The global extension cord market is experiencing steady growth, driven by rising demand across residential, commercial, and industrial sectors. According to a report by Grand View Research, the global power cord and extension reel market was valued at USD 22.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing construction activities, the proliferation of electronic devices, and stringent safety regulations favoring high-quality, durable cords—particularly heavy-duty variants like 10-gauge extension cords, known for their superior power handling and longer run capabilities. With safety and performance becoming critical differentiators, manufacturers specializing in industrial-grade extension cords are gaining prominence. In this competitive landscape, identifying the top 10 heavy-duty 10-gauge extension cord manufacturers offers valuable insights for contractors, distributors, and procurement professionals seeking reliable, performance-tested products backed by strong manufacturing expertise and innovation.

Top 10 Heavy Duty 10 Gauge Extension Cord Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Heavy Duty Cord & Plug

Domain Est. 1996

Website: kordking.com

Key Highlights: Kord King’s heavy-duty extension cords, designed for durability and performance in industrial applications. High-quality, reliable power solutions….

#2 Extension Cord Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: Conveniently choose from the leading extension cord manufacturers and suppliers in the USA who offer affordable and energy efficient extension cords….

#3 Extension Cords

Domain Est. 1994

Website: southwire.com

Key Highlights: Keep your home or workplace powered up with our selection of durable and reliable extension cords….

#4 Heavy Duty Extension Cords

Domain Est. 1997

Website: centurywire.com

Key Highlights: All our heavy duty extension cords have excellent abrasion resistance, great working flexibility in cold weather, and superior resistance to many chemicals….

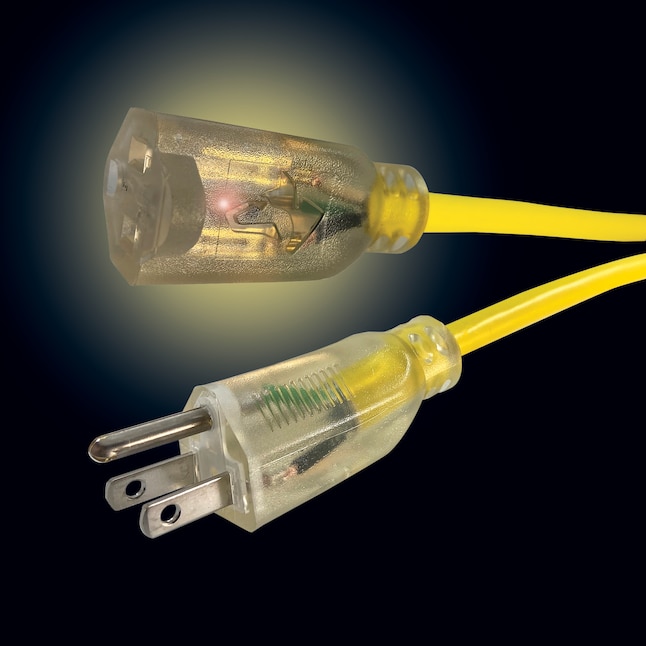

#5 10 Gauge Extension Cord for Enhanced Performance

Domain Est. 1999

Website: americord.com

Key Highlights: Free delivery 30-day returns10 Gauge extension cords have extreme resistance to sunlight, ozone, cracking & chemicals and they are used in industries and many more applications….

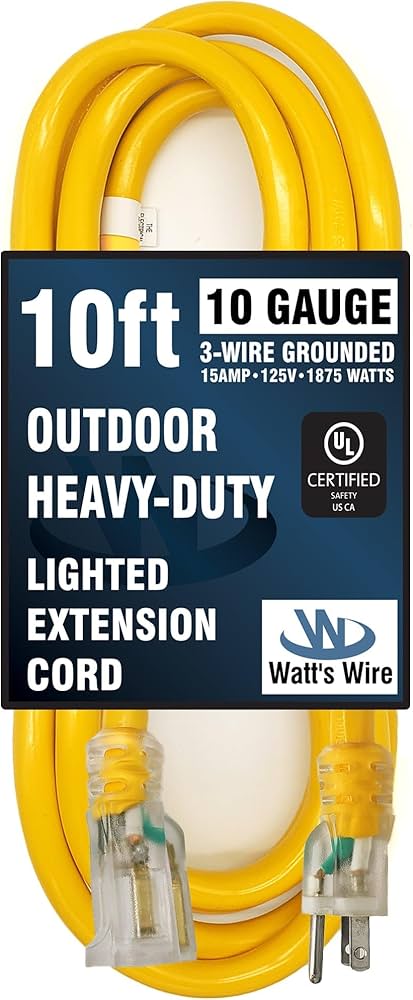

#6 Watt’s Wire Heavy Duty Extension Cords

Domain Est. 2016

Website: wattswire.com

Key Highlights: We offer custom and large quantity orders on 10 gauge, 12 gauge and 14 gauge extension cords. For more information or to request a quote please contact us at: ……

#7 Extension Cord Price/Cost, Power Amps Rating, Custom Types …

Domain Est. 2016

Website: 1xtechnologies.com

Key Highlights: When it comes to an extension cord, Made in the USA, 1X Technologies is your go-to supplier. We’ll supply you with a variety of extension cord ……

#8 10 Gauge Extension Cords

Domain Est. 2017

#9 Extension Cords

Domain Est. 2018

Website: voltecindustries.com

Key Highlights: Voltec 10/3 Heavy-Duty Yellow Extension Cords with Lighted Plug – High-Visibility, Flexible Vinyl Jacket, SJTWPricing Not Available ……

#10 Shop Extension Cords: Heavy-Duty, Outdoor, & More

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day deliveryShop premium extension cords at Do it Best, including regular extension cords and retractable extension cord reels. Get same day pick-up or home delivery….

Expert Sourcing Insights for Heavy Duty 10 Gauge Extension Cord

H2: Projected 2026 Market Trends for Heavy Duty 10 Gauge Extension Cords

The global market for heavy-duty 10 gauge extension cords is expected to experience steady growth by 2026, driven by rising demand across construction, industrial, agricultural, and residential sectors. As power tools and high-amperage equipment become more prevalent, the need for reliable, durable, and safe electrical cabling solutions like 10 gauge extension cords will continue to expand.

One major trend shaping the 2026 landscape is the increasing emphasis on safety and compliance. Regulatory bodies in North America and Europe are tightening electrical safety standards, pushing manufacturers to adopt UL, CSA, and CE certifications more rigorously. Consumers and professionals alike are prioritizing cords with weather-resistant jackets, reinforced connectors, and overheat protection—features that 10 gauge cords are well-suited to support due to their thicker copper conductors and robust insulation.

Additionally, the growth of outdoor and off-grid applications—including outdoor events, RV lifestyles, and remote job sites—is boosting demand for longer, more durable cords. The 10 gauge extension cord, capable of handling 30 amps over extended distances with minimal voltage drop, is becoming a preferred choice for powering heavy machinery, welders, air compressors, and large heaters.

Another key trend is the shift toward eco-conscious manufacturing. By 2026, leading brands are expected to incorporate recyclable materials, reduce packaging waste, and improve energy efficiency in production. Some companies may introduce smart cords with integrated surge protection or usage monitoring, although this remains more common in lighter-duty consumer models.

Regionally, North America is projected to remain the largest market due to high construction activity and stringent safety regulations. Meanwhile, the Asia-Pacific region will see rapid growth, fueled by industrialization and infrastructure development in countries like India and Vietnam.

In summary, the 2026 market for heavy-duty 10 gauge extension cords will be defined by heightened safety standards, technological enhancements, and growing demand from both professional and DIY users. Manufacturers who innovate in durability, sustainability, and compliance will be best positioned to capture market share.

Common Pitfalls When Sourcing Heavy Duty 10 Gauge Extension Cord (Quality, IP)

Sourcing a Heavy Duty 10 Gauge Extension Cord requires careful attention to quality standards and intellectual property (IP) considerations. Buyers, resellers, and manufacturers often encounter pitfalls that can compromise safety, performance, and legal compliance. Below are the most common issues to avoid.

Quality-Related Pitfalls

1. Substandard Wire Gauge and Material Composition

One of the most frequent issues is receiving cords that claim to be 10 gauge but are made with undersized or inferior copper wire. Some suppliers use copper-clad aluminum (CCA) instead of pure copper, which increases resistance and overheating risks. Always verify material specifications and request third-party test reports (e.g., UL, ETL) to confirm true 10 AWG copper conductors.

2. Inadequate Insulation and Jacketing

Heavy-duty cords must withstand outdoor conditions, abrasion, and temperature extremes. Poor-quality PVC or thermoplastic elastomer (TPE) jackets can crack in cold weather or degrade under UV exposure. Ensure the jacket material meets standards like SJTW or SJOOW for outdoor and industrial use.

3. Misleading IP (Ingress Protection) Ratings

Many suppliers advertise high IP ratings (e.g., IP67) without proper certification. A true IP67 rating means the cord is dust-tight and can withstand immersion in water up to 1 meter for 30 minutes. Unverified claims are common. Always request test documentation and verify whether the rating applies to the entire cord or just connectors.

4. Lack of Overload and Overheat Protection

Not all heavy-duty cords include thermal protection or overload safeguards. Using an unregulated cord with high-power tools can lead to fire hazards. Ensure the design incorporates safety features, especially for prolonged use.

5. Poor Connector Build Quality

Cheaply molded connectors with loose prongs or inadequate strain relief are prone to failure. Look for brass contacts (not steel) and robust housing. Check if connectors are rated for the same current and environment as the cord.

Intellectual Property (IP) Pitfalls

1. Counterfeit or Copycat Designs

Many manufacturers replicate branded extension cords (e.g.,模仿知名品牌) without authorization. These clones may infringe on design patents, trademarks, or utility patents. Sourcing such products exposes buyers to legal risks, including customs seizures and infringement lawsuits.

2. Unauthorized Use of Safety Certifications

Some suppliers falsely claim UL, CSA, or CE certification. These marks are intellectual property protected by law. Using them without proper certification is illegal and dangerous. Always verify certification through official databases (e.g., UL Product iQ).

3. Lack of Brand Licensing Agreements

If sourcing cords under a private label or white-label brand, ensure all designs, logos, and packaging are either original or properly licensed. Unauthorized use of third-party branding—even through OEMs—can result in IP disputes.

4. Copying Proprietary Features

Innovative features like twist-lock connectors, smart surge protection, or retractable reels may be patented. Replicating these without due diligence risks patent infringement. Conduct a freedom-to-operate analysis before mass production.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request certified test reports, audit supplier facilities, verify IP rights, and work with reputable manufacturers. Investing in compliance and authenticity up front prevents safety hazards, legal issues, and reputational damage down the line.

Logistics & Compliance Guide for Heavy Duty 10 Gauge Extension Cord

Product Overview

The Heavy Duty 10 Gauge Extension Cord is designed for high-power applications such as construction equipment, industrial tools, and outdoor events. With its 10 AWG (American Wire Gauge) copper conductors, it supports high current loads (typically up to 30 amps) and features durable insulation, weather-resistant jackets, and robust connectors. This guide outlines key logistics handling, shipping requirements, and compliance standards necessary for safe distribution and legal sale.

Regulatory Compliance

Ensure the extension cord meets all applicable national and international safety and electrical standards. Key compliance requirements include:

– UL 817 Certification (USA): Listed by Underwriters Laboratories for safety of attachment plugs, cord sets, and power-supply cords.

– CSA C22.2 No. 21 (Canada): Compliant with Canadian Standards Association requirements for cord sets and power supply cords.

– RoHS Compliance: Restriction of Hazardous Substances Directive (EU) for lead, mercury, cadmium, and other restricted materials.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals regulation compliance.

– FCC Part 15 (if applicable): Electromagnetic interference standards, especially if the cord includes surge protection or electronics.

– California Proposition 65: Warning labels required if the product contains chemicals known to cause cancer or reproductive harm.

Electrical & Safety Standards

- Rated for 125V or 125/250V depending on configuration.

- Maximum continuous load: 30 amps.

- Jacket material must be SVT (Service Vacuum Thermoplastic) or SJT (Service Junior Thermoplastic) for durability and flexibility.

- Outdoor-rated models must feature weather-resistant, UV-stabilized jackets (e.g., STW or SJOOW type).

- All models must include grounding (3-prong) configuration for safety.

Packaging & Labeling Requirements

- Clearly label each unit with:

- Voltage and amperage rating (e.g., 125V 30A)

- Wire gauge (10 AWG)

- Cord length

- Manufacturer name and model number

- UL/CSA certification marks

- Country of origin (e.g., “Made in USA” or “Assembled in Mexico”)

- Prop 65 warning (if applicable)

- Use retail-ready packaging with hang holes or clamshell design where appropriate.

- Include multilingual instruction sheets if selling in Canada or EU.

Shipping & Handling Logistics

- Weight & Dimensions: Account for heavy gauge copper and thick insulation; typical 50 ft cord weighs 8–10 lbs. Use appropriate dunnage and stacking limits.

- Palletization: Stack no more than 5–6 layers high on standard 48”x40” pallets to avoid compression damage.

- Temperature Control: Avoid prolonged exposure to extreme heat (>140°F/60°C) or cold (< -20°F/-29°C), which can degrade insulation.

- Moisture Protection: Store and ship in dry environments; use moisture barriers in sea containers.

- Hazard Class: Not classified as hazardous, but heavy weight requires proper lifting procedures.

Import & Customs Documentation (International Shipments)

- Provide accurate HS Code (e.g., 8544.42.00 for insulated wire with connectors, USA).

- Include commercial invoice, packing list, and bill of lading/air waybill.

- Certify compliance with destination country standards (e.g., UKCA for UK, INMETRO for Brazil).

- For EU imports, ensure presence of an EU Responsible Person and CE marking.

Storage Guidelines

- Store in climate-controlled, dry warehouses away from direct sunlight.

- Avoid contact with oils, solvents, or sharp objects.

- Use pallet racking to prevent floor moisture absorption and physical damage.

- Rotate stock using FIFO (First In, First Out) to ensure freshness of materials.

End-of-Life & Environmental Considerations

- Promote recycling through take-back programs or partnerships with e-waste recyclers.

- Inform customers that copper conductors and plastic jackets are recyclable.

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives in the EU.

Quality Assurance & Testing

- Conduct periodic batch testing for:

- Dielectric strength (high-pot testing)

- Pull tests on connectors

- Flex life and abrasion resistance

- Continuity and grounding integrity

- Maintain test records for at least 5 years for audit purposes.

Customer Support & Documentation

- Provide downloadable manuals and safety warnings on product website.

- Train customer service teams on proper usage, limitations (e.g., no indoor cords outdoors), and troubleshooting.

- Report any field failures or safety incidents to regulatory bodies as required (e.g., CPSC in the U.S.).

Adherence to this logistics and compliance guide ensures safe, legal, and efficient distribution of Heavy Duty 10 Gauge Extension Cords across domestic and international markets.

In conclusion, sourcing a heavy-duty 10-gauge extension cord is a critical decision for ensuring safe, reliable, and efficient power delivery, especially for high-demand tools and outdoor equipment. The 10-gauge wire’s low resistance allows for longer cord lengths (typically up to 100 feet) while minimizing voltage drop and overheating risks. When selecting a cord, prioritize features such as outdoor-rated jacket material (like SJTW or SOOW), UL certification, grounded plugs and connectors, and durable construction for harsh environments. Additionally, consider the intended application—such as construction sites, RV power, or heavy machinery—to match the cord’s amperage rating (commonly 30 amps) and length to your needs. Sourcing from reputable suppliers or manufacturers ensures compliance with safety standards and product longevity. Ultimately, investing in a quality heavy-duty 10-gauge extension cord enhances operational safety, reduces equipment damage risk, and supports optimal performance in demanding conditions.