The global wire rope sling market is experiencing steady expansion, driven by increasing infrastructure development, growth in heavy industries, and rising demand for lifting and rigging solutions across sectors such as construction, oil & gas, and manufacturing. According to Mordor Intelligence, the global wire rope market was valued at USD 10.8 billion in 2023 and is projected to grow at a CAGR of over 5.6% through 2029. This upward trajectory underscores the critical importance of reliable, high-performance products like Hercules wire rope slings—renowned for their durability, load capacity, and safety compliance. As demand intensifies, identifying leading manufacturers who combine innovation, rigorous quality standards, and global reach becomes essential for procurement professionals and project managers alike. Below, we highlight the top three Hercules wire rope sling manufacturers shaping the industry with proven track records and scalable, data-backed solutions.

Top 3 Hercules Wire Rope Sling Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hercules Wire Rope & Sling Co., Inc.

Domain Est. 2004

Website: herculeswirerope.com

Key Highlights: Hercules Wire Rope & Sling Co., Inc. provides industrial rigging solutions including wire rope, slings, chains, and hardware. Serving Louisiana, Mississippi ……

#2 Wire Rope Slings

Domain Est. 2023

Website: herculeslifting.com

Key Highlights: WIRE SLING 1” X 20′ C/W 12″ STANDARD EYES EACH END. Vendor: Herc. WIRE SLING 1” X 20′ C/W 12″ STANDARD EYES EACH END. Part #SS1620. In Stock….

#3 Wire Rope Slings

Domain Est. 2006

Website: herculesslr.com

Key Highlights: Hercules SLR offers comprehensive services for wire rope slings, ensuring both professional inspection and maintenance, as well as the ……

Expert Sourcing Insights for Hercules Wire Rope Sling

H2: 2026 Market Trends Analysis for Hercules Wire Rope Sling

The global market for lifting and rigging equipment, including Hercules Wire Rope Slings, is poised for notable evolution by 2026, driven by industrial expansion, technological advancements, and heightened safety regulations. Below is a detailed analysis of the key market trends expected to influence the demand, innovation, and competitive landscape for Hercules Wire Rope Slings in 2026.

-

Growth in Heavy Industrial and Construction Sectors

By 2026, sustained investments in infrastructure development—particularly in emerging economies across Asia-Pacific, the Middle East, and Africa—are expected to boost demand for high-capacity lifting solutions. Hercules wire rope slings, known for durability and load-bearing strength, will remain essential in construction, oil & gas, shipbuilding, and renewable energy projects such as offshore wind farms. The global infrastructure boom, supported by government stimulus and public-private partnerships, will directly increase the need for reliable rigging equipment. -

Emphasis on Safety and Regulatory Compliance

Stringent occupational health and safety standards—including OSHA (U.S.), ANSI/ASME B30.9, and ISO 4309—are driving end-users to adopt certified, high-performance slings. Hercules, as a reputable brand under Columbus McKinnon Corporation, benefits from its compliance with international standards and traceable quality control. By 2026, increased regulatory scrutiny and corporate ESG (Environmental, Social, and Governance) commitments will push industries to invest in premium, inspected, and documented lifting gear—favoring established brands like Hercules. -

Technological Innovations and Product Enhancements

Hercules is expected to continue integrating advanced materials and smart technologies into its wire rope sling offerings. Anticipated trends include: - Use of high-tensile, corrosion-resistant steel alloys for extended service life.

- Integration of IoT-enabled load monitoring systems (e.g., smart tags or RFID tracking) for real-time sling condition and usage tracking.

-

Development of lightweight yet high-strength synthetic hybrid solutions for niche applications.

These innovations will enhance operational safety, reduce downtime, and improve lifecycle cost efficiency—key decision factors for industrial buyers. -

Shift Toward Rental and Managed Lifting Solutions

A growing trend in the industrial sector is the adoption of equipment rental and managed service models. By 2026, more companies may opt for leasing Hercules slings through certified rigging service providers rather than outright purchases. This shift supports cost optimization, ensures regular inspection and maintenance, and reduces liability—further solidifying Hercules’ position in service-oriented B2B contracts. -

Sustainability and Circular Economy Considerations

Environmental regulations and corporate sustainability goals are prompting a reevaluation of equipment lifecycle management. Hercules wire rope slings, with their long service life and recyclability, align well with circular economy principles. By 2026, manufacturers like Columbus McKinnon may emphasize eco-friendly production processes, remanufacturing programs, and end-of-life recycling—enhancing brand appeal among environmentally conscious clients. -

Competitive Landscape and Market Consolidation

The rigging equipment market is moderately consolidated, with Hercules competing against brands such as Crosby, WireCo WorldGroup, and Lankhorst. By 2026, strategic partnerships, mergers, and digital distribution channels (e.g., e-commerce platforms for industrial goods) will shape market dynamics. Hercules’ strong distribution network, brand trust, and integrated product ecosystems (e.g., compatibility with other Columbus McKinnon lifting devices) will provide a competitive edge. -

Regional Market Dynamics

- North America: Steady demand due to industrial modernization and energy sector activities.

- Europe: Growth driven by renewable energy projects and strict safety enforcement.

- Asia-Pacific: Fastest-growing region due to rapid urbanization and manufacturing expansion.

- Latin America and Africa: Emerging opportunities in mining and infrastructure.

Conclusion

By 2026, the Hercules Wire Rope Sling market will be shaped by a confluence of regulatory pressures, technological innovation, and global infrastructure development. The brand’s reputation for reliability, coupled with ongoing product and service enhancements, positions it favorably to capture growing demand across key industrial sectors. Companies investing in safety, sustainability, and digital integration will lead the market, with Hercules well-placed to maintain its leadership in the global wire rope sling industry.

Common Pitfalls When Sourcing Hercules Wire Rope Slings (Quality, IP)

Sourcing Hercules wire rope slings requires due diligence to ensure safety, performance, and compliance. Overlooking key factors can lead to equipment failure, safety hazards, and legal issues. Below are common pitfalls related to quality and intellectual property (IP):

Quality-Related Pitfalls

1. Selecting Non-Compliant or Substandard Materials

A major risk is purchasing slings made from inferior wire rope that does not meet industry standards such as ASME B30.9, ISO 4309, or EN 13414. Substandard materials may exhibit reduced tensile strength, poor fatigue resistance, or inadequate corrosion protection—compromising sling integrity and leading to premature failure under load.

2. Inadequate Manufacturing and Inspection Processes

Some suppliers may lack rigorous quality control systems. Without proper splicing, swaging, or heat treatment procedures—and documented third-party inspections—there’s no assurance the sling meets Hercules’ performance benchmarks. Missing or falsified test certificates increases liability and safety risks.

3. Misrepresentation of Load Capacity and Safety Factors

Unverified claims about Working Load Limits (WLL) or safety factors (typically 5:1 for slings) are common. Suppliers may inflate ratings without engineering validation, leading to overloading and catastrophic failures during lifting operations.

4. Poor Traceability and Documentation

Lack of batch traceability, material test reports (MTRs), or unique identification tags makes it difficult to verify quality or conduct recalls. This is especially critical in regulated industries like oil & gas, construction, or offshore operations.

Intellectual Property (IP) and Brand Integrity Risks

1. Counterfeit or “Copycat” Products

Hercules is a recognized brand in lifting equipment. Counterfeit slings bearing Hercules branding—or mimicking its design—circulate in the market. These products often lack IP licensing and do not undergo Hercules’ quality assurance, posing serious safety and legal exposure.

2. Unauthorized Use of Trademarks and Patents

Suppliers may illegally use Hercules’ trademarks, logos, or patented design features (e.g., specific splice patterns or terminations). Sourcing from such vendors exposes buyers to IP infringement claims and undermines brand reputation.

3. Grey Market Imports

Purchasing from unauthorized distributors or parallel importers may result in genuine Hercules products that lack regional compliance certifications (e.g., CE, UKCA) or come without proper warranty support. These slings may not be serviceable or traceable through official Hercules channels.

4. Insufficient Due Diligence on Supplier Authenticity

Failing to verify a supplier’s authorization status with Hercules or the manufacturer can lead to unintentional IP violations. Always request proof of distribution rights and validate through Hercules’ official channels.

Best Practices to Avoid Pitfalls

- Source only from Hercules-authorized distributors or certified partners.

- Request full documentation: certificates of conformance, MTRs, IP licensing proof, and traceability records.

- Inspect physical slings for proper branding, markings, and build quality.

- Conduct periodic audits or third-party testing, especially for bulk purchases.

Avoiding these pitfalls ensures operational safety, regulatory compliance, and protection against IP and supply chain risks.

Logistics & Compliance Guide for Hercules Wire Rope Sling

This guide outlines essential logistics considerations and compliance requirements for the safe handling, storage, transportation, and use of Hercules Wire Rope Slings. Adherence to these guidelines ensures operational safety, regulatory compliance, and product longevity.

Product Identification and Specifications

Ensure all Hercules Wire Rope Slings are clearly labeled with critical information, including:

– Manufacturer name (Hercules)

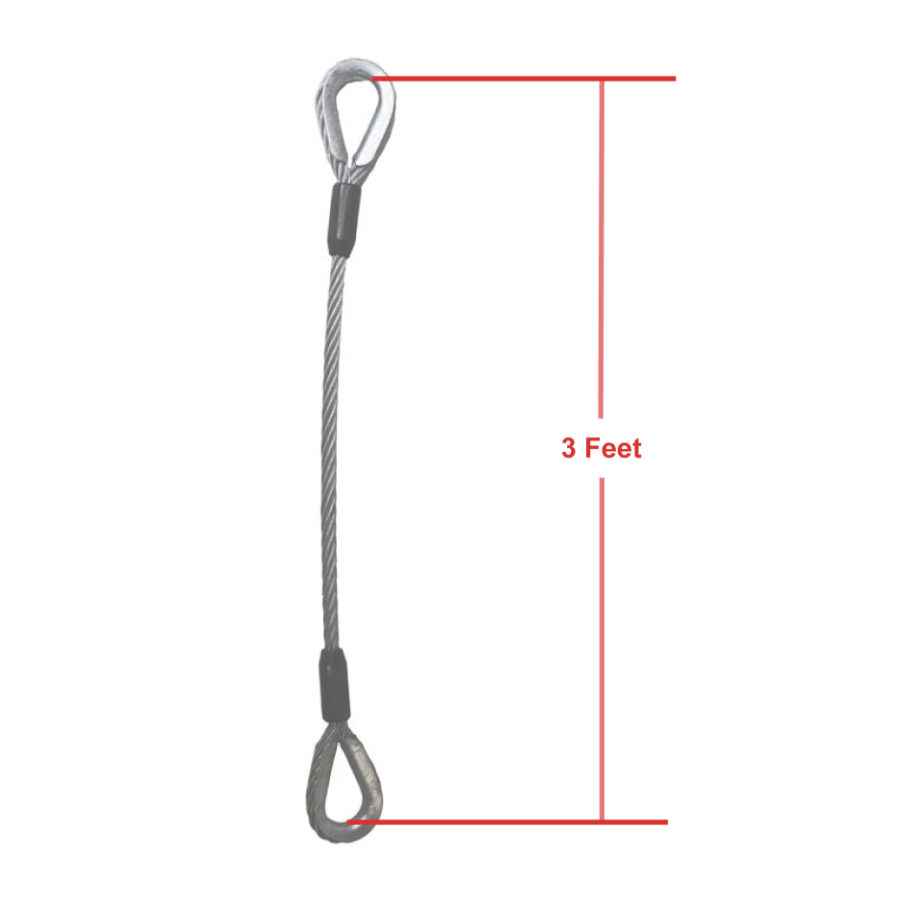

– Sling type (e.g., single leg, two-leg, endless)

– Rated load capacity (in tons or kilograms) for applicable hitch types (vertical, choker, basket)

– Wire rope diameter

– Length (from fitting to fitting)

– Date of manufacture

– Unique serial or identification number

Maintain accurate records of sling specifications and certifications for traceability and compliance audits.

Handling and Transportation

Handle Hercules Wire Rope Slings with care to prevent damage:

– Never drag slings across surfaces; use lifting or carrying methods.

– Avoid kinking, crushing, or dropping slings during transport.

– Use designated sling containers or reels when moving multiple slings.

– During vehicle transport, secure slings to prevent shifting, and protect from sharp edges or abrasive contact.

– Shield slings from extreme environmental exposure (e.g., rain, direct sunlight) during transit.

Storage Conditions

Store Hercules Wire Rope Slings in a controlled environment to maintain integrity:

– Keep in a clean, dry, and well-ventilated area away from moisture and corrosive substances.

– Hang slings on designated racks or store coiled neatly on shelves—do not pile heavy objects on top.

– Avoid exposure to extreme temperatures, chemicals, or UV radiation.

– Inspect storage areas regularly for potential hazards such as pests or leaks.

Inspection and Maintenance

Perform regular inspections to ensure sling safety and compliance:

– Pre-Use Inspection: Check for broken wires, kinks, corrosion, distortion of fittings, and wear before each use.

– Periodic Inspection: Conduct detailed inspections by a qualified person at intervals defined by OSHA, ASME B30.9, or site-specific safety policies (typically monthly or quarterly).

– Remove damaged or defective slings from service immediately and tag them as “Do Not Use.”

– Keep inspection logs with dates, findings, and inspector details.

Regulatory Compliance

Ensure all operations involving Hercules Wire Rope Slings meet applicable standards:

– OSHA 29 CFR 1910.184 – General industry requirements for slings.

– ASME B30.9 – Safety standard for below-the-hook lifting devices, including wire rope slings.

– EU Machinery Directive and Lifting Operations and Lifting Equipment Regulations (LOLER) – For use in European markets.

– Confirm that slings are certified and include documentation such as a Certificate of Conformance or Material Test Report when required.

Training and Documentation

Provide comprehensive training for all personnel involved in sling use:

– Train workers on proper sling selection, hitch configurations, load capacity limitations, and safe rigging practices.

– Ensure only qualified personnel perform inspections and approve slings for service.

– Maintain up-to-date training records and make compliance documentation readily available.

Disposal and Retirement

Retire Hercules Wire Rope Slings when they exhibit any of the following:

– Ten randomly distributed broken wires in one rope lay.

– Five broken wires in one strand within one rope lay.

– Severe corrosion, distortion, or loss of original shape.

– Worn diameter reduced by 1/3 of the original size.

– Evidence of heat damage or chemical degradation.

Dispose of retired slings in accordance with local environmental and safety regulations—cut into pieces to prevent reuse.

Emergency Procedures

In the event of sling failure or accident:

– Immediately cease operations in the affected area.

– Secure the site and report the incident to the safety officer.

– Conduct a root cause investigation and document findings.

– Review and update procedures as necessary to prevent recurrence.

Following this logistics and compliance guide ensures the safe and efficient use of Hercules Wire Rope Slings, protecting personnel, equipment, and operations.

Conclusion for Sourcing Hercules Wire Rope Sling:

Sourcing Hercules wire rope slings presents a reliable and cost-effective solution for heavy lifting operations across industries such as construction, manufacturing, oil & gas, and logistics. Known for their durability, high breaking strength, and resistance to wear and abrasion, Hercules slings ensure operational safety and efficiency when proper load capacities and usage guidelines are followed.

When sourcing these slings, it is essential to partner with certified suppliers who provide compliance with industry standards such as ASME B30.9 and OSHA regulations, along with valid test certificates and traceability documentation. Assessing factors like sling configuration (single, double, or multiple leg), eye terminations, and environmental conditions will help in selecting the most suitable product for specific applications.

Additionally, prioritizing regular inspection, proper handling, and ongoing maintenance contributes to extending the service life of Hercules wire rope slings and ensures workplace safety. In conclusion, strategic sourcing of Hercules wire rope slings—balancing quality, compliance, and supplier reliability—enhances lifting operations’ performance while supporting long-term operational safety and productivity.