHS compliance is mandatory for metal components.

Regulatory & Safety Standards

Hinge Latches must comply with applicable safety and material regulations:

– RoHS (EU): Restriction of hazardous substances—lead, cadmium, mercury levels must be below thresholds.

– REACH (EU): Registration, Evaluation, Authorization of Chemicals—SVHC screening required.

– Proposition 65 (California, USA): Warning labels if containing listed chemicals like lead.

– UL/CSA (if applicable): For latches used in certified enclosures or fire-rated doors.

Customs Clearance & Duties

Provide accurate Harmonized System (HS) code 8302.41 to customs authorities. Duty rates vary by country (e.g., 3.5% in the U.S., 2.7% in the EU). Use Incoterms clearly (e.g., FOB, DDP) to define responsibility for duties and taxes. Retain compliance documentation for a minimum of 5 years.

Returns & Reverse Logistics

Establish a returns process for defective or damaged units. Returned items must be inspected, documented, and either refurbished or disposed of per WEEE or local waste regulations. Coordinate with logistics partners for cost-effective reverse shipping solutions.

Sustainability & Environmental Compliance

Ensure manufacturing and packaging processes follow ISO 14001 environmental management standards. Use recyclable materials where possible. Report environmental impact data annually, including carbon footprint per shipment, to support corporate sustainability goals.

In conclusion, sourcing hinge latches requires careful consideration of factors such as material quality, dimensional specifications, load-bearing capacity, environmental resistance, and compliance with industry standards. Evaluating suppliers based on reliability, cost-efficiency, lead times, and their ability to support customization is crucial to ensuring consistent product performance and supply chain continuity. By establishing clear sourcing criteria and conducting thorough supplier assessments, organizations can secure hinge latches that meet both functional requirements and long-term operational needs, ultimately contributing to improved product durability and customer satisfaction.