The global trailer and truck equipment market has experienced steady expansion, driven by rising freight transportation demands and growth in e-commerce logistics. According to Grand View Research, the global commercial vehicle aftermarket was valued at USD 376.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030—reflecting increased investment in truck customization and efficiency-enhancing accessories. Within this niche, headache racks have emerged as essential safety and utility components for flatbed trucks, protecting both drivers and cargo. With North America accounting for a significant share of flatbed truck usage—particularly in industries like construction, oil & gas, and heavy equipment transport—the demand for high-quality headache rack solutions has intensified. This surge has led to a competitive landscape among manufacturers offering durable, customizable, and compliant rack systems. Based on performance metrics, material quality, customer reviews, and market presence, we’ve identified the top 8 headache rack manufacturers catering specifically to flatbed operators in 2024.

Top 8 Headache Rack For Flatbed Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 rackitinc: Rack

Domain Est. 2003

Website: rackitinc.com

Key Highlights: Trusted in-house manufacturing. Our dedication to customer support. The legacy of a family, driven to offer a quality custom truck Rack at a fair price….

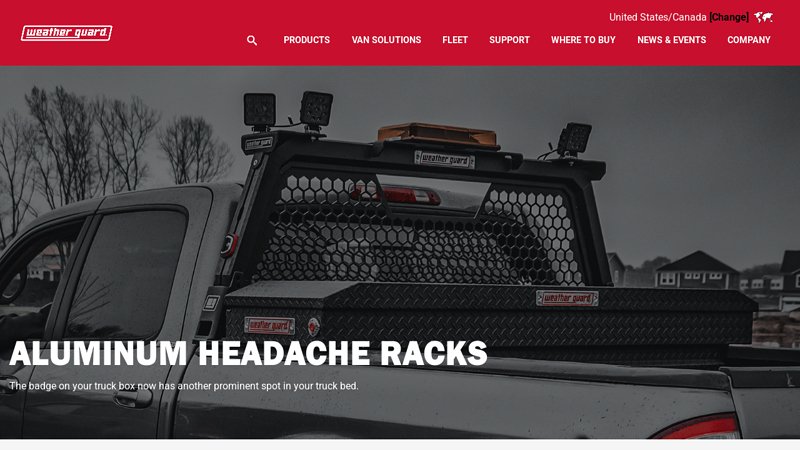

#2 Aluminum Headache Racks

Domain Est. 1996

Website: weatherguard.com

Key Highlights: Truck headache racks, or cab protectors, are designed to protect your pickup cab from serious damage from large shifting loads in the cargo area….

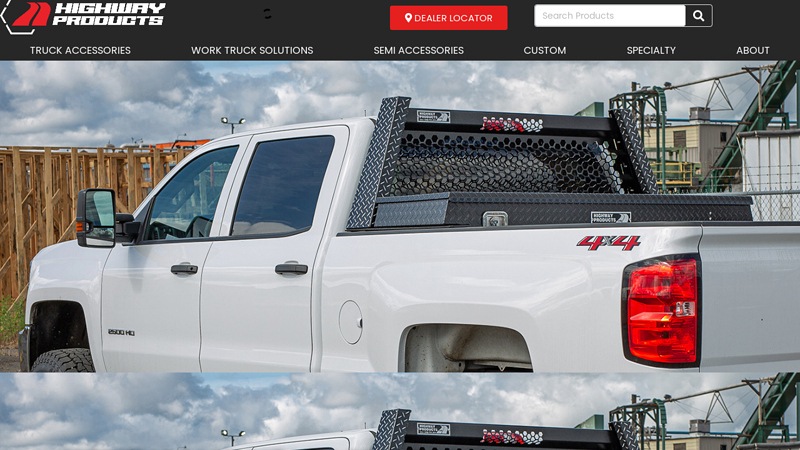

#3 Honeycomb Headache Rack

Domain Est. 1996

Website: highwayproducts.com

Key Highlights: Rating 4.8 4 The Honeycomb Headache Rack is our most popular and versatile back rack. Choose between 3 adjustable center grille configurations and 3 different standard ……

#4 Headache & Cab Racks for Truck Beds

Domain Est. 1998

#5 Headache Racks and Cab Guards for Work Trucks

Domain Est. 1998

Website: knapheide.com

Key Highlights: Prevent cargo from hitting your cab during transit or loading and causing unwanted dents, rear window breakage, and possible passenger injury….

#6 Headache Racks for Semi Trucks

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: Free delivery over $199 60-day returnsOur semi headache racks are built to last, constructed from durable yet lightweight aluminum. Qualifying orders ship free….

#7 Truck Flatbeds, Toolboxes & Headache Racks

Domain Est. 2014

Website: wickumweld.com

Key Highlights: Each product is handmade by skilled American welders using high-grade aluminum and steel, ensuring durability you can trust….

#8 Merritt Products

Domain Est. 2015 | Founded: 1951

Website: merrittproducts.com

Key Highlights: Discover the official home of Merritt® Aluminum Products—the industry standard for headache racks, toolboxes, and accessories since 1951….

Expert Sourcing Insights for Headache Rack For Flatbed

H2: 2026 Market Trends for Headache Racks for Flatbed Trailers

The market for headache racks for flatbed trailers is poised for steady growth and transformation by 2026, driven by evolving transportation regulations, material innovations, and increased demand for safety and customization in commercial trucking. As essential safety components on flatbed trailers, headache racks—also known as cab guards—protect drivers from shifting cargo and improve overall vehicle durability. Below is an in-depth analysis of key market trends expected to shape the industry in 2026.

1. Rising Emphasis on Driver Safety and Regulatory Compliance

Safety regulations from the Federal Motor Carrier Safety Administration (FMCSA) and similar global bodies will continue to reinforce the need for protective equipment on commercial vehicles. By 2026, stricter enforcement of load securement rules and increased awareness of driver protection are expected to drive demand for high-performance headache racks. Fleets are likely to upgrade older models to meet compliance standards, particularly in North America—the largest regional market.

2. Shift Toward Lightweight and Durable Materials

The industry is witnessing a transition from traditional steel racks to lightweight alternatives such as aluminum and composite materials. Aluminum headache racks offer corrosion resistance, reduced trailer weight (improving fuel efficiency), and easier installation. By 2026, aluminum-based models are projected to capture a growing market share, especially among owner-operators and logistics companies focused on fuel economy and payload optimization.

3. Customization and Modular Design Trends

Customization is becoming a major differentiator. In 2026, buyers will increasingly seek headache racks with modular features such as integrated lighting, ladder mounts, access doors, and custom branding options. Manufacturers are responding with configurable designs that meet specific fleet requirements or regional preferences. This trend is particularly evident among specialized hauling sectors like construction, utilities, and oil & gas.

4. Growth in E-Commerce and Infrastructure Development

The boom in e-commerce and ongoing infrastructure projects in the U.S., Canada, and parts of Asia is increasing flatbed trailer utilization. As more goods are transported on open-deck trailers, the need for protective equipment like headache racks is rising. By 2026, this sustained demand will support market expansion, particularly in emerging economies where transportation infrastructure is rapidly modernizing.

5. Expansion of Aftermarket and Retrofit Segments

The aftermarket for headache racks is expected to grow significantly by 2026. Many fleet operators and independent truckers are opting to retrofit older trailers rather than purchase new ones. This trend favors cost-effective, easy-to-install headache rack solutions. Online sales channels and direct-to-consumer marketing will further boost accessibility and competition in the retrofit segment.

6. Technological Integration and Smart Features

Although still in early stages, some manufacturers are exploring smart headache racks with integrated sensors or cameras to monitor cargo movement and improve safety. While not mainstream by 2026, the foundation for technology-enhanced racks will be laid, potentially leading to advanced driver assistance features in future iterations.

7. Sustainability and Recycling Initiatives

Environmental considerations are influencing material sourcing and manufacturing processes. By 2026, leading headache rack producers may adopt greener production methods and increase the use of recyclable materials, aligning with broader sustainability goals in the transportation industry.

Conclusion

The headache rack market for flatbed trailers in 2026 will be shaped by safety regulations, material innovation, customization, and infrastructure-driven demand. With a strong focus on performance, durability, and compliance, manufacturers who adapt to these trends—especially in lightweight design and aftermarket solutions—are likely to gain a competitive edge. As the commercial trucking industry continues to evolve, headache racks will remain a critical component, not just for protection, but as a symbol of modern, efficient, and safe freight transport.

Common Pitfalls When Sourcing a Headache Rack for Flatbed: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Headache Rack For Flatbed

Product Overview

A headache rack is a protective barrier mounted behind the cab of a flatbed truck, designed to shield the driver and cab from shifting cargo in the event of sudden stops or accidents. It is a critical safety component for flatbed hauling operations.

Dimensions & Weight Specifications

- Typical Height: 36 to 48 inches

- Width: Matches flatbed trailer width (commonly 102” or 8.5 feet)

- Material: Usually steel or aluminum

- Weight Range: 80–200 lbs, depending on material and design

- Ensure these specs are verified per model to avoid compatibility issues with trailers or load capacity limits.

Packaging & Handling Requirements

- Headache racks are typically shipped unassembled or partially assembled.

- Units should be crated or securely strapped to pallets to prevent damage during transit.

- Use lifting straps or forklifts with care to avoid denting or warping structural components.

- Store in a dry, covered area to prevent corrosion, especially for steel models.

Transportation & Shipping Guidelines

- Use flatbed, step-deck, or enclosed trailers for transport depending on quantity and destination.

- Secure the rack using rated tie-down straps (minimum 5,000 lbs working load limit) to prevent shifting.

- Over-dimensional loads may require permits if combined cargo exceeds state size limits.

- Label shipments with “Fragile” and “This Side Up” if applicable.

Installation & Compatibility Standards

- Verify compatibility with specific trailer make/model and mounting system (e.g., stake pocket or weld-on).

- Follow manufacturer’s torque specifications and installation instructions.

- Use grade 8 bolts and proper hardware to meet DOT safety standards.

- Confirm structural integrity post-installation—no cracks, loose fittings, or misalignment.

Regulatory & Compliance Considerations

- FMVSS Compliance: While headache racks are not federally mandated, they contribute to compliance with FMVSS 571.223 (Rear Impact Guards) by protecting the cab in certain impact scenarios.

- DOT Inspections: Ensure racks do not obstruct required lighting, reflectors, or license plates.

- Bridge Formula & Weight Limits: Account for rack weight when calculating gross vehicle weight (GVW) to remain within federal and state limits.

- State Variations: Some states have additional requirements for load securement and cab protection—verify local regulations.

Maintenance & Inspection Protocols

- Conduct regular visual inspections for cracks, rust, or loose fasteners.

- Check anchor points and welds at least quarterly or after significant impact.

- Lubricate hinges or moving parts (if applicable) to prevent seizing.

- Replace damaged racks immediately to maintain safety and compliance.

Safety Best Practices

- Never overload the area behind the cab; the headache rack is not a load-bearing structure.

- Ensure cargo is secured properly in front of the rack to prevent dynamic forces from compromising integrity.

- Train drivers on proper use and limitations of headache racks.

- Equip racks with reflective tape or lighting if used during low-visibility operations.

Documentation & Recordkeeping

- Retain manufacturer specifications, installation records, and inspection logs.

- Include headache rack details in vehicle maintenance files for DOT audit readiness.

- Keep proof of compliance with any applicable safety standards.

By following this guide, carriers and operators can ensure safe, compliant, and efficient use of headache racks in flatbed transportation operations.

Conclusion:

Sourcing a headache rack for a flatbed trailer requires careful consideration of quality, durability, compatibility, and cost. After evaluating various suppliers, materials, and design options, it is clear that investing in a well-constructed, DOT-compliant headache rack from a reputable manufacturer is essential for ensuring driver safety, protecting the cab in case of cargo shift, and maintaining compliance with transportation regulations. Factors such as steel gauge, mounting style, and additional features like light brackets or access doors should align with operational needs. Ultimately, choosing a reliable supplier that offers a balance of value, warranty support, and prompt delivery will contribute to long-term efficiency and safety in flatbed hauling operations.