The global cabinet hardware market is experiencing steady growth, driven by rising demand for modern kitchen designs and premium architectural millwork. According to Mordor Intelligence, the global cabinet hardware market was valued at USD 6.8 billion in 2023 and is projected to grow at a CAGR of 4.5% from 2024 to 2029. A key contributor to this expansion is the increasing preference for concealed or hidden hinges—particularly for inset cabinet doors, where clean lines and seamless integration are paramount. Inset cabinetry, often associated with custom and high-end kitchens, requires precision-engineered hinges that offer both functionality and aesthetic discretion. As homeowners and designers prioritize minimalist aesthetics without compromising usability, manufacturers specializing in high-performance hidden hinges are gaining prominence. This report highlights the top eight manufacturers excelling in hidden hinge solutions for inset cabinet doors, selected based on product innovation, load capacity, adjustability, durability testing, and market presence—offering architects, cabinetmakers, and renovators data-backed insights to inform sourcing decisions in a competitive landscape.

Top 8 Hidden Hinges For Inset Cabinet Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AIR The truly concealed hinge

Domain Est. 1997

Website: salice.com

Key Highlights: Air delivers full functionality to furniture manufacturers. It is inserted into the top and bottom of the cabinet and the door and is practically invisible….

#2 SOSS Invisible Hinge Archives

Domain Est. 1995

Website: soss.com

Key Highlights: Cabinet (8) … At SOSS®, we opened the door of innovation with our original invisible hinge, and continue to be pioneers in concealed door hardware….

#3 Hinges for furniture & offices

Domain Est. 1996

Website: hettich.com

Key Highlights: Hettich hinges offer practical solutions for every application. Find out more about: ✓ Fast-assembly hinges ✓ Damping ✓ Opening systems….

#4 Motion in cabinetry

Domain Est. 1998

Website: blum.com

Key Highlights: They’re three-dimensional. All Blum hinges come with side, depth and height adjustment, giving you a perfectly precise gap layout every time….

#5 Adjustable Cabinet Hinges

Domain Est. 2000

Website: hardwareresources.com

Key Highlights: Hardware Resources offers a vast selection of cabinet hardware including: cabinet hardware hinges, soft close cabinet hinges, ……

#6 Blum Inset Hidden Hinge

Domain Est. 2002

#7 Tectus Hinges

Domain Est. 2009

Website: tectushinges.com

Key Highlights: TECTUS is the most comprehensive concealed hinge system for premium flush doors. Easily adjustable in 3-Dimensions….

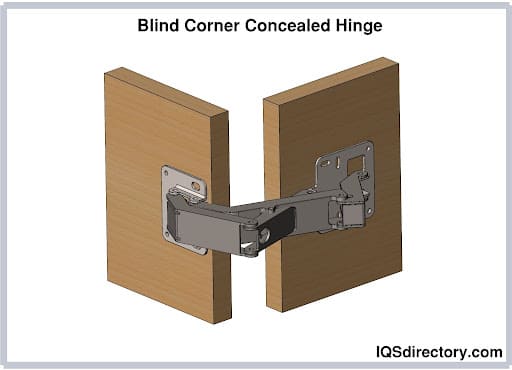

#8 Concealed Hinge Suppliers

Domain Est. 2015

Website: hingemanufacturers.org

Key Highlights: Cabinets with inset doors require invisible hinges; hence pivot concealed hinges are employed. They are made up of two flat leaves, the L bracket fastened to ……

Expert Sourcing Insights for Hidden Hinges For Inset Cabinet Doors

H2: 2026 Market Trends for Hidden Hinges for Inset Cabinet Doors

The global market for hidden hinges for inset cabinet doors is projected to experience steady growth through 2026, driven by evolving consumer preferences, advancements in kitchen design, and increasing demand for high-end, seamless cabinetry. This analysis explores key trends shaping the market landscape over the forecast period.

-

Rising Demand for Seamless Kitchen Aesthetics

Homeowners and designers are increasingly favoring minimalist and modern kitchen layouts where clean lines and flush surfaces dominate. Hidden hinges, especially those designed for inset doors, support this trend by eliminating visible hardware and enabling doors to sit perfectly flush with cabinet frames. This seamless integration is expected to boost demand, particularly in premium residential markets in North America, Europe, and parts of Asia-Pacific. -

Growth in High-End Residential Construction and Renovation

The expansion of luxury housing and the rise in kitchen remodeling projects are key drivers for hidden hinge adoption. Inset cabinetry—once reserved for custom, high-cost kitchens—is becoming more accessible due to improvements in manufacturing and installation techniques. As more mid-to-high-tier builders and renovators adopt inset door styles, the need for reliable, adjustable hidden hinges will rise. -

Technological Advancements in Hinge Design

Manufacturers are investing in R&D to improve the functionality and ease of installation of hidden hinges. Trends include soft-close mechanisms, enhanced adjustability (3D adjustment—vertical, horizontal, and depth), and increased durability. European brands like Blum, Grass, and Hafele continue to innovate, setting performance benchmarks. By 2026, smart hinges with integrated sensors or self-adjusting features may begin to emerge, particularly in smart home-integrated kitchens. -

Expansion of E-Commerce and DIY Markets

Online retail platforms are making high-quality hidden hinges more accessible to both professionals and DIY consumers. Detailed installation guides, video tutorials, and compatibility filters are lowering the barrier to entry for inset cabinetry in home renovation projects. This democratization of access is expected to expand the customer base beyond custom cabinet shops to include skilled homeowners and small contractors. -

Sustainability and Material Efficiency

Environmental considerations are influencing hardware selection. Leading hinge manufacturers are adopting eco-friendly materials, recyclable packaging, and energy-efficient production processes. As green building certifications (such as LEED and BREEAM) gain traction, demand for sustainable hardware components—including hidden hinges—will increase. -

Regional Market Dynamics

North America and Europe remain dominant markets due to established cabinetry traditions and strong demand for custom kitchens. However, the Asia-Pacific region—particularly China, India, and Southeast Asia—is expected to register the highest growth rate. Urbanization, rising disposable incomes, and Western-inspired interior design trends are fueling demand for premium kitchen solutions in this region. -

Supply Chain and Manufacturing Shifts

Post-pandemic supply chain adjustments have prompted manufacturers to diversify production geographically and increase local sourcing. By 2026, we may see more regional manufacturing hubs emerging, reducing lead times and import dependencies. This shift will enhance availability and pricing competitiveness for hidden hinges in emerging markets.

Conclusion

By 2026, the hidden hinges for inset cabinet doors market will be defined by innovation, aesthetic demand, and broader accessibility. As consumers prioritize design, functionality, and sustainability, manufacturers who adapt to these trends—offering high-performance, easy-to-install, and eco-conscious products—are likely to capture significant market share. The convergence of design trends and technological progress positions hidden hinges as a critical component in the future of premium cabinetry.

Common Pitfalls When Sourcing Hidden Hinges for Inset Cabinet Doors (Quality and Intellectual Property)

Logistics & Compliance Guide for Hidden Hinges For Inset Cabinet Doors

Product Overview and Classification

Hidden hinges for inset cabinet doors are precision hardware components designed to allow doors to sit flush within the cabinet frame when closed, providing a clean, seamless appearance. These hinges are typically categorized under HS (Harmonized System) code 8302.41 or 8302.42, depending on material composition (e.g., steel or zinc alloy). Accurate classification is essential for customs declaration, duty calculation, and import/export compliance.

Packaging and Labeling Requirements

Ensure each unit is securely packaged to prevent damage during transit. Use anti-corrosion materials such as polybags or foam inserts, and pack in sturdy corrugated cardboard boxes. Each package must include:

– Product name and model number

– Quantity per pack

– Manufacturer or supplier name and address

– Country of origin

– Barcodes or SKUs for inventory tracking

– Compliance labels (e.g., RoHS, REACH if applicable)

International Shipping and Documentation

For global shipments, prepare the following documentation:

– Commercial invoice with detailed description, unit value, and total worth

– Packing list specifying carton dimensions, gross/net weight, and item count

– Bill of lading (B/L) or air waybill (AWB)

– Certificate of origin (if required by trade agreements)

Ensure all documents use standardized product descriptions aligned with the HS code to avoid customs delays.

Regulatory Compliance

Hidden hinges must comply with regional safety and environmental regulations:

– EU: Adhere to REACH and RoHS directives restricting hazardous substances. CE marking is not typically required for standalone hinges but may be necessary if part of a larger assembly.

– USA: Comply with CPSIA (Consumer Product Safety Improvement Act) if intended for consumer use; ensure lead and phthalate limits are met.

– Canada: Follow Health Canada’s safety standards under the Canada Consumer Product Safety Act (CCPSA).

– Other Regions: Verify local standards (e.g., UKCA marking post-Brexit, INMETRO in Brazil).

Import Duties and Tariff Considerations

Import duties vary by destination country and hinge material. For example:

– In the U.S., hinges of iron or steel may face tariffs under HTSUS 8302.41.00, typically ranging from 3.7% to 5.8%.

– In the EU, the import duty for similar hinges is generally 2.7% under CN code 8302 41 00.

Use binding tariff rulings or consult a customs broker to ensure accurate duty assessment and explore preferential rates under free trade agreements (e.g., USMCA, CETA).

Quality Control and Testing Protocols

Implement pre-shipment inspections to verify:

– Material durability and corrosion resistance (e.g., salt spray testing per ASTM B117)

– Operational smoothness and adjustment range

– Conformance to specifications (dimensions, load capacity)

Maintain test reports and QC documentation for audit purposes and customer assurance.

Sustainability and Environmental Compliance

Source materials from suppliers with environmental certifications (e.g., ISO 14001). Recyclable packaging is recommended. Disclose compliance with WEEE if the product is part of electronic cabinetry systems. Minimize hazardous substance use and maintain documentation for substance declarations (e.g., via IPC-1752).

Storage and Handling Recommendations

Store in a dry, temperature-controlled environment to prevent oxidation. Avoid stacking beyond recommended limits to prevent box compression. Use FIFO (First In, First Out) inventory rotation. Handle with clean gloves to avoid oil contamination on metal surfaces.

Returns and Warranty Logistics

Establish a clear returns policy for defective or non-conforming products. Include:

– Return authorization (RMA) process

– Packaging standards for return shipments

– Warranty duration (e.g., 5–10 years) and coverage scope

Coordinate with logistics partners for reverse logistics efficiency.

Final Compliance Checklist

Before shipment, verify:

✅ HS code accuracy

✅ All required certifications are obtained and documented

✅ Labels and markings meet destination country requirements

✅ Packaging protects against shock, moisture, and corrosion

✅ Shipping documents are complete and error-free

Adhering to this guide ensures smooth logistics operations and regulatory compliance for hidden hinges used in inset cabinet doors across global markets.

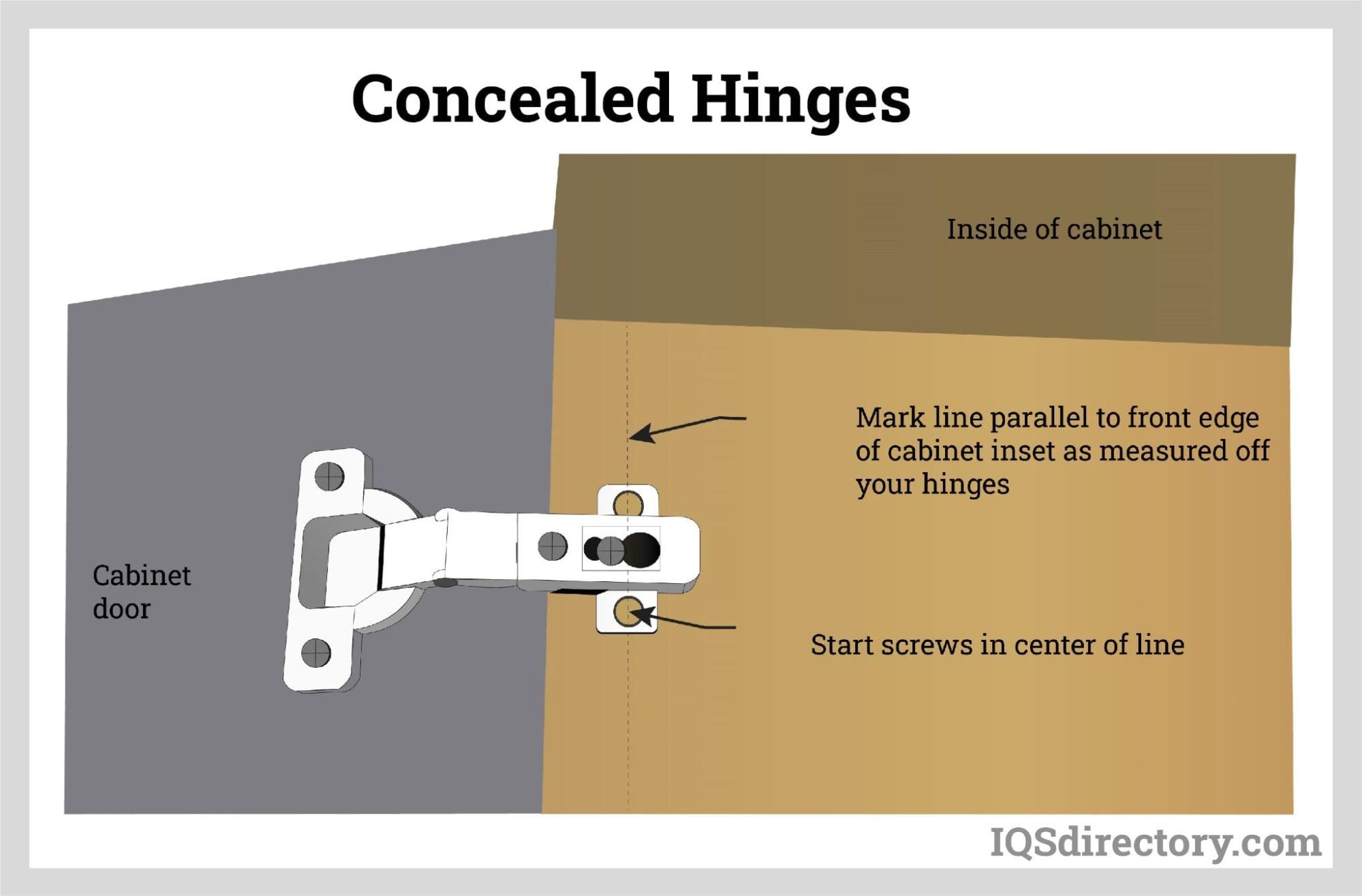

In conclusion, sourcing hidden hinges for inset cabinet doors requires careful consideration of hinge type, compatibility, quality, and supplier reliability. European-style concealed cup hinges are typically the best choice for a clean, seamless look and smooth operation. Key factors such as door thickness, overlay requirements, and cabinet construction must align with the hinge specifications to ensure proper function and durability. It is advisable to source from reputable hardware suppliers or manufacturers known for precision engineering, such as Blum, Hettich, or Grass, to guarantee long-term performance and ease of adjustment. Additionally, obtaining samples when possible allows for verification of fit and finish before large-scale procurement. With the right research and supplier partnerships, achieving a professional, high-quality inset door installation is both feasible and rewarding.