The global ceramic adhesive market is experiencing robust growth, driven by increasing demand across aerospace, automotive, electronics, and industrial manufacturing sectors. According to a 2023 report by Grand View Research, the global ceramic adhesives market was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This surge is attributed to the rising need for materials capable of withstanding extreme temperatures and harsh environments, particularly in high-performance applications. High-temperature ceramic glues—formulations engineered to bond ceramics, metals, and composites at temperatures exceeding 1,000°C—are playing a pivotal role in enabling advanced thermal management and structural integrity. As innovation accelerates and industries push the limits of material performance, a select group of manufacturers has emerged at the forefront of this niche yet critical segment. Here are the top 7 high-temperature ceramic glue manufacturers leading the charge in product development, reliability, and global reach.

Top 7 High Temp Ceramic Glue Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

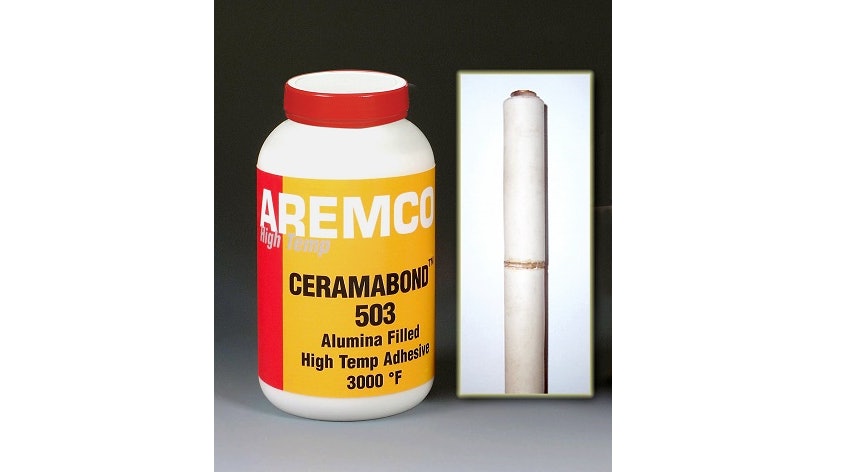

#1 Aremco

Domain Est. 1996

Website: aremco.com

Key Highlights: Aremco is a leading global developer and producer of high temperature ceramics, adhesives and coatings. Our solutions meet the most demanding applications….

#2 Permabond Adhesive

Domain Est. 1996

Website: permabond.com

Key Highlights: Permabond manufactures many types of industrial adhesive products to suit the varied needs of a number of different industries….

#3 Adhesives, Sealants and Coatings

Domain Est. 1996

Website: masterbond.com

Key Highlights: Master Bond is a leading manufacturer of epoxy adhesives, sealants, coatings, potting and encapsulation compounds. Master Bond specializes in epoxies, ……

#4 Cotronics

Domain Est. 1997

Website: cotronics.com

Key Highlights: Cotronics manufactures and distributes high temp adhesives, epoxies, ceramics, putties, sealants, conductive and insulating adhesives, insulation materials….

#5 High Temperature Ceramic Adhesive for ceramic tiles

Domain Est. 2019

Website: wear-ceramic.com

Key Highlights: We’re professional high temperature ceramic adhesive for ceramic tiles manufacturers and suppliers in China, specialized in providing high quality ceramic ……

#6 High temperature adhesives

Domain Est. 2004

Website: polytec-pt.com

Key Highlights: The high-temperature-resistant adhesives, casting compounds and coatings that we offer consist primarily of ceramic, refractory materials….

#7 High temperature ceramic adhesive

Domain Est. 2006

Website: final-materials.com

Key Highlights: Ceramic adhesives can be used up to 2000°C. Final Advanced Materials provides a wide range of ceramic adhesives Cotronics….

Expert Sourcing Insights for High Temp Ceramic Glue

H2: Projected Market Trends for High-Temp Ceramic Glue in 2026

The high-temperature ceramic glue market is poised for significant growth and transformation by 2026, driven by advancements in material science, rising industrial automation, and expanding applications across high-performance sectors. This H2 analysis explores key market dynamics, technological developments, regional trends, and growth drivers shaping the industry landscape.

-

Increased Demand from Aerospace and Defense

By 2026, the aerospace and defense sectors are expected to be leading consumers of high-temp ceramic glue. The push for lighter, more heat-resistant materials in jet engines, hypersonic vehicles, and spacecraft thermal protection systems will boost demand. Ceramic adhesives capable of withstanding temperatures exceeding 1,200°C are critical for bonding ceramic matrix composites (CMCs), contributing to fuel efficiency and durability. -

Growth in Electric Vehicles (EVs) and Energy Storage

The proliferation of electric vehicles and next-generation battery technologies will drive demand for high-temp ceramic glues in battery pack assembly, thermal management systems, and power electronics. These adhesives offer superior thermal conductivity and electrical insulation—essential for maintaining performance under high thermal loads. Manufacturers are increasingly formulating ceramic-based thermal interface materials (TIMs) to meet EV safety and longevity requirements. -

Advancements in Material Formulations

Innovation in nanotechnology and ceramic-polymer hybrid systems is expected to dominate R&D efforts by 2026. New formulations will offer improved flexibility, faster curing times, and enhanced adhesion to diverse substrates (e.g., metals, ceramics, and composites). Solvent-free, environmentally friendly adhesives will gain market share due to tightening global regulations on volatile organic compounds (VOCs). -

Expansion in Industrial and Manufacturing Applications

High-temp ceramic glues will see increased adoption in industrial furnaces, 3D printing of ceramics, and semiconductor manufacturing. The need for reliable bonding solutions in extreme environments—such as in glass-to-metal seals or high-temperature sensors—will expand opportunities in automation and smart manufacturing. -

Regional Market Shifts

Asia-Pacific, particularly China, Japan, and South Korea, is projected to lead market growth due to robust electronics manufacturing, government investment in advanced materials, and expanding aerospace programs. North America will maintain strong demand driven by defense spending and innovation in clean energy. Europe’s growth will be bolstered by green technology initiatives and strict emissions standards, increasing the use of high-performance adhesives in automotive and renewable energy sectors. -

Supply Chain and Raw Material Challenges

Despite growth, the market may face volatility in raw material supply (e.g., rare earth oxides, silicon-based precursors). Companies are expected to invest in vertical integration and alternative sourcing strategies to mitigate risks. Recycling and reprocessing of ceramic waste materials may emerge as a sustainable trend. -

Competitive Landscape and Strategic Collaborations

By 2026, major players such as Henkel, 3M, Permabond, and Morgan Advanced Materials are likely to expand their product portfolios through mergers, acquisitions, and partnerships with research institutions. Customized adhesive solutions for niche applications will become a key differentiator in a competitive market.

In conclusion, the 2026 high-temp ceramic glue market will be characterized by technological innovation, sector-specific customization, and strong growth in high-tech industries. Companies that prioritize sustainability, performance scalability, and global supply chain resilience will be best positioned to capture emerging opportunities.

Common Pitfalls When Sourcing High-Temperature Ceramic Glue (Quality & IP)

Sourcing high-temperature ceramic glue requires careful attention to both performance specifications and intellectual property (IP) considerations. Overlooking these aspects can lead to product failure, safety hazards, regulatory non-compliance, and legal risks. Below are key pitfalls to avoid:

Inadequate Performance Verification

Many suppliers claim extreme temperature resistance (e.g., 1200°C+), but actual performance varies significantly based on formulation, substrate, and environmental conditions. Without rigorous testing under real-world conditions—such as thermal cycling, vibration, or chemical exposure—users risk adhesive failure. Always demand third-party test data and conduct application-specific validation.

Misunderstanding Chemical Composition and Limitations

Not all “ceramic” glues are created equal. Some are silicone-based with ceramic fillers, suitable up to ~300–400°C, while true inorganic ceramic adhesives (e.g., phosphate or silicate-based) withstand much higher temperatures. Confusing these types leads to premature degradation. Ensure the chemistry aligns with the intended operating environment, including oxidation, moisture, and thermal shock.

Overlooking Curing Requirements and Processing Constraints

High-temp ceramic adhesives often require specific curing conditions—such as elevated temperatures or extended cure times—that may not be feasible in production. Failing to account for these needs results in incomplete curing, reduced bond strength, and field failures. Confirm compatibility with existing manufacturing processes before selection.

Neglecting Intellectual Property (IP) Risks

Using or reverse-engineering proprietary adhesive formulations, even unintentionally, can expose companies to IP infringement claims. Suppliers may hold patents on unique chemistries, curing methods, or application techniques. Always verify freedom to operate (FTO), especially when developing or sourcing custom formulations. Use non-disclosure agreements (NDAs) and audit supplier IP documentation.

Relying Solely on Datasheets Without Due Diligence

Datasheets often present idealized performance under laboratory conditions. They may omit critical details like shelf life, storage conditions, or long-term durability. Overreliance on datasheets without engaging in technical discussions or requesting samples leads to mismatched expectations. Conduct pilot trials and consult with materials engineers.

Ignoring Regulatory and Environmental Compliance

Certain high-temp adhesives contain regulated substances (e.g., heavy metals, hazardous solvents). Using non-compliant products can result in failed audits, import restrictions, or liability. Ensure the adhesive meets relevant standards such as REACH, RoHS, or aerospace/material-specific regulations.

Selecting Based on Price Alone

Low-cost alternatives may use inferior raw materials or lack quality control, compromising performance and safety. The total cost of ownership—including rework, downtime, and failure risk—often outweighs initial savings. Prioritize suppliers with proven quality systems (e.g., ISO 9001) and traceable batch records.

By addressing these pitfalls proactively, organizations can ensure reliable performance, maintain IP integrity, and avoid costly setbacks in applications ranging from aerospace to industrial manufacturing.

H2: Logistics & Compliance Guide for High Temp Ceramic Glue

H2: Product Overview

High Temp Ceramic Glue is a specialized adhesive formulated to bond ceramics, metals, and other high-heat-resistant materials in extreme temperature environments (typically up to 1,200°C or higher, depending on formulation). Commonly used in industrial, automotive, aerospace, and DIY applications, this product requires careful handling, storage, and transportation to ensure performance, safety, and regulatory compliance.

1. Storage Requirements

- Temperature: Store in a cool, dry place between 10°C and 25°C (50°F–77°F). Avoid exposure to temperatures above 40°C (104°F) or below freezing.

- Humidity: Maintain relative humidity below 60% to prevent premature curing or moisture absorption.

- Containers: Keep in original, tightly sealed containers to prevent contamination and evaporation of solvents.

- Shelf Life: Typically 12 months from date of manufacture when stored properly. Check expiration date before use.

- Light Exposure: Protect from direct sunlight and UV radiation; store in opaque or amber containers if necessary.

2. Handling & Personal Protection

- Ventilation: Use only in well-ventilated areas. Local exhaust ventilation is recommended in enclosed workspaces.

- Personal Protective Equipment (PPE):

- Nitrile or chemical-resistant gloves

- Safety goggles or face shield

- Lab coat or protective clothing

- Respiratory protection (NIOSH-approved organic vapor respirator) if vapor or dust is present

- Avoid: Skin and eye contact. Do not ingest. Avoid inhalation of vapors or mists.

- Hygiene: Wash hands thoroughly after handling. Do not eat, drink, or smoke while using the product.

3. Transportation & Shipping

- Classification: Classified as a hazardous material under certain regulations (e.g., UN3082, ENVIRONMENTALLY HAZARDOUS SUBSTANCE, LIQUID, N.O.S., Class 9, PG III – if applicable based on formulation).

- Packaging:

- Use UN-certified packaging suitable for Class 9 or flammable liquids (if applicable).

- Inner containers must be leak-proof; outer packaging must be impact-resistant.

- Include absorbent material if shipping liquids.

- Labeling:

- Hazard labels (e.g., Class 9 – Environmentally Hazardous) as per UN Model Regulations.

- Proper shipping name and UN number.

- GHS pictograms if required (e.g., Health Hazard, Environmental Hazard).

- Documentation:

- Safety Data Sheet (SDS) must accompany shipments.

- Provide transport emergency cards (e.g., TREM card) if required.

- Modes of Transport:

- Road (ADR): Comply with ADR regulations for dangerous goods in Europe.

- Air (IATA): Follow IATA Dangerous Goods Regulations; may be restricted or require special approval.

- Sea (IMDG): Conform to IMDG Code; declare properly with marine pollutant marking if applicable.

4. Regulatory Compliance

- GHS Compliance:

- Label must include:

- Product identifier

- Signal word (e.g., “Warning” or “Danger”)

- Hazard statements (e.g., H315: Causes skin irritation)

- Precautionary statements (e.g., P280: Wear protective gloves)

- Pictograms (e.g., GHS07 for health hazard)

- REACH (EU): Ensure registration of substances if imported into the EU in quantities >1 metric ton/year.

- TSCA (USA): Verify all components are listed on the TSCA Inventory.

- Prop 65 (California): Check if any ingredients are listed as carcinogens or reproductive toxins.

- RoHS/REACH SVHC: Confirm absence of restricted heavy metals or substances of very high concern.

5. Disposal & Environmental Precautions

- Waste Disposal: Dispose of waste, empty containers, and spilled material in accordance with local, regional, and national regulations (e.g., EPA, EU Waste Framework Directive).

- Environmental Hazards: May be harmful to aquatic life. Avoid release into drains, soil, or waterways.

- Clean-up: Use absorbent materials (e.g., sand, vermiculite) for spills. Collect and dispose of as hazardous waste.

- Incineration: Dispose via licensed hazardous waste incinerator if permitted.

6. Emergency Procedures

- Spills:

- Evacuate non-essential personnel.

- Contain spill with absorbent material.

- Ventilate area and avoid ignition sources.

- Wear full PPE during clean-up.

- Fire:

- Use dry chemical, CO₂, or foam extinguishers.

- Firefighters should wear self-contained breathing apparatus (SCBA).

- Combustion may release toxic fumes (e.g., NOx, CO).

- First Aid:

- Skin Contact: Wash with soap and water. Remove contaminated clothing.

- Eye Contact: Rinse thoroughly with water for at least 15 minutes. Seek medical attention.

- Inhalation: Move to fresh air. Administer oxygen if needed. Seek medical help.

- Ingestion: Do NOT induce vomiting. Rinse mouth and seek immediate medical assistance.

7. Training & Documentation

- Ensure all personnel involved in handling, storage, or transport are trained in:

- Hazard communication (HazCom)

- Safe handling procedures

- Emergency response

- Keep up-to-date SDS (Safety Data Sheet) on file and accessible to all users.

- Maintain records of training, incidents, and waste disposal.

Note: Always consult the specific Safety Data Sheet (SDS) provided by the manufacturer for the exact formulation of your High Temp Ceramic Glue, as properties and regulatory classifications may vary.

This guide is for informational purposes only and does not replace official regulatory requirements. Users must comply with all applicable local, national, and international regulations.

In conclusion, sourcing a high-temperature ceramic glue requires careful consideration of several key factors including maximum operating temperature, bonding strength, chemical resistance, ease of application, and cure time. It is essential to select a product specifically engineered for the intended application—whether it involves industrial machinery, kilns, exhaust systems, or household ceramics—to ensure safety, durability, and long-term performance. Reputable suppliers and manufacturers with proven track records in high-temperature adhesives should be prioritized to guarantee product quality and consistency. By evaluating technical specifications, user reviews, and application requirements, businesses and individuals can make informed decisions and secure a reliable high-temperature ceramic adhesive that meets both performance standards and safety regulations.